AMAZON multi-meters discounts AMAZON oscilloscope discounts

Sections 1 through 5 provide some preparation for design: a perspective on energy, water, and material resources; an understanding of human comfort and indoor air quality; an analysis of the climate resources available on site; a list of the general design strategies appropriate to various climates; a discussion of the basics of heat transfer calculations; and some attention to requirements for the components of the building envelope. Hence, we now know much about the variables outside of a building, the desired conditions inside, and the individual components of a building's skin. In this Section, all these variables are integrated into the process of designing for heating and cooling with the important related factor of daylighting. The design of mechanical support systems is introduced in Section 9.

The information in this Section is organized from the general to the particular. It also serves two distinct kinds of buildings-buildings using on-site energy resources and more conventional buildings using imported energy.

1. ORGANIZING THE PROBLEM

How should the building envelope respond to the sometimes conflicting needs for heating, cooling, and daylighting? Heating and cooling design strategies were related to climate in Section 4, where it became evident that internal heat gains can shift the appropriate design strategies for a building toward cooling, perhaps eliminating heating needs entirely. Typically, much of this internal heat is pro vided by electric lighting. Daylighting can replace electric lighting for most of the typical working day in most building types-if the building is designed to allow daylight to reach most of the interior.

(a) Fenestration

Codes and standards typically prescribe a relation ship between floor area and fenestration area (residential buildings) or total wall area and fenestration area (nonresidential buildings). These prescriptions assume that a building will be designed convention ally, that is, to rely on imported energy for lighting, heating, and cooling. Thus, prescribed areas of fenestration tend to be rather small. If a designer wishes to rely on daylighting to a greater extent, then some proof of benefit will be needed.

Daylighting is accompanied by large glass areas, which increase a building's heating needs in winter; yet in such buildings, less heat from electric lighting is available to fill those needs. Another complication is that adequate daylight requires much larger glass areas under dim winter skies than under bright summer skies. If the glass area is sized for winter daylighting, then excessive daylight---and, along with it, excessive heat--might be admitted in summer. With proper controls, day lighting can reduce summer cooling loads, relative to electric lighting, but it will usually increase winter heating loads. Where passive solar heating or surplus heat from another source is readily avail able, this trade-off is attractive.

One of the earliest and most difficult questions for the designer is how much fenestration is optimum for a building. Some of the major energy end uses in buildings are: 30% for space heating, 11% for space cooling and ventilation, and 14% for electric lighting. By building type and location, however, this proportion of energy use can change substantially. Daylighting and the related square footage of windows are considered first because they so largely determine whether space heating or space cooling will be the dominant need within the building.

(b) Building Form

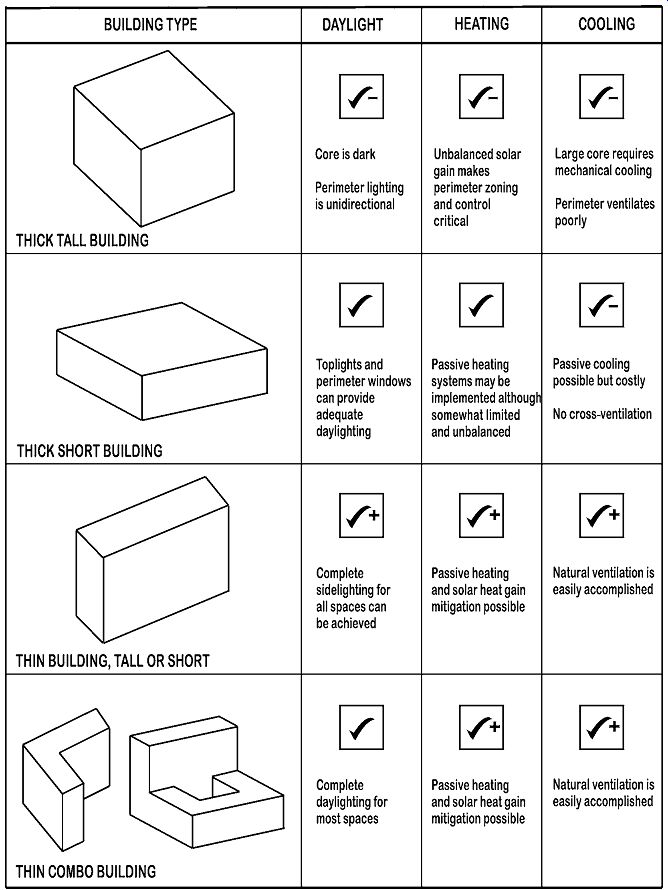

At its simplest, form can be reduced to questions of tall or short, thick or thin. FIG. 1 compares these form variations to their impacts on heating, cooling, and daylighting solutions. Thicker, taller buildings have more floor space away from climate influences; being electrically lit rather than daylit, they generate heat and need cooling all year. These buildings are called internal load dominated (ILD). In contrast, thinner buildings-in which nearly all spaces have an exterior wall-need heating in cold weather and cooling in hot weather; electric lighting by day is largely unnecessary. These buildings are called skin load dominated (SLD).

The ultimate choice of building form is determined by a combination of design issues; the energy use issue can help in the selection process. Once the building form has been chosen, the functions can be distributed according to typical architectural criteria, including thermal zoning considerations.

In the selection of a building form, some particularly important questions accompany each energy use. Because the question of daylighting versus electric lighting frequently is so influential in deter mining whether heating or cooling will be the dominant concern, we begin with daylighting.

DAYLIGHTING ISSUES

1. What will be the relative emphasis on sidelighting (characterized by uneven distribution and glare in the visual field but little glare on horizontal surfaces) and top-lighting (the reverse characteristics)?

2. What role will direct sun play in daylighting? In winter, can solar heat without glare be admitted?

3. How can seasonal adjustments be made in the size of daylight openings?

4. To what extent will daily changes in daylighting control be necessary?

5. How can adequate daylight be admitted in an even way, such that unwelcome dark-appearing places are avoided?

FIG. 1--The effect of building form on environmental control strategies.

The illustration shows how building layout affects cooling, daylighting, and

heating opportunities.

HEATING ISSUES

1. Can the sun be used to heat spaces? If so, how will south-wall design be affected?

2. How can openings in walls facing other directions be kept to a minimum without daylight being shut out? Where such openings are desirable, how low a fenestration U-factor can be justified?

3. What role will direct sun through south glass or skylights play in daylighting?

4. How can daylight be admitted but the chilling effects of large, cold glass surfaces be minimized?

5. How can incoming fresh air be warmed before it chills the people sitting near the fresh air opening?

6. Is there surplus heat elsewhere in the building that can be used to help warm perimeter spaces?

COOLING ISSUES

1. Will the strategy be to open the building to breeze or close the building for cooling retention, or to use a combination of these alternatives (open by night, closed by day)?

2. How can direct sun be kept out of the building? Can east and west windows be minimized and adequate daylight still be provided?

3. How can adequate daylight be admitted for winter conditions without overlighting (and thus overheating) for summer conditions?

4. When can cooling be provided by outdoor air rather than by a refrigeration cycle?

5. Can the operation of refrigeration machinery be concentrated during the coldest (nighttime) hours, when electric power is cheapest?

6. How can incoming fresh air be cooled before it warms the people sitting near the fresh air opening?

7. Can the structure of the building be used to absorb heat by day, then be flushed with night air in climates with cool nights?

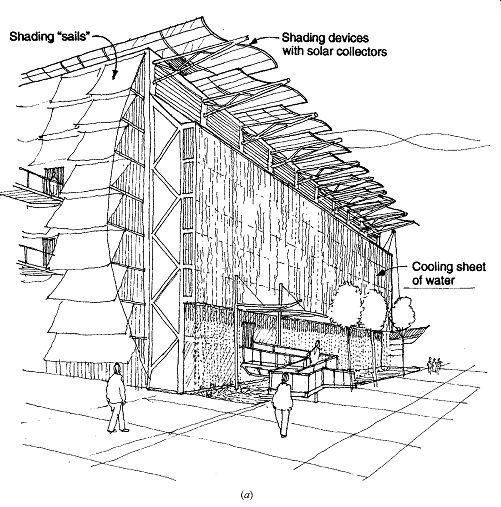

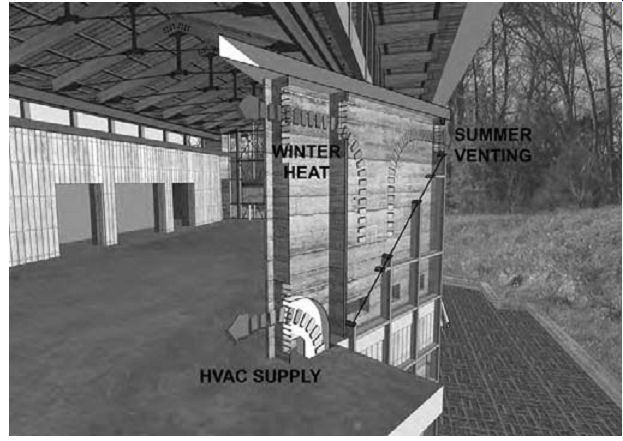

(c) Building Envelope

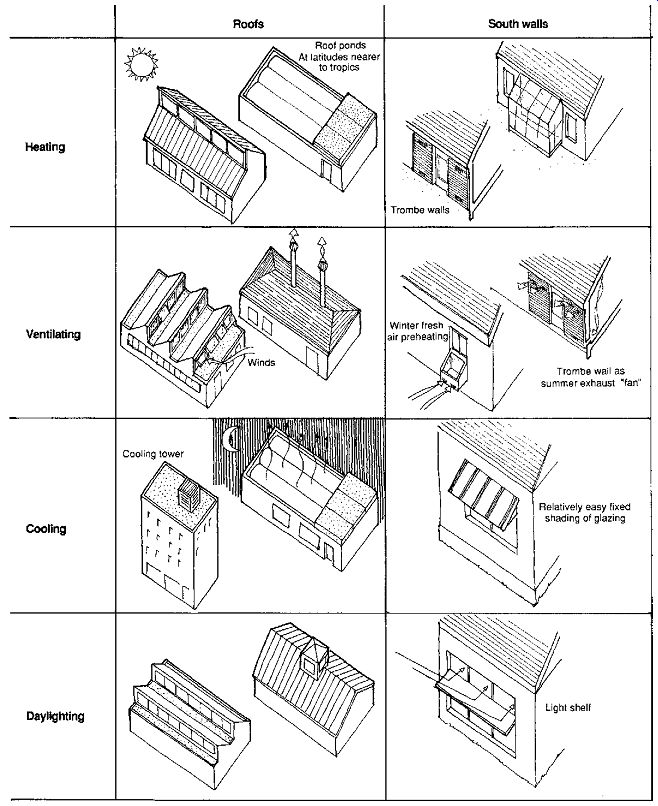

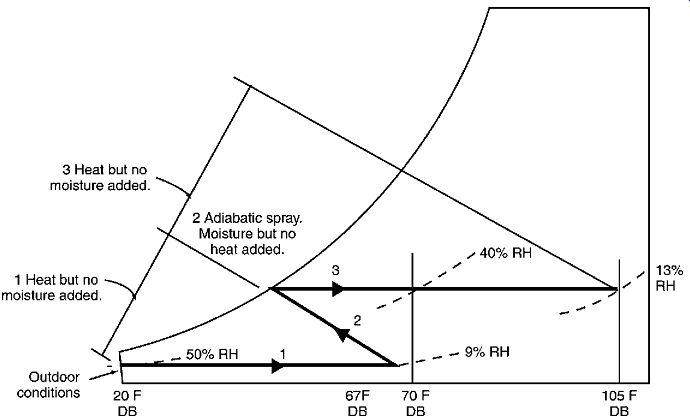

The next design step involves relating the climate to the design of the building's skin. Each skin element provides an opportunity for thermal and luminous exchange between inside and out side; heating, cooling, ventilating, and daylighting devices can be mixed as needed. FIG. 2 shows some of the most common of these devices for varying orientations. Sections in this Section give numerical criteria for sizing these skin elements, with an emphasis on the use of on-site, renewable energy resources. These criteria may conflict with the size relationships that may be prescribed by codes and standards for conventional buildings.

