AMAZON multi-meters discounts AMAZON oscilloscope discounts

This Section continues the discussion that began in Section 9, with a focus now on more complex systems for larger buildings with many thermal zones. Those using this book for reference rather than as a text may have gone directly to this Section without reading the preceding material. If so, pay attention to the following comments.

Before Selecting an HVAC System for a Large Building:

The choice of an HVAC system should consider preliminary design issues that are discussed in Section 5 and sections of Section 9:

Section 5, "Indoor Air Quality," discusses the relationship between comfort, zoning, and equipment that helps maintain acceptable air quality in buildings.

9.1 "Review of the Need for Mechanical Equipment," reviews the relative thermal role of building envelopes compared to their internal heating, cooling, and ventilating systems.

9.2 "Heating, Ventilating, and Air Conditioning (HVAC): Typical Design Processes," outlines the decisions made by the architect and the engineer.

9.5 "Refrigeration Cycles," reviews both the compressive and the absorptive refrigeration processes.

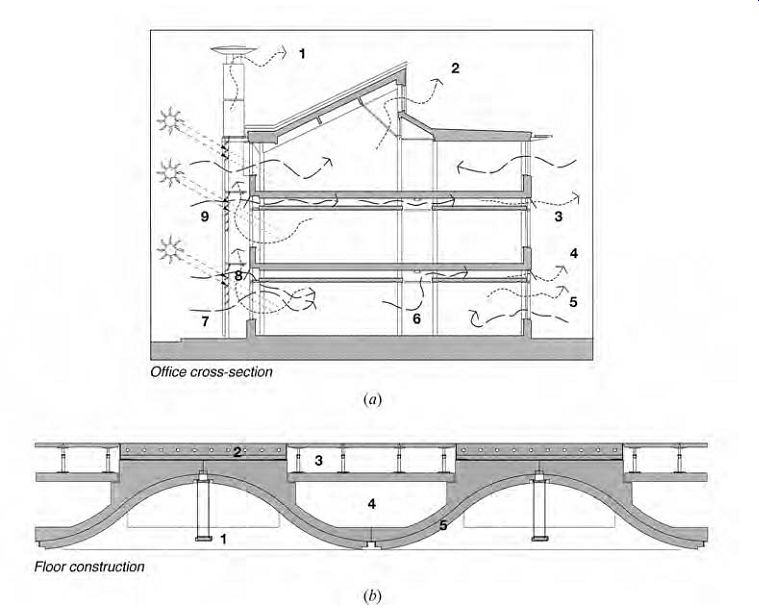

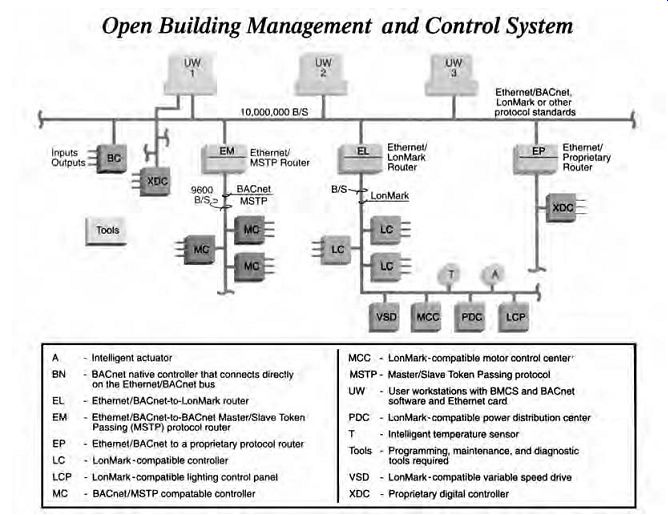

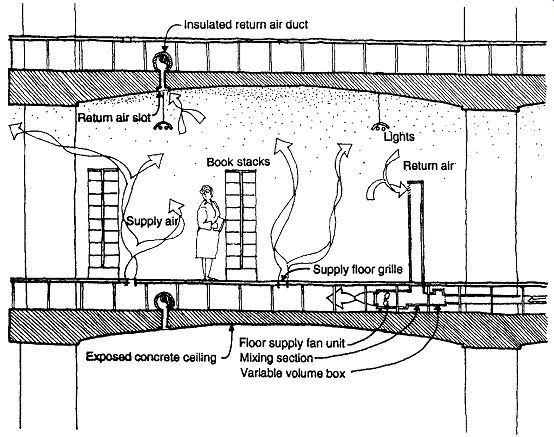

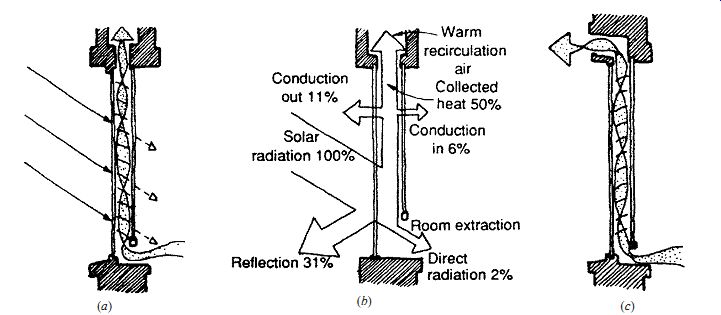

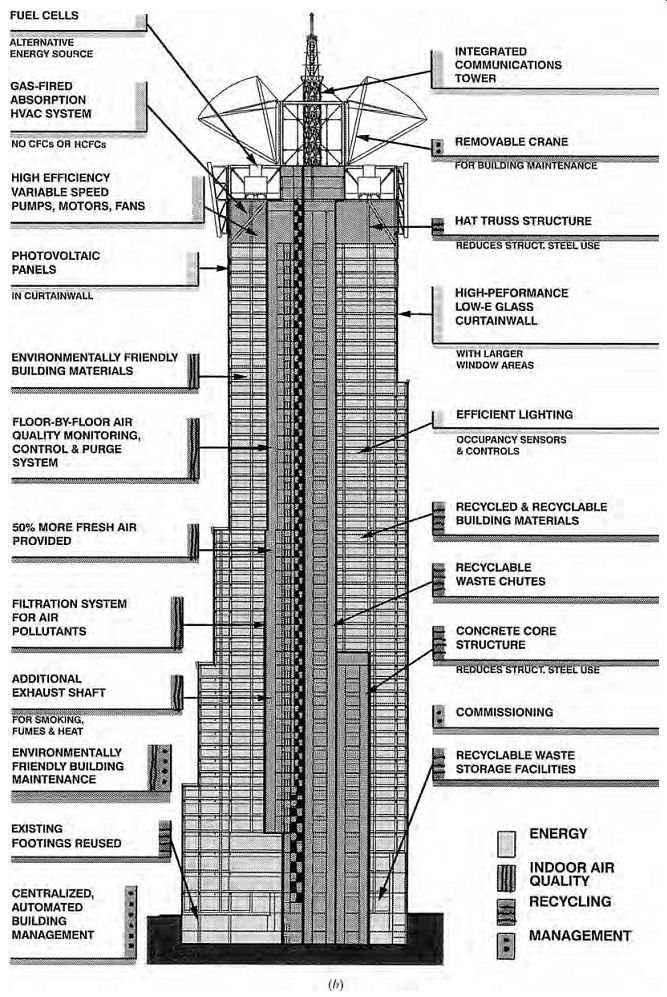

At the onset of the twenty-first century, large building HVAC is showing several trends. One is the increasing willingness to let mechanical equipment share its tasks with natural ventilation and day lighting. Building automation has made this easier to manage. Another trend is toward an underfloor plenum air supply (related to, but not identical to, displacement ventilation approaches commonly used in critical-environment facilities) rather than using ducts connected to diffusers and return grilles, both on the ceiling. Concern about air quality indoors and the environment outdoors is producing a variety of approaches to increased ventilation effectiveness.

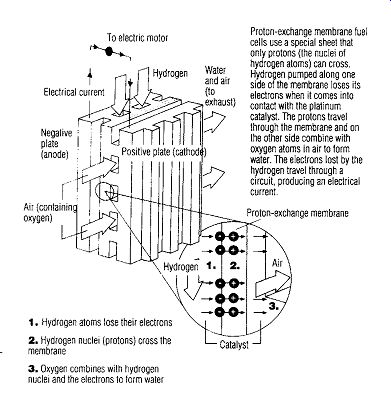

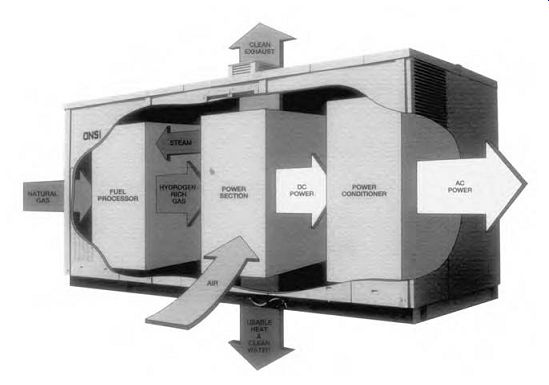

Refrigerants containing CFCs and HCFCs are being avoided. Fuel cells and photovoltaics are promising increased energy autonomy to larger buildings.

1. HVAC AND BUILDING ORGANIZATION

By this time, many decisions about a building's design have been made: design strategies appropriate to the climate and the building's activities have been identified, and the basic siting and overall form of the building have been determined from daylighting and thermal considerations, among others. This section begins by considering the internal yet broad issues of zoning and system choice and ends with a discussion of the more detailed consequences of sys tem choice. A general guide to estimation of a building's thermal zone requirements was presented in Section 8.2, which discussed the importance of differences in function, schedule, and orientation.

(a) Zoning

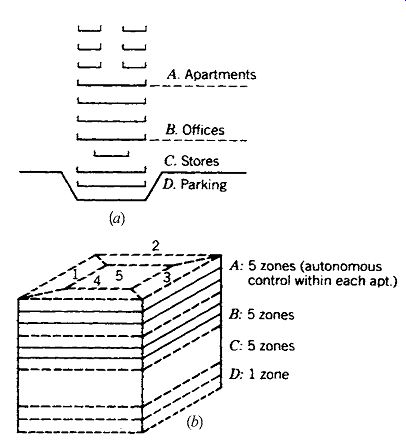

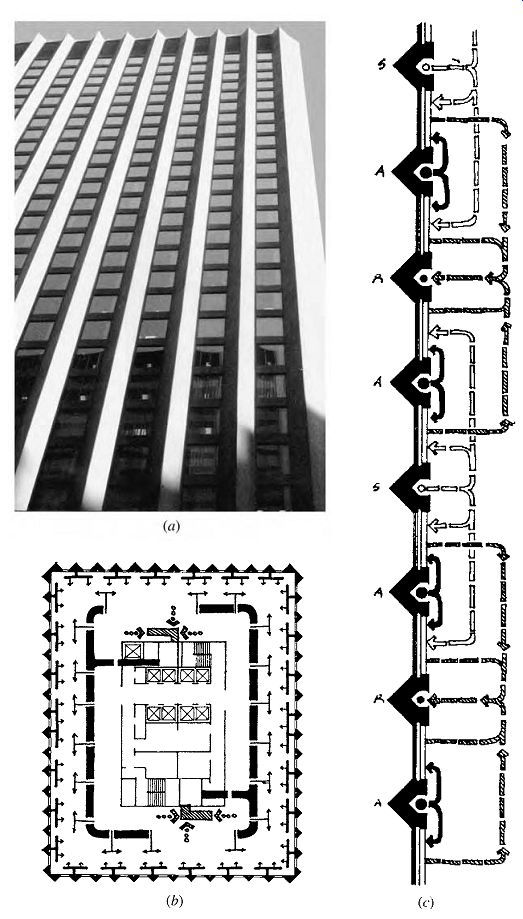

The minimum number of thermal zones for a conventionally designed multipurpose building is shown in Fig. 1. A need for more than these 16 zones could result from differences in scheduling within a zone, such as between offices and stores. As is true of the other occupied floors, apartments have a minimum of five zones (based on orientation); however, the emphasis on individual controls-and the variation in usage patterns- often produces as many zones as there are apartments. When the details of zoning are added to the other preliminary design decisions, the details of HVAC systems can be considered.

(b) System Anatomy

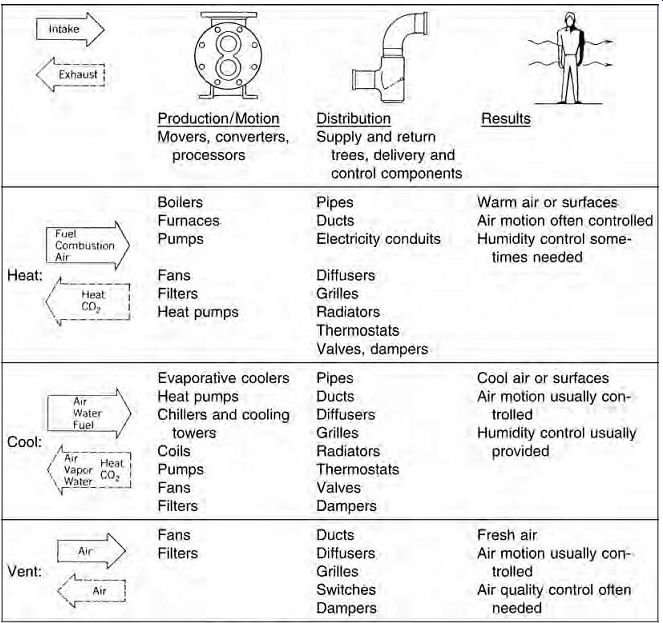

Table 1 describes the basic organization of any HVAC system. Three kinds of common tasks (heating, cooling, and ventilating) are done by production components; usually, they require distribution and delivery components. Intake supplies and exhaust by-products accompany each task.

Although the eventual choice of HVAC system should follow an analysis of the zone's needs, some early concepts underlie system choices.

Fig. 1 The minimum number of thermal zones for a rather large, conventionally

designed, multipurpose building.

(c) Central versus Local Systems

Central systems require one or several large mechanical spaces (often in basements and/or on roofs), sizable distribution trees, and complex control systems. The noise, heat, and other characteristics of such mechanical rooms can be controlled fairly easily, because the machinery is concentrated at a few locations. Similarly, maintenance is easy to perform without interrupting normal activities, although breakdowns in central equipment can paralyze the entire building. Air quality can be controlled by locating the air intakes high above the pollution at street level and by regular maintenance of the centralized air-filtering equipment. Longer equipment life can be expected with regular maintenance. Energy conservation can be served by the recovery of one machine's heat by-product for a nearby machine's heat input.

Although there are many ways to provide for the differing thermal needs of the many zones served by central systems, one important drawback of central systems is the size and length of the distribution trees necessary to carry centralized ser vices to many local receivers. Another drawback s a difference in zone scheduling: when the entire system must be activated to serve one zone (such as computer operations in an office building on a weekend), energy is wasted.

Table 1 Basic HVAC Systems: Tasks and Components

Local systems therefore become increasingly attractive as scheduling differences multiply. Also, pronounced differences in other factors-function (with resulting comfort expectations) or placement within the building, for example-can lead to the choice of local systems. Large and central zed equipment spaces are not required with focal systems; rather, production equipment is distributed throughout the building (or over the roofs of low-rise structures). Dispersal of equipment minimizes the size of distribution trees and greatly simplifies control systems. Moreover, sys tem breakdowns affect only small portions of the building. However, noise and other by-products of multiple machines pose numerous potential threats to occupied spaces, and maintenance is demanding, because access to so many separate locations is often disruptive or constricted. Then, too, air quality depends on the regular cleaning of many filters scattered over the building, often within occupied spaces. The potential for energy conservation seems promising, because heating or cooling is produced only as locally needed, but there is little chance to use one zone's waste heat as another's needed source.

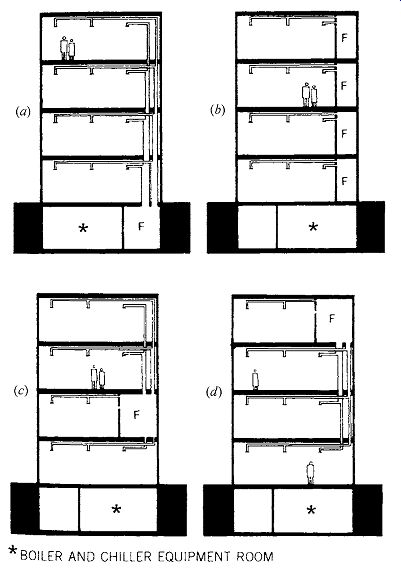

Central heat/cool, local air distribution has become a popular way to take advantage of the favorable characteristics of both central and local approaches. This is shown in Fig. 2b, with a central boiler/chiller space remotely located and fan rooms on each floor. This minimizes the bulky distribution tree for air; although the distribution tree for heated and chilled water is extensive, it is also of much smaller diameter and therefore is relatively easily accommodated. The central equipment room makes energy recovery systems from boilers and chillers more feasible.

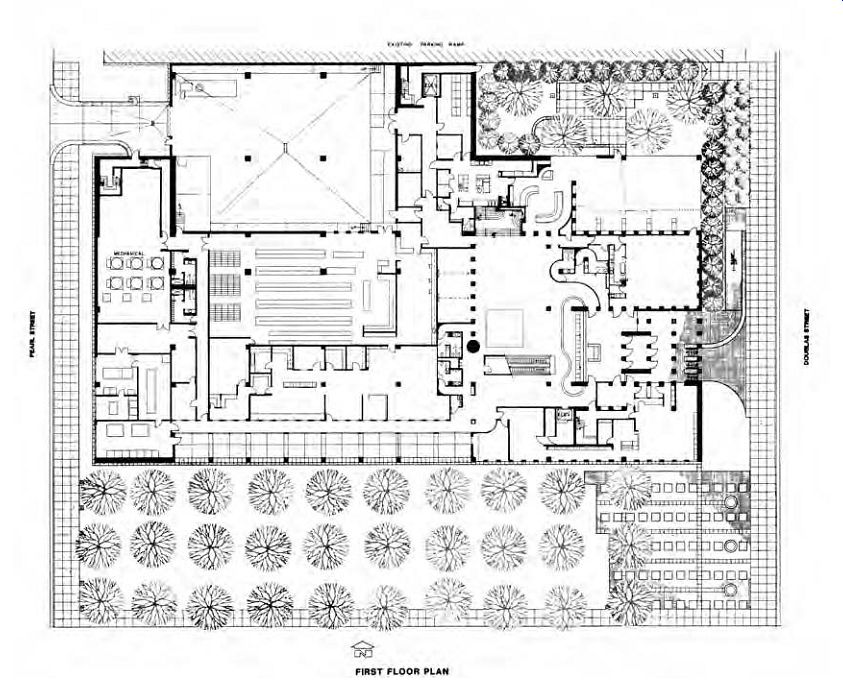

Fig. 2 Fan rooms (F) can

either be combined with or separated from boiler/chiller "equipment" rooms

(*). (a) Common location for a central combined equipment room. (b) Increasingly

common arrangement of a small fan room on each floor, with an equipment room

in the basement. (c) An intermediate floor may be able to provide space for

a central fan room, while the heavier and noisier equipment remains in the

basement. (d) With a top-floor central fan room, the equipment may be located

either on the roof or in a mechanical penthouse, or may remain in the basement.

(d) Uniformity versus Diversity

How similar should the interior environments of buildings be? This question encompasses not only thermal experiences, but visual and acoustical ones as well.

The advantages of uniformity are most evident in a rapidity of design and construction that, through mass production and speed, often brings lower first costs. Uniformity of ceiling heights, light fixture placement, grille locations, and so on promotes flexibility in office arrangements that can extend a building's usable life span. However, there are at least four types of offices, which may need to be interchangeable within such "flexible" space.

The typical enclosed office has the privacy of four walls and a door. The bullpen office has repeated, identical workstations, with low dividers at about the height of the desk surface. The uniform open plan office resembles the bullpen, but with higher divider partitions for added privacy. The free-form open plan office has some individually designed workstations with divider partitions of varying heights (sometimes reflecting the varying status of workers). In the bullpen and uniform open plan office, the resulting uniformity is not always attractive to users, and diversity is often encouraged at a more personal level-with office furnishings, for example. A more thorough approach to diversity can provide stimulus to the user who spends many hours away from the variability of the exterior climate.

If offices must be uniform in ceiling lighting, air handling, and size, the corridors that connect them and the lounges or other supporting service spaces can deliberately be made different. Diversity requires a complete and detailed design of places; it gives the builder a more complex and interesting task; and it can provide orientation and interest to the users. The attractiveness of diversity is evident in most collections of retail shops, in which light and sound-and sometimes heat and aroma-are used to distinguish one shop from the next.

Diversity in the thermal conditions to be maintained, such as warmer offices and cooler circulation spaces in the winter, can be used to enhance the comfort of the office users. Designers have long recognized that a space can be made to seem brighter and higher if it is preceded by a dark, low transition space. Thermal comfort impressions can be manipulated similarly. Less than comfort able conditions in circulation spaces or other less critical zones not only make the critical spaces seem more comfortable by contrast, but also save significant amounts of energy over the life of a building. Furthermore, such conditions can make passive strategies more attractive.

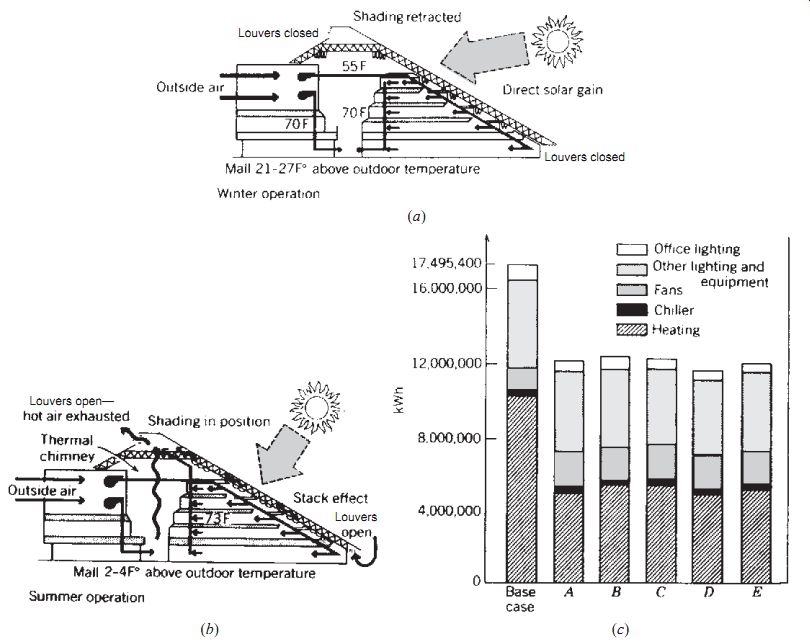

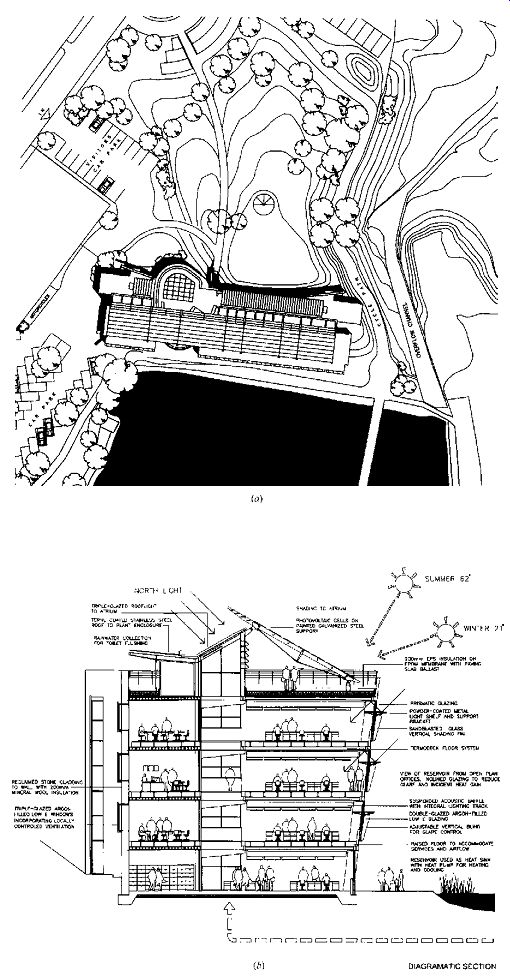

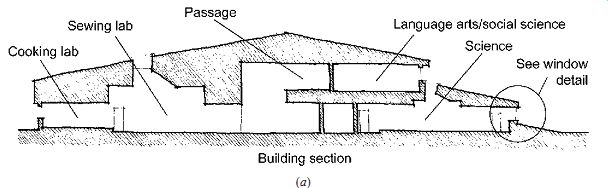

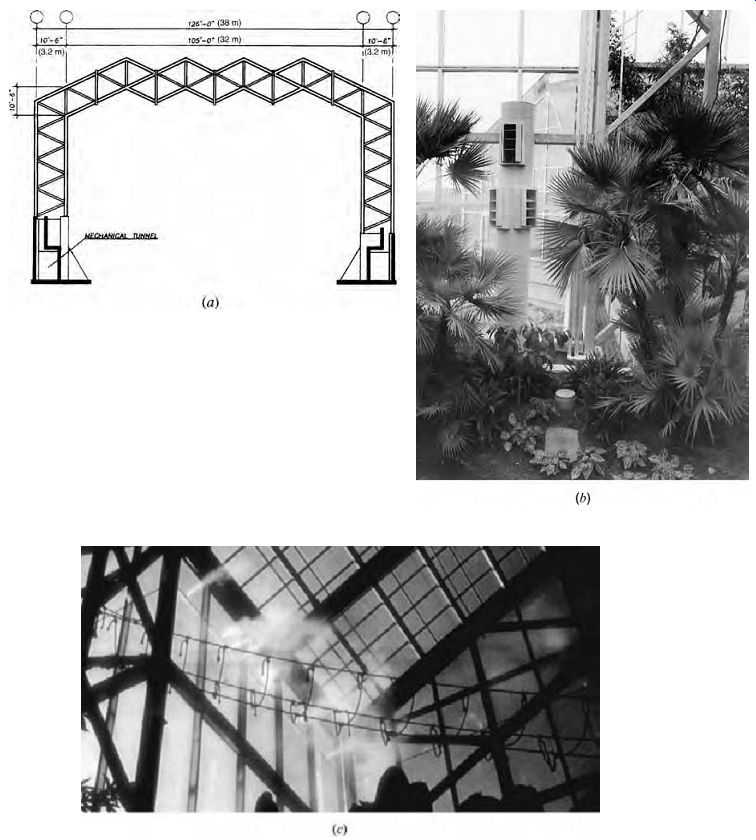

A large-scale demonstration of diversity in thermal zones is shown in Fig. 3. Passive solar heating can make a significant contribution, even through a shallow-sloped, single-glazed cover in cloudy Glasgow, Scotland, largely because the mall area and leisure areas are allowed a much wider thermal range than would be permitted in stores and offices. The overcast skies are quite suitable for daylight, and the addition of summer sunshading makes natural ventilation (through the stack effect, assisted by fans) possible during the cool summers. U.S. Pacific Northwest climate conditions are similar.

Fig. 3 St. Enoch's Square, Glasgow, Scotland: a proposal to use passive

solar heating, daylighting, and natural ventilation. Reiach & Hall and

GMW Partnership, architects (joint venture); Cosentini Associates, energy consultants;

Princeton Energy Group, daylighting consultants. (a) Schematic section showing

winter operation; the mall temperature varies around 63ºF (17ºC) during operating

hours, while offices are kept near 70ºF (21ºC). (b) Schematic section showing

summer operation; the mall temperature varies from about 68 to 74ºF (20 to

23ºC) during operating hours. (c) Estimates of annual energy consumption for

a conventional-design base case and several alternative configurations. Note

the significantly lower heating energy requirements, resulting in part from

the lower winter temperatures allowed for the less-critical zones such as the

mall and the leisure areas in configurations A to E.

(e) Comparing Systems and Zones

In the process of selecting systems from among the wide variety available, it is helpful to consider the match between the zones' characteristics and those of various systems. Among the considerations are zone placement (close to or away from the building skin), the zone's thermal loads, the comfort determinants based on the zone's activities, the space available for system components within the zone, and the life-cycle costs of various system alternatives.

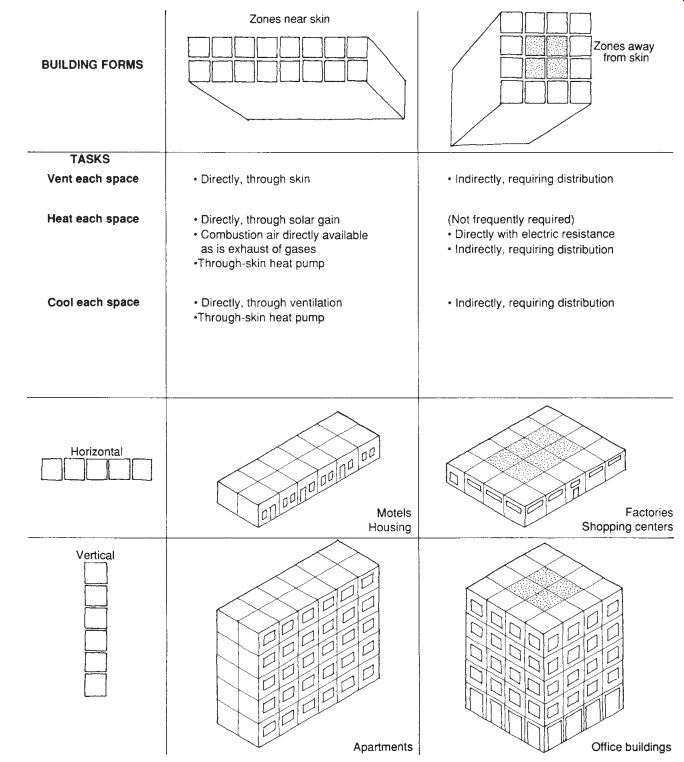

Fig. 4 Zone placement

and building form are related to heating, cooling, and ventilating tasks; some

applications take on typical building forms. ( University of Oregon.)

Zone placement will sometimes preclude local systems, which depend on easy access to outdoor air both for fresh air and for a heat source or sink.

Local systems for interior (away-from-skin) zones are awkward. Relationships between zone placement and building forms are shown in Fig. 4.

The thermal loads on each zone determine the extent to which heating or cooling is the dominant problem-which, in turn, can influence the choice of system. A zone with little cooling load and low moisture production may be well served by a simple system of fresh air plus heating, with no humidity control. Zones that require cooling will usually also require more complete control of air motion and relative humidity. Although it is risky to generalize about which comfort determinants are most important (given the differences between activities and between individuals), it can generally be assumed that comfort and thermal tasks are related.

Thus, the choice of systems can be based partly on whether the system provides good control of the more important comfort determinants.

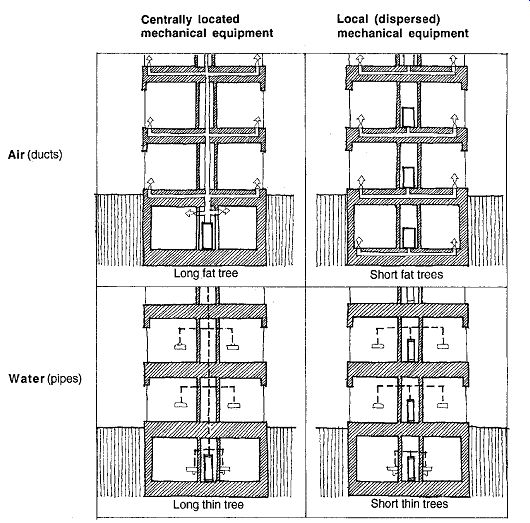

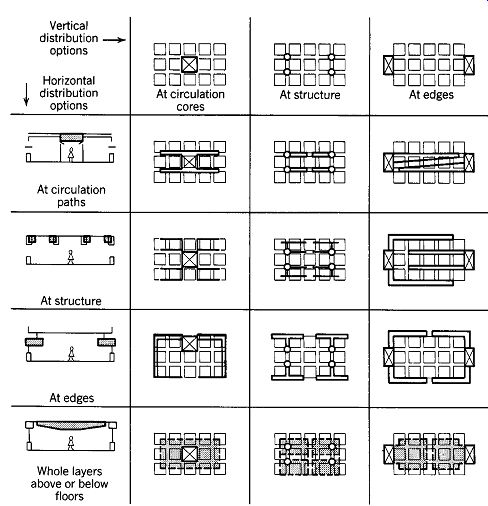

Fig. 5 Matrix of distribution trees.

Table 2 Procedure for Matching Zones and Systems

(f) Distribution Trees

How many, what kind (air or water), and where should HVAC distribution trees be placed within buildings? HVAC system choice is influenced by the amount of space the system requires. In some cases, it is easy to provide small equipment rooms at regular intervals throughout a building, such that little or nothing in the way of a distribution tree will be required. In other cases, a network of distribution trees and central, large equipment spaces are easier to accommodate. These central systems typically fall into one of three classifications:

All-air (the largest distribution trees)

Air and water

All-water (the smallest distribution trees, with local control of fresh air)

The details of these systems can be found in Sections 10.5 to 10.7, along with typical applications and space requirements. Figure 10.5 shows the matrix of central-local, air-water influences on distribution trees.

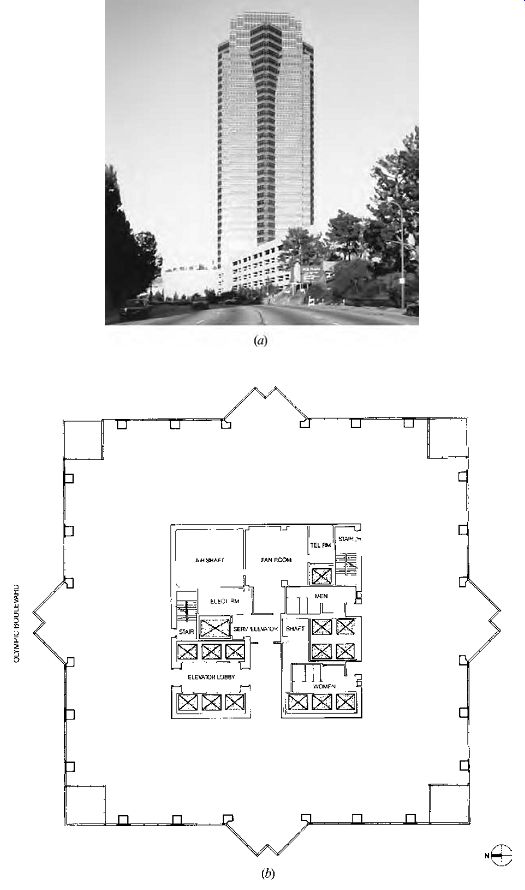

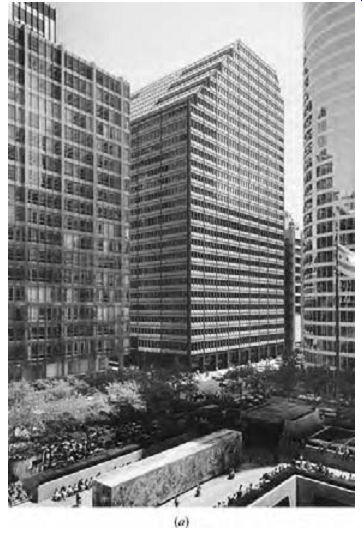

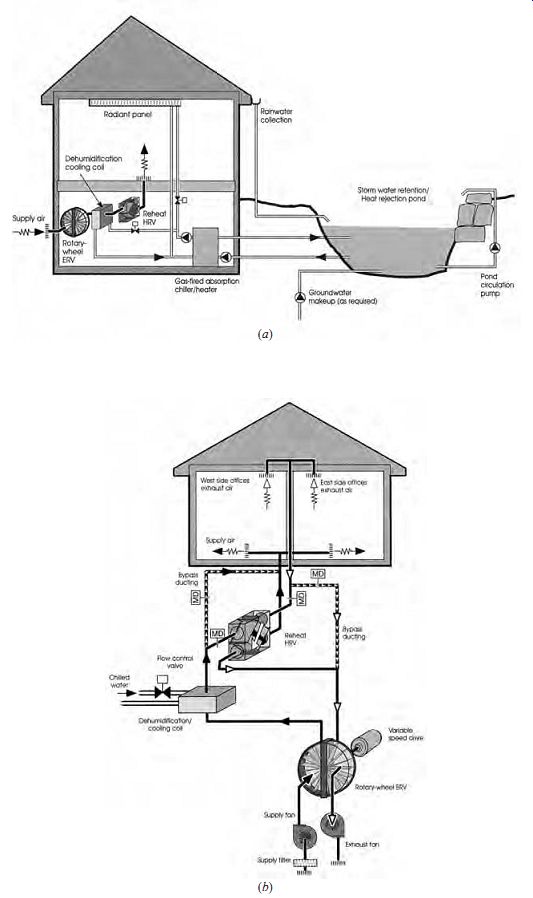

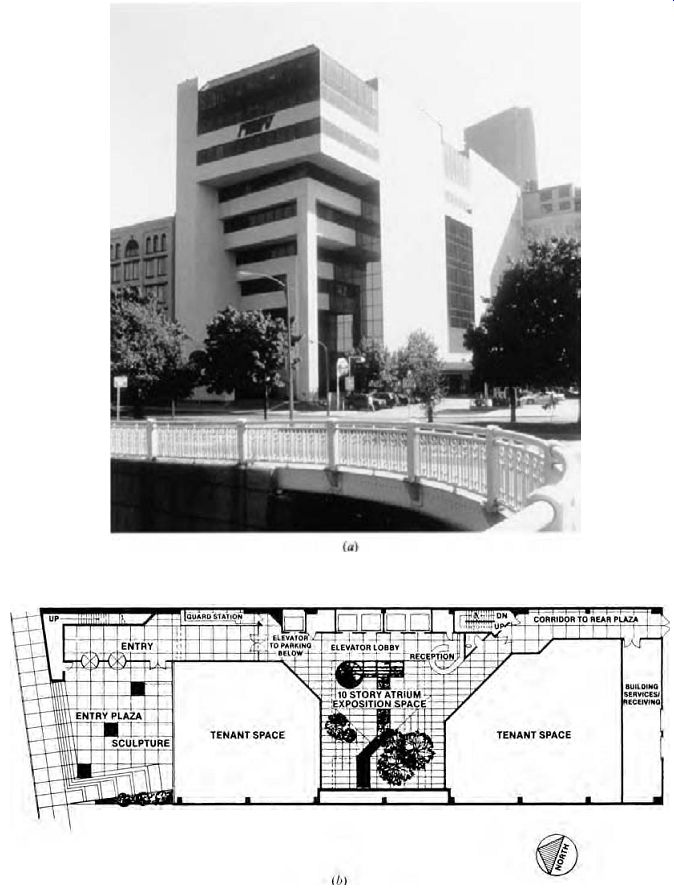

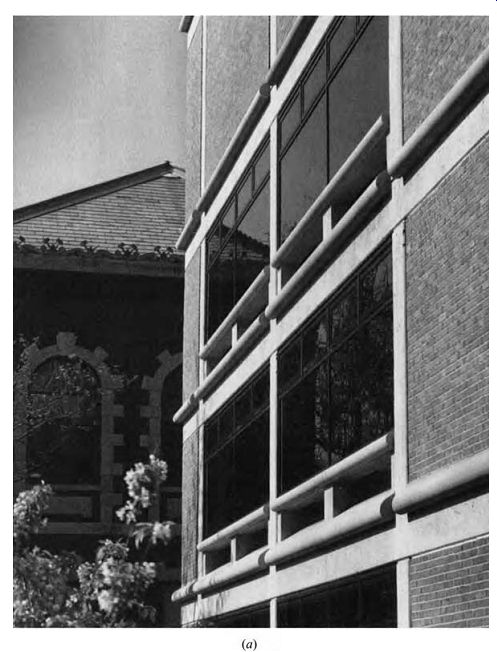

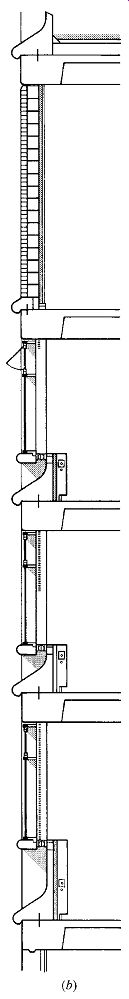

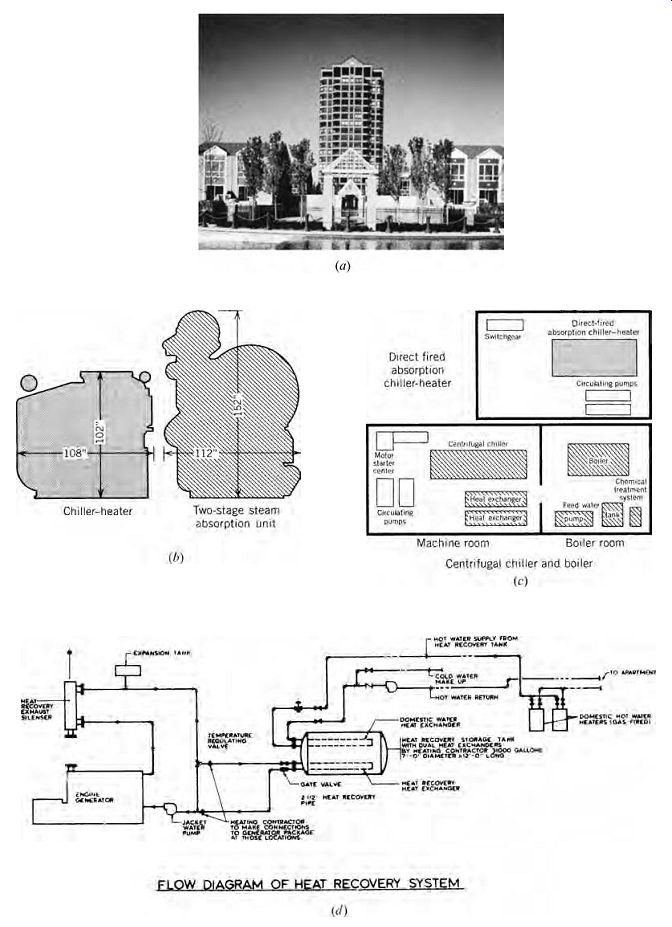

Fig. 6 The Fox Plaza Building, San Francisco. Victor Gruen Associates,

Inc., architects and engineers. (a) Elongated façade facing northeast shows

the 16 floors of apartments above, the 10 floors of offices below, and the

13th-floor mechanical space. In that space are chillers, and pumps for cooling

tower water and chilled water, as well as boilers and converters (steam to

hot water) for the fan-coil units in the residential stories above and hot

water coils in the office stories below. Air handling for the offices is also

located here, down-fed by high-velocity ducts. Residences are heated; offices

are heated and cooled. (The roof has the cooling tower and the domestic hot

water generator-storage units for the residential stories.) (b) Construction

photo with air-handling units visible on the 13th floor, and downfeed ducts

that supply high-velocity hot and cold air to the office floors.

A simplified procedure for matching zones and systems is shown in Table 2, in which preliminary system choices are made for a building such as the multipurpose structure shown in Fig. 1. In this process, the original 16 zones are translated into three local systems and three central systems: one all-air, one air and water, and one all-water.

The Fox Plaza Building in San Francisco, which illustrates many of the matches between systems and zones, is shown in Fig. 6. This project includes four major building types in one structure:

1. Underground garage for the storage of cars

2. Commercial center at ground level, including a bank, a women's specialty store, and other commercial establishments

3. Ten floors of offices

4. Sixteen floors of apartments

The mechanical level is located between the office portion of the building and the apartments above.

The distribution trees-heating, air conditioning, electrical, and so on-are thus directed both upward and downward, resulting in two shorter trees rather than one longer tree. The spatial requirements of offices and those of apartments are quite different; thus, the floor-to-floor heights, window treatment, and heating, cooling, electrical, elevators, and other services are different. The placement of the mechanical level between the offices and the apartments also provides for a definite visual separation between the two functions.

Quite unusual is the placement of the steam boilers on the 13th floor instead of in the conventional basement location. Only a small amount of auxiliary equipment is located on the roof and in a small portion of the garage. Residential areas have hot-water heating (residential cooling being rarely needed in San Francisco), offices have dual duct, high-velocity heating/cooling, and commercial (ground-floor) tenants are supplied with hot and chilled water for individual climate control requirements.

(g) Central Equipment Location

The Fox Plaza Building has an intermediate location for the heating and cooling production equipment-one that separates floors of apartments from floors of offices. Other typical locations for central equipment are in the basement (where machine noise is most easily isolated, utilities are easily accessed, and machine weight is little problem) and on the roof, where access to air as a sink for reject heat is easiest of all, and headroom is unlimited.

Very tall buildings may require several intermediate mechanical floors. Examples of these approaches are found throughout the rest of this Section.

The equipment's considerable heat, moisture, air motion, noise, and vibration potentially annoy occupants on nearby floors (or even neighboring buildings). As shown in the Fox Plaza example, the equipment placement can be expressive of building services and can play a useful demarcation role between vertical layers of high-rise buildings. Moving the equipment off the roof also frees this prestigious view location for high-rent occupancy and allows a roof form much more expressive of great height than a flat roof with a cooling tower.

(h) Concealment and Exposure

The pipes, ducts, and conduits that take the necessary resources to and from the interior are often carried within a network of spaces unseen by anyone except builders and repair people. The advantages of concealment include less noise from moving water and air, fewer surfaces requiring cleaning, less care necessary in construction (leaks, not looks, are important), and more control over the appearance of the interior ceiling and wall surfaces. Although maintenance access to such hidden supply lines is more difficult, various types of readily removable covers are available, particularly in suspended ceilings.

However, the exposure of these supply net works provides an honest and direct source of visual (and occasionally acoustical) interest. Exposure in corridors and service areas and concealment in offices constitute an approach used in many office buildings. Flexibility is usually encouraged by expo sure; changes can be easily made when there is no need for neatly cut holes in concealing surfaces.

However, flexibility from full-height movable partitions requires constant ceiling heights-a feature of the suspended-ceiling approach.

One of the more spectacular examples of exposed mechanical (and structural) systems is shown in Fig. 7--the result of a design competition for a museum of modern art, reference library, center for industrial design, center for music and acoustic research, and supporting services in down town Paris.

When users are invited to play an active role in adjusting conditions inside, exposure of the switches they manipulate is helpful. Visible mechanisms not only remind users of their opportunities but also encourage user interaction. In this way, adjustments are sometimes discovered that the designer had not anticipated.

Fig. 7 Centre Georges Pompidou, Paris. A view of the mechanical support

systems. Piano + Rogers, architects.

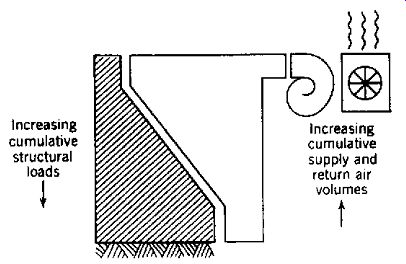

Fig. 8 Distribution trees: with rooftop centralized air handling, the supply

and return air duct sizes decrease as they approach the ground. Conversely,

the structural load increases toward the ground.

(i) Mechanical-Structural Integration or Separation

The similarity of these two technical support systems-structures and environmental controls- has intrigued designers ever since mechanical systems began to require substantial volume for distribution, as in air-duct systems. As the complexity and size of the mechanical distribution systems was increasing with technological development (typically, more air is required to cool a space than to heat it because of a lower delta_t), the increased strength of materials was reducing the size of the structural system. The uncluttered floor areas between the more widely spaced columns became desirable for flexibility in spatial layout. With the mechanical systems at or within these columns, floor areas remained clear, thus giving mechanical-structural integration further impetus. With the new expectations for cooling, the refrigeration cycle's cooling tower often moved to the roof, often taking the air-handling machinery with it. This further encouraged the merging of systems, for one system was growing wider as the other diminished (Fig. 8). Thus, a fixed-column cross section, consisting mostly of the structural column at the base and the air duct at the top, became possible.

Yet the functions of these systems differ widely: compared to the dynamic on-off air, water, and electrical distribution systems, the structural sys tem is static-gravity never ceases. The moving parts in mechanical systems need maintenance far more frequently than the connections of structural components. Changes in occupancy can mean enormous changes in mechanical systems, requiring entirely different equipment; structural changes of such magnitude usually occur only at demolition.

Mechanical systems can invite user adjustment; structural systems rarely do. Thus, although it is possible to wrap the mechanical systems in a structural envelope, it is of questionable long-term value, given the differing life spans and characteristics of these systems.

The probability of future change suggests that the mechanical system be the exposed one, despite the appeal to many designers of the structural system's cleaner lines.

Fig. 9 Distribution tree placement options, both vertical (with impact

on the plan) and horizontal (with impact on the section). (From class notes

developed by G. Z. Brown, University of Oregon.)

(j) Distribution Tree Placement Options

These options are summarized in Fig. 9. Vertical placement options are important because they affect floor space, influencing the flexibility of spatial layout and the availability of usable (or rentable) floor space. Horizontal placement options affect ceiling height-a particular issue in daylighting design and sometimes a critical factor when overall height limits are imposed yet maximum usable floor space is desired. (In Washington, DC, for instance, no building can rise higher than the Capitol.) Both vertical and horizontal distribution at the edges can have a dramatic impact on building appearance.

The history of distribution trees and high-rise buildings is one of trends and countertrends. Initially, multistory buildings relied upon daylight and cross-ventilation, so a thin, relatively high-ceiling plan with much perimeter was favored (refer to Fig. 3.33). The heat gain and loss was all at the perimeter, so perimeter distribution trees (carrying only steam or heated water, and of quite small diameter) were generally used. As electric lighting and thus the need for air conditioning increased, so did the thickness of floor plans; large central internal areas needed a lot of forced, cooled air.

Central boilers, chillers, and fan rooms were the norm. Thus, bulky air distribution trees appeared.

At about the same time, the glass curtain wall and its slick, two-dimensional look of modernity became fashionable. The air distribution trees were so visually intrusive on the façades that they were pushed to the core, where cooling needs were relatively steady. However, the thin glass perimeter experienced extreme needs for both heating and cooling; getting from vertical trees at the core to the perimeter required larger cavities above suspended ceilings. This pushed the ceiling in the offices down to keep floor-to-floor distances economical. Vast office areas resulted that were visually dull, low-ceilinged, and without daylight.

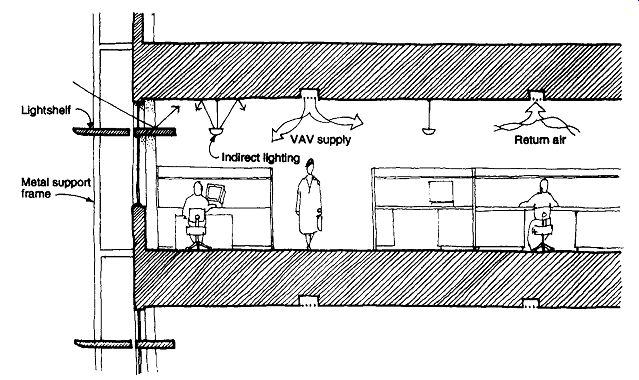

Now, countertrends include decentralized air handling, with small fan rooms on each floor.

Vertical air distribution trees are shrinking, horizontal ones becoming more common. At the same time, daylighting is pushing office ceilings higher; so is a preference for indirect lighting and its compatibility with computer screen visual comfort.

Night cooling utilizing thermal mass is encouraging the exposure of concrete structure and favoring raised-floor air supply/ventilation systems.

A renewed interest in sun control is encouraging three-dimensional façades, replacing two-dimensional reflective glass façades (which merely redirect the sun toward someone else). With increased three-dimensionality at the façade, perimeter distribution trees are once again conceivable.

It is logical to place at the perimeter the parts of the system that deal with the effects of sun, shade, and temperature change in the several perimeter zones, leaving at the core a separate network to handle the more stable interior areas. The disadvantages of perimeter distribution include (usually) higher construction costs and an environment that is more thermally hostile due to the extremes of out door temperature.

Vertical distribution within internal circulation cores is very common, as it leaves a maximum of plan flexibility for the rest of each floor and does not disturb the prized floor areas nearest windows.

However, one centralized vertical distribution trunk will require large horizontal branches near the core, so with this choice early thought must be given to the horizontal placement options.

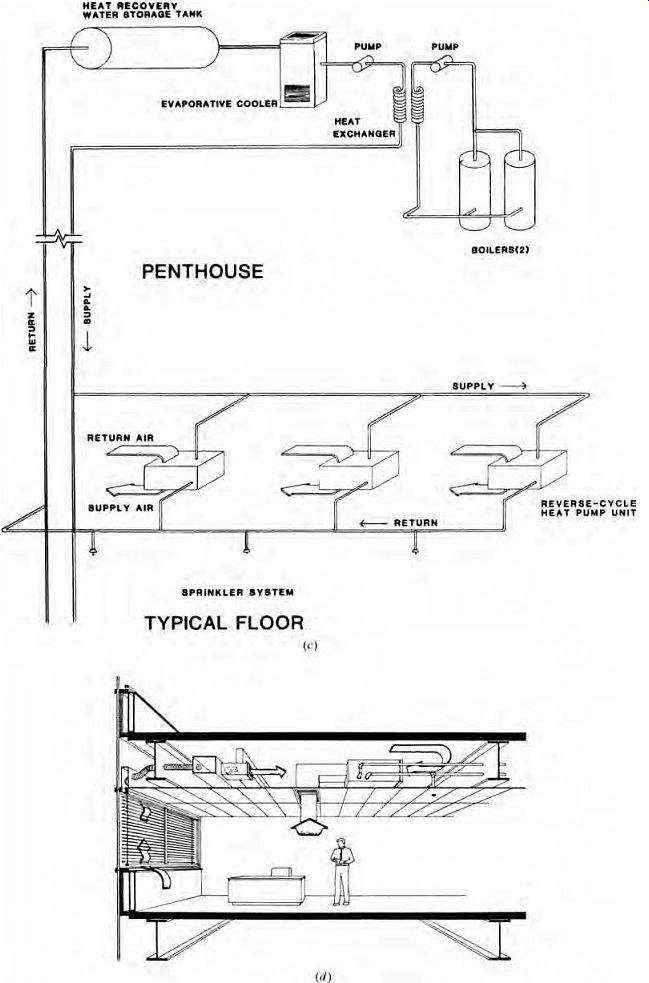

An unusual example of vertical air distribution at the core is shown in Fig. 10. The Fox Plaza, Los Angeles, office building's unique features include both fan rooms on each floor and a large central vertical air shaft. This air shaft begins at the bottom as a fresh air intake to each floor and tapers to become, at the top, an exhaust (heated) air outlet from each floor. Thus, the stack effect is utilized to help supply fresh and exhaust stale air from a large building, with help from small supply fans at each floor.

Vertical distribution integrated with structure creates some intriguing possibilities where the structure-HVAC integration concept is suitable. Multiple HVAC trees are implied (because there are multiple columns with which they are integrated), so the horizontal branches tend to be small. However, these branches often join the vertical trunk at the same place where critical column-to-girder structural connections need to be made; interference is common and can be costly to correct. Vertical distribution at the edges is potentially dramatic in form but costly to enclose (if outside) or wasteful of prime floor space (if inside).

Horizontal distribution above corridors is very common, since reduced headroom here is more acceptable than in the main activity areas.

Furthermore, corridors tend to be away from windows, so their lower ceilings do not interfere with daylight penetration. Because corridors connect nearly all spaces, horizontal service distribution to such spaces is also provided. Furthermore, exposure of these services above corridors can heighten the contrast between such serving spaces and the uncluttered, higher ceilinged offices that are served. Horizontal distribution at the structure is sometimes chosen, particularly where U-shaped beams or box beams provide ready channels for HVAC distribution. However, the penetration of horizontal structure members by these continuous service runs must be coordinated. Horizontal distribution at the edges can be integrated usefully with sunshading devices and light shelves; it can also act as a spandrel element that contrasts with the window strips. Horizontal distribution within whole layers below floors (or above ceilings) is often utilized, now increasingly common with displacement ventilation systems.

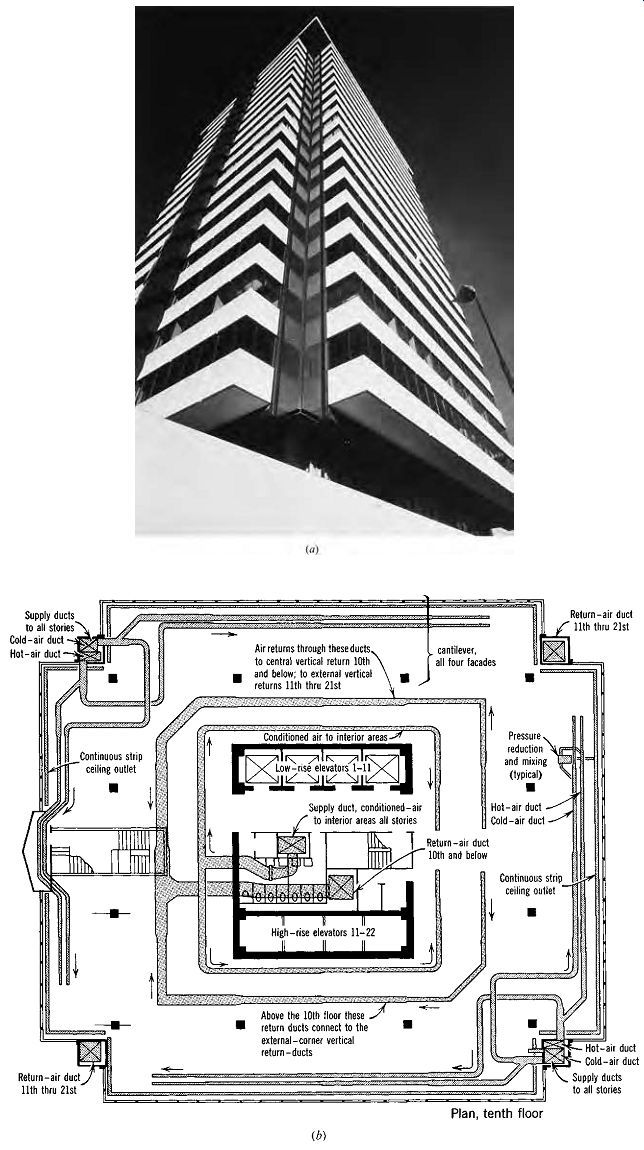

An example of supply at the edge for both vertical and horizontal distribution is found in the International Building in San Francisco (Fig. 11). Here the vertical shafts are prominently exposed at the corners; these shafts carry supply and return ducts serving the four perimeter air conditioning zones. Air-handling equipment and a 750-ton refrigeration plant are located on the floors just below the terrace level (those least desirable for renting). Each corner duct branches to serve two zones, which are separately controlled. Pressure reduction and blending are done by equipment in the hung ceiling, and from these points air flows to strip diffusers directly above the glass on the four sides of the building. Local controls offer comfort to personnel in each area.

Interior zones on each floor are supplied by a riser duct in the building core, which branches at each floor to a loop just outside the line of elevators. The loop serves ceiling diffusers. Between the perimeter loop and the interior loop, a return loop collects air for return to the central station (second and third floors). These return loops on the 11th to 21st floors are picked up by external return risers on alternate exterior corners. From the 10th floor down, the loops are picked up (as shown in Fig. 11) by an interior return riser that extends down through the core in front of the blank faces of the high-rise elevators. To provide a clear space between the elevator banks on the main floor (fourth or terrace), the two core ducts' risers are offset at the ceiling of that story.

In summary, perimeter air for all stories is sup plied through corner ducts. Central air for all stories is supplied through a core duct. All return air above the 10th floor is carried down through the return ducts at the other two corners. Return air from the 10th floor and below is carried down by a return duct in the core.

Further examples of the relationships among HVAC systems, their distribution trees, and buildings are given in examples that accompany the more detailed descriptions of large-building HVAC systems in Sections 10.4 to 10.7.

Fig. 10 The Fox Plaza, Los Angeles, office building is a 34-story, 800,000-ft^2

(74,320-m^2) granite and glass tower (a) with an unusual vertical distribution

tree. (b) Typical lower-floor plan (floors 6 to 16) shows both a fan room and

a large vertical air shaft. At this lower level, most of the shaft area is

supplying outdoor air (from an intake in the bluff face below the building);

the remainder is exhausting stale air toward the roof. Note the lack of columns

between the core and perimeter, contributing to office layout flexibility.

(c) Typical upper-floor plan (floors 31 to 33) shows fewer elevators; by this

level, most of the shaft area is exhausting stale air toward the roof. (d)

Section shows the tapered interior of the constant-cross-section central air

shaft, which relies upon the stack effect to bring in (usually cooler) outdoor

air at the base and expels hotter exhaust air at the top.

Fig. 11 The International Building, San Francisco. Anshen and Allen, architects; Eagelson, Engineers (Charles Krieger, E.E.), mechanical designers. (a) Photo of one of the four corner main duct enclosures. (b) Tenth-floor plan. Column

bay spacing is 24 ft, 6 in. (7.5 m), with a 16-ft (4.9-m) cantilever on all

four façades. The major supply ducts (both hot and cold) to all 21 floors are

located in two opposite corners. Each of these supply distribution trees serves

two adjacent sides of perimeter offices. The conditioned air is supplied from

a third-floor mechanical space. In the opposite two corners, return air from

the upper 11 floors is collected and taken down to the mechanical space. The

remainder of the return air is taken down through the core.

2. HVAC SYSTEM TYPES

Large buildings have so many thermal zones, and there are so many ways to move heat from one place to another, that hundreds of HVAC system variations have been devised. A few of the most typical are introduced in this section; the following section treats in detail the major components of HVAC production and delivery. Finally, some common variations on each of the four main system classifications are presented.

One way to classify HVAC systems is by the media used to transfer heat. Although thousands of liquids and gases can be used as carriers of heat, the three most common in building applications are air, water, and refrigerant. Traditionally, there are four main system classifications:

Direct refrigerant systems All-air systems Air and water systems All-water systems In the last three cases, the heating/cooling production equipment typically is located centrally in a large building, often rather far from the thermal zones it serves. The air-handling components may be either centrally served or served floor by floor.

Distribution tree size and placement thus become important issues when those systems are selected.

In direct refrigerant systems, the heating/cooling machine usually is located adjacent to the zone(s) it serves; thus, the machine's environment-the microclimate it creates and its needs relative to the zone's environment-becomes an important consideration.

(a) Direct Refrigerant Systems

These systems (see Section 9) nearly eliminate the distribution trees of air or water, relying instead on a heating/cooling device adjacent to or within the space to be served. Thus, they are prevalent in skin load-dominated buildings with extensive perimeter zones; these tend to be smaller buildings.

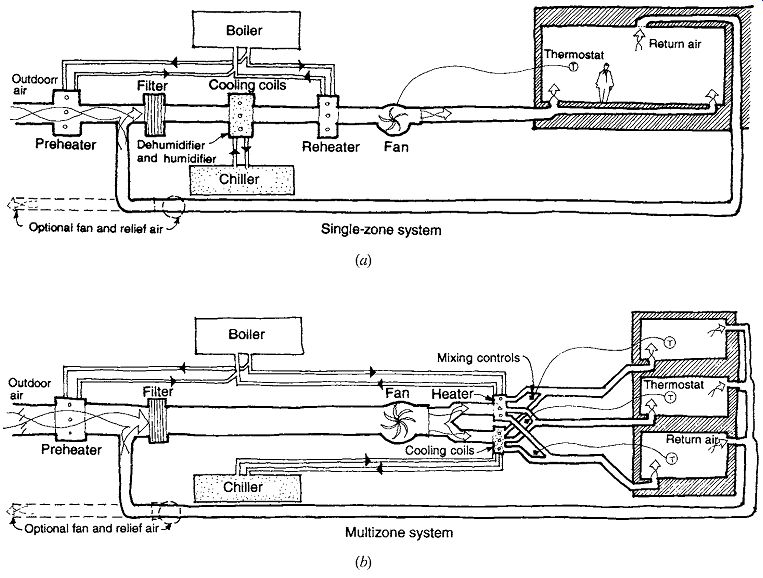

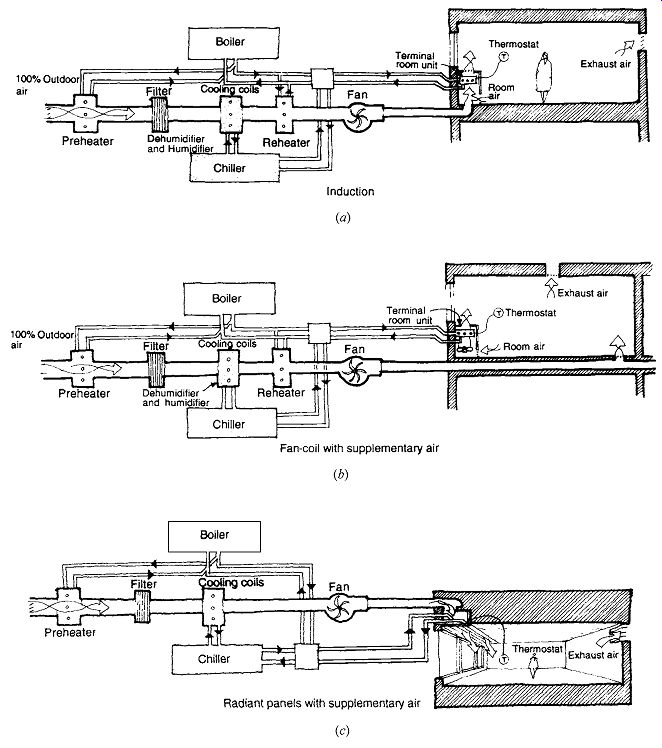

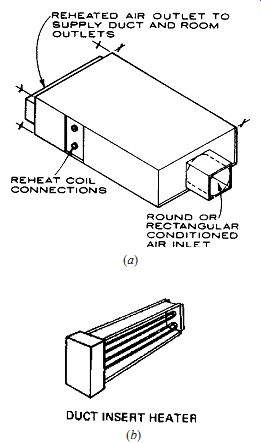

(b) All-Air Systems

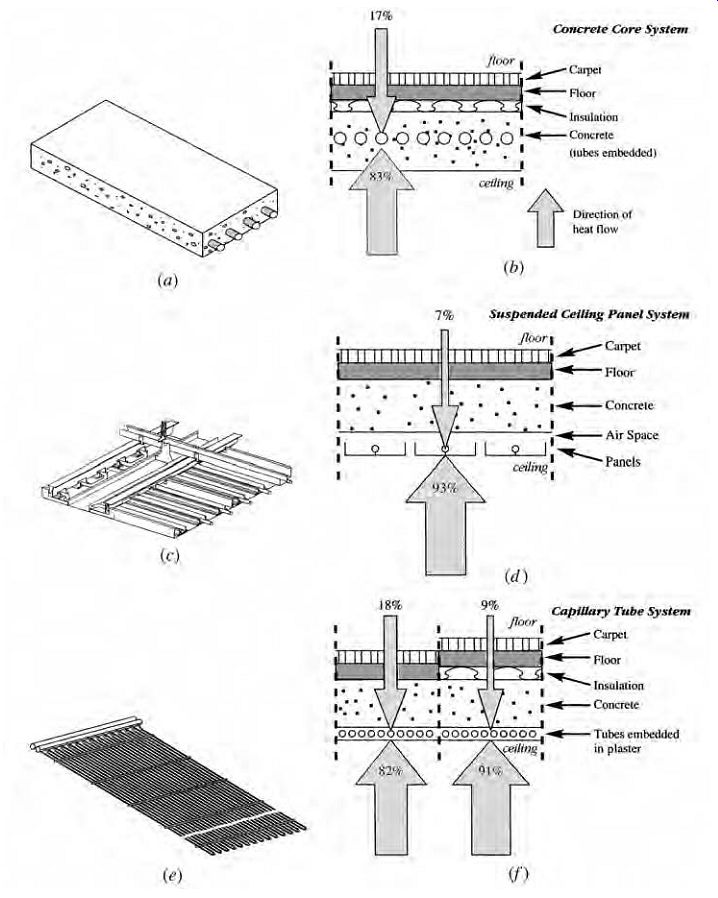

The more common variations on all-air systems are shown in Fig. 12. Because air is the only heat transfer medium used between the mechanical room (central station) and the zones it serves, and because air holds much less heat per unit volume than water, the distribution trees for this class are quite thick. Sometimes, to reduce duct sizes, higher velocities are used for supply air. This generates more noise and higher friction, resulting in more energy used by fans; higher velocity should be used only sparingly, where space limitations are extreme.

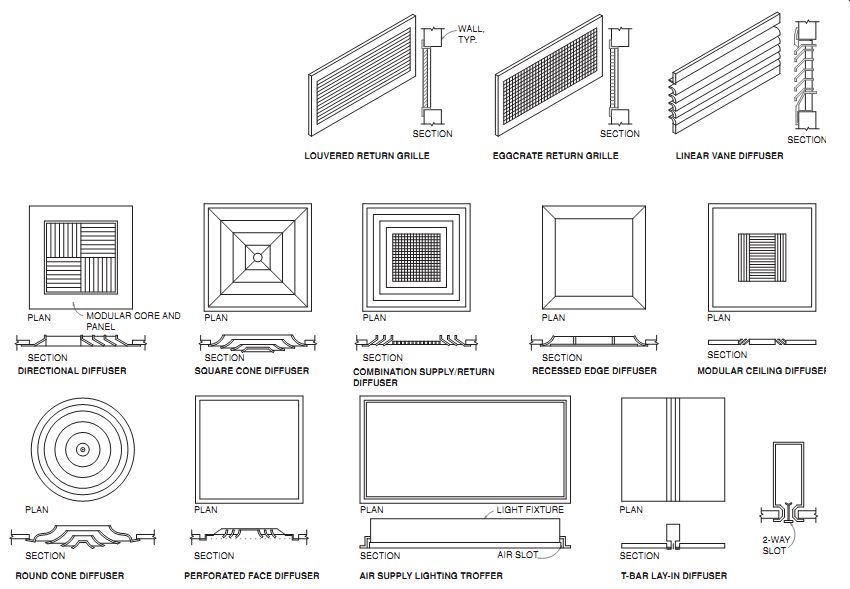

For comfort, however, these systems are, over all, the best. The quantities of air moved through the central station(s) are heated or cooled, humidity controlled, filtered, and freshened with outdoor air-all under controlled conditions. Within the zones, supply diffusers/registers and return grilles allow a well-planned stream of conditioned air to thoroughly permeate all work areas. More details on air distribution are found in Section 10.4 and on this HVAC type in Section 10.5.

Single-Zone Systems. This (Fig. 12a) is the common small-building forced air-system con trolled by a single thermostat.

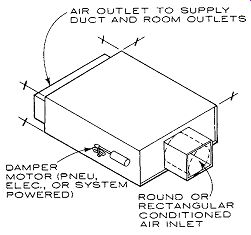

Single-Duct, Variable-Air-Volume (VAV) Systems. This (Fig. 12c) is the most popular large building system of recent years. Its single duct requires less building volume for distribution than do multiduct systems, and the variation of air volume flow rate (rather than of air temperature) saves energy relative to the single duct with reheat (Fig. 12e). Depending on outdoor conditions and prevailing indoor needs, the central station supplies at normal velocity either a heated or a cooled stream of air. Automatic volume controls (linked to each zone's thermostat) adjust the volume admitted to that zone within an air terminal diffuser (often located above a suspended ceiling). When the central station is supplying cold air, a zone that needs more cooling will get more air; an unoccupied room with no internal gains, or a space with heat loss through an exterior wall, will get less air. Clearly, such a system is well suited to serve the interior, always-hot zones of internal-load-dominated buildings. Less clear is its suitability for the perimeter zones of buildings in cold, cloudy conditions.

Fan-Powered VAV Systems. This variation (Fig. 12f ) allows individual units to heat when the main supply system is cooling; it might therefore serve perimeter zones. In this case, the cool air is reduced to the minimum required for acceptable indoor air quality (IAQ), and the unit's fan draws additional air from a ceiling (or floor) plenum, heating it as required.

Multizone Systems. Because each zone has an individual centrally conditioned airstream, the total distribution tree volume grows to astonishing size with only a few zones. The central station produces both warm and cool airstreams, which are mixed at the central location to suit each zone. These systems (Fig. 12b) are more likely to be found on medium-sized buildings or on larger buildings in which smaller central stations are located on each floor. The single-return airstream collects air from all zones (as is the case for the other systems in this class). Energy savings result when a "bypass" deck is added, allowing each zone to choose some un-thermally treated return air as part of the supply air.

Single-Duct with Reheat. This (Fig. 12e) system (along with VAV) has the smallest distribution tree of this class, because at each zone the only object added to the duct is a small reheat coil (heat provided by steam, hot water, or electric resistance). (Technically, this could also be called an air and water system.) The central station provides a single stream of cold air that must be cold enough to meet the maximum cooling demand of any one zone. All other zones reheat this air as needed. In cold weather, outdoor air at temperatures as low as 38ºF (3ºC) can be used; the colder this single central airstream, the less air need be circulated (and the smaller the ducts). For buildings with large interior zones in most U.S. climates, however, the central air stream must be cooled most of the time; then more energy must be spent to reheat the airstream at most zones. These systems thus are notorious for energy wastage, although careful engineering can make them attractive for some climates.

Fig. 12 (a-f) Schematic diagrams of all-air HVAC systems. An underfloor

air supply is shown here to simplify the diagram, but a ceiling supply is much

more common.

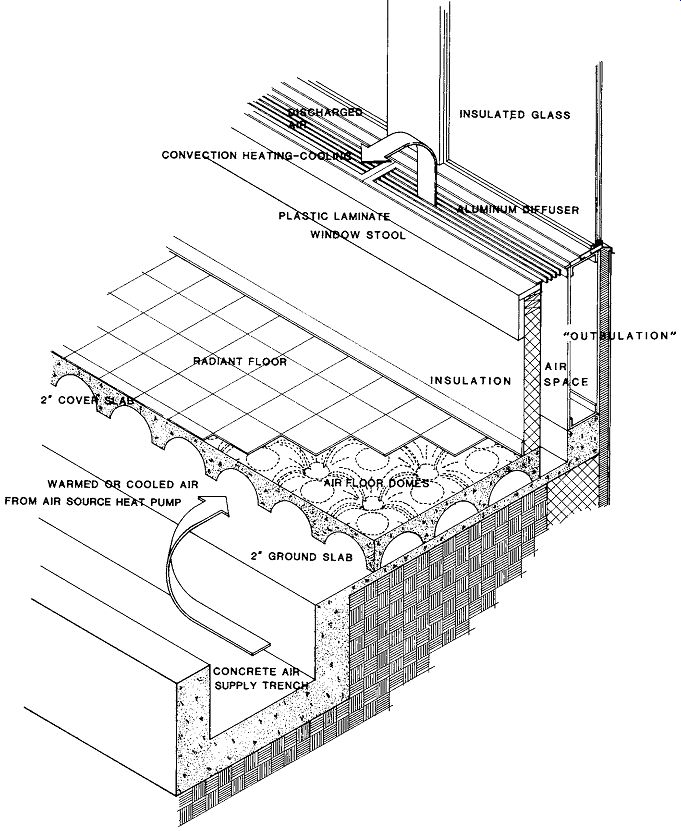

Fig. 13 (a-c) Schematic diagrams of air and water HVAC systems. An underfloor

air supply is shown here to simplify the diagram, but a ceiling supply is more

common. In (b) the supplementary air is often delivered directly to the fan-coil

unit.

Dual-Duct, Constant-Volume Systems. The dual- (or double-) duct system requires two complete distribution trees (Fig. 12d); at the height of summer the cooling airstream does all the work, whereas in the coldest winter conditions the heating airstream carries the load. Most of the time, air from these two streams is mixed to order at each zone's air terminals. Because both temperature and volume can be controlled, this system offers better comfort under reduced load conditions (for example, an only partially occupied room) than does the single-duct VAV system. However, it is much more expensive to install, consumes much building volume for the two distribution trees, and usually consumes more energy than the single-duct VAV system that has largely replaced it.

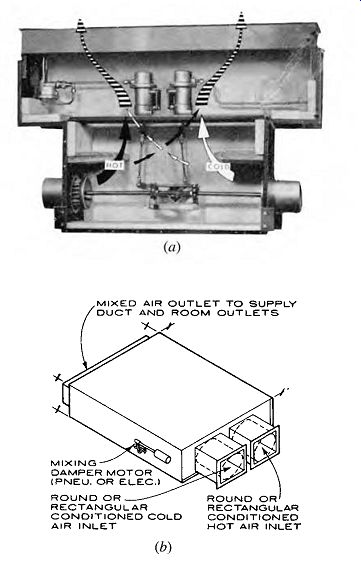

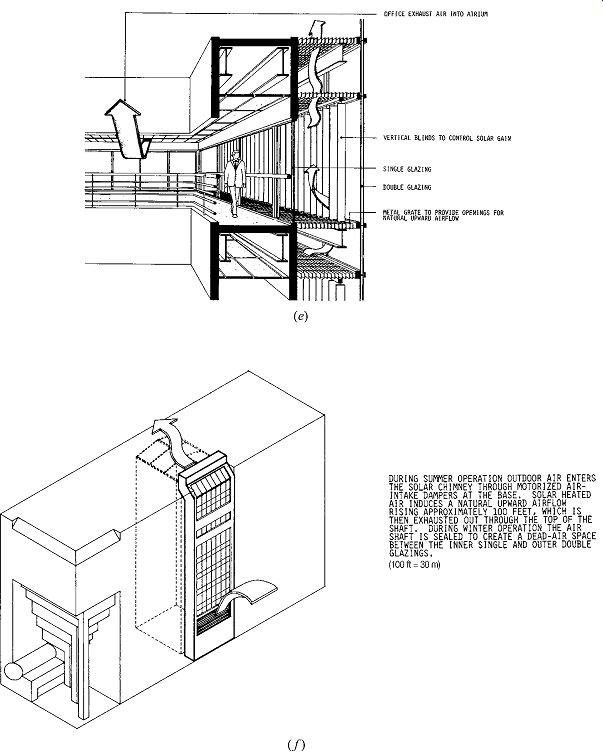

(c) Air and Water Systems

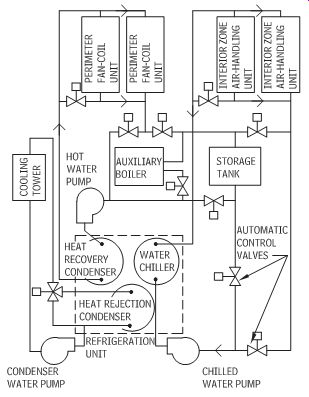

Several variations on air and water systems are shown in Fig. 13. Most of the heating and cooling of each zone is accomplished via the water distribution tree, which is much thinner than the tree needed by air. For air quality-filtering, humidity, freshness-a small, centrally conditioned airstream, equal to the total fresh air required, is pro vided. Thus, several distribution trees are involved, yet the total space they require is almost always less than that required by all-air systems.

Exhaust air may be gathered in a return air duct system, making heat recovery possible. Or (as a cheaper alternative) air can be exhausted locally to avoid the construction of yet another distribution tree. If the water distribution provides either heating or cooling only, it is called a two-pipe system (shown throughout Fig. 13). If it provides simultaneous heating and cooling, it is a four-pipe system.

(Three-pipe systems are a lower-first-cost alternative allowing simultaneous heating and cooling [from two supply pipes with a single return pipe], but they waste energy by mixing hot return and cold return water flows in one return pipe. They are no longer permitted in most locales.) This class of system frequently serves the perimeter zones of large buildings, whereas all-air systems (commonly, single-duct VAV) are used for the interior zones. More details on this HVAC class can be found in Section 10.6.

Induction Systems. This (Fig. 13a) previously common system's terminal units may be found below windows throughout the United States. A high-velocity (and high-pressure), constant-volume fresh air supply is brought to each terminal, where it is forced through an opening in such a way that air already within the room (bypass, or secondary, air) is induced to join the incoming jet of air. A fairly thorough circulation of room air is thus accomplished with only a little centrally treated air. Air then passes over finned tubes for heating or cooling. Thermostats control the unit's output by controlling either the flow of the water or the flow of secondary air.

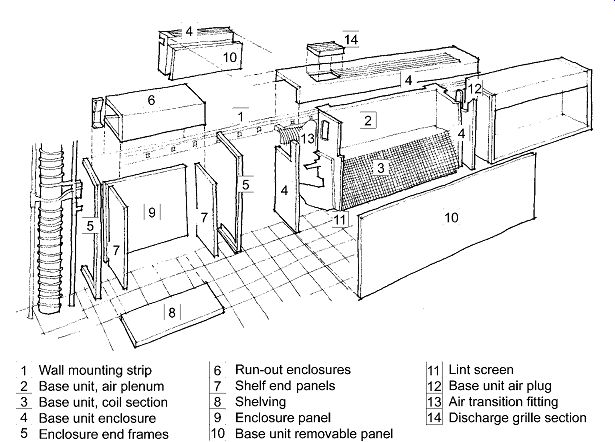

Fan-Coil with Supplementary Air. Another (Fig. 13b) familiar piece of below-window equipment is the fan-coil, which moves room air as it provides either heating or cooling. Centrally conditioned, tempered fresh air is brought to the space in a constant-volume stream; the fan moves both fresh and room air across a coil that either heats or cools the air, as required.

Radiant Panels with Supplementary Air. As suggested in Fig. 13c, either ceiling or wall panels contain the heated or cooled water to provide a large surface for radiant heat exchange. Centrally conditioned, tempered fresh air is brought to the space in a constant-volume stream. The "piece of equipment" within the space is replaced by a large surface, which must be kept clear of obstructions to radiant heat exchange.

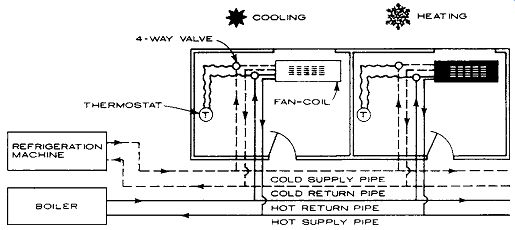

Fig. 14 Schematic diagram of all-water HVAC systems. Four-pipe distribution

trees require smaller volumes than do those for air systems; however, less

thorough provision of outdoor air is a potential concern.

Water Loop Heat Pumps. Because individual heat pumps are used, this system is closely related to direct refrigerant systems. It is often considered an all-water system, but may be configured with a central outdoor air supply (as in an air-water sys tem). Heat pumps (water-to-air) either draw heat from the water circulation loop (in heating mode) or discharge heat to it (in cooling mode). For a large building in cold weather, excess heat from the interior zones is used to warm the perimeter zones. The loop's temperature ranges between 65ºF and 90ºF (18ºC and 32ºC); in hot weather, a central cooling tower disposes of the loop's excess heat, whereas in cold weather a central boiler adds needed heat to the water loop. The loop is sized to carry 2 to 3 gpm (0.13 to 0.19 L/s) per ton, where the total tonnage equals the sum of the capacity of all the individual units (often greater than the actual load).

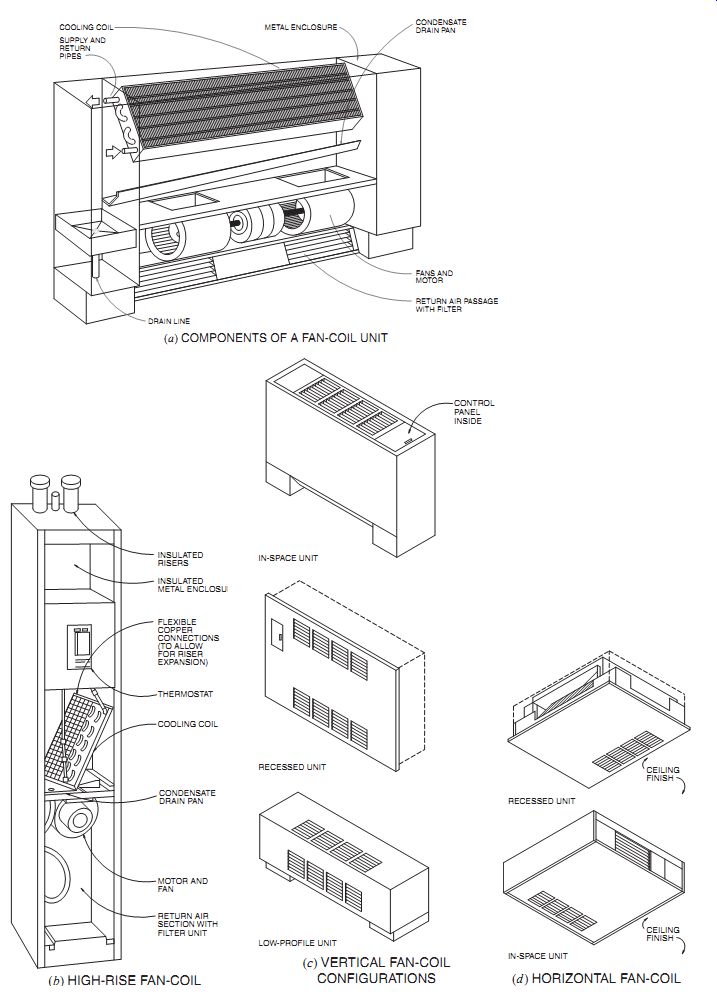

(d) All-Water Systems

The more simple-appearing all-water systems are shown in Fig. 14. These systems only heat and cool; the distribution trees are indeed slim. Air quality is dealt with elsewhere-either locally, by means of infiltration or windows; or by a separate fresh air supply system; or simply by fresh air from an adjacent system, such as a ventilated interior zone. This ambiguity about fresh air leads to similar ambiguities about whether a system is air-and-water or all-water. A fan-coil terminal is often employed so that air motion occurs along with heating or cooling. (Sometimes the fan-coil unit is located against the exterior wall so that fresh air may be brought in and mixed with the room air through the fan.) Both baseboard and valence (above-window) units are also commonly available.

Because air is handled so locally, there is very little mixing of air from one zone to another, making this attractive where potential air contamination (or smoke from a fire) is a special concern. It is also an easy system to retrofit. However, maintenance is high; filters in each fan-coil must be cleaned, and drain pans are potentially problematic.

More details on this HVAC system class can be found in Section 10.7.

Two-pipe water distribution systems were shown throughout Fig. 13. They provide either heating or cooling. One pipe is for supply, the other for return. In a typical large-building application, they are used for heating in winter, cooling in sum mer. This raises the question of what changeover period will be required, a problem made much easier with the following alternative system.

Four-pipe systems are shown in Fig. 14.

They allow quick changeover between heating and cooling, utilizing two supply and two return pipes. A four-pipe system also allows for simultaneous cooling and heating in different zones within a single distribution system.

(e) Equipment Space Allocations

An important early design decision is whether to integrate or separate the heating/cooling equipment and the air-handling equipment (see Fig. 2). If they are integrated, one or a few central mechanical room(s) can serve many floors, and each mechanical room will need area and height sufficient for both heating/cooling and air-handling equipment.

If separated, one (or several, in tall buildings) large space for heating/cooling equipment is typically located in the basement or the penthouse, with a smaller fan room on each floor.

Each mechanical room should have both a central location relative to the area it serves and direct access to the outside-contradictory requirements in many cases. Central locations within the area served minimize the distribution tree size; access to the outdoors facilitates the use of outdoor air as a heat source (winter) or sink (summer) and allows equipment to be installed or removed in later remodeling. Mechanical rooms serving both heating/cooling and air-handling equipment need relatively high ceilings; 12-ft (3.7-m) clear is a typical minimum, 20-ft (6-m) clear a typical maximum.

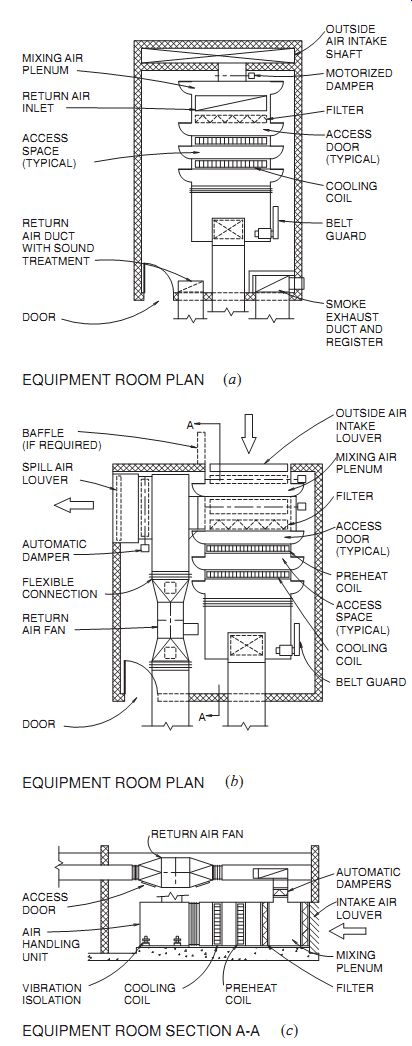

Tables 3 and 4 present the approximate space requirements for conventional mechanical systems. (For a more detailed look at equipment room space requirements, see Figs. 18, 29, and 42.)

Table 3 Approximate Space Sizes for Major Heating and Cooling Equipment

Table 4 Approximate Space Sizes for Air-Handling Equipment

The sizing graphs shown in Tables 10.3 and 10.4 are generous if buildings are designed with energy conservation in mind. For buildings with large heat gains or losses, these graphs may slightly undersize the areas needed. These graphs are intended to give a very fast approximation of areas; more detailed procedures for sizing are presented in Section 10.3 (for boilers, chillers, fan rooms) and Section 10.4 (for air ducts).

Cooling equipment capacity is often rated in tons of refrigeration. The relationship between tons and floor area served is explored in Table 5.

For the thermally well-designed detached residence of today, a design guideline is 1000 ft^2 of floor area/ton (26 m^2/kW).

Table 5 Tons of Refrigeration: Design Guidelines

Fig. 15 Some basic components of HVAC central equipment. (a) A simplified diagram of a cooling cycle, in which chilled water is circulated to air-handling coils and heat is disposed of through a cooling tower. (b) Schematic diagram of major components of central equipment for both heating and cooling.

3. CENTRAL EQUIPMENT

The many HVAC systems that are included in the categories of all-air, air and water, and all-water have in common a dependence on central equipment for the generation of heating and cooling, and/or air quality control. Figure 10.15 shows the basic relationships between some of the major pieces of central equipment and the spaces they serve. This section offers a general guide to some central equipment options and sizes. The consulting engineer chooses such equipment based upon a much more detailed analysis.

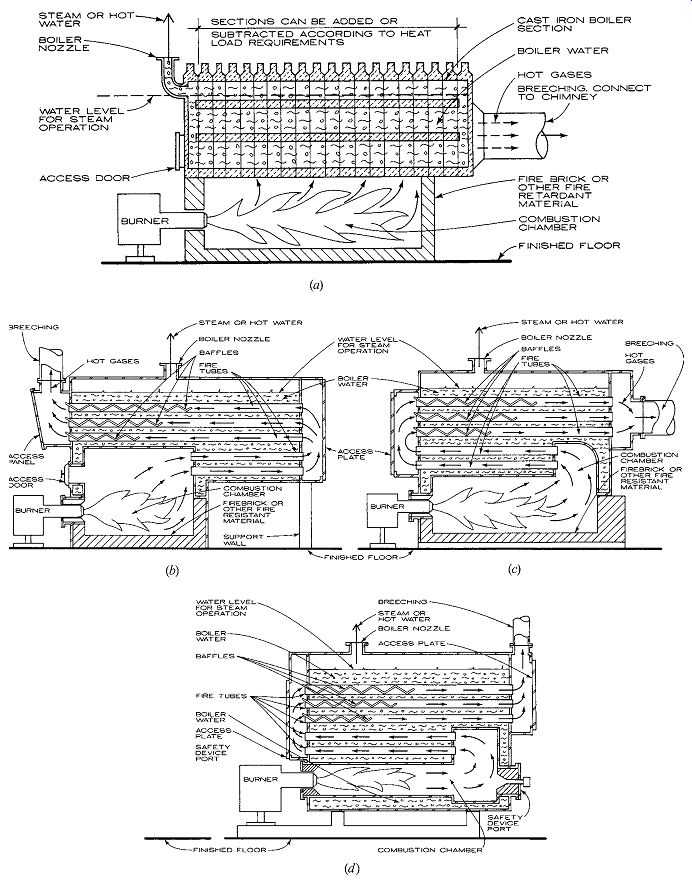

(a) Boilers

These devices heat the recirculating hot water sys tem used for building heating. The type of boiler selected depends on the size of the heating load, the heating fuels available, the desired efficiency of operation, and whether single or modular boilers are to be installed. Boiler sizes are commonly stated either in Btu/h of net output or in (gross) boiler horsepower, where, in I-P units, boiler horsepower heating load(Btu / h)

%bo = iiler efficiency

× 33,470 Btu/h per horsepower

In SI units, boiler horsepower heating load(kW)

%boile = r r efficiency × 9.81 kW per horsepower

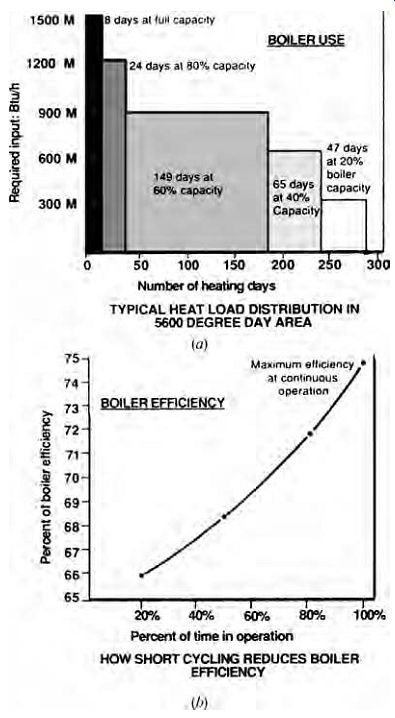

Efficiency depends partly on the number of passes that the hot gases make through the water- the more passes, the higher the efficiency. It also depends on burner efficiency and on regular maintenance. Finally, efficiency is best when the equipment is operating near its capacity. Figure 10.16 compares typical boiler types, including two- and three-pass boilers.

Fire Tube Boilers. The hot gases of the fire are taken through tubes that are surrounded by the water to be heated. Firebox boilers place the boiler shell on top of the combustion chamber. Scotch marine boilers feature multiple passes of the combustion gas through tubes. Fire tube boilers can be either dryback or wetback. Dryback designs have chambers outside the vessel to take combustion gases from the furnace to the tank. Wetback designs have water-cooled chambers that conduct the combustion gases.

Water Tube Boilers. The water to be heated is taken through tubes that are surrounded by the boiler's fire. They hold less water than the fire tube models, and so respond faster and can generate steam (where desired) at higher pressures.

Cast-Iron Boilers. Often used in residential and light-commercial applications, these are lower pressure and lower-efficiency boilers. They do have the advantage of being modular.

In addition to the boilers themselves, there are choices of burner types (depending on the fuel[s] used), burner controls, and boiler feedwater systems. Consult the latest ASHRAE Handbook-HVAC Systems and Equipment for details.

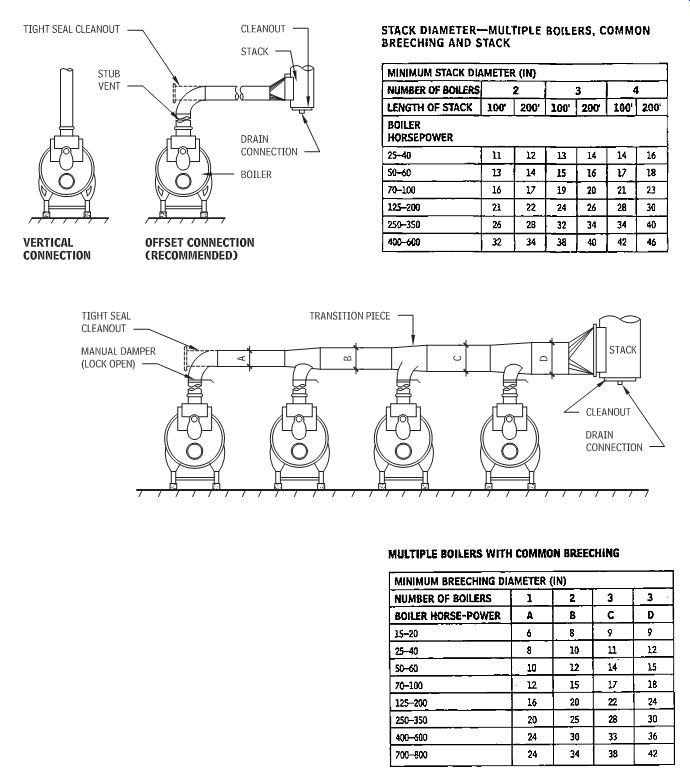

Fossil fuel-burning boilers need flues for exhaust gases, fresh air for combustion, and required air pollution control equipment. The exhaust gas is usually first taken horizontally from the boiler; this horizontal enclosure, or flue, is called the breeching.

The vertical flue section is called the stack. Guide lines for sizes and arrangements of breeching and stacks are shown in Fig. 17. Local codes deter mine the quantity of air required for combustion; local air pollution authorities set pollution control requirements. As a general rule, combustion air can be supplied in a duct to the boiler at an average velocity of 1000 fpm (5.1 m/s). The duct should be large enough to carry at least 2 cfm (1 L/s) per boiler horsepower. Furthermore, ventilation air to the boiler room should be provided; preferably, the inlet and outlet should be on opposite sides of the room.

Minimum sizes: enough for 2 cfm (1 L/s) per boiler horsepower at a velocity of about 500 fpm (2.5 m/s).

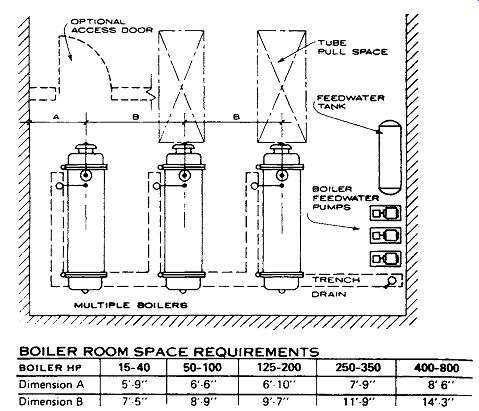

Space requirements for boilers are summarized in Fig. 18, which shows multiple boilers. Note that clear space within the room must be provided so that the tubes of the boiler can be pulled when they must be replaced. Access for eventually replacing entire boilers must be considered.

Several types of single boilers are discussed here. The final boiler type discussed, the modular boiler, is preferred for energy conservation.

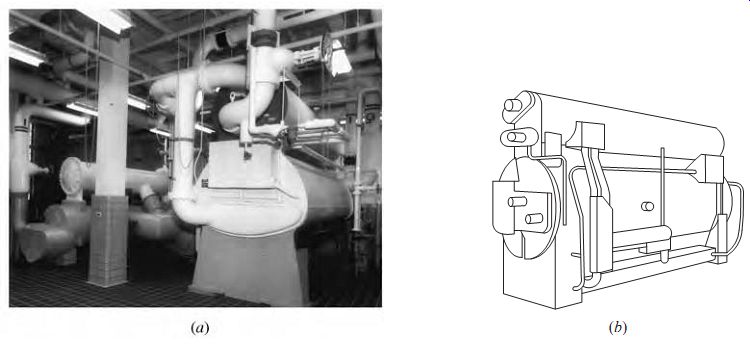

1. High-output, package-type steel boiler. For large buildings that use steam as a primary heating medium, one or several such boilers may be used. Direct use of steam can be seen in Fig. 15b, supplying preheat and reheat coils and also a humidifying unit. The relative lightness of this boiler type, compared to the older styles with ponderous masonry bases (boiler settings), makes it suitable for use on upper floors of tall buildings. Figure 10.6 shows two such boilers on the 13th floor of the Fox Plaza Building.

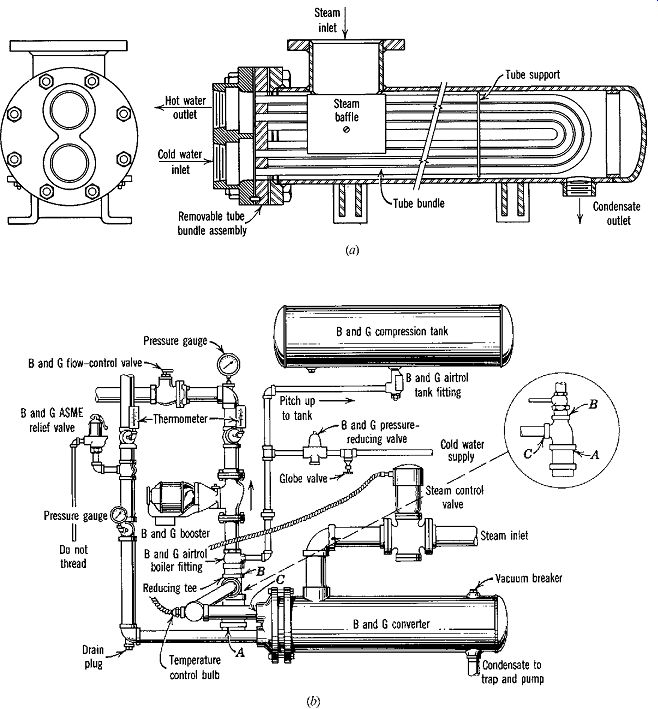

2. Converter, steam to hot water. When, in a building that uses primary steam boilers, secondary circuits that use hot water for heating are required, a converter (Fig. 19) is used. It is considered a heat exchanger. In Fig. 6, there is downfeed steam supply for the two boilers on the 13th floor to two such converters, one for hot water heating in the apartments and one below the garage ceiling for hot water heating in the commercial area. A converter may also be used to transfer heat from steam to domestic (service) water. Converters are frequently used where central steam supply systems are available, as in large-city downtown areas. The easier, quieter distribution of heat by hot water has largely replaced steam heating distribution trees within buildings.

3. Electric boilers. Where electricity costs are competitive with those of fossil fuels, electric boilers are sometimes used. Both hot water and steam electric boilers are available. The advantage of electric boilers is the elimination of combustion air, the flue, and air pollution at the building.

The disadvantages are the use of a high-grade energy source for a relatively low-grade task and the pollution impact at the electric generating plant. In order to protect against high electric demand charges, a large number of control steps are desirable.

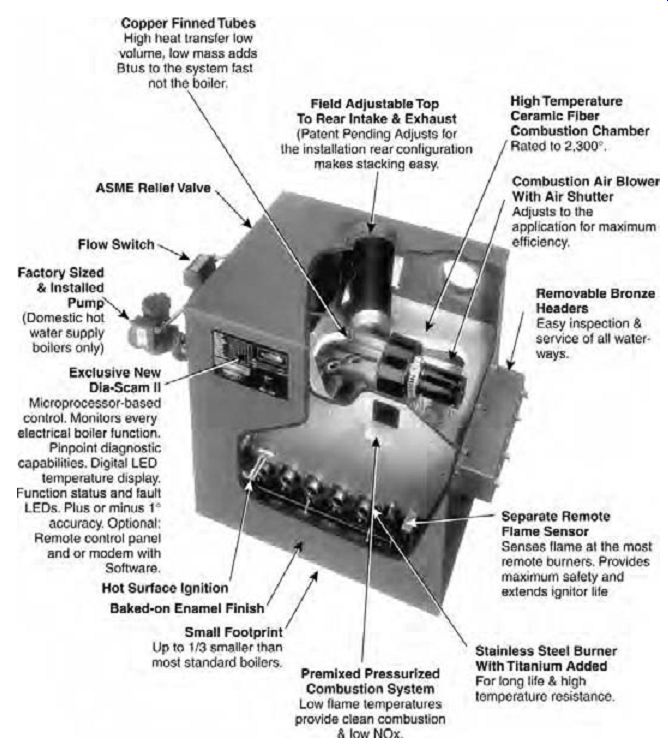

4. Compact boilers. Smaller-dimension boilers (Fig. 20) with high thermal efficiencies are available. In addition to their space-saving footprint, they feature a variety of venting options that make them easily adaptable to smaller equipment rooms.

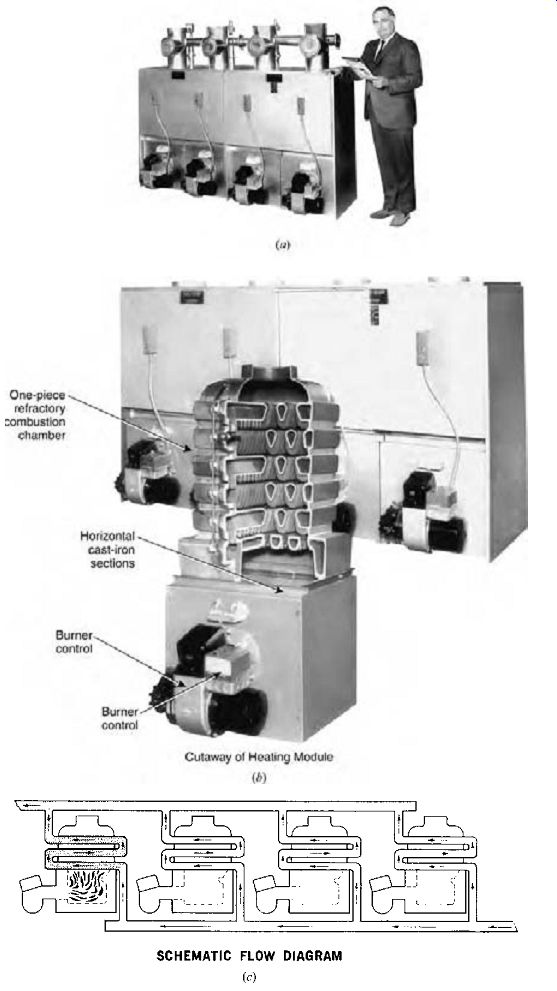

5. Modular boilers. The primary advantage of modular boilers (Fig. 21) is efficiency.

Boilers achieve maximum efficiency when they are operated continuously at their full rated fuel input. The single boilers discussed previously operate this way only under outside design conditions, which by definition occur, at most, during 5% of a normal winter. In a modular boiler design, each section is run independently. Therefore, only one section need be fired for the mildest heating needs; as the weather gets colder, more sections are gradually added.

Because each section operates continuously at full-rated fuel input, efficiency is greatly increased (Fig. 22). Each module, being rather small, requires little time to reach a useful temperature and (unlike the larger single boilers) does not waste a lot of heat as it cools down. Thus, modular boilers usually produce a 15% to 20% fuel savings for the heating season relative to single boilers. Their other advantages include ease of maintenance (one module can be cleaned while others carry the heating load) and small size (allowing easy installation and replacement in existing buildings).

Modular boilers also eliminate the initial cost of oversizing heating equipment. In cold climates, conventional boiler systems often use two or three large boilers to ensure that heat is available even if one large boiler fails. When two such boilers are used, it is common practice to size each boiler at two-thirds of the total heating load; an oversize of one-third results. When three such boilers are used, it is common practice to size each boiler at 40% of the total heating load; an oversize of 20% results. However, when a minimum of five modular boilers are used, oversizing can be eliminated because the failure of a single module will not have a crippling impact on the overall heat output.

Gas-fired pulse boilers are an even smaller and more energy-efficient choice for modular boilers.

Fig. 16 Comparisons of boiler types. (a) Cast-iron sectional type. (b)

Two-pass fire tube. (c) Three-pass fire tube. (d) Three-pass wetback Scotch

marine.

Fig. 17 Breeching and stack size guidelines for fossil-fuel-fired boilers.

Fig. 18 Boiler room space requirements. Dimension A includes an aisle of

3 ft 6 in. (1 m) between the boiler and the wall. Dimension B between the boilers

includes an aisle of at least 3 ft 6 in. (1 m), and up to 5 ft (1.5 m) for

the largest boilers.

Fig. 19 Conversion unit that transfers heat from steam to hot water. (a)

Section illustrating the principle of heat transfer from steam to water. (b)

A converter connected to the steam supply and equipped with all devices necessary

for a complete hot water heating system.

Fig. 20 Burkay Genesis hot water boiler, fueled by either natural gas or

propane, is available in ratings from 200,000 to 750,000 Btu/h (58,620 to 219,825

W). All units are 30 in. high × 24 in. deep (762 mm × 610 mm); the smallest

boiler is 23 in. (584 mm) wide, and the largest is 57 in. (1454 mm) wide. The

copper heat exchanger has an 83.7% thermal efficiency rating, and a variety

of venting options are available.

Fig. 21 Modular boilers. (a) A bank of four modules-with a total input

1.5 million Btu/h (439 kW). (b) Details of one module (20 x 32 x 48 in. H [510

x 812 x 1220 mm]) with a 385,000 Btu/h (113 kW) input. (c) Schematic of flow

conditions in mild weather, with only one module in operation.

Fig. 22 One large boiler versus many smaller ones. (a) Boilers rarely operate

at full capacity; instead, they respond to part loads the majority of the time.

(b) Under part load conditions, a boiler will often short-cycle, which on a

single large boiler could drop the annual efficiency into the 66% to 75% range.

Fig. 23 (a) An absorption chiller driven by heat to produce chilled water.

(b) Two-stage absorption chiller utilizing steam, producing 200 to 800 tons

(700-2800 kW) of cooling.

Pulse boilers utilize a series of 60 to 70 small explosions per second, making the hot flue gases pulse as they pass through the fire-tube. This makes for very efficient heat transfer. Pulse boilers are available up to about 300,000 Btu/h (88 kW).

Pulse boilers operate with lower water temperatures so that water vapor in the flue gas can condense and drain. This change of state liberates additional heat, allowing these pulse boilers to achieve efficiencies up to 90%. They exhaust moist air, not hot smoke, so flues can be small-diameter plastic pipe rather than large-diameter, heat-resistant materials.

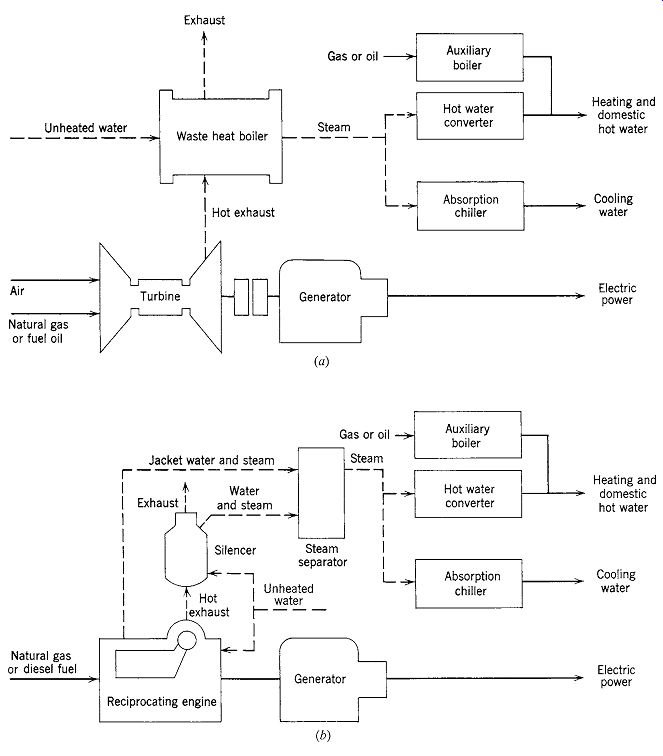

(b) Chillers

These devices remove the heat gathered by the recirculating chilled water system as it cools the building. The selection of chillers depends largely on the fuel source and the total cooling load. Chillers include both absorption and compressive refrigeration processes in a wide range of sizes.

New developments in chillers continue to result from a combination of concerns about the role of CFCs and HCFCs in global climate change and from changes in utility regulations that are producing unstable energy prices in many areas.

Chillers capable of changing quickly between electricity and natural gas are becoming available as a result.

Fig. 24 (a) A centrifugal chiller-a machine of large capacity using the

compressive refrigeration cycle. (b) Centrifugal chiller with a flooded cooler

and condenser within a single outer shell. This low-pressure unit typically

produces 100 to 400 tons (350-1400 kW) of cooling. Typical dimensions are:

14 ft L x 5 ft W x 8 ft H (4.3 x 1.5 x 2.4 mm), at 16,000 lb (7260 kg).

The single-effect, indirect-fired absorption chiller (Fig. 23) is attractive where central steam or high-temperature water (from solar collectors, as waste heat from an industrial process, a fuel cell, etc.) is available. This device uses the absorptive refrigeration cycle. Direct-fired absorption chillers use natural gas to power the cycle. In general, absorption equipment is less efficient than compressive refrigeration cycle equipment, although a cheap or even free heat source to power the cycle can rapidly overcome efficiency disadvantages. Absorption machines have fewer moving parts (and therefore require less maintenance) and are generally quieter than compressive cycle equipment. They are environmentally attractive, despite their much higher waste heat output (about 31,000 Btu/ton, compared to at most 15,000 Btu/ ton for compressive cycle equipment), because they do not use CFCs or HCFCs and because they require far less electricity to operate. Newer developments include the double-effect absorption chiller (see Fig. 3) and the triple-effect chiller, each accompanied by an increase in efficiency.

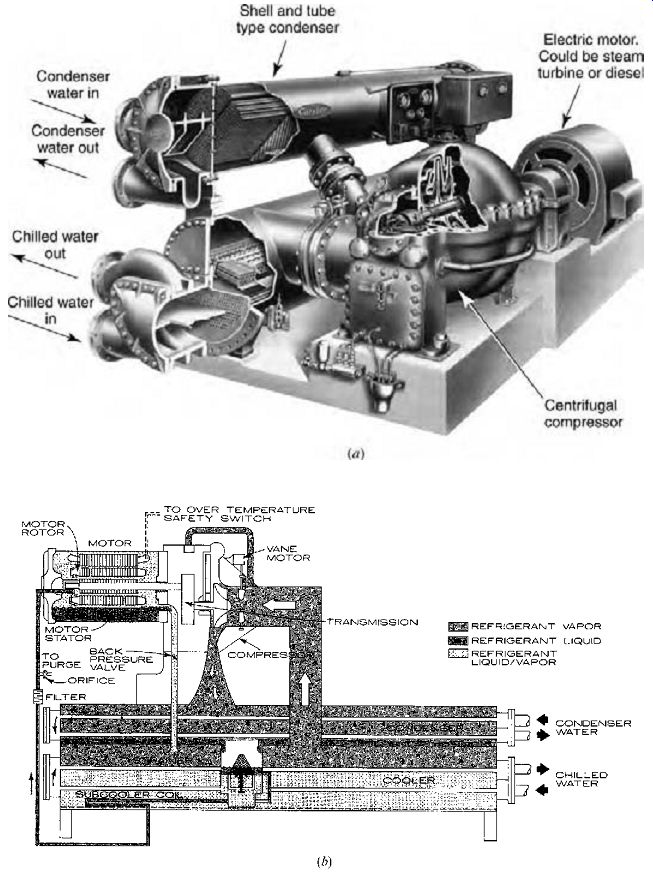

The compressive refrigeration cycle (explained in Fig. 9.1) is used in the other types of chillers.

Larger units are centrifugal chillers (Fig. 24), whose compressors either can be driven by an electric motor or can utilize a turbine driven by steam or gas. (When a steam-driven turbine is used, the exhaust steam is often used to run an auxiliary absorption cycle machine. These two devices make an efficient combination, and the steam plant that supplies them in summer can supply heating in winter.) Centrifugal chillers usually require about 1 hp/ton (0.57 kW, or 10 ft 3 gas, or about 15 lb of steam per ton). These large chillers usually require a cooling tower. Dual-condenser chillers (Fig. 25) can choose whether to reject their heat to a cooling tower (via the heat rejection condenser) or to building heating (via the heat recovery condenser).

Fig. 25 Dual-condenser chiller. Heat drawn from the chilled water system

is either rejected to the cooling tower or recovered for use in building heating.

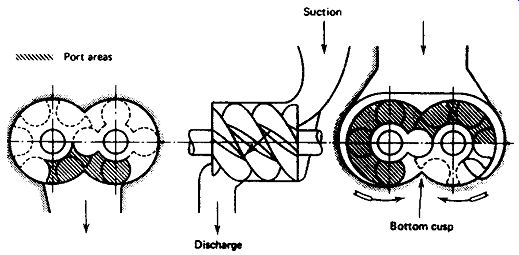

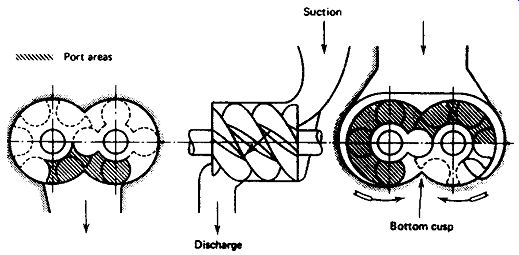

Somewhat smaller chillers use either twin screws or a scroll in place of a piston in the compressor. The screw compressor (Fig. 26) has a pair of helical screws; as they rotate, they mesh and thus compress the volume of the gas refrigerant.

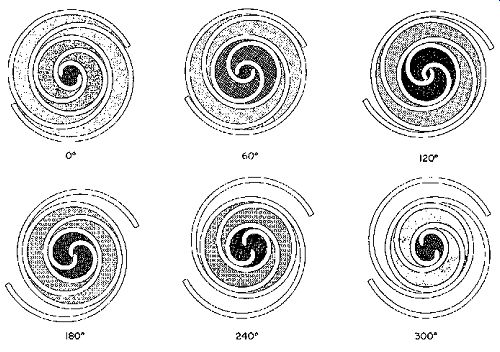

They are small and quiet, with little vibration. The scroll compressor (Fig. 27) uses two inter-fitting spiral-shaped scrolls. Again, the refrigerant gas is compressed as one scroll rotates against the other fixed one. Gas is brought in at one end while the compressed gas is released at the other. Quiet and low-maintenance, they are also more efficient than reciprocating compressors.

Even-smaller compressive-cycle machines are called reciprocating chillers (Fig. 28). Usually electrically driven, they are often combined with an air-cooled heat rejection process rather than a cooling tower. This makes them a closer relative of the smaller direct refrigerant machines discussed in Section 9.8.

Chilled water is usually supplied at between 40ºF and 48ºF (4ºC and 9ºC). When the chilled water is supplied cold and returns much warmer, the large rise in temperature reduces the initial size (cost) of equipment and increases its efficiency (thereby reducing the operating cost as well). Water treatment may be needed for chilled water to control corrosion or scaling.

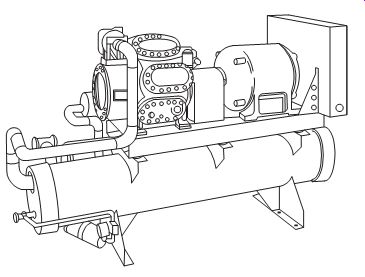

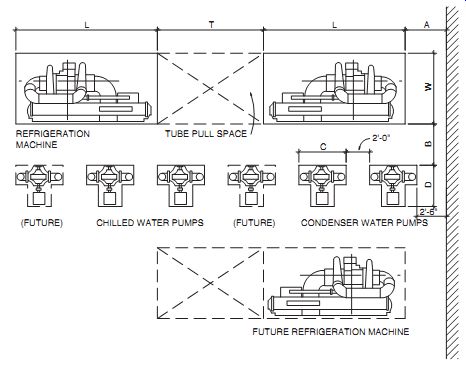

Typical cooling capacities and space requirements of chillers are shown in Fig. 29-with dimensions as tabulated. Each refrigeration machine in this illustration requires two pumps- one for the chilled water (to cool the building) and one for condenser water (to deal with reject heat). Typically, space is provided for future chiller additions, which may be required by building expansion and/or by higher internal gains from as-yet-uninstalled equipment, such as computer terminals within offices. Improved-efficiency chillers may replace older ones when energy costs and environmental regulations become compelling.

Adequate clearance access to the equipment room is a major design issue.

Fig. 26 A screw, or helical, compressor is a quieter, smaller machine with

little vibration.

Fig. 27 Scroll compressor rotates one scroll form against another, with

a quiet and efficient compression of the refrigerant.

Fig. 28 A reciprocating

chiller-a small-capacity machine that uses the compressive refrigeration cycle.

Typically, this type of chiller produces less than 200 tons (700 kW) of cooling.

Such a machine might be around 8 ft L x 3 ft W x 5 ft H (2.4 x 0.9 x 1.5 m)

and weigh 3500 lb (1590 kg).

(c) Condensing Water Equipment

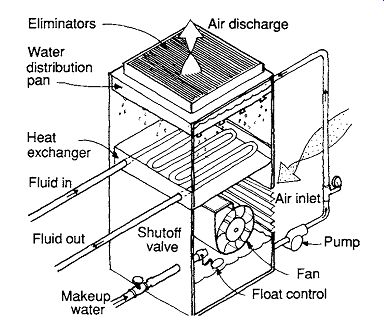

With chillers, there must be a way to reject the heat that is removed from the recirculating chilled water system. Reject heat is handled by the condensing water system, which serves the condensing process within refrigeration cycles. For larger buildings, the condensing water requirement is most likely to be met by a cooling tower.

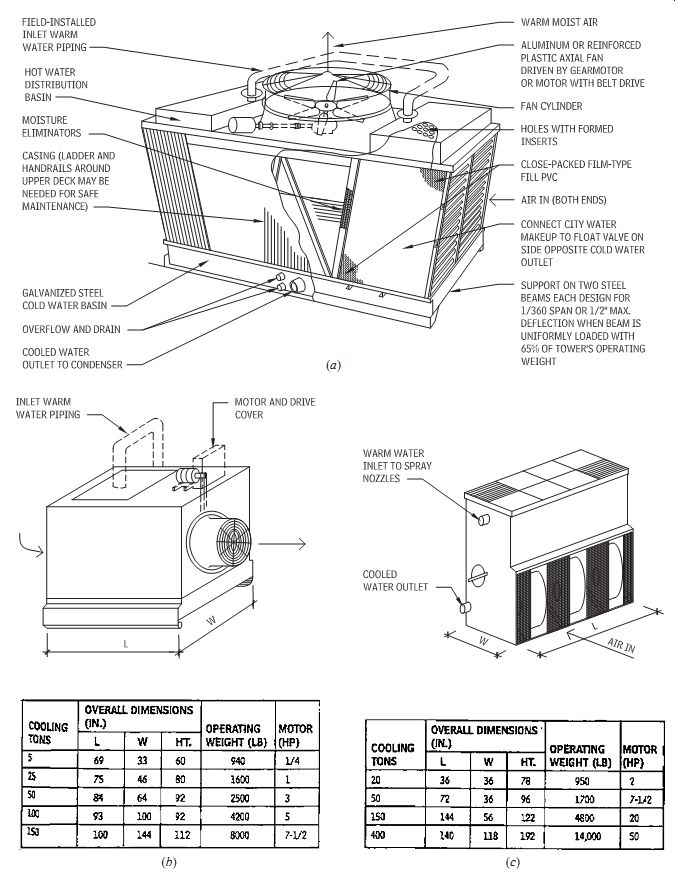

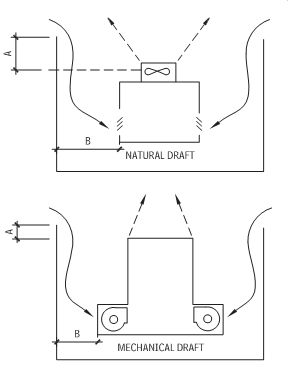

The cooling tower's place within the over all equipment layout was shown in Fig. 15b; a more detailed guide to sizes and types is given in Figs. 10.30 and 10.31. The object is to maximize the surface area contact between outdoor air and the heat condensing water. In crossflow towers, fans move air horizontally through water droplets and wet layers of fill (or packing), whereas in counterflow towers (prevalent in larger buildings), fans move the air up as the water moves down.

Cooling towers create a special-and usually unpleasant-microclimate. They demand huge quantities of outdoor air (approximately 300 cfm [142 L/s] per ton), which they make considerably more humid. In cold weather, they can produce fog. They are typically very noisy-a natural consequence of forced-air motion. The condensing water flows are about 2.8 gpm (0.18 L/s) per ton of compressive refrigeration and about 3.5 gpm (0.22 L/s) per ton of absorption refrigeration.

The water that escapes as vapor from the tower is between 1.6 and 2 gph (1.7 and 2.1 mL/s). This water must be replaced, which is done automatically. The steady evaporation and exposure to the outdoors under hot and humid conditions spells trouble for the condensing water: Controls for scaling, corrosion, and bacterial and algae growth are especially important. Ozone treatment systems have the advantage of reliable biological control and leave no chemical residue. Since the discovery of the link between Legionnaire's disease and cooling towers, biological control has assumed greater importance.

Fig. 29 Chiller room space requirements. Each refrigeration machine is

served by two pumps (chilled water and condenser water).

The vapor that escapes the cooling tower should be kept from the vicinity of fresh air intakes, and from neighboring buildings or parked cars, where feasible. The floor space requirements can be approximated from Table 3, or use the average of 1/500 of the building gross floor area (for towers up to 8 ft [2.4 m] high) or 1/400 of the building gross floor area (for higher towers).

Although it is tempting to try to block the noise of cooling towers with solid barriers, it is critical that noise control not interfere with air circulation.

The manufacturer's recommended clearances to solid objects near cooling towers must be consulted an always-closed loop, while a separate body of water is recirculated through the cooler, with steady evaporation and attendant problems. It requires much less makeup water than the cooling towers.

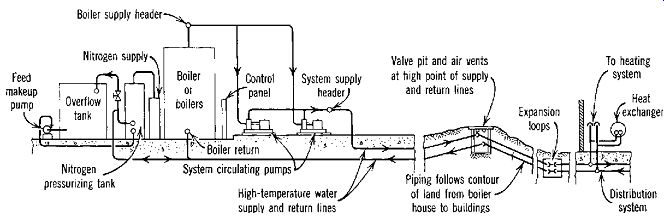

(d) Energy Conservation Equipment

Fig. 30 Cooling towers that serve the condensing water system for large

buildings. (a) Cutaway view of a large-capacity (200 to 700 tons [700-2460

kW]) crossflow induced-draft package cooling tower. (b) Size ranges for crossflow

induced-draft package cooling towers. (c) Size ranges for counterflow induced-draft

package cooling towers.

Fig. 31 For cooling towers, the more wall clearance, the better the operation.

A = maximum height of enclosure above the tower outlet; minimize this dimension.

B = as large as possible, especially if walls have no air openings.

One big advantage of central equipment rooms is the opportunity they present for energy conservation. Regular maintenance is simplified when all the equipment lives in a generous space kept at optimum conditions; with regular maintenance comes increased efficiency of operation. Another conservation opportunity is that of heat transfer between various machines, or between distribution trees, where one's waste meets another's need.

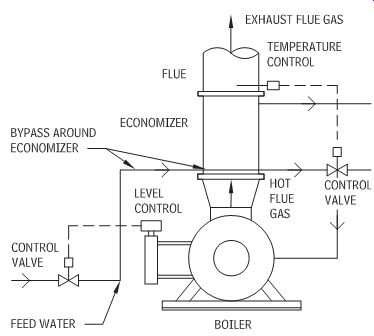

Boiler flue economizers achieve heat transfer by passing the hot gases in a boiler's stack through a heat exchanger, thus preheating the incoming boiler water (Fig. 34).

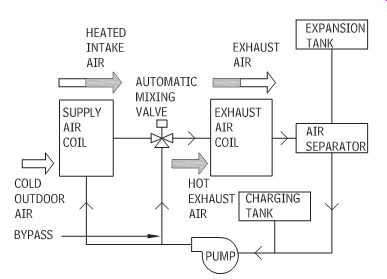

Runaround coils (Fig. 35) can be used for heat transfer between intake and exhaust air ducts when these two airstreams are rather far apart. This circulating heat-transfer fluid usually contains anti freeze; it provides simple sensible heat transfer, with no restrictions on exhaust and intake location. No contamination of intake air by exhaust air is caused by this arrangement. The efficiency of such coils runs between 50% and 70%, and they are available in modular sizes up to 20,000 cfm (9440 L/s).

Heat exchange between incoming and exhaust airstreams, which was discussed in Sections 5.6(c) and 5.6(d), allows heat pipes and thermal transfer wheels to play major roles in energy conservation.

The thermal transfer wheels can add to the central equipment space requirements. Other desiccant systems were discussed in Section 5.6(d).

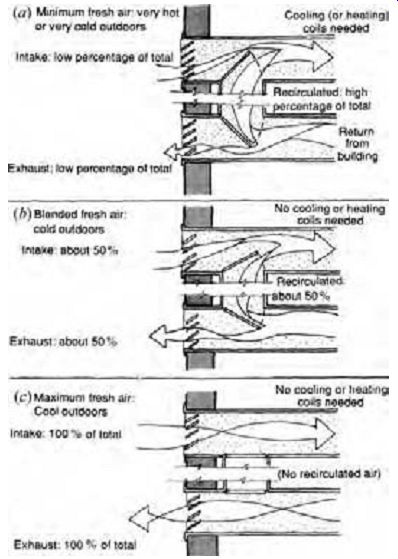

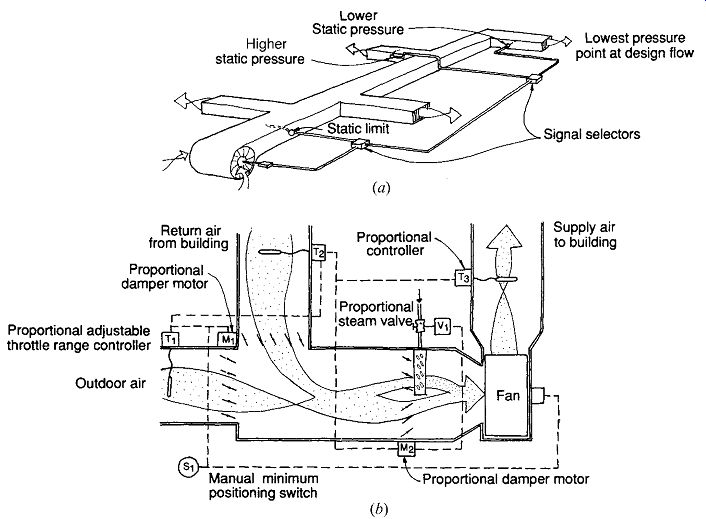

Economizer cycles (Fig. 36) use cool outdoor air, as available, to ease the burden on a refrigeration cycle as it cools the recirculated indoor air. The economizer cycle can thus be thought of as a central mechanical substitute for the open window; when it is cool enough (below the supply air temperature), 100% outside air can be provided and no chilled water is needed. When the outdoor air temperature is higher than the supply air temperature but lower than the return air temperature, 100% outdoor air is still brought in, but chilled water is used to lower its temperature. Above the return air temperature, outdoor air is reduced to that volume required for IAQ.

Relative to open windows, this cycle has several advantages: energy-optimizing automatic thermal control, filtering of the fresh air, tempering of the cool outdoor air to avoid unpleasant drafts, and an orderly diffusion of fresh air throughout the building. Its disadvantages are the loss of personal control that windows offer and thus loss of awareness of exterior-interior interaction. In hot, humid climates, the moisture brought by 100% outdoor air may be unwelcome.

Economizer cycles are available as options on most direct refrigerant machines (such as single package rooftop units) and are typically installed for large-building central air supply systems.

Buildings with high internal gains (internal load dominated) are particularly good targets for economizer cycles because they need cooling even when the outside temperature is chilly. Economizer cycles lend themselves readily to a cooling strategy of night ventilation of thermally massive structures because they have a built-in option for 100% outdoor air.

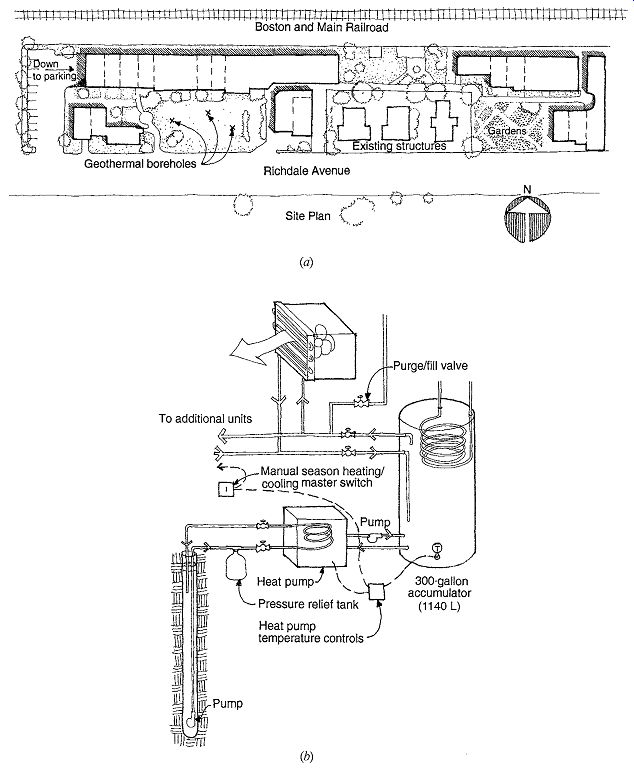

(e) Geo-exchange Systems

Using the earth as a heat source and sink for small buildings was explored in Section 9.8(d). Four typical applications were shown in Fig. 9.44. Larger buildings can also utilize such systems. A late 1990s building just east of Central Park, in New York City, utilizes two wells 1500 ft (457 m) deep; all but the top 50 ft (15 m) are lined by bedrock. Heat is taken from (or discharged to) water, which is pumped from one well and discharged to the other-a "groundwater source" system. The average year-round temperature in these deep wells (in an intensely urban area) is estimated at 56ºF (13ºC), about the temperature at which chilled air is delivered to a space in summer.

Going to such depths is perhaps the only geothermal option in densely built-up areas.

Fig. 32 A plume of mist hovers ghostlike above a cooling tower in full

public view near the Denver performing arts complex.

Fig. 33 Closed-circuit evaporative coolers, which cool the condensing water

system while protecting it from contact with outside air. A self-contained

water system is circulated through the evaporative cooler; steady evaporation

losses are replaced by makeup water.

Fig. 34 Heat recovery for boilers. Flue gas entering at 500ºF (260ºC) leaves the "economizer" at 325ºF (163ºC), a temperature still high enough to prevent condensation in the stack. The heat recovered here is added to incoming

boiler water, raising its temperature from 200 to 248ºF (93 to 120ºC).

Fig. 36 The economizer cycle controls the relationships among fresh, exhaust, and recirculated air. (a) When outside air is hot (or very cold), the economizer

cycle is inactive, and minimum fresh air is introduced. (b) As very cold outside

air gets warmer, it can be blended with recirculated air, and neither heating

nor cooling coils are needed. (c) When outside air is cool, it can completely

replace circulated air, making mechanical cooling inactive.

Fig. 35 Runaround coils for heat transfer between fresh intake air and

stale exhaust air, used where the air streams are in separate locations. Efficiencies

can range from 50% to 70% and coil capacities up to 20,000 cfm (9400 L/s).

Fig. 37 Cambridge (Massachusetts)

Cohousing development takes advantage of three boreholes on its urban site

(a) to provide central heating and cooling, serving individual residential

fan-coil units. It also preheats water (b) for the DHW (domestic hot water)

system. The residences are sited to provide winter solar access, and a positive

fresh air intake is located on the side sheltered from adjacent railroad tracks.

Underground parking preserves open space for gardens and recreation.

Fig. 38 The Hyndburn Borough Council ( England) headquarters faces south

toward a reservoir (a) that provides an evaporatively cooled microclimate and

also acts as a heat source/sink for a water-water heat pump. (b) As suggested

in the diagrammatic section, daylighting, passive solar heating, PVs, and a

well-insulated shell are featured. Termodeck is a precast hollow-core slab

that stores coolth on summer nights and pre-cools ventilation air. The supply

air then rises from the plenum created by the raised floor.

The Cambridge ( Massachusetts) Cohousing Project (Fig. 37) is also located in a densely settled urban neighborhood. The 41 living units feature passive solar heating, underground parking (this reserves some 20,000 ft 2 [1860 m2] of the surface for open green space), and centralized heating/cooing utilizing ground source heat pumps with locally controlled thermal zones. In this urban setting, the relative quiet of the indoor heat pump's compressors and the lack of noisy hot air (summer) or cold air (winter) discharges are welcome amenities.

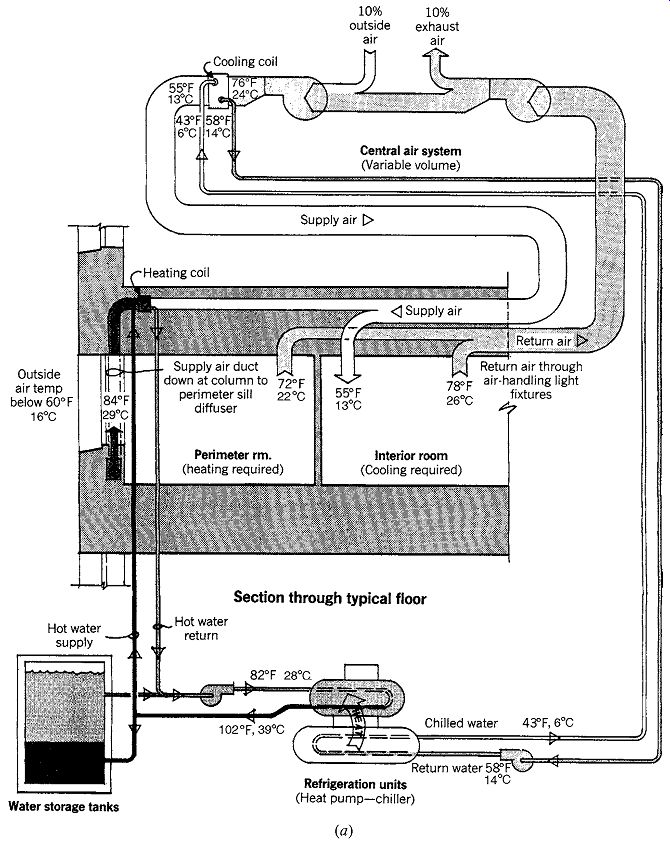

In England, the Hyndburn Borough Council decided that their new headquarters building should set an example as a "zero energy" building: that is, over a typical year, it should generate as much energy as it imports. The 38,750-ft 2 (3600-m2) building (Fig. 38) is elongated east-west and boasts an ambitious section that combines daylighting, photovoltaics (PV), a well insulated skin, and even rainwater collection to use for flushing toilets. Windpower adds to electricity generation. Summer cooling is by ventilation (assisted by night ventilation of mass) through a raised "Termodeck" system. This is a prefabricated hollow-core slab through which cool night air circulates, storing coolth to assist the next day's hottest hours. (This is a concept explored by the Oregon office building in Fig. 8.6.) The raised floor then provides a distribution plenum, with a design rate of 4 air changes per hour (ACH).

For more extreme future summer cooling, but now mostly for winter heating (beyond that pro vided by passive solar heating), an adjacent reservoir acts as a thermal sink. A "lake closed source heat pump" will serve the mechanical ventilation system. The lake is south of the building, providing some local evaporative cooling in summer and inviting a very climate-oriented south façade, behind which are open-office areas. The north façade faces the city and is more traditionally institutional in character, as are the individual offices behind it.

(f) Energy Storage

We commonly experience daily changes from warmer to colder conditions, both in winter and in a hot, dry summer. Central storage equipment for large buildings can take advantage of this cycle to increase operating efficiency, save energy, and significantly reduce electricity demand charges. Some electric utilities offer incentives to install thermal storage in order to reduce the peak strain on their generating facilities.

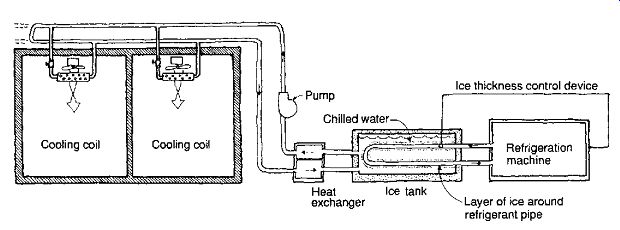

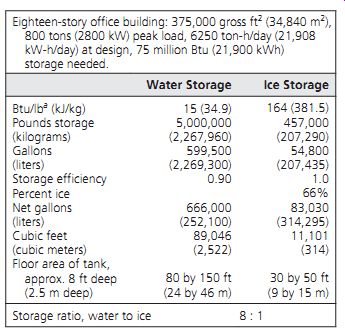

Water storage tanks are one common approach to storage, such as those shown in Fig. 39. On typical winter days, the total internal heat generated by a large building can be somewhat greater than its total need for heating at the perimeter zones. Instead of being thrown away as exhaust air, this surplus heat is captured and stored in large water tanks, from which it can be withdrawn and used on cold winter nights and weekends. In the summer, chillers can work at night, when efficiency is high because cool outdoor air helps the refrigeration cycle reject its heat. By storing the coolth produced, less work need be done by chillers during the next day's peak, when electric rates are highest and operating efficiency is lowest.