AMAZON multi-meters discounts AMAZON oscilloscope discounts

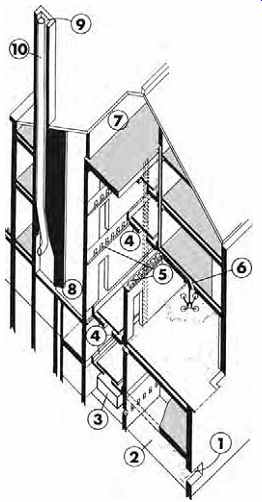

SINCE THE ADVENT OF MODERN HVAC systems, ventilation has generally been addressed via heating and cooling system design efforts. In centuries past, however, there were special systems to provide outside air to buildings, even at the residential scale. Banham (1969) describes both large and small buildings where outside air was deliberately introduced. In the home that Dr. John Hayward built for his family in 1867, the Octagon in Liver pool, England (Fig. 1), outdoor air was brought into the basement, slowed down to precipitate some particulates, then heated to help it rise throughout the four-story building. Ceiling vents just above gas lights drew "vitiated" air from each room, which was then vented to a "foul air chamber" in the attic.

From there, a large shaft functioned using a combined siphon and stack effect. Powered at its low point by ever-present heat from the kitchen cooking range, it drew the foul air down, then up a very high chimney to discharge.

FIG. 1 Fresh air intake, stale air exhaust at the Octagon, Grove Street,

Liverpool, 1867. Dr. John Hayward built this exhaust system. Dirty air outside

(coal-fired industries and buildings were common) and inside (gas lamps) probably

produced an IAQ considerably worse than today's norms. 1. Fresh air intake;

2. Settling chamber in the basement; 3. Heating coils; 4. Air passages in lobby floors; 5. Air passages in the cornice; 6. Extract above a gas lamp; 7. Foul air chamber; 8. Foul air down a duct; 9. Foul air chimney; 10. Flue from a kitchen range. (Reprinted by permission from Banham, Reyner. 1969. The Architecture of the Well-Tempered Environment. The Architectural Press. London.)

1. INDOOR AIR QUALITY AND BUILDING DESIGN

Several trends have combined to bring indoor air quality (IAQ) concerns back into prominence.

First, an increasingly large percentage of people's time is now spent indoors, and in more tightly con trolled environments, as a service-based economy overtakes a manufacturing-based one. Second, the oil embargo of 1973 raised the world's consciousness regarding finite energy sources, producing a sudden and powerful rush toward energy-con serving designs. This, in turn, encouraged designers to limit the introduction of outdoor air that required cooling in summer and heating in winter.

Third, a proliferation of chemicals in our environment has produced a vast array of potential air pollutants-from synthetic products permanently installed within buildings, from equipment used indoors, and from cleaning fluids used in maintenance. With more time spent in less fresh air and surrounded by more pollution sources, increasing numbers of buildings have seen experiences with sick building syndrome (SBS). SBS (by one definition) is a situation wherein more than 20% of the occupants complain of symptoms associated with SBS-such as headaches, upper respiratory irritation, and irritations of the eyes, among others. If these symptoms disappear after occupants leave the workplace (weekends are especially good periods of contrast), SBS is strongly indicated.

The building designer has an elusive task when air quality is at issue, because so little can be accurately predicted. Heat flow rates, occupancy schedules, and typical weather patterns can be combined to estimate with some confidence how much energy will be consumed by a building; construction types can then be altered in the design stage to yield predictably different results. Designers have few tables that provide rates of outgassing for various materials at given temperatures and no well-established data on design conditions for the quality of local or regional outdoor (fresh) air, even though there is readily available and reliable information for air temperature and humidity.

Controlling the quality of indoor air may be as important to building occupants as controlling for thermal or acoustical comfort. Designers know that saving energy for heating and cooling lowers the cost of maintaining a building; employers know that lost productivity from either on-the-job illness or sick leave can result in much greater costs.

One estimate for a large office building compared the cost of increasing ventilation and improving air filtration to the value of projected health and productivity benefits. Initial improvements yielded estimated benefit-to-cost ratios of 50 to 1 (increased ventilation) and 20 to 1 (improved filtration). Acceptable thermal conditions and accept able IAQ are not synonymous. Buildings that are thermally comfortable can still cause SBS when pollutants are sufficiently numerous.