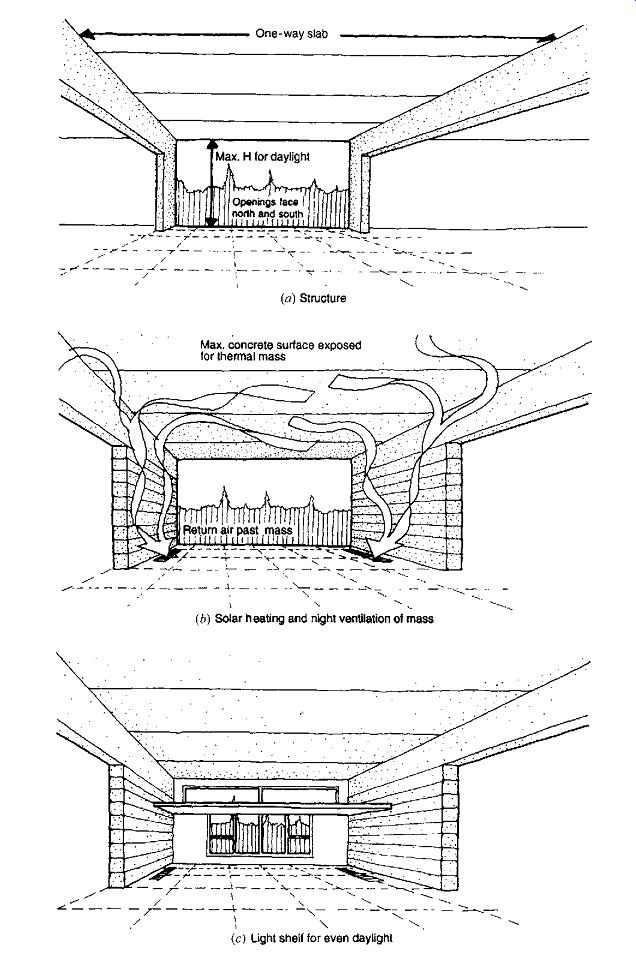

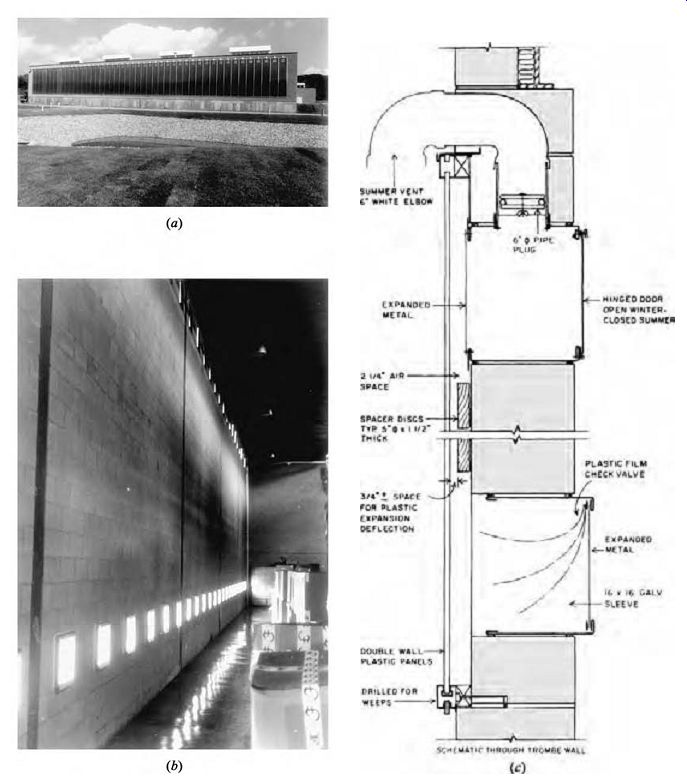

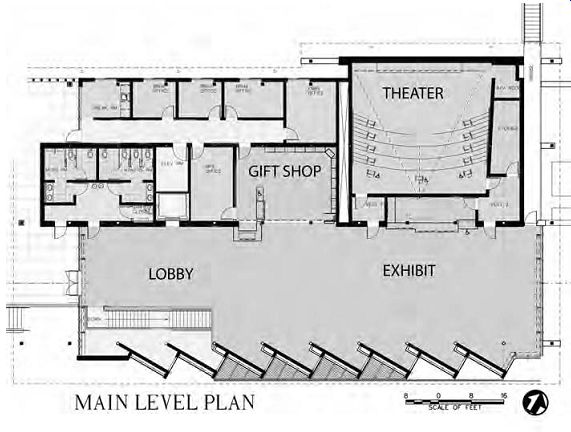

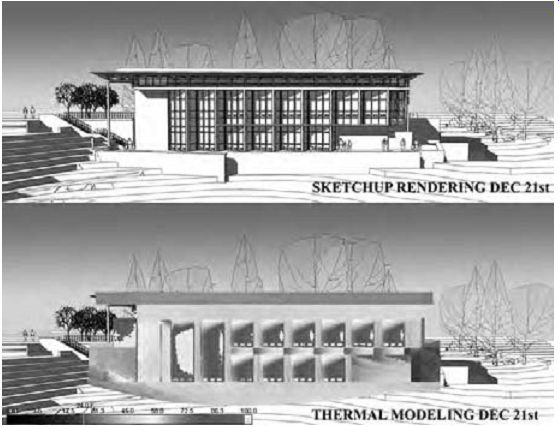

An example of how lighting, heating, and cooling considerations can combine with other criteria (structural and acoustic, in this example) is shown in FIG. 3. These design diagrams explore opportunities in an office building in a cool-winter, dry summer climate; the actual resulting building is shown in FIG. 6.

2. ZONING

Before calculating winter heat loss and summer heat gain, zoning should be considered. Dividing the calculations into zones facilitates later decisions about sizes of equipment as well as fenestration and areas of thermal mass. The thermal and luminous zoning of a building recognizes that different envelopes and support systems may be required around and within the building. The more carefully zoning is considered in these early design stages, the better will be the lighting and thermal performance and the lower will be the annual energy consumption. (Also, the less likely it will be that all sides of a building will have an identical appearance.) Zoning is most often influenced by the following factors:

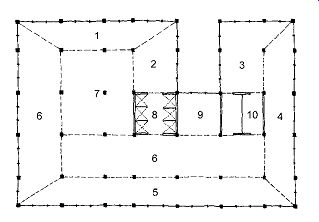

1. Function. Particularly important because of the variations in internal heat gains between functions, function may also influence the zonal organization of a building, as in FIG. 4. Comfort conditions may vary considerably between functions; air temperatures can be lower for a strenuous activity than for a sedentary activity, or heat tolerance may be greater for some activities (restaurant kitchens) than for others. Some functions thrive in daylight; others shun it. Some functions adversely affect the IAQ of other functions.

2. Schedule. Closely related to function, scheduling can influence both the envelope and the support system. An activity scheduled only between 9:00 A.M. and 4:00 P.M. can often be entirely daylit at a time when the outside temperatures are the warmest of the daily cycle.

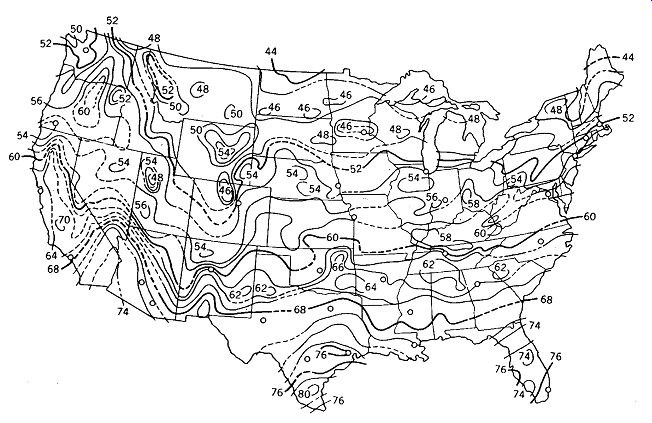

By contrast, an activity that takes place only from 9:00 P.M. to 4:00 A.M. will be entirely dependent on electric lighting, whose heat can be used to over come the chill of the outside temperatures during these hours in winter. (In the summer, such heat can be flushed away with the cool outside night air in many U.S. locations.) Support systems are often divided by scheduling considerations: If one activity has operating hours different from those of the remainder of the building, a separate mechanical system is often provided. This saves energy, because large equipment will not be underused to provide heating or cooling for only one zone.

3. Orientation. The degree of exposure to day light, direct sun, and wind is obviously important to zoning. Consider the block-square office building floors (FIG. 4) on a cold, sunny, and windy day. Perimeter spaces with direct sun through the windows may gain more heat than is lost and thus need cooling. This might be done by the opening of windows, but too much cold air (especially on the windy side of a building) may make the workers near the windows uncomfortable. Perimeter spaces without direct sun may have a net heat loss due to heat loss through glass, infiltration, and reduced electric lighting (because daylight is adequate). These spaces will need heat from a mechanical support system. Interior (no-daylight) spaces are overheated by electric lighting because they cannot lose heat. These spaces will need cooling from the support system.

Zoning considerations are among the most important influences on building form and external design, along with the familiar aesthetic, social, legal, economic, and technical influences that combine in a tug of war familiar to the building designer.

3. DAYLIGHTING CONSIDERATIONS

Sizing of windows and analysis of daylighting performance will generally use the same guide lines for recommended daylight factor. Such guidelines are described in detail in Section 14, where they are discussed as a means of predicting daylighting performance. In previous Sections, windows and skylights have been seen as a liability because of winter heat loss and summer heat gain. It is time to consider their benefits numerically. This section will use daylighting guidelines in a preliminary example of window sizing for an office building.

When a building is designed to rely on day lighting, a prime design concern is the daylight factor (DF), which is expressed as a percentage of the outdoor illuminance under overcast skies that is available indoors.

DF = indoor illuminance from daylight outdoor illuminance × 100%

Some simple target overcast-sky daylight factors and the simplest design guidelines that provide these target daylight factors are presented in Tables 14.2 and 14.3. These design guidelines consider two factors: How high is the window in the wall, and how large is the window or skylight area compared to the floor area for each daylit space? The target daylight factors listed in Table 14.2 provide sufficient light during most of the daylight hours on overcast winter days. The relationship between office working hours, daylight, and out door temperature is explored in the climatic time tables of FIG. 5 for the building whose design diagrams appeared earlier (see FIG. 3). Much more light will be available on summer days- probably more light than is needed, bringing heat along with it. When sizing windows and skylights, remember that controlling direct sun is necessary and that less opening area is needed in summer than in winter.

FIG. 2 The components of a building's envelope can be used both to conserve

energy and to admit on-site or natural energy sources.

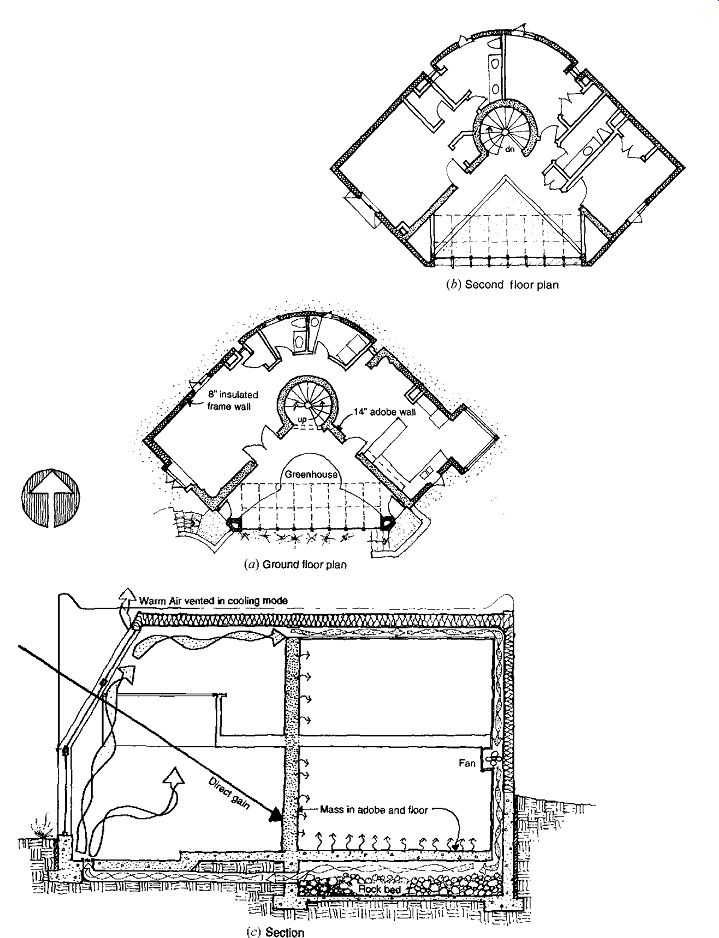

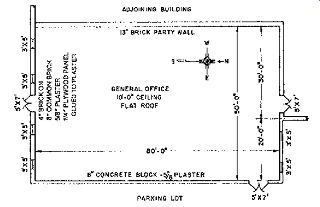

EXAMPLE 1

Many of the design guidelines presented in this Section will be illustrated by applying them to a typical bay of the building in FIG. 6. This 24,000-ft 2 (2230-m^2) office building for an electric utility is located in Eugene, in western Oregon's wet-winter, dry-summer climate typical of the U.S. Pacific Northwest. Energy conservation and daylighting considerations played a major role in this building's design and were integrated with solar heating, night ventilation of mass, structure, and acoustics (see FIG. 3).

EXAMPLE 1 is an ongoing illustration. Applications of various design guidelines will continue to appear in the context of this example throughout this Section. TABLE 2 presents the type of information about a building that will be required in order to apply these design guidelines.

Part A. Daylight design Part B. Overall rate of heat loss (Btu/DD ft^2) Part C. Approximate solar savings fraction (SSF) Part D. Approximate heat gain Part E. Cross-ventilation guidelines Part F. Night ventilation of thermal mass guidelines Part G. January balance point temperature Part H. Annual SSF based upon the load to collector ratio (LCR) Part I. Clear January day indoor temperature swing Part J. Detailed night-cooling of mass calculation.

FIG. 3 Design diagrams explore opportunities in an office building in western

Oregon (see FIG. 6 for the resulting building). (a) Choosing a one-way structure

allows windows to be placed as high as possible for deeper daylight penetration.

(b) Maximizing exposed interior surfaces that are thermally massive facilitates

both winter solar heat storage and summer night cooling. Carpet was installed

at the insistence of the client. (c) Shaping the window with additional area

above a light shelf helps reduce the visual contrast near the window. (d) Indirect

electric lighting is facilitated when higher ceilings are available; less glare

on computer screens results. (e) With so much exposed mass surface, sound absorption

is a must. This solution continues to expose the concrete ceiling and does

not cast shadows from incoming daylight.

FIG. 4 Zoning for a mixed-use building with perimeter and internal zones

as well as varying types of use. Scheduling and/or internal load differences

within any one of these zones could require division into additional zones.

(Amanda Clegg.)

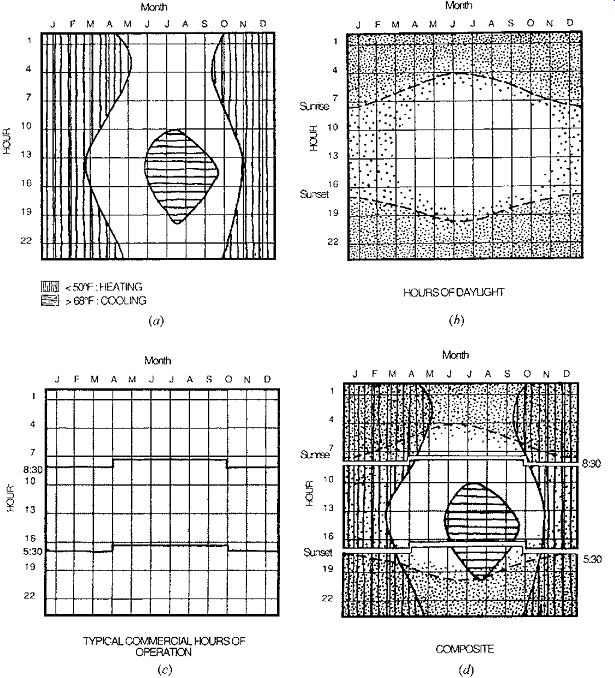

FIG. 5 A series of climate timetables was prepared while designing the office

building for the Emerald People's Utility District near Eugene, Oregon (FIG. 6). (a) Average outdoor temperatures show little daily variation in winter

but a large daily range in summer. (b) Daylight peaks around noon near the

summer solstice. (c) Work schedule shows the effect of summer's daylight saving

time. (d) A composite timetable indicates that daylight is available during

almost all working hours and that half of the hottest hours occur after the

building closes on summer afternoons-thanks to daylight saving time. Cool nighttime

temperatures make night ventilation of thermal mass an attractive cooling option

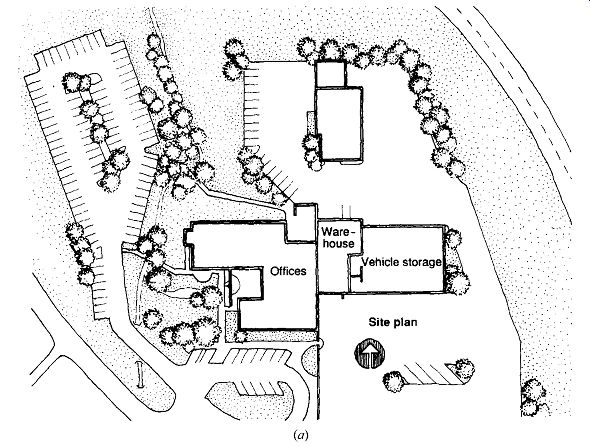

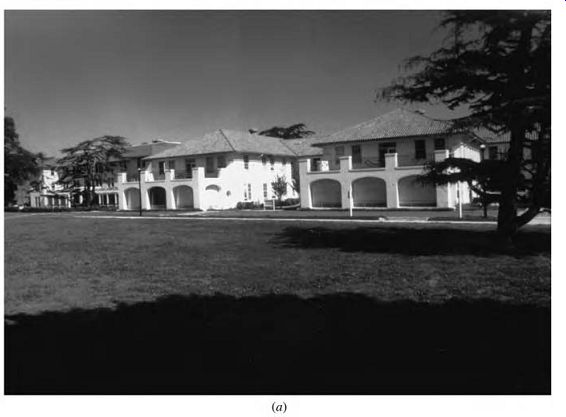

FIG. 6 The office building for the Emerald People's Utility District near

Eugene, Oregon, is elongated east-west for maximum window areas facing north-south.

(a) The site plan, (b) the ground-floor plan, (c) the second-floor plan, and

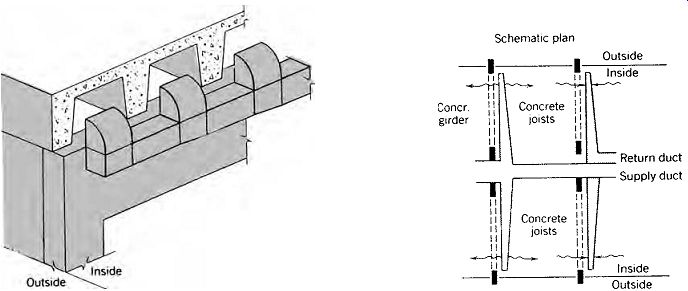

(d) a section through a two-story wing. The cutaway axonometric (e) of a typical

open-office two-story bay shows air flush through hollow cores of exposed precast

concrete slabs, windows and shading, and suspended sound-absorbing baffles.

The deciduous vines on trellises at the south façade change the building's

appearance by season; (f) at the summer solstice, the shading stripes will

soften as vines leaf out with age; at the fall equinox, the leaves will still

shade, whereas at the spring equinox (g) the branches will be bare to allow

sun to reach the windows; (h) at the winter solstice, most of the window is

exposed to the sun.

EXAMPLE 1, PART A

Daylighting design for this office building began with design diagrams (FIG. 3) and an assessment of daylighting potential (FIG. 5). After it was established that daylighting was avail able during almost all normal working hours, the building plan was organized so that almost all windows faced either south or north (FIG. 6) to avoid the problems of low-altitude sun (year-round glare and summer heat gain) that accompany east- and west-facing windows. Then the building section was designed so that the height of the windows (H) was related to the depth of the floor plan served by those windows (2.5H).

After a generous target DFav = 4.0% was chosen from Table 14.2, the next step was to size the windows and clerestories (as skylights), using the DF guidelines from Table 14.5. Applicable formulas for both sidelighting and for vertical monitor sky lights:

DFav = 0.2 window (or skylight) area floor area

Applied to an entire typical bay, DFav = 0.2 97 ft north+ 97 ft south+132 ft c 22 2 llerestory 1440 ft 2 = 0.45, or 4.5% slightly above the target DFav of 4.0%.

Note that in this example, DFmin from the side lighting occurs near the center of the building, at about the point (on the second floor) where the most light is available from the skylight. Therefore, relatively even daylighting distribution is expected on the upper floor. This is helped by the use of light shelves and the T-shaped windows shown in FIG. 6e.

The seasonal window size question (more needed in winter, less in summer) was answered in this example by the use of deciduous vines outside the south windows. In winter and cool spring, the vines are bare of leaves. Warm weather brings leafy shade lasting well into the warm fall (FIG. 6f ).

4. PASSIVE SOLAR HEATING GUIDELINES

When the building's function, climate, and site are favorable, winter solar gains can contribute greatly to a properly designed building. One of the first criteria to be considered is energy conservation; there is the envelope and infiltration. To determine the whole-building heat loss rate, list for each envelope component (roof, walls, floor, windows, etc.) the U-factor (Section 7 and Section E) and the total exposed area A; then simply multiply U × A. (For slab floors on grade, see Section 7 for deter mining perimeter heat losses.) For the special cases of walls below grade, such as berm walls, an approximation is needed. During the coldest weather, the temperature outside such walls will nearly always be higher than the outdoor air temperature, so any procedure based on Btu/DD will over-predict the heat loss through these walls.

As a result, designers often calculate the UA of below-grade walls by using their actual U-factor but using only half of their actual area; this lesser UA roughly compensates for the lesser ?t through these walls.

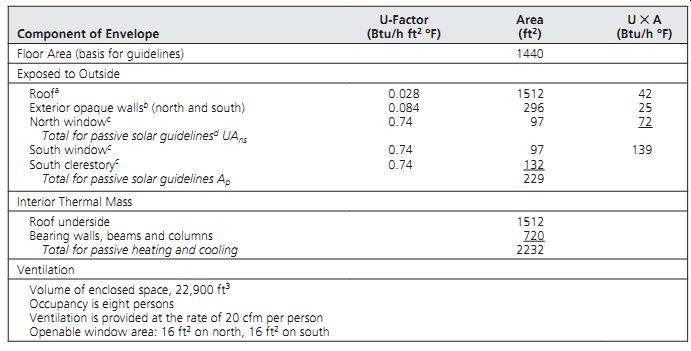

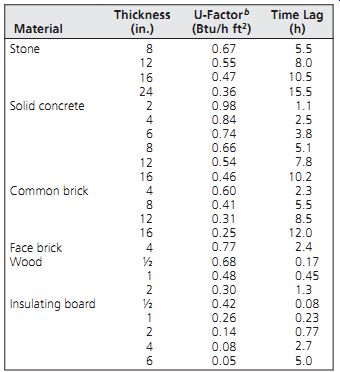

TABLE 2 Design Data for a Typical Second-Floor Bay of the Office Building

(FIG. 6e)

TABLE 3 Overall Heat Loss Criteria for Solar Guidelines

For infiltration, determine the number of air changes per hour (ACH) under winter design conditions and multiply this infiltration (or fresh air) rate little benefit in pouring solar heat into a leaky building. For solar designers, the motto should be "Insulate before you insolate."

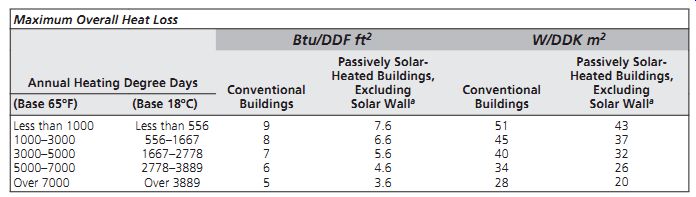

(a) Whole-Building Heat Loss Criteria

The recommended maximum rates of heat loss (in Btu per degree days [DD] per square foot) shown in TABLE 3 are the basis for development of the following passive solar heating guidelines. They are also useful as a quick check on overall envelope performance in residential or small commercial buildings. (Some states have adopted similar criteria as part of their building codes; be sure to check the applicable code before relying on these numbers for code compliance.) The heat loss rates are shown for two conditions:

1. Conventional (non-passively solar-heated)

small buildings. The overall rate of Btu/DD ft^2 is based on total heat loss, including all portions of by a constant that accounts for density and specific heat:

or ACH (volume, m ) 0.33 =

ACH (volume, ft ) 0.018 = 3 3

UA for infiltration

Add the envelope UA values to those for infiltration, multiply by 24 h/day to account for DD, and divide by the building's total heated floor area:

(+ )24h totalh envelope infiltration UA UA × heated floor area(ft )

=Btu/DDft^2 2

2. Passively solar-heated buildings. Here the overall rate of Btu/DD ft 2 excludes the solar collecting portion(s) of the envelope; otherwise, it is based on total heat loss from all other portion(s) of the envelope, and it includes infiltration. The equation used to determine the overall solar building rate is as follows:

( envelope, except south glass infiltr UA UA + a ation 2 ) 24h total heated floor area(ft )

×

= Btu/DD ft^2

One of the biggest unknowns in this procedure is the assumed rate of infiltration. A care fully designed and constructed small building can easily achieve a rate of 0.75 ACH; with increased attention to air barrier installation, caulking of all cracks, and so on, rates below 0.33 ACH have been demonstrated.

Passive solar heating and energy conservation have a complex relationship. Relative to conventional buildings, passively solar-heated buildings usually conserve purchased energy; yet, buildings that aim at very high percentages of solar heating can use more total heating energy than is used by buildings with smaller window areas. Designers interested primarily in saving purchased energy may aim at lower solar percentages and more insulation; designers interested in buildings that closely relate to climate and climatic changes may aim at higher solar percentages (and more daylighting), along with higher thermal masses and, probably, greater ranges of indoor temperature.

(b) Solar Savings Fraction (SSF)

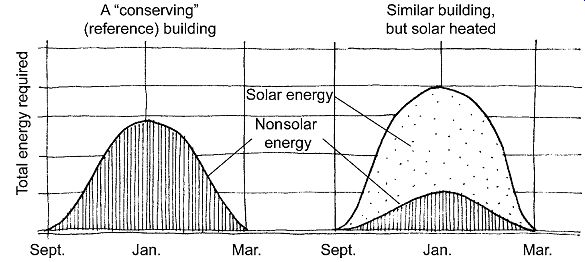

The term solar savings fraction is used to express a building's solar heating performance. The SSF is the extent to which a solar design reduces a building's auxiliary heat requirement relative to a "reference" building-one that has, instead of a solar wall, an energy-neutral wall that experiences neither solar gain nor heat loss; otherwise, the solar building and the reference building are identical. The SSF compares the auxiliary energy needed by the solar building to the auxiliary energy needed by the reference building, as illustrated in FIG. 7. Remember that the SSF is not the percentage of the solar building's heat supplied by the sun; typically, the sun provides a much higher fraction of a building's total space heat than suggested by the SSF. Rather, the SSF is more a measure of the solar building's conservation advantage.

FIG. 7 The solar savings fraction compares the auxiliary heat needed by

solar-heated buildings to that needed by a non-solar but energy-conserving

building that is otherwise similar (called the "reference" building).

For example, if the solar building needs 25 units of auxiliary (non-solar)

heat per year and the reference building needs 70 units, the difference is

70 - 25 = 45 units, or 64% of the reference 70 units. Therefore, SSF = 64%.

(Note, however, that the solar building is 75% solar heated.)

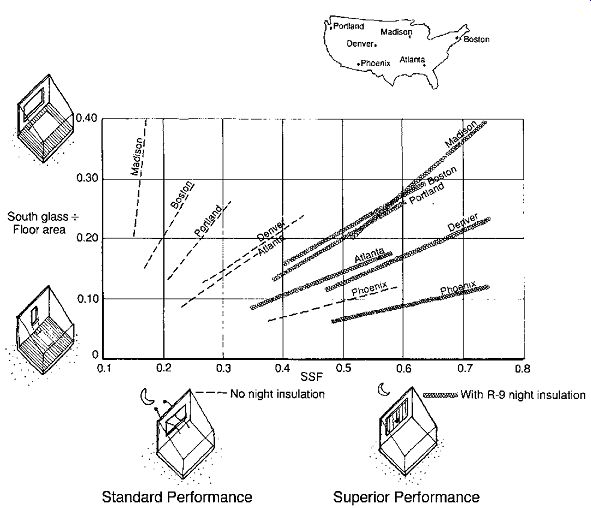

FIG. 8 Design guidelines for passive solar heating: ratio of south glass

to floor area. The information in Table F.1 is presented graphically for six

U.S. cities. "No night insulation" = standard performance; "With

R-9 night insulation" = superior performance.

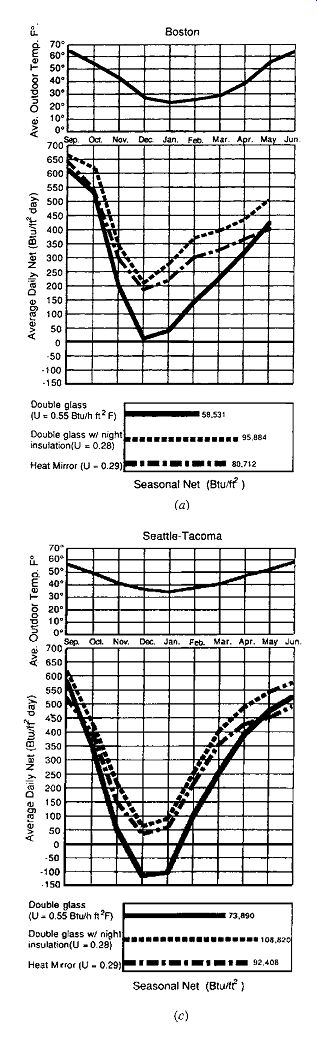

FIG. 9 Average daily net heating, per square foot of south window, for three

glazing assemblies in three climates. (a) In Boston, ordinary double glazing

is a slight energy plus even in December. (b) In Madison, ordinary double glazing

is a net loser for almost 2 months. (c) In Seattle, ordinary double glazing

is a net loser for more than 2 months.

A starting point for passive solar preliminary design is Table F.1. For your location, both a range of SSF values and a range of ratios of areas of south glass/floor area can be determined. The table shows the SSF ranges for both "standard performance" (simple double-glazed windows) and "superior performance" (for either night-insulated or super window) solar openings. This same information is shown graphically for six geographically diverse locations in FIG. 8. (Add your own location's information from Table F.1 to a copy of this graph.) The difference between standard and superior performance is explored in FIG. 9 for the September-June period in Boston, Madison, and Seattle. The solid line charts the lower performance of simple double glazing (listed as U = 0.55 Btu/h ft^2 ºF). The other two higher-performance alternatives (movable insulation and superwindows) show why the newer superwindows have made movable insulation nearly obsolete: without the need for any actions by the user, superwindows have a higher net heat gain than movable insulation in all three locations.

(c) Thermal Mass

Another early design question involves the amount of thermal mass (area) necessary to store the solar heat admitted each day. This reveals the simplistic, early-design nature of Table F.1, because it does not distinguish between the various approaches to passive solar heating (direct gain, indirect gain, and isolated gain, as discussed in Section 4). Table F.2 details the simple relationship between SSF and the area (also the weight) of water or masonry that should be provided in direct-gain designs.

The distribution of the thermal mass is also important, however. Indirect gain systems (Trombe wall and water wall systems) usually place the thermal mass in full sun for the entire day, often just inside the glazing. In direct-gain systems, this thermal mass should be within (or should enclose) the direct-gain heated space, and the exposed surface area of the mass should be at least three times the glazing area. Masonry surfaces are less thermally effective (on a daily basis) beyond a depth of about 4 to 6 in. (100 to 150 mm). Note that the thermal storage area is relatively unimportant at low SSF values, but as the SSF increases, so does the relative proportion of thermal mass area to solar glazing.

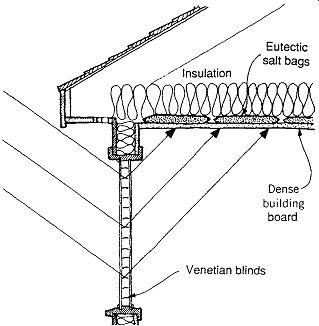

Phase-change materials are an alternative to simple thermally massive masonry surfaces. Flat bags of eutectic salts are shown in FIG. 10. Thin, horizontal tiles packed with these phase-change materials can store great quantities of heat with the phase change from solid to liquid. This change can be formulated to occur in the low 70s ºF (20s ºC) to pre vent overheating of the space. As flat tiles enclosing bags of salt, they can form the finished surface in any horizontal application-floors, ceilings, or counter- and tabletops, for example. Tubes and trays of salts can be arranged as desired. Because the function of these materials is to keep room temperatures steady, their performance in preventing overheating on a sunny winter day will also be appreciated on hot summer days, provided they are taken below the phase change or melting temperature at night. For U.S. locations with large daily temperature ranges in summer (see example mean daily range values in Section B), thermal storage surfaces for passive solar heating in winter are potentially useful for night ventilation cooling in summer.

As a preliminary guide, the phase-change tile surface area = one to three times the area of solar opening. Additional information on these materials can be found in Johnson (1981).

FIG. 10 Using bags of phase-change material (eutectic salt) for thermal

storage above a flat ceiling. Mirrored-surface venetian blinds reflect direct

sun to the ceiling, where it strikes a heavy (at least 90 lb/ft 2 [440 kg/m2])

board product with high conductivity. Metal ceilings or plaster are also suitable;

ordinary gypsum board is not sufficiently conductive. Bags of salt weighing

5 lb/ft 2 (25 kg/m2) are in contact with the ceiling material and must be installed

in a horizontal position. They are usually formulated to melt between 70 and

75ºF (21 and 24ºC). (Johnson, 1981.)

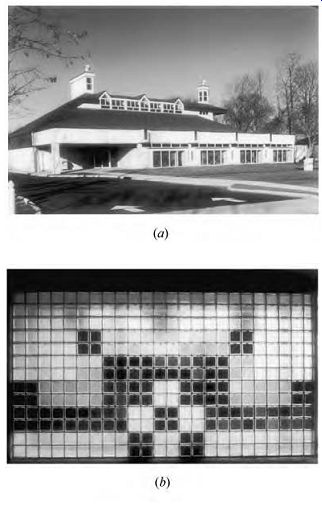

The Society for the Protection of New Hampshire Forests building utilizes phase-change storage above a metal ceiling (FIG. 11). It also uses water filled tubes as an interior partition, masonry interior walls, and a concrete floor slab to help store the winter daily solar gain.

The New Canaan Nature Center (FIG. 12) is another innovative New England example using many passive/low-energy components. In addition to eutectic salts used in the south-facing railing on the upper level, the 4000-ft 2 (372-m2) building utilizes extensive clear, double-glazed south glass, movable insulating shades, operable vents at the skylight for stack-effect ventilation, ceiling fans, a woodstove, solar collectors placed inside the skylight monitor (their water is used for warming planting beds), warm air heat recovery ducts, a well-insulated envelope, and even a rainwater collection system. The manually operated switches for ventilation, insulation, and shading represent an unusual degree of user-building interaction. There is also unusual attention to microclimates and the transition between inside and outside in this award winning building.

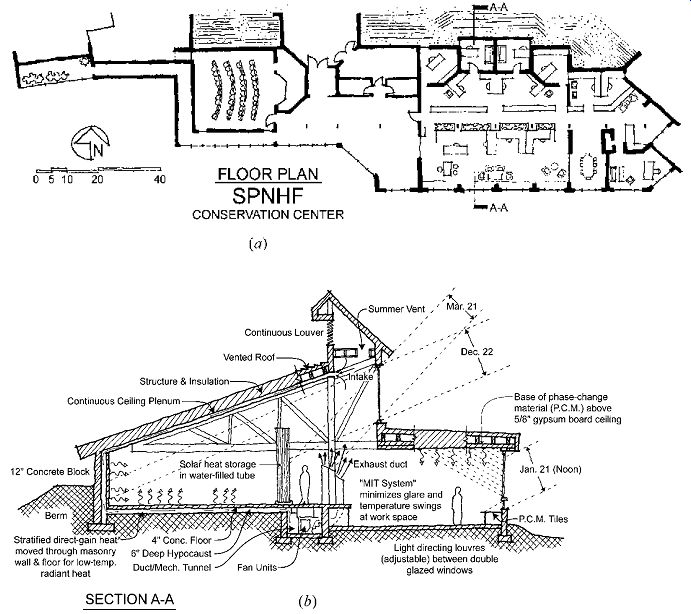

FIG. 11 The Conservation Center for the Society for the Protection of New

Hampshire Forests, Concord, Banwell White Arnold Hemberger & Partners,

Architects. (a) The plan is elongated on the east-west axis to maximize southern

exposure and facilitate daylighting. Direct gain serves the reception area,

workroom, and offices, and a sunspace double envelope combination warms the

lecture room. A wood-fired boiler provides backup heat. (b) Section with south

glazing and thermal storage materials: trans lucent water tubes, masonry walls,

and phase-change materials in ceiling and windowsill positions. The circulation

of hot air that collects at the clerestory is also shown. In summer, the hot

air is vented, and an awning shades the clerestory. Daylighting is dif fused

through translucent tubes to the spaces on the north side. (c) At the workroom,

mirror-finish venetian blinds reflect direct sun to the phase-change materials

in bags above the dark metal deck ceiling.

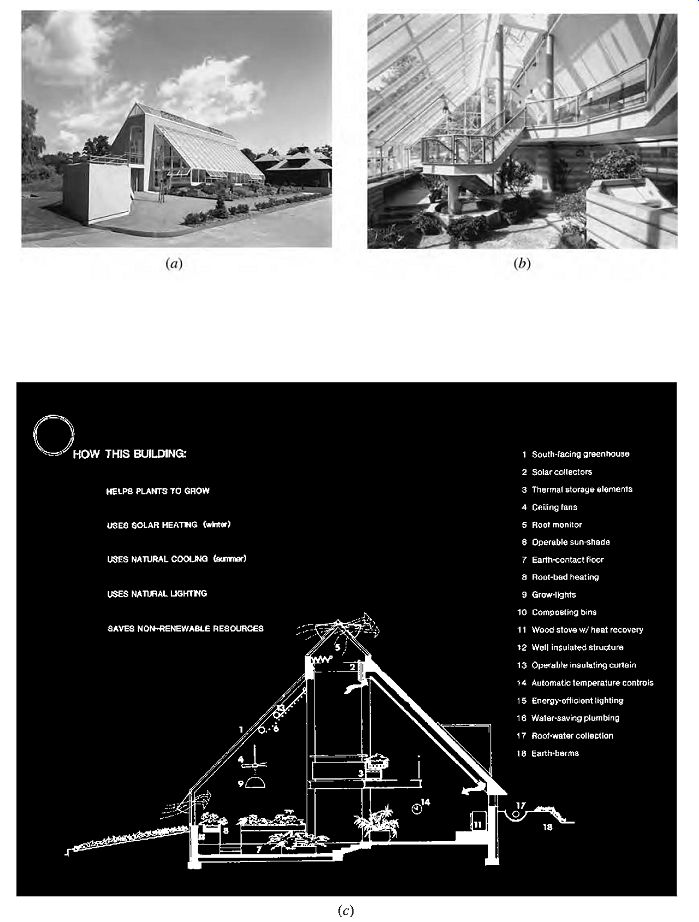

FIG. 12 The New Canaan ( Connecticut) Nature Center (a, b) illustrates many

passive and low-energy components. (c) Section illustrates the design features

that utilize renewable energy and enhance energy conservation. The thermal

storage elements are filled with eutectic salts that absorb excess solar heat

via phase change (from solid to liquid) by day, then again change phase (from

liquid to solid) at night to release their stored heat to the space.

Rock beds are sometimes used to store the excess heat that isolated-gain (sunspace) systems can generate. They are typically placed directly beneath a concrete floor slab. The disadvantage of this approach is that any below-grade location raises suspicions of condensation and/or ground water that may facilitate mold growth, yet cleaning of the rock bed is difficult.

The general guidelines cited by Mazria (1979) are as follows:

Rock bed volume, ft 3, per ft 2 of solar opening

Cold climates: ¾ to 1½

Temperate climates: 1½ to 3

Rock bed surface area in contact with floor above

Cold climates: 75% to 100% of floor area above

Temperate climates: 50% to 75% of floor area above

(d) Orientation

How important is it that the passive solar opening face due south? The general recommendation is that this orientation be within 30º of south. In The Passive Solar Design Handbook, the average penalties for off-south orientation are listed as follows.

5% decrease in SSF at 18º east or 30º west of true

south 10% decrease in SSF at 28º east or 40º west of true

south 20% decrease in SSF at 42º east or 54º west of true

south

See Section 10 for more detailed coverage of passive heating performance that distinguishes among direct, indirect, and isolated gain systems and includes the expected annual auxiliary energy needed by a passively solar-heated building. Select 20% of the floor area for south glass: SSF = 51. Thermal mass can be estimated from Table F.2; for SSF = 50, either 30 lb of water or 150 lb of masonry (per square foot of south glass) should be provided. Using brick as a thermally massive surface, 3.7 ft^2 of brick should be provided for each square foot of south glass

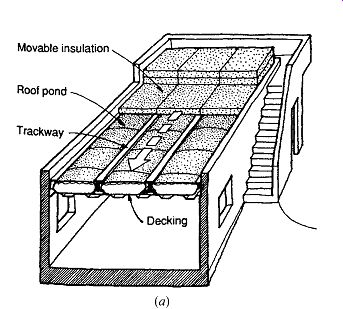

(e) Roof Ponds

This is yet another approach to passive solar heating, one not covered by the preceding guidelines. In general, roof ponds are used in warmer, less humid areas of the southern United States, where snow will not impede the movement of roof insulating panels, and the winter sun is higher in the sky than at northern latitudes. They are frequently sized for their summer cooling performance. In the U.S. southern latitudes, a pond sized for cooling will usually be adequate to absorb the needed winter sun.

As a check for the pond's heating capacity, Mazria (1979) recommends the following guidelines:

Roof pond area = 85% to 100% of floor area for winter average outdoor temperatures of 25ºF to 35ºF (-4ºC to +2ºC)

Roof pond area = 60% to 90% of floor area for winter average outdoor temperatures of 35ºF to 45ºF (2ºC to 7ºC)

These guidelines are for roof ponds that have two layers of enclosing material between the water and the sky (i.e., are "double-glazed") and movable night insulation.

(f) Active Solar Heating

In contrast to passive systems, which incorporate sun collection and storage as part of a building's walls, floors, or ceilings, active solar heating uses mechanical equipment to collect and store solar energy. The most common early design questions for such systems involve the area of the solar collectors, their tilt and azimuth, and the size of the thermal storage. (Domestic hot water [DHW] solar heating information is given in Section 21.) For active solar space-heating systems, the rules of thumb are reasonably complex. Building heating needs vary by function and climate. The percentage of space heating that can economically be provided with active solar systems is another big variable. Nevertheless, a rough guide is desirable as a design starting point:

Collector/floor area ratio = the smaller of the two window/floor area ratios listed in Table F.1 This should provide a portion of the annual heating load somewhere in the range of high-performance SSF from Table F.1. Larger arrays of collectors can be designed, of course, but they rarely will be economically attractive.

For collector tilt and azimuth optima:

Optimum tilt = latitude plus 10º to 15º; optimum azimuth is from due south to 15º W of south where the tilt angle is measured up from horizontal.

The orientation somewhat west of south is attractive in climates with frequent morning fog. Also, because air temperatures are higher in the after noon, collectors lose less heat then and therefore operate more efficiently.

The design guidelines for storage size are as follows:

2 gal of water storage per ft^2 (81 L per m^2) of collector or 0.5 to 0.75 ft^3 of rock bed per ft^2 (0.15 to 0.23 m^3 per m^2) of collector

The large arrays of collectors necessary for space heating must be served by pipes or ducts. Whereas pipe size rarely influences design, air ducts for air type collectors can consume fairly large amounts of space. The following flow rates are typical for active solar collectors:

water flow rate of 0.25 to 0.5 gpm per ft^2 (0.17 to 0.34 L/s per m^2) of collector or airflow rate of 2 cfm per ft^2 (10 L/s per m^2) of collector

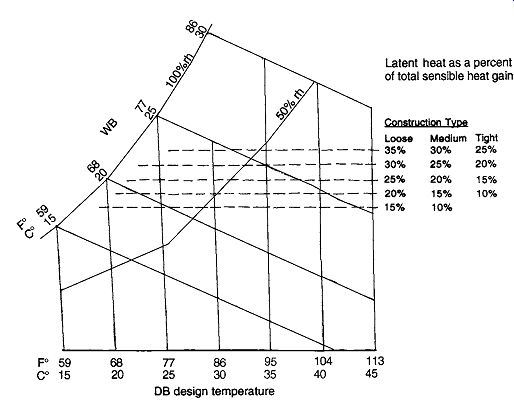

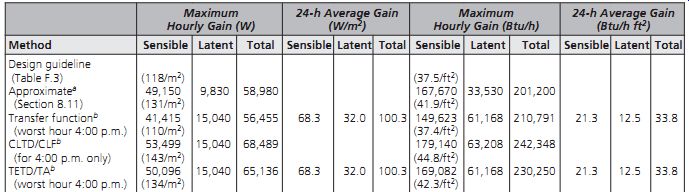

5. SUMMER HEAT GAIN GUIDELINES

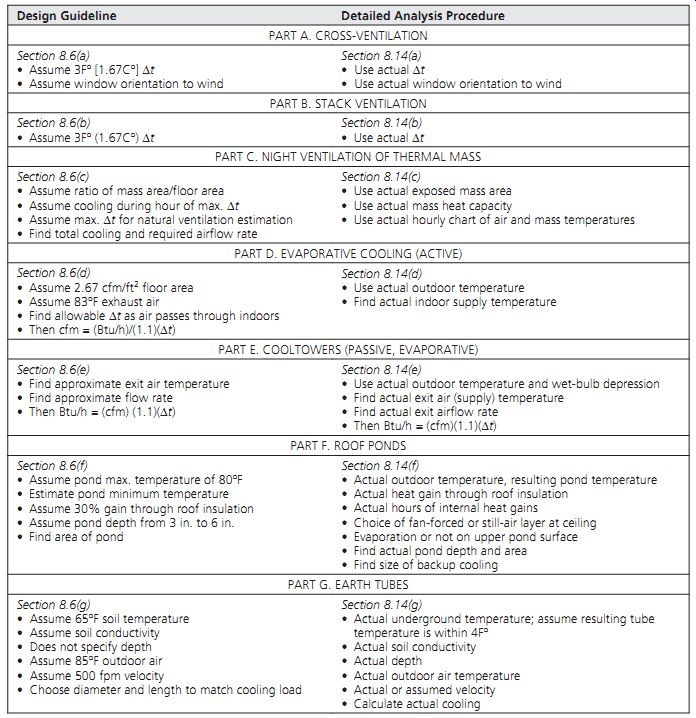

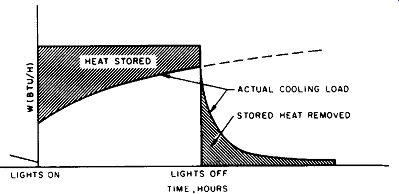

Design guidelines for cooling are complicated by the fact that cooling loads frequently are more closely related to individual building characteristics than to climate; sunshading and internal heat gains are particularly influential on cooling loads. Because passive cooling guidelines (Section 6) are expressed in heat to be removed per unit of floor area, it is first necessary to estimate the extent of the heat gain problem. Later, more detailed passive cooling procedures are shown. A comparison of the guidelines with these more detailed procedures is given in TABLE 4.

TABLE 4 Comparing Passive Cooling Design Guidelines with Detailed Calculation

Procedures

Detailed calculations for heat gain are presented in Sections 11 and 13. For now, Table F.3 gives a quick approximation. Many buildings (restaurants, factories, stores selling heating appliances, etc.) have special heat sources within. For these unusually heat-loaded situations, Table F.3 will be inadequate. As a starting point for preliminary passive-cooling sizing for typical buildings, however, it should be helpful. Climate information is available from a variety of sources, including the ASHRAE Handbook-Fundamentals (extensively updated climate data produced by a recently completed research project was included in electronic format in the 2005 edition) and ASHRAE Standard 90.1-2007. The data in these two sources are derived from different approaches. Updated (2005) climate information for various U.S., Canadian, and Mexican locations is included in Appendices B.1-B.4. For some of the example problems that follow, climate data referenced to Section B.5 are indicated (these are legacy data for locations not available in the 2005 data set). Notations herein to Tables B.1-B.5 refer to Section B.

Note that "open" buildings, such as those that are naturally ventilated, do not have heat gains from infiltration, because they assumedly maintain internal temperatures that are slightly above exterior temperatures (and air leakage would cool). However, these buildings do experience heat gains through windows, walls, and roofs due to solar impacts on these surfaces. For "closed" buildings, heat gain from infiltration or ventilation must be added, because these structures maintain internal temperatures lower than outside temperatures.

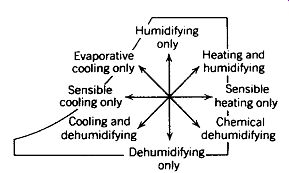

6. PASSIVE COOLING GUIDELINES

The design guidelines for passive cooling are much newer and less tested than those for passive heating. It is important that the designer first check the match between the climate and the cooling strategy, as was done in Section 4, before applying these guidelines to a building design.

(a) Cross-Ventilation

One of the oldest methods known, this strategy provides plentiful fresh air but maintains a building at temperatures slightly above those out doors. The cross-ventilation inlet (window) areas, expressed as percentage of total floor area, are related to wind speed and resulting heat removal in FIG. 13. Remember that an equal (or greater) area of outlet openings must also be provided. Furthermore, any internal obstructions (such as partitions) must have a total area of openings at least equal to this required inlet area. The assumptions about wind direction and indoor-outdoor temperature differences that were used to produce these guidelines are explained in the figure. For more detailed wind speed and direction information, see Section 14.

FIG. 13 Cross-ventilation design guidelines for heat removed per unit floor area and relationship of inlet openings and wind speed. The total inlet opening area is expressed as a percentage of the total floor area served by cross-ventilation. Note: Outlet areas must also be at least equal to inlet areas. This graph is based on an internal temperature 3Fº (1.7Cº) above the exterior temperature and assumes that the wind is not quite perpendicular to the window openings, for a wind effectiveness factor of 0.4 (see Section 14).

The ?t of 3Fº used in FIG. 13 is deliberately kept small to encourage open strategies in milder summer climates. Thus, an interior temperature of 83ºF, which is comfortable with sufficient air motion, lower RH, and comfortable surface temperatures, would be obtainable with an outside temperature of 80ºF. However, a greater ?t is often appropriate-for example, for spring or fall cooling of office buildings, or for summer cooling of factories or kitchens where internal temperatures may remain in the low 90s. In such cases, find the percentage of inlet area required; then multiply by the ratio 3Fº actual ?t to obtain required cross-ventilation areas for any specific temperature difference (see EXAMPLE 1, Part E).

See TABLE 4 for a comparison of these design guidelines with the more detailed calculations of Section 14 for both cross- and stack ventilation.

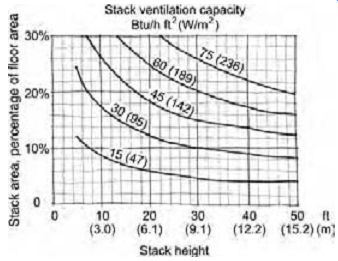

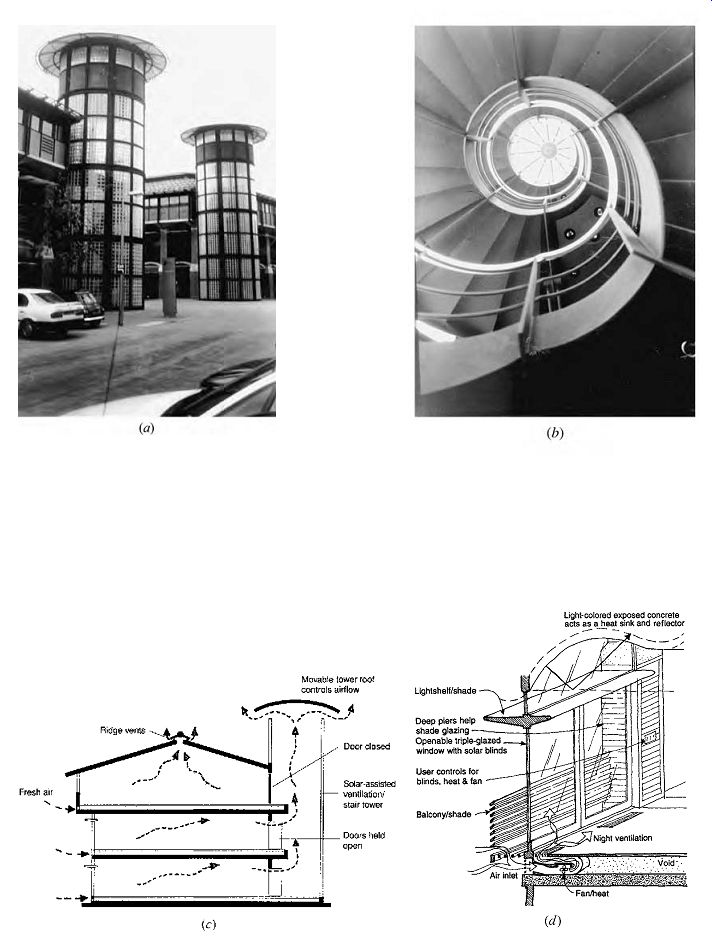

(b) Stack Ventilation

This is another historically useful strategy, which, like cross-ventilation, provides plentiful fresh air but maintains a building at temperatures slightly above outdoor temperatures. The stack inlet areas, expressed as percentage of total floor area, are related to stack height and the resulting heat removal in FIG. 14. Remember that an equal (or greater) area of stack outlet openings, as well as at least an equal cross-sectional area through the vertical stack, is also required. Again, consider internal obstructions: partitions must have a total of openings at least equal to this required inlet area. The assumptions about indoor-outdoor temperature differences that were used to produce this guideline are explained in the figure.

FIG. 14 Stack ventilation design guidelines for heat removed per unit floor

area and the relationship of stack height and inlet openings. The area of stack

inlet/throat/outlet is expressed as a percentage of the total floor area served

by stack ventilation.

Note: Outlet areas and the stack throat area must also be at least equal to inlet areas. This graph is based on an internal temperature of 83ºF and an exterior temperature 80ºF, for a 3Fº differential (28.3ºC internal, 26.7ºC external, for a 1.6Cº differential).

FIG. 15 The Thoreau Center for Sustainability occupies renovated hospital

buildings (a) in San Francisco's Presidio National Park. (b) Relatively narrow

floor plans facilitate daylighting and natural ventilation. (c) Interior at

the center corridor. (d) Section illustrates day lighting and cross-ventilation.

Very small stack openings relative to the floor area served limit the stack

effect to a minor role.

Adjustment of the ?t for this guideline is similar to the procedure for cross-ventilation. It requires multiplication of the required percentage of stack area by the ratio

3ºF actual ?t

to obtain the required stack ventilation areas for any other specific temperature difference.

Until the advent of air conditioning, these methods of cross- and stack ventilation were used in virtually all commercial buildings. In some climates with mild summers, newer buildings are turning to these older methods (refer to FIG. 46). FIG. 15 shows the Thoreau Center for Sustainability in San Francisco's Presidio National Park. An older military hospital was renovated for offices for nonprofit environmental organizations.

To maximize daylighting and passive cooling, the original operable windows are utilized. Interior partitions are kept low enough to facilitate cross ventilation, with integral indirect electric lighting using the high white ceiling. The section indicates that both cross-ventilation and stack effect are anticipated. However, the stack openings to the attic and, subsequently, through the roof are less than 1% of the total floor area. The most likely benefit of the stack effect here is to keep the attic at cooler summer temperatures (with air drawn in at the eave vents, not flowing outward as shown).

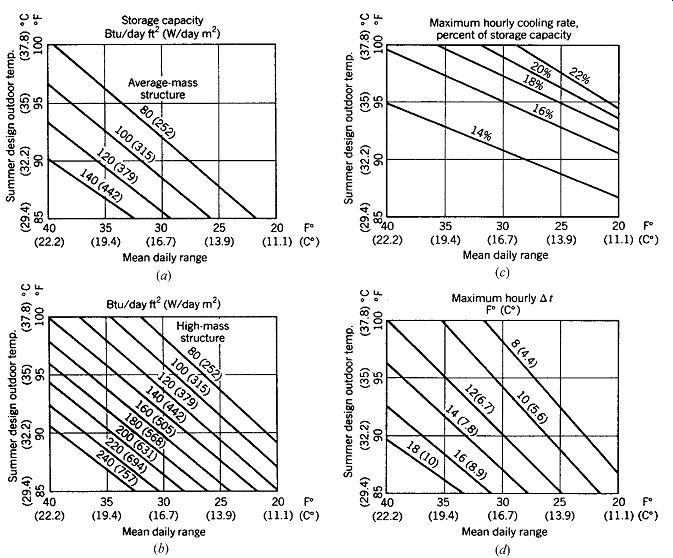

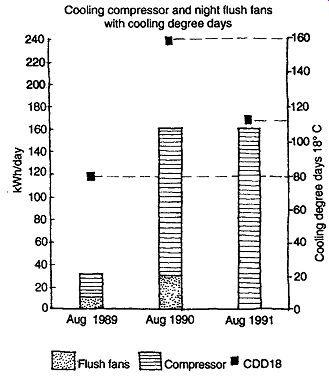

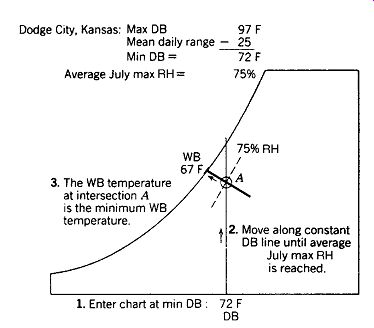

(c) Night Ventilation of Thermal Mass

This strategy maintains a building at temperatures lower than those outside by day and flushes the building with plentiful fresh air by night. The sizing procedure is shown in FIG. 16, where climate data are related to two representative types of thermally massive building. For each type, the graphs show the daily Btu per square foot of floor area that can be stored. The "average" mass building is represented by a building with an exposed concrete floor 4 in. (100 mm) thick (or an exposed ceiling of equivalent construction). There is one unit area of exposed mass for each unit floor area.

The "high" mass building is similar to the typical passively solar-heated, direct-gain building or to a multistory building with an exposed concrete structure, in which both sides of the floor slab are available for thermal storage, or an equivalent exposed mass area in walls, and so on. For this building, there are two units of exposed mass for each unit of floor area.

The climate data needed for FIG. 16 (maximum summer design DB temperature and mean daily range) are given in Appendices B.1 through B.5. These data also allow calculation of the mini mum summer design DB temperature; that is, maximum design DB temperature minus mean daily range. This minimum temperature is of interest here because the thermal mass of the building will be lowered toward (but not quite to) it during night ventilation. For high daily range climates, the lowest temperature obtained by the thermal mass will be about one-fourth of the mean daily range above the minimum air temperature (for lower daily range climates-30Fº or less-one-fifth of the mean daily range).

FIG. 16 Night ventilation of thermal mass design guidelines. Parts (a) and

(b) show Btu/day stored and removed per ft 2 of floor area (W/day per m2 of

floor area). Enter these graphs with your location's summer design outdoor

DB temperature and the MDR (mean daily range). (a) "Average mass" structure

has one unit area of mass surface exposed per unit area of floor area, where

the mass is a 4-in. (100-mm) ordinary-density concrete slab. (b) "High-mass

structure" has two units areas of mass surface exposed per unit area of

floor area, where the mass is a 3-in. (75-mm) ordinary-density concrete slab

(or both sides of a 6-in. [150-mm] concrete wall or slab exposed). Both average-

and high-mass structures go into "open" mode when the outdoor temperature

drops below 80ºF (26.7ºC); therefore, the highest mass temperature is assumed

to be 80ºF (26.7ºC). Part (c) shows the approximate percentage of the daily

total heat stored that is removed during the nighttime hour of maximum cooling.

Part (d) shows the ?t between the outside air and inside mass that exists during

that hour of maximum cooling. Required ventilation rates can then be determined

from (c) and (d).

Before this information can be fully utilized, the number of hours for which the building must be "closed" must be determined. During these hours, heat will be stored in the structure, up to the maxi mum storage indicated in FIG. 16. Typically, these buildings will go into the thermally closed mode (allowing minimum ventilation only) at about 6:00 A.M. for a day with 100ºF maximum or about 8:00 A.M. for a day with 85ºF maximum, remaining in the closed mode until the outdoor tempera ture drops below 80ºF. (To approximate this hour, assume that the midpoint outdoor temperature, between daily high and daily low, occurs at around 10:00 P.M.) Thus, the typical office building remains thermally closed during the 8 or 9 hours of summer occupancy. All the heat generated during the closed mode-8 to 9 daytime hours-must be stored in the structure:

Heat to be stored/ft^2 floor area = hours occupied in closed mode × heat gain, Btu/h ft^2 floor

Having found the amount of heat that can be stored each day, the designer must then solve the problem of removing the heat by night. Either natural or forced ventilation can be used, but in many locations wind speed is very low on summer nights.

The ventilation rate is determined by the "best hour" of cooling during the night, that is, the hour during which the temperature difference, ?t, between inside mass and outside air is greatest, and hence the most heat is removed. This "best hour" information can be found in FIG. 16c and FIG. 16d. Then the cross- or stack ventilation rules of thumb can be used to size the openings.

See TABLE 4 for a comparison of these guide lines and more detailed calculation procedures for night ventilation of thermal mass.

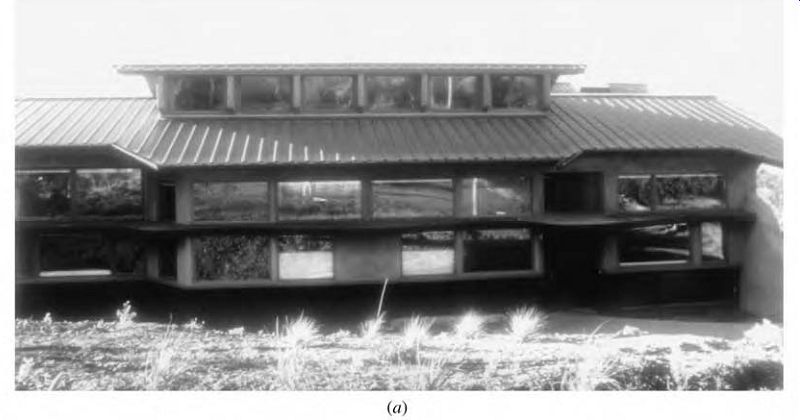

The administration building for the Fetzer Winery sits among grapevines in northern California's Mendocino Valley (FIG. 17). The summer design condition is approximately 96/68, with MDR 30Fº (35.6/20, MDR 16.7Cº). As an average-mass structure, this building could store and remove about 60 Btu/ft 2 day (190 W/m2 day); as a high-mass structure, it could store and remove about 100 Btu/ft^2 day (315 W/m^2 day).

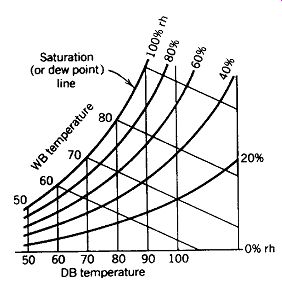

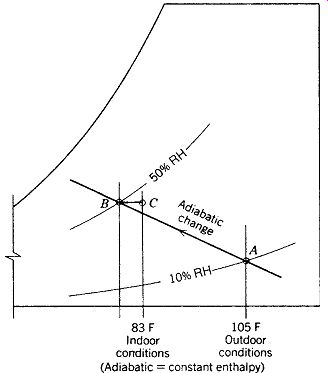

(d) Evaporative Cooling

The most common evaporative cooler is not strictly passive cooling, as it depends on a fan to force large quantities of outdoor air through a wet filter, thereby lowering the air's temperature and raising its RH before delivering the air to the space to be cooled. In hot and arid climates, the energy used by the fan in evaporative systems is less than the energy needed to achieve conventional cooling based on the compressive refrigeration cycle. Although this process requires quantities of water, it does not use refrigerants that may pose a threat to the Earth's environment.

Before using these guidelines, be sure to check the cooling strategy chart in Section 4 to determine whether evaporative cooling is appropriate for your climate. It is unlikely that evaporative cooling will be helpful in the humid southeastern United States.

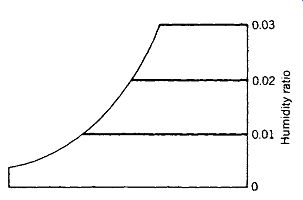

The rates of evaporative cooling presented in FIG. 18 are based upon a rather high airflow of 2.67 cfm per ft^2 of floor area. (In conventional cooling, an airflow rate closer to 1 cfm per ft 2 is more common.) With this amount of air motion, a highest indoor air temperature of 83ºF is assumed; so the evaporatively cooled air, after absorbing heat from the space, exits at 83ºF. (Note: this may still be well below the outdoor temperature: might it do some useful cooling?) To use FIG. 18, first find in Table B.1 the summer design DB and mean coincident WB temperatures for your location.

Enter the graph at these two data points, and at their intersection find the approximate amount of heat in Btu/h ft^2 that evaporative cooling can remove. As WB temperatures surpass 68ºF (rep resented by dotted lines in the graph), indoor conditions become increasingly humid, producing almost certain discomfort with an indoor WB temperature of 75ºF.

A more thorough method for evaluating evaporative cooling potential is presented in Section 14, where various airflow rates and temperatures of supply air and exit air can be examined.

See TABLE 4 for a comparison of this guideline and the more thorough method.

(e) Cool towers

FIG. 17 The Fetzer Winery administration building (a) in its rural Mendocino County, California, setting. The south-facing clerestory and a deciduous vine and trellis are the more visible parts of the daylighting, passive solar heating, and passive cooling strategies. (b)

Plan shows the relation of a workstation to north and south daylight. (c) Section with ducts for the night air flush as well as for conventional heating and cooling. (d) North-side dormers are for night air intake and exhaust.

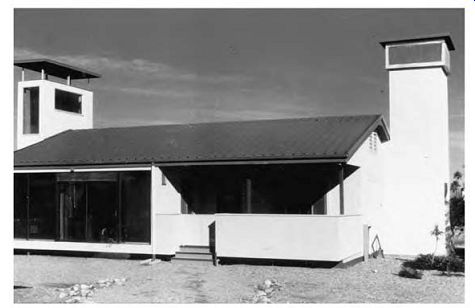

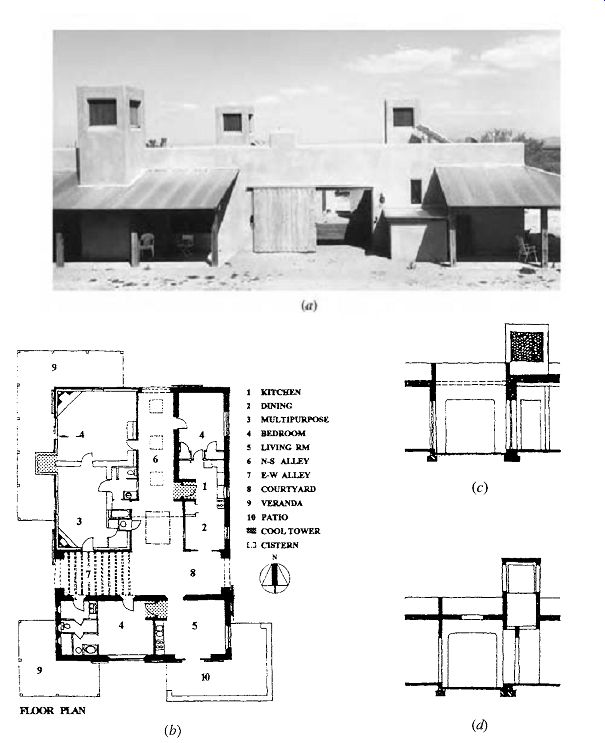

A more passive approach to evaporative cooling appears as a tower on the residence in FIG. 19.

This University of Arizona experimental building near the Tucson Airport has a cooltower with wetted pads on all four faces at the top. Hot, dry air is cooled as it passes through the pads, dropping to the base of the tower and then into the house. Analysis by Givoni (1994) indicates that such a tower's delivery of wetter, cooler air is almost independent of wind speed and also is not dependent on the second tower at the opposite end of this building, a solar chimney through which air from the house is discharged.

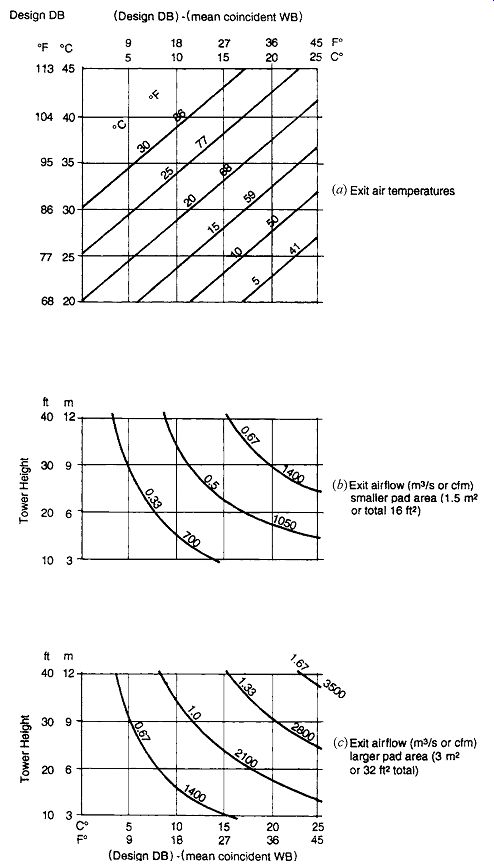

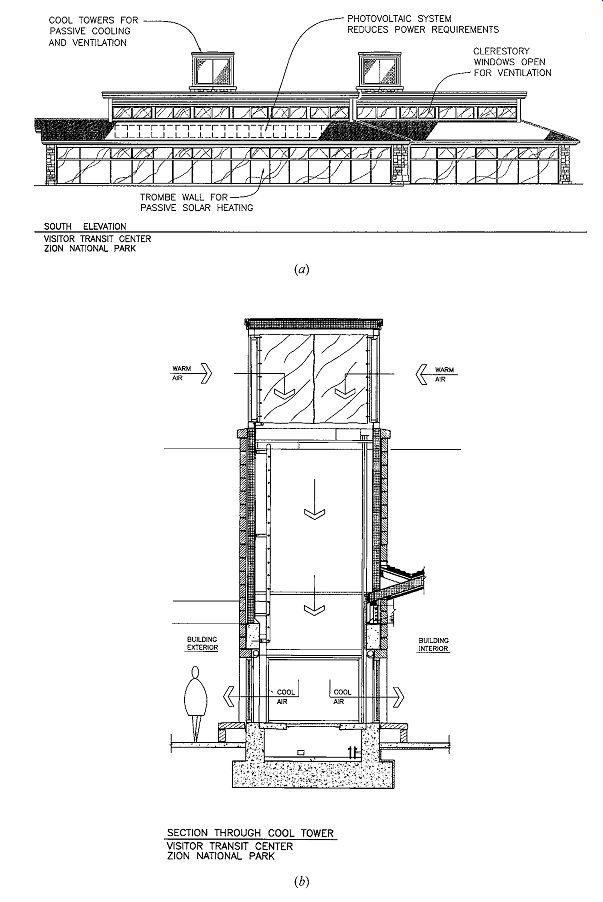

Temperature and flow rate of air delivered to a building by a passive cooling tower can be approximated from FIG. 20, but such data are based on very little experimental work. A well-regarded building using this principle, as well as Trombe wall passive solar heating, is the Zion National Park Visitor Center (FIG. 21).

FIG. 18 Fan-forced evaporative cooling design guideline for Btu/h removed per ft^2 of floor area (W per m^2). A forced airflow rate of 2.67 cfm per ft^2 of floor area (13.56 L/s per m^2 of floor area) is assumed, as is an exiting (exhaust) air temperature of 83ºF (28.3ºC). The dashed lines toward the left side of the graph represent increasingly humid indoor air, which may cause discomfort.

FIG. 19 An experimental residence in Tucson, Arizona, is passively and evaporatively

cooled by a cooltower (at the right in the photograph). Hot, dry air passes

through the wetted pads at the tower's top and undergoes a drop in DB temperature

that causes it to fall, entering the residence at the bottom of the tower.

The tower at the left is a solar chimney to help speed the flow of warmed exhaust

air.

FIG. 20 Design guidelines for cooltowers. (a) The temperature of the air

as it leaves the cooltower (enters the building) depends on the outdoor DB

temperature, as well as the difference between the DB and WB temperatures.

The flow rate of the exiting air depends on the tower height, as well as the

difference between the DB and WB temperatures. (b) Flow rate for a smaller

area of wetted pads, 1.5 m^2 (16 ft^2). (c) Flow rate for a larger area of

wetted pads, 3 m^2 (32 ft^2).

FIG. 21 The Visitor Center at Zion National Park ( Utah) features both cooling

by cooltowers and solar heating (a) by Trombe walls and a clerestory. Because

many of the building's functions can be performed outside, each cooltower (b)

has both an indoor and an outdoor outlet, either of which can be closed off

when not needed. Air enters through wet media pads at the top of the tower

(c). An X-baffle then diverts the air downward. The building also features

photovoltaics (PV) and water harvesting.

(f) Roof Ponds

This promising strategy has rarely been implemented, possibly due to water phobia among architects and clients alike. Yet it demonstrates the most stable interior temperatures of any of these techniques, needing electricity only to open and close the sliding insulation panels on the roof. Roof ponds sized for cooling will likely be nearly equal in area to the floors of the buildings they cool. Average pond depth is between 3 and 6 in. (75 and 150 mm). A more detailed and precise procedure for determining pond area is presented in Section 14, but here is the quick approximation:

• Pond maximum* temperature: 80ºF (*this temperature is based upon the assumption that any higher pond temperature would fail to produce cooling for the building interior)

• Pond minimum temperature = minimum night time DB (= max. daytime temp - mean daily range)

• Pond ?t = pond maximum of 80ºF - pond minimum temperature

• Pond's allowable daily heat stored (from building), Btu/day ft^2 = (0.7) (pond ?t) (pond depth, feet*) (62.5 lb/ft^3 water)(1.0 Btu/lb ºF) (*depth not to exceed 0.75 ft) (This equation assumes 70% of the pond's daily heat gain from the building below and 30% through the insulated panels above the pond)

• Required size of pond (ft^2 pond per ft^2 floor area) building total heat gain per day = (Btu/day ft floor area) pond allowable hea 2 t t stored per day (Btu/day ft 2 floor area)

See TABLE 4 for a comparison of the design guideline and the more detailed calculations for roof ponds.

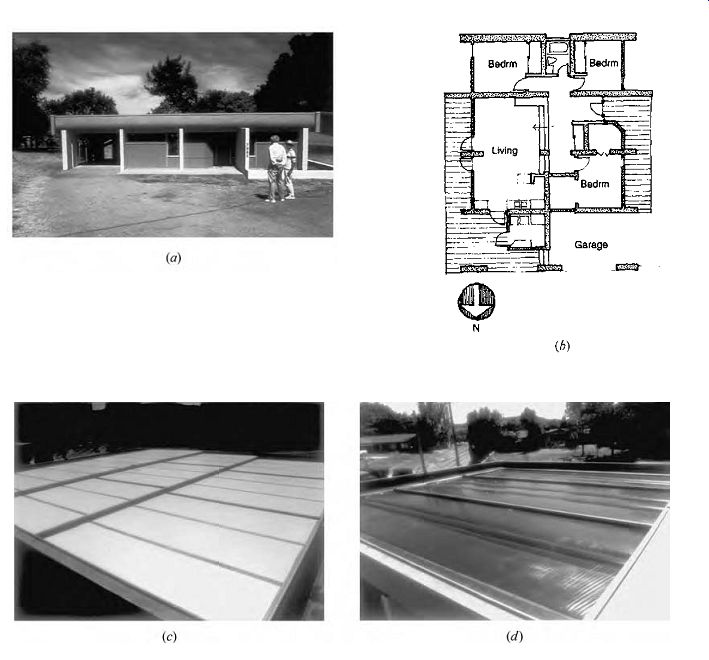

The residence in FIG. 22 is one of the first roof-pond structures. Located in Atascadero, California, at about 35º N latitude, it has a remarkable history of thermal stability, providing both passive solar heating in winter and passive cooling in sum mer. Roof-pond inventor Harold Hay donated the building to California State Polytechnic at San Luis Obispo in the late 1990s. To emphasize the pond as the solar heating device, this house has almost no south-facing glass (most windows face east toward a small lake). The sliding insulation panels are stacked when open (by day in winter, by night in summer) over the carport on the north end of the building.

FIG. 22 One of the first roof pond buildings, this Atascadero, California,

residence is now a research building for California State Polytechnic University

at San Luis Obispo. (a) The exterior from the west. (b) Plan. South exposure

is minimal; the roof is the surface of interest for heating and cooling. (c)

The roof insulating panels in the closed position (as on a summer day). (d)

The roof insulating panels in the open position (as on a summer night). Water

is contained within plastic bags laid directly on the metal deck ceiling. (e)

Sections showing summer day roof pond insulation and night exposure. (f) Sections

showing winter day roof pond exposure and night insulation. (g) Year-long record

of the indoor temperature range compared to the outdoor range. (Drawings based

in part on Sandia National Laboratory, Passive Solar Buildings: A Compilation

of Data and Results, SAND 77-1204, 1977.)

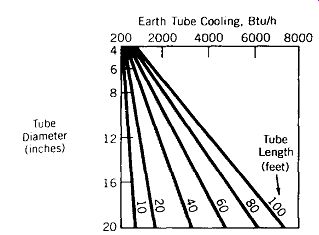

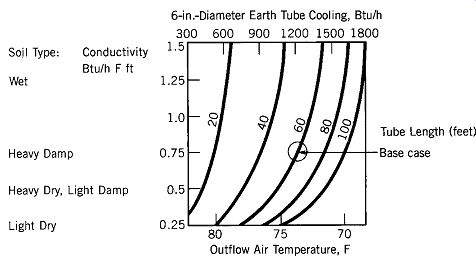

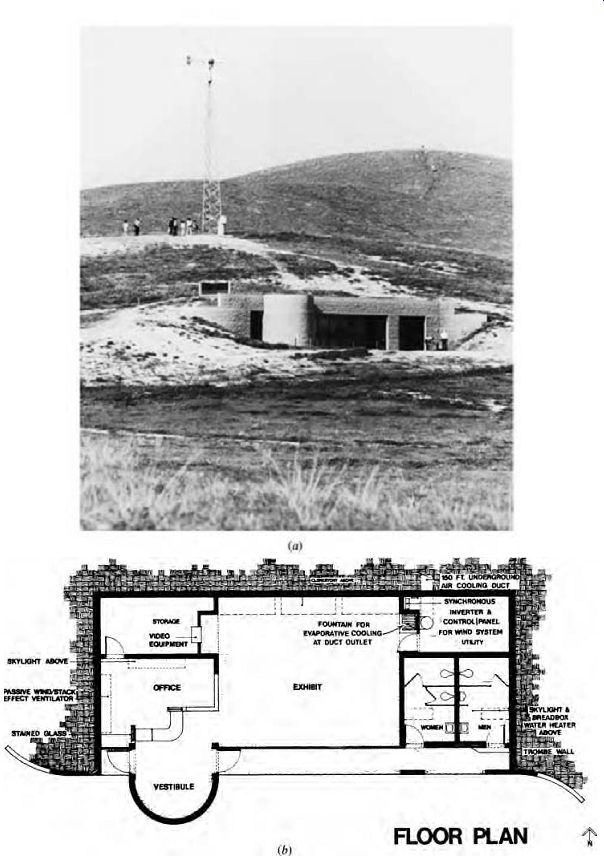

(g) Earth Tubes

These provide a way to cool outdoor air before it enters a building. A fan is used to force sufficient quantities of air through these long tubes. Because earth tubes need to be well underground as well as rather long in order to cool outdoor air, it is rarely economical to install enough earth tubes to completely meet a building's need for cooling. If long trenches are needed for another purpose (under ground water lines, for example), an earth tube is more feasible. Where earth tubes are considered, the component of building heat gain that is represented by cooling fresh air can sometimes be mitigated using this strategy.

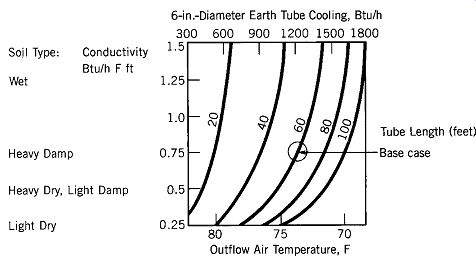

The estimate of cooling for the earth tubes described in FIG. 23 is based on Abrams (1986), who assumed a soil conductivity equal to that of heavy, damp earth. One of the most influential variables in earth tube performance is soil conductivity, so FIG. 24 compares the cooling performance of 6-in. (152-mm)-diameter earth tubes when soil conductivity changes. Note that this design guideline presents Btu/h cooling of the outdoor air in the tube rather than total building Btu/h ft 2 (for a typical ft 2 of building floor area). Therefore, two adjustments must be made: first, find the Btu/h cooling load of the outdoor air alone; second, adjust for the difference between hotter air outdoors and cooler air desired within the building.

See Section 14(g) for a more detailed calculation procedure for earth tubes in which tube depth, soil temperature, and soil conductivity are variable. See TABLE 4 for a comparison of the design guideline with the more detailed calculation procedure.

FIG. 23 Cooling of intake air provided by an earth tube in Btu/h. This tube

is set in heavy, damp soil (k = 0.75 Btu/h ºF ft) whose temperature around

the tube is 65ºF. The outdoor air entering the tube is at 85ºF and is moved

at a flow velocity of 500 fpm.

TABLE 4 compares the design guidelines for passive cooling with the more detailed calculation procedures that are given in Section 7 (basement walls and floor) and later in Section 14.

FIG. 24 Six-inch-diameter earth tube cooling capacities as soil conductivity

varies. The base case is a 6-in.-diameter earth tube 60 ft long, shown in FIG. 23 to deliver 1200 Btu/h of cooling at soil conductivity of 0.75, with other

conditions as specified in FIG. 23.

7. REINTEGRATING DAYLIGHTING, PASSIVE SOLAR HEATING, AND COOLING

At this point, preliminary investigations of envelope component U-factors and fenestration/floor area ratios have proceeded through various codes, standards, and design guidelines. It is quite likely that conflicting advice has resulted. Depending on the location, building type, and client's objectives, a very different mix of glass, insulation, and thermal mass could result from prescriptive conservation approaches compared to a passive solar heating focus or any of several approaches to passive cooling.

When prescriptive standards (such as those presented in Table G.1) appear to preclude either passive solar heating or passive cooling strategies in a building, the designer should remember that there are procedures for either window area trade-offs (in which more insulation in walls or roofs might allow more glass area) or methods to compare whole building annual energy consumption that can demonstrate the superiority of using well-designed passive strategies over a simple conventional pre scribed approach.

8. CALCULATING WORST HOURLY HEAT LOSS

Section 7 showed how heat is exchanged by transfer through a building envelope (q) and through ventilation of a building (qv). By combining these rates of heat exchange, we can obtain a building's total hourly heat loss in winter. (To calculate the total hourly heat gain in summer, other gains must be added; this more complicated procedure is discussed in Sections 11 and 13.) The total hourly heat loss of a building can be calculated under several different assumptions reflecting different purposes.

(a) Maximum Hourly Loss: Sizing Conventional Heating Equipment

The most typical use of q + qv is to determine the maximum amount of heat per hour that heating equipment must provide. Two important assumptions are usually made:

1. No internal heat gains (lights, people, etc.) and no solar gains are present in the building.

2. The design lowest outdoor temperature is occurring.

These are conservative assumptions that lead to the installation of heating equipment that is rarely used to capacity. Such equipment does provide a safety margin for those times when even lower than design temperatures occur or when windows are inadvertently left open or other temporary and unexpected heat leaks occur in very cold weather.

Thus, to obtain design hourly heat loss, calculate qtotal = q + qv where q = (?UA) ?t with ?UA the sum, for all exposed components of the building's envelope, of U × A; ?t = (interior temperature - exterior design temperature); and qv = 1.1V ?t (1.2V ?t; SI units) where V is the volume in cfm (L/s) of outdoor air introduced.

(b) Maximum Hourly Heat Loss: Sizing Auxiliary Heating for Passive Solar Buildings

The one important difference between the maxi mum heat loss calculations for conventional and passive solar buildings is the following assumption:

No internal heat gains (lights, people, etc.) are present, but there is sufficient stored solar energy to at least cancel out the heat losses through the south solar collection area.

Otherwise, the procedure is the same as that for conventional buildings:

qtotal = q + qv where q = ?UAns ?t qv = 1.1V ?t (?t again based on the design condition, Section B) (1.2V ?t; SI units)

?UAns

excludes the solar collector area

This can lead to occasional chilly interiors, as when several days of heavily overcast skies coincide with design-condition outdoor temperatures. In some locations, therefore, designers use the more conservative, conventional procedure for sizing the auxiliary heating for passive solar buildings.

(c) Maximum Hourly Loss: Checking Design Criteria

The calculations that produce q and qv are also useful in reviewing a building's design. By showing where most of the heat loss is occurring, they can quickly pinpoint opportunities for energy conservation and increased comfort. If much of the building's heat loss is occurring through large windows in one wall, for example, consider the following options:

1. Reduce the window size. (Architectural and daylighting considerations may override.)

2. Go to a lower window U-factor to reduce heat loss and increase the winter surface tempera ture of this large glass area. (Cost and detailing considerations may override.)

3. Add thermal shades or shutters to dramatically reduce heat loss and increase winter surface temperature. (Architectural, view, cost, and detailing considerations may override.) If much of the building's heat loss occurs through outdoor air, consider these options:

1. Reduce infiltration by tighter construction (or reduce mechanical ventilation toward the code-required minimum).

2. Add a heat exchanger between outgoing and incoming air.

These calculations can also be used to check your building against published criteria for thermal performance . Redesign of building envelopes to meet such criteria is fairly common in the early stages of building design.

(d) Hourly Rates of Fuel Consumption

When outdoor temperatures in winter drop below the building balance point (see Section 9), heating systems usually begin to operate. The hourly rate of fuel consumption depends on the hourly heat loss from the building. If the boiler (or furnace) is selected to run continuously at the outdoor, critical winter design temperature, then it will cycle (run intermittently) at higher outdoor temperatures.

The equipment, however, is selected on the basis of the maximum winter demand rate and therefore relates to the calculated heat loss at the design temperature. Sometimes your energy supplier will ask for the maximum hourly rate.

TABLE 5 Approximate Heat Values of Fuels

9. CALCULATIONS FOR HEATING SEASON FUEL CONSUMPTION (CONVENTIONAL BUILDINGS)

The following method of estimating the fuel used for space heating in a typical season best applies to residences and small commercial buildings that are skin-load dominated and not passively solar heated beyond SSF = 10%. To the extent that the combi nation of internal and solar gains can be predicted accurately, this method yields a reasonable estimate of annual fuel consumption for any building. (For passively solar-heated buildings, use instead the method given in Section 10.) Internal and solar gains make almost any building warmer than the outdoors during the heating season. The furnace (or other space heating device) is not needed until the outdoor temperature drops to the point at which these internal and solar gains are insufficient to heat the building by themselves, that is, when the heat lost through the building's skin and infiltration matches the heat gained through solar plus internal loads. This particular outdoor temperature is called the balance point; it represents the beginning of the need for space-heating equipment usage.

To estimate the annual energy needed for a building's space heating, it is necessary to know the following:

• The building's heat-loss rate (envelope and infiltration)

• The building's internal plus solar gain rate

• The building's balance point temperature

• The time period during which the outside temperature falls below the building's balance point temperature (DD)

(a) Balance Point Temperature

When a building needs neither heating nor cooling, the internal gains equal the external losses:

Qi

= balance point qtotal where Qi

= internal gains plus solar gains (Btu/h or W) balance point qtotal

= UAtotal (ti - tb) tb = balance point temperature ti

= average interior temperature over 24 hours, winter UAtotal

= total heat loss rate-envelope plus infiltration (Btu/h ºF or W/ºC) Rewriting this equation to solve for the balance point temperature:

tb = t Q UA i i

total

To determine the total heat loss rate UAtotal , combine the envelope (or skin) losses and the infiltration (or ventilation) losses.

The quantity Qi cannot be determined so straightforwardly. The internal gains can be estimated as shown in Table F.3 (remember, these are summertime gains) or calculated more precisely from known building population, lighting, and equipment data. For residences, the following daily total internal gains are considered typical:

People: Two adults and two children (average times of occupancy): 23,000 to 24,500 Btu/day (6.7 to 7.2 kWh/day) Lights and equipment: See TABLE 6 for individual heat sources, but if actual appliances are unknown, then:

53,000 Btu/day (15.5 kWh/day) for standard efficiency equipment

100,000 Btu/day (29.3 kWh/day) for old and inefficient equipment

For more details on internal gains in residences, see the 2009 ASHRAE Handbook-Fundamentals, Section 17.

The solar gains are elusive; each month has a different average gain. For simplicity in the heating season, use the average January daily insolation on a vertical surface (found in Section C) with this approach.

During the heating season:

Qi = internal gains (Btu/day) 24 h + January insolation area (ft ), (Btu/ft da 2 2 y y average), south vertical surface glass

TABLE 6 Typical Residential Daily Internal Heat Gains from Appliances and

Lighting

The balance point temperature, tb, can be used to do several things besides predict fuel consumption. By noting the tb on a graph of monthly out door temperatures, the designer can quickly see the relative importance of heating versus cooling for a specific building in a given climate. Also, it can be used to gain a better understanding of how zones in a building interrelate. Once the tb is calculated for each zone, it can be determined when the entire building needs heating (outdoor temperature below any zone's tb) or cooling (outdoor temperature above any zone's tb), or when one zone's surplus heat can be another zone's space-heating source (outdoor temperature higher than one zone's tb but lower than that of another). If thermal exchange between zones occurs for a major portion of the typical year, the choice of either a heating or a cooling strategy could be influenced.

(b) Degree Days (DD)

These data are published for each climate station and are calculated to various base temperatures. Heating degree days (HDDs) to a specified base temperature, such as HDD65, refer to average daily temperatures below the base temperature of 65ºF. Cooling degree days (CDDs) to a specified base temperature, such as CDD50, refer to average daily temperatures above the base temperature (of, say, 50ºF). (Climate data previously showed cooling degree hours [CDH], such as CDH74, referenced to the average number of hours above a base temperature of 74ºF. These data appear to have been generally displaced by CDD data.) For smaller buildings, such as residences, HDDs are in much wider usage than are CDDs (or CDHs), and many data sources simply list DD65; this notation is interchangeable with HDD65. Until recently, degree days were always based on 65ºF, because older, indifferently insulated buildings, with low internal gains, had a typical balance point of about 65ºF. The combination of much higher levels of insulation and much more electric equipment has shoved the average building's balance point temperature downward; hence DD50, DD55, and DD60 are included with the traditional DD65 in Section C.

To derive HDD for a particular climate and X base temperature (HDDX), each day's mean temperature (halfway between high and low) is subtracted from the base temperature; the result is the number of HDDX for that day. If the mean tempera ture equals or exceeds the base temperature, no HDDX are recorded. Then the HDDX are totaled for an average year.

For example, assume that a day in Troy, New York, had a high of 60ºF and a low of 34ºF. The mean temperature was (60 - 34/2) + 34 = 47ºF.

65 - 47 = 18 DD65 60 - 47 = 13 DD60 55 - 47 = 8 DD55 50 - 47 = 3 DD50

Clearly, a building with a 65ºF balance point will need more heat on a given day than will a building with a 50ºF balance point temperature.

To convert DD I-P to DD SI, simply multiply DD I-P by 0.56:

DD SI = 0.56 DD I-P

TABLE 7 Some Typical Values of Annual Fuel Utilization Efficiency (AFUE)

To obtain the DD balance point needed to estimate a particular building's heating needs, interpolate between the various base DDs as required. (If the balance point is below 50ºF, get lower DD base figures from your local weather station. Do not extrapolate!) (c) Yearly Space-Heating Energy To estimate the heating energy needed over an average year for a building, E, calculate

[...]

where E is in units of fuel consumed per year (therms of gas or kWh of electricity) UA is the total heat loss rate, envelope + infiltration (Btu/h ºF, or W/ºC) DD balance point is obtained as just described AFUE is the annual fuel utilization efficiency, displayed on all furnaces manufactured within the United States (TABLE 7) V is the heating value of the fuel from TABLE 5

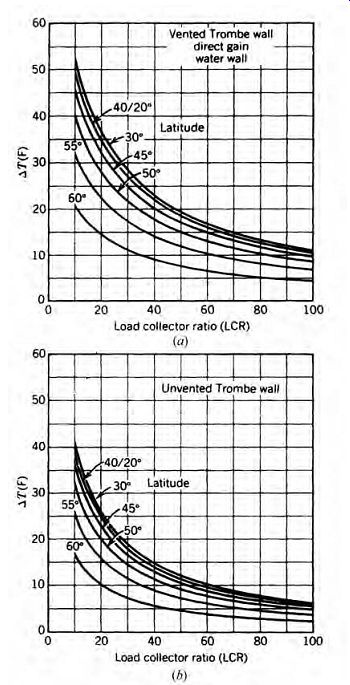

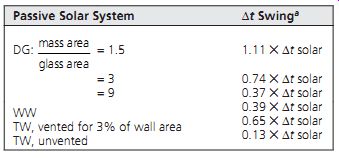

10. PASSIVE SOLAR HEATING PERFORMANCE

Section 4 presents design guidelines for determining solar opening size, thermal mass, and the solar savings fraction (SSF). As a building design takes shape, more detailed information becomes useful: Which passive system matches the architectural program? Which performs better thermally? For a given solar opening, what exactly is the resulting SSF? How much auxiliary fuel consumption per year must accompany that SSF? If a building over heats on sunny winter days, how hot will it get? To this point, passive solar heating has been treated as a single approach; the design guidelines for SSF distinguished only between standard and superior system performance. Important architectural differences, however, characterize the various passive solar heating approaches, as summarized in TABLE 8. On the basis of the wider architectural implications presented in TABLE 8 and the detailed sizing information found in Section H, the designer can select a passive solar heating approach with some confidence in its applicability and its yearly need for auxiliary space heating.

(a) Glazing Performance

In the reference systems of Table H.1, the glazing is assumed to face due south. The choices of glazing conditions include single, double, and triple glazing, and night insulation "no" or "yes." Single, double, and triple glazing with no night insulation are common approaches. Movable night insulation, once common (FIG. 25), has largely been sup planted by superwindows. Yet, which of the current superwindows might provide a performance approximately equivalent to double glazing with R-9 night insulation? The 24-hour averaged U-factor of the double glazed fixed window with R-9 night insulation is found as follows: a double-glazed window, with a wood/vinyl frame, corresponds to window #5 in Table E.15, with a U = 0.49. "Night insulation" assumes adding R-9 insulation, in place from 5:30 P.M. to 7:30 A.M. This extra-insulated window should at night then have an overall R of at least (1/0.49) + 9 = R-11; then nighttime U = 1/11 = 0.09.

U24av =

(14 h)(0.09)] [(10 h)(.49) 24 h

? = 0 0.257

The equivalent superwindow would then have these characteristics, based on window #5's solar gain:

U = 0.26, SHGC = 0.58, VT = 0.57

Such a combination may be difficult to obtain.

Here are some choices for superwindow substitutes for the "double/yes n.i." option within the Section H reference types:

• Where listed, choose the triple-glazing option instead of the double/yes n.i.

• Use window #7, Table E.15, with U = 0.33, SHGC = 0.55, VT = 0.52, with nearly identical solar gain characteristics, and interpolate between double/yes n.i. and double/no n.i. on the basis of U-factors:

Double/no n.i., U = 0.49

Double/yes n.i., U = 0.26

Window #7, U = 0.33

This places window #7 at about one-third of the difference, closer to double/yes n.i.

• Use the clear triple-glazed window (#12, Table E.15) in place of double/yes n.i., and given its U = 0.34, SHGC = 0.52, VT = 0.53, interpolate for U-factor as with window #7.

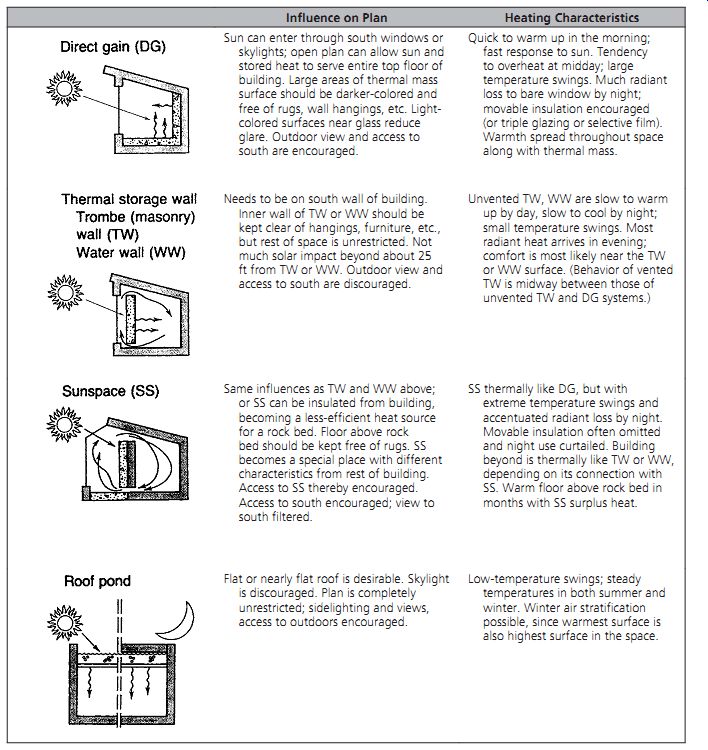

------------- TABLE 8 Passive Solar Heating Systems Compared

Influence on Plan Heating Characteristics Sun can enter through south windows or skylights; open plan can allow sun and stored heat to serve entire top floor of building. Large areas of thermal mