A home’s basement walls and floor act like the hull of a ship, supporting the superstructure above but also holding back thousands of pounds of earth and subterranean moisture. Although there is no danger your home will sink, if your basement is taking on water it offers little potential for expanding living space and may not even be a safe place to store things.

After showing how basements are constructed, this section explains how to dry up a wet basement, then goes on to get you started converting it into comfortable living space.

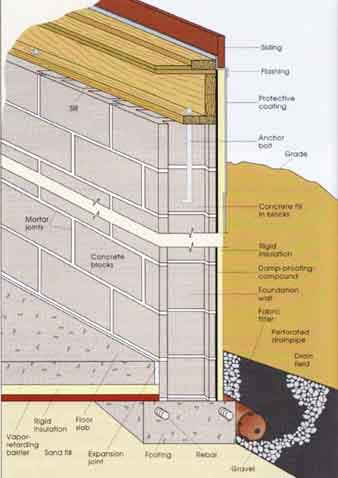

MASONRY BASEMENT CONSTRUCTION

Most basements are constructed of poured concrete or concrete blocks, stone, or occasionally other masonry materials. In the typical example at the right, reinforced concrete footings sup port foundation walls of concrete blocks, and a poured concrete slab forms the basement floor. Expansion joints around the slab’s perimeter are made of asphalt, rubber, or other soft material that flexes as the floor expands and contracts.

Under the slab, compacted sand or gravel fill absorbs groundwater that might otherwise rise and crack the slab. A plastic vapor-retarding barrier helps prevent condensation from building up on the floor. Homes in cold-winter climates may have a layer of rigid board insulation under the slab.

Outside, a drain field captures water and diverts it from the foundation to a dry well or a downgrade area. It consists of coarse gravel, a fabric filter that prevents clogging, and perforated drain pipe that carries the water away.

MASONRY BASEMENTS are typically made of concrete blocks

set in mortar. A footing supports the walls and floor, as well as the weight

of the entire house above. A drain field around the perimeter captures water

that could undermine the foundation. Vapor-retarding barrier; Rigid Insulation;

Damp-proofing compound; Expansion joint

Asphalt-based damp-proofing compound seals the exteriors of basement walls. As with floors, some basement walls are insulated, others are not. With exterior insulation, rigid panels with a protective coating are glued to the foundation walls.

At the top of a basement wall, anchor bolts are embedded in concrete poured into cavities in the upper courses of block. These secure the sill that supports the floor and wail framing above.

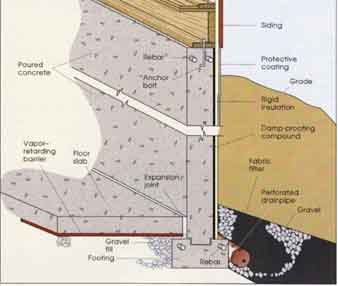

POURED CONCRETE BASEMENTS

Poured concrete basements resemble masonry basements except that their walls are made of solid concrete. After stalling footings, the builder constructs forms and fills them with concrete, which is usually reinforced with steel rods called rebars (reinforcing bars). After the concrete has set, the forms are removed, the drain field is installed, and earth is backfilled against the outsides of the foundation walls. A poured concrete foundation usually costs more than masonry block walls. But because there are no mortar joints this type of construction, it's somewhat less prone to developing cracks through which moisture can penetrate.

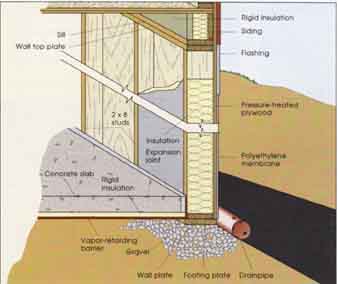

WOOD BASEMENTS

Basements in a few newer homes are made entirely of pressure-treated wood. After excavating, the builder installs a gravel footing pad, then a pressure-treated lumber footing plate. Walls on top of this plate are framed with 2 x 6-, 8-, or 10-inch pressure-treated studs and sheathed with pressure-treated plywood. A polyethylene membrane protects the outer surface of the plywood. Batt or blanket insulation between the studs keeps the basement warm. Some basements have concrete slab floors; others are framed with pressure-treated wood in much the same way as above-ground floor illustrated below. Wood basements are warmer than those made of masonry or concrete, and because they are flexible enough to ride out minor shifts in the earth, cracking is rarely a problem.

POURED CONCRETE BASEMENTS have the same elements as

masonry basements, but their walls are concrete instead of block.

WOOD BASEMENTS are constructed of lumber and plywood

that has been pressure-treated to withstand decay from moisture and insect

damage.

Fundamentals of Basement Repair and Improvement

- Introduction

- Diagnosing Basement Problems

- Sealing Basement Walls

- Installing a Water-Channeling System

- Shelling-In a Basement

- Installing a Subfloor

Other articles in this series: Complete Step-by-Step Home Repair and Improvement