ASHRAE (Standard 62.1, 2007) has defined acceptable indoor air quality as: "air in which there are no known contaminants at harmful concentrations as determined by cognizant authorities and with which a substantial majority (80% or more) of the people exposed do not express dissatisfaction." There are two components to this definition-a comfort response and a health benchmark. Providing acceptable IAQ depends upon four major considerations, three of which depend largely on the designer:

1. Limiting pollution at the source (choosing materials and equipment carefully)

2. Isolating unavoidable sources of pollution

3. Providing for an adequate supply and filtering of fresh air (and recirculated air)

4. Maintaining a building and its equipment in a clean condition

Dealing with indoor pollution at its source, by choosing materials and equipment with care whenever possible, rather than increasing outdoor airflow rates (and related energy consumption) is the most rational IAQ strategy. The designer can further provide for improved IAQ by carefully locating a building on its site; zoning to isolate pollutant sources; and providing clean, adequate, and well-distributed outdoor air, air-cleaning devices, and building commissioning. Providing a flush mode following completion of construction might be considered. It is up to a building's managers to maintain IAQ by means of a regular equipment maintenance program, regular interior cleaning, and a careful selection of cleaning agents.

Furthermore, a flush of the building after every unoccupied weekend or holiday period is helpful in removing pollutants accumulated from finishes and furnishings.

Table 1 Common Air Pollutants

=============

Pollutant Sources Effects Control Strategies

Excess moisture, Cooking (heating open liquids), washing, exhaling Increases growth of fungi, bacteria, and dust mites Exhaust ventilation at source; dehumidification Carbon dioxide (CO2) Human respiration Minor discomfort at high concentrations; "stuffiness" CO2 is a good indicator of the ventilation rate in tightly enclosed spaces or where occupancy is high Carbon monoxide (CO) Incomplete combustion: furnaces, stoves, fireplaces; motor vehicle exhaust Headaches, dizziness, sleepiness, muscle weakness, potentially lethal Sealed combustion burners, adequate combustion air, safe exhaust flues Nitrogen oxides High-temperature combustion Irritation, possible immune suppression Safe exhaust flues, sealed combustion burners Sulfur oxides Combustion fuels containing sulfur (oil, coal) Potential irritant, burning eyes, reduces lung function Alternative fuels, safe exhaust flues, sealed combustion burners Polynuclear aromatic hydrocarbons Smoking, combustion of wood or coal, barbecuing, burnt food Irritants and carcinogens Prohibit smoking, lower temperature in cooking, use clean fuels, burn wood in enclosed firebox with adequate oxygen supply Ozone Laser printers, photocopiers, small motors, electronic air cleaners Inflammation of bronchia, wheezing and shortness of breath, dizziness, asthma attacks Remove sources or exhaust at source, maintain electronic air cleaners Volatile organic compounds (VOCs)

Formaldehyde Particle board, interior laminated panels, glues, fabric treatments, paints Burning eyes and nose, skin rash, shortness of breath, headaches, nausea, dizziness, fatigue Use alternative materials, seal particle board if used, ventilate Others Paints, solvents, carpets, soft plastics, adhesives, caulkings, softwoods, paper products, cleaning and maintenance products Intoxication, burning eyes and nose, shortness of breath, headaches, nausea, dizziness, loss of judgment, panic Use alternative materials, age materials before installing, ventilate Lead Pre-1970s paint, pre-1985 pipes and solder, dust and soil near roads (residue from leaded gas) Neurotoxic, especially if ingested by young children; learning disabilities, nausea, trembling, numbness of extremities Identify and remove or seal old paint, replace pipes and solder, avoid foods grown by roadside Pesticide residues Treated basements and foundations, treated ceiling and wall cavities, treated cabinets and closets, treated soil outside foundation Neurotoxic or long-term risk of liver, kidney, and other diseases, including cancers Identification and removal by expert if history known, sealing in pesticide if possible Asbestos fiber Pre-1975 steam pipe and duct insulation, furnace and furnace parts, pre-1980 reinforced vinyl floor tile, and fiber cement shingles and siding Long-term cancer risk from inhaling fibers Leave material undisturbed, get expert identification and removal if required, seal with special sealant and cover with sheet metal if not crumbling Mineral and glass fiber Thermal insulation, pipe insulation, fire-resistant acoustic tile and fabrics Potential irritant, burning eyes, itching skin, long-term risk of lung damage and cancer Handle only with respirator and gloves, seal and enclose, do not disturb in place Fungus particles, dust mites Grow in basements, damp carpet, bedding, fabrics, walls and ceilings, closets Very allergenic, burning eyes and nose, sneezing, skin rash, congestion, and shortness of breath Keep surfaces dry and clean, cover bedding and upholstery with barrier cloth, ventilate, use borax treatments to retard fungus Hazardous bacteria (e.g., Legionella) Standing warm water, untreated hot tubs, air conditioning drain pans, humidifier reservoirs Severe respiratory illness, potentially lethal Prevent standing water, clean and treat tubs and reservoirs Radon gas Natural radioactivity in soils Increased lifetime lung cancer risk Seal foundation and floor drains, ventilate subsoil Methane and other soil gases Decomposing garbage in landfills, leaking sewage lines, toxic waste Possibly explosive or toxic, nuisance odors Know site history before building, remove soil if necessary, seal foundation and floor drains, ventilate subsoil

=============

2. POLLUTANT SOURCES AND IMPACTS

Indoor air pollution can be described both in terms of the types of contaminants (gaseous, organic, or particulate) and the types of effects (odors, irritants, toxic substances) involved. People not only inhale contaminants, but also absorb and ingest some- the nose is not the only pollutant receptor/sensor.

Table 1 summarizes some common indoor air pollutants, their effects, and simple strategies to ameliorate them. For some contaminants, the only method of avoidance is to design for their exclusion; equipment will not remove them, although increased ventilation can reduce their impact.

Examples are asbestos, radon, and pesticides.

(a) Odors

One of the most immediate indicators of IAQ problems is odor. People are sensitive to odors over an extraordinary range, whereas equipment to detect and classify odors is woefully lacking. Odors are perceived most strongly on initial encounter; then "fatigue" occurs and perception fades. Thus, visitors are more likely to detect odors than are the long term inhabitants of a space. Odors may be simply unpleasant, with psychological consequences, or may be indicators of a more serious IAQ problem with physiological consequences. When an unfamiliar odor is detected, our reactions are positive, neutral, or negative, depending upon whether we perceive a threat or enjoyment through the odor.

Sometimes odors are directly traceable to a source, but in office environments odors are usually more complex. A typical office environment odor blend may include body odors, grooming products (perfumes, colognes), copy machines, food products, cleaning fluids, and outgassing from materials. More rarely, in a decreasing number of locales, tobacco smoke may also be present. This complexity produces an interesting reaction; people tend to become less sensitive to each of the component odors, with a resulting overall masking. However, an architecturally imposed masking approach-the deliberate introduction of a "perfume" to cover offending odors- is rarely successful. (Sweet-and-sour may work nicely for the palate, but olfactorily it can be uniquely nauseating.) Conversely, as the indoor environment is freed of multiple odors, people become more sensitive to the one or two odors that remain.

Often a simple measurement of carbon dioxide (CO2) concentration is used as a first indicator (a surrogate) of potential IAQ problems related to occupancy, because the CO2 concentration indoors is generally proportional to the human concentration.

Filtering odors from indoor air is usually accomplished with electronic or activated char coal filters, described in Section 6.

(b) Irritants

Unlike odors, which are immediately perceived and fade with prolonged exposure, irritants are often imperceptible at first but cause increasing distress over time. Symptoms of irritants include itching or burning eyes, sneezing, coughing, dry nose and throat, sore throat, and tightness of the chest. Most irritants are present in the form of particles and gas dispersoids (Table 2).

Sources of irritants typically include the building itself and the equipment and occupants within.

New and newly renovated buildings are particularly prone to problems from outgassing of paints, adhesives, sealants, office furniture, carpeting, and vinyl wall coverings. Volatile organic compounds (VOCs) are chemicals containing carbon molecules that are volatile; that is, they off-gas or evaporate from material surfaces at room temperatures. The VOC list is long: methane, ethane, methylene chloride, trichloroethane, chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), hydrofluorocarbons (HFCs), formaldehyde, and hydrocarbons such as styrene, benzene, and alcohols. All are now found frequently in new buildings.

Long-term occupancy brings other irritants. Ozone, valuable in the upper atmosphere but a smog component below, is produced by copy machines, high-voltage electrical equipment, and-ironically-electrostatic air cleaners. Mineral fibrous particles can be produced by the breakdown of duct liner/insulation and fire proofing. Hydrocarbon compounds come from copy machines and copy papers. Tobacco smoke is a mixture of gases and fine particles especially irritating to many individuals. Low humidity can exacerbate problems with irritants, producing symptoms similar to those from chemicals. Carpet shampooing yields organic solvents and ammonia; nighttime cleaning coinciding with reduced or nonexistent ventilation is especially problematic.

In contrast, night maintenance with increased ventilation rates-as with cooling by night ventilation of thermal mass-can reduce this threat.

As with odors, the impacts of irritants can be reduced with an increased outdoor air supply.

Filters for the removal of irritants usually consist of particulate filters; less common are gaseous removal filters, air washers, and electronic air cleaners. These are discussed in Section 6.

(c) Toxic Particulate Substances

At the top of this list is asbestos, widely used in buildings until its toxicity was realized in the 1970s. Asbestos in tightly bound form is encountered as asbestos-cement and in vinyl-asbestos floor tiles, and in loosely bound form as sprayed on asbestos insulation. The latter is particularly dangerous, readily releasing toxic asbestos fibers over the life of the material. With asbestos, neither increased ventilation nor filtering is acceptable; it must be either removed under stringent isolation controls or sealed and left in place.

Some of the respirable particles (see Table 2) that result from incomplete combustion are toxic.

Incomplete combustion can occur from tobacco smoking, in woodstoves, fireplaces, and gas ranges, and from unvented gas or kerosene space heaters.

Lacking control of combustion at its source, the remedies are to isolate the source insofar as possible, exhaust air from the immediate vicinity, increase the outdoor air supply to the area, and utilize particle filtering.

(d) Biological Contaminants

Because living things inhabit both buildings and outdoor air, there will be biological contaminants such as bacteria, fungi, viruses, algae, insect parts, and dust within buildings. Moisture encourages both the retention and growth of these contaminants; standing water (which may occur in HVAC system components) and moist interior surfaces are likely trouble sites. Allergic reactions and infectious and noninfectious diseases can result. Outbreaks of Legionnaire's disease have occurred when improperly maintained HVAC systems incubated and then distributed disease-causing microorganisms.

Now residential humidifiers, dehumidifiers, and air-conditioner drain pans are suspect.

Remedies for biological contaminants begin with good design and end with vigilant maintenance. Although exposure to ultraviolet radiation is sometimes used as a control strategy, filters are rarely an effective solution for these contaminants.

(e) Radon and Soil Gases

Radon is a radioactive gas that decays rapidly, releasing radiation at each stage. It is colorless and odorless, and thus is undetectable by human sense. If we inhale radon, radiation release in the lungs can cause lung cancer. Other soil gases include methane (usually odiferous) and some pesticides that can volatize and enter buildings with soil gases. Effects on human beings are not likely to be beneficial.

In many buildings with high levels of radon, the problem has been traced to exposure to soil.

Radon penetrates through floor and wall cracks and openings around plumbing pipes; thus, below-ground spaces are particularly at risk. Penetrations of below-grade walls and floors should be both minimized and well sealed; under-slab ventilation may be appropriate, especially in areas of high radon risk.

3. PREDICTING INDOOR AIR QUALITY

Assuming that pollutant sources have been minimized, designers essentially need to know how much outdoor air and what extent of filtering will produce acceptable indoor air quality. These questions are difficult to answer.

(a) Ventilation Rate

The most common remedy for SBS (after con trolling pollution sources) is to increase the rate of outdoor air ventilation. Recommended rates of ventilation are found in Tables E.25 (nonresidential) and E.26 (residential). Although very small amounts of outdoor air will provide sufficient oxygen, and although human body odor control is usually achievable at a rate of from 6 to 9 cfm (cubic feet per minute) (3 to 4.5 L/s) of outdoor air per occupant, outdoor air has more to do than provide oxygen and control odors. Defining minimum outdoor air supply rates has proven to be a controversial task. The current ASHRAE ventilation standard (Standard 62.1-2007-for other than low-rise residential buildings) establishes minimum rates (Table E.25) on the basis of an occupancy component and a building component in recognition of these distinct contaminant sources. Some feel that the outdoor air requirements are too high, others that they are too low.

Two units have been proposed to integrate the various indoor air pollutants in the same way that they are perceived by human beings. The olf is a unit of pollution (1 olf = the bio-effluents produced by the average person); the decipol is a unit of perceived air quality. These are related in this proposed comfort formula:

Q = 10 G CC io -

where

Q = ventilation rate, L/s

G = total pollution sources, olf

Ci = perceived indoor air quality, decipol

Co = perceived outdoor air quality, decipol

At present, Ci is recommended to be set at 1.4 decipol, which represents an expectation of 80% of occupants satisfied with IAQ. Co and G may be roughly estimated from Table 3. These proposals are discussed in more detail in Fanger (1989).

Table 4 Air Replacance Compared to Input Air Changes per Hour (ACH)

Table 3 Estimating Indoor Air Quality

The concept of replacance affects the design of ventilation systems. Table 4 shows that at the rate of 1 air change per hour (ACH) of outdoor air, an indoor space would have only 63% "new" air after 1 hour; about 8 hours at this rate is required for all the "old" air to be exhausted. There is, then, a difference between the fresh air input rate (ACH) and the replacance-the fraction of air molecules at one specified time that was not in the indoor space at an earlier reference time. This relation ship, along with details of air pollutants (and of heat exchanger design for energy conservation), is thoroughly discussed in Shurcliff (1981).

The campus for the Environmental Protection Agency (EPA) in Research Triangle Park, North Carolina, was designed with special emphasis on IAQ (Fig. 2). The designers considered several alternatives for fresh air provision, deciding that a simple variable air volume (VAV) system, set at a minimum of 3 ACH (of combined fresh and recycled air) would be acceptable. If the system had been designed with a typical minimum, only 1 ACH would have resulted during periods when neither heating nor cooling was required (typical spring and fall conditions). A 6 ACH alternative, on the other hand, would have dramatically increased energy consumption.

(b) Testing

When a client is especially interested in IAQ, full-scale time tests can be used. At the new EPA campus (Fig. 2), the contractor was given a target for allowable contaminant concentrations (Table 5, Part B). Any material assembly deemed likely to contribute more than one-third of these allowable concentrations, and used in large quantities, was to be tested before acceptance. One desirable outcome of such testing and associated materials specifications is the possible avoidance (or shortening) of an anticipated flush-out of a completed building before occupancy.

4. ZONING FOR IAQ

After pollution control is implemented at the source (cleaner equipment, prohibiting smoking, careful material choices, etc.), remaining unavoidable pollutant sources should be identified. Then more sensitive building areas should be isolated from the key contaminators. This is sometimes difficult, as in "open offices" where walls are unwelcome but copying machines are essential. In such cases, the method is to erect as much of a barrier as possible around an offender, then task ventilate to remove the contaminated air immediately. Sometimes air pollution sources also produce unwanted sound, in which case the argument for a more complete barrier may become more compelling.

Many health-care and laboratory buildings have "clean" and "dirty" zones, and even separate circulation pathways. Differential air pressures are often maintained to discourage air flow from dirty to clean zones-with higher pressure in clean areas, lower pressure in dirty areas. Lower pressure areas can be created simply by exhausting air from such spaces, as well as by limiting the volume of supply air. Higher-pressure areas can be created by installing makeup air equipment, as well as increasing the volume of supply air from the HVAC system.

FIG. 2 The campus of the U.S. Environmental Protection Agency at Research Triangle Park, North Carolina, features concentrated parking separate from the buildings. High exhaust stacks disperse air from laboratories; intakes are kept well away from exhaust. (Courtesy of Hellmuth, Obata + Kassabaum, Washington, DC.)

Table 5 Air Quality Standards

Table 6 Design Decisions and Impacts: EPA Campus, Research Triangle Park

========

Item Decision Impact on IAQ Siting of building

Locate exhaust downwind from air intakes, separate by >100 ft (30 m) Maximize separation between parking areas and air intakes Minimizes reentrainment of laboratory exhaust air at air intakes Reduces the potential for vehicular exhaust entering building Location of parking garages Locate parking structure away from the building Reduces the potential for vehicular exhaust entering building Laboratory exhaust stacks Increase stack height to 30 ft (9 m) based on wind tunnel testing Minimizes reentrainment of laboratory exhausts into air intakes Radon Site-specific testing confirmed low levels of radon Confirmed that radon levels are safe Delivery/loading zone Maintain negative pressure in loading area, positive pressure in building Eliminates entrainment of delivery vehicle exhaust Landscaping

Low-maintenance and nonsporulating plants selected Plants used as a barrier to vehicle exhaust Intake of spores, fertilizer, or chemicals entering building is reduced Minimizes entrainment of delivery vehicle exhaust Laboratory fume hoods Install flow gauges and alarms Provides warning of air contaminants present in laboratory areas due to loss of flow Acoustic insulation of ducts Ductwork increased in size to reduce need for acoustical insulation; in select areas, mylar coated duct silencers are used as ductwork transitions out of equipment rooms Minimizes release of fibers into the airstream and possible contamination of the HVAC system (duct liners are difficult to monitor or to clean and can be sites of microbial growth) Moisture accumulation Install drain pans pitched toward drain pipe Reduces moisture, which could result in introduction of bacterial contamination into HVAC system Humidity control No moisture carryover into system Minimizes moisture in HVAC system and resultant bacterial contaminants due to moisture Corrosion inhibitors, Inhibitors do not contain volatile amines Eliminates exposure to certain air contaminants System maintenance Provide access panels at ductwork appurtenances and ample clearance around equipment Maximizes ease of maintaining HVAC system Outside ventilation rate 100% outdoor air in laboratories; 20 cfm (10 L/s) per person in offices Flexibility to increase ventilation rate 20% for unexpected sources Maximizes occupant comfort and removal of air contaminants Minimizes possible occupant exposure to contaminants Airflow efficiency

Minimum airflow rate set at 3 ACH for VAV system in office areas Flexible connections to room diffusers in open office areas Increases air movement and ventilation effectiveness Facilitates modifications to enhance airflow as necessary Air cleaning

ASHRAE 30% efficiency pre-filters with 85% final filters Flexibility to add scrubbers to laboratory exhaust Use bird-proofing mesh screen Minimizes dust and other aerosols entering indoor air via the HVAC system Minimizes release of contaminants to ambient air Eliminates bird droppings and possible microorganism infection in the HVAC system Thermal control Building automated control system Fixed windows Provides optimum control of temperature and pressure Prevents unconditioned air from entering building; maintains positive pressure in laboratories Exhaust system

100% exhaust for photocopying rooms, laboratories, food preparation areas Photocopiers located within 10 ft (3 m) of exhaust vent Eliminates potential to recirculate contaminants and odors through the building via the HVAC system Controls potential source of air contaminants; recirculated air is filtered prior to its return Smoking Designate building as nonsmoking Eliminates exposure to secondhand smoke and recirculation of tobacco smoke via the HVAC system Building materials, finishes, furnishings Materials selected to minimize release of contaminants from products Minimize occupant exposure to contaminants as a result of off-gassing from building materials, finishes, furnishings

========

On a site-planning scale, try to locate air intakes upwind from pollution sources. Because winds frequently change direction, this may be more a matter of adequate separation distance than direction. The most obvious example is a major air intake for a central HVAC system, which should be as far as possible from parking areas, delivery docks, and streets-and from the exhaust outlets from that same HVAC system or outlets from other building systems. Even exhaust outlets should be located carefully, because there is a possibility that at times outdoor air can be drawn into these exhaust openings. A mechanical equipment room is the typical location for both intake and exhaust; energy conservation devices such as heat exchangers benefit from close proximity of intake and exhaust. Most animals use the same "ducts" to breathe in and exhale, obviously inviting air reentrainment. For a building, however, separation of these openings is prudent design.

The campus for the EPA (Fig. 2) is an example of pre-design planning for IAQ. This is a 1,000,000-ft2 (92,900-m2) building complex serving a population of more than 2000 on 133 acres (54 hectares) of farm land that has reverted to second-growth hardwoods. Table 6 gives a summary of design decisions and their impact on IAQ. Some of the more visible design consequences are the separation of parking and building, the concentration of parking in a structure (less impact on the existing landscape, more control of vehicle fumes), and the height of the exhaust stacks from the laboratories. Many other design decisions are hidden within the building's materials and HVAC system, as detailed in Table 6.

The topic of zoning includes decisions about local versus central equipment. Should individual exhaust fans be installed (creating selective lower-pressure areas) or a central exhaust fan (that can discharge up a very tall stack)? Should air cleaners be installed locally, where they can be selected according to the degree of pollution, or centrally, where they can be more easily and regularly maintained? What about heat exchangers for tempering incoming air: many smaller ones or one large one? The larger and more complex a building is, the more likely the development of a mix of local, specialized zones and a large, more general zone that is centrally served.

Figure 3 explores the issue of the location of an office copier: at the edge, where task ventilation is easy, but plentiful daylight and a view may be "wasted" on this function, or away from the edge, where a central exhaust system is more likely to be utilized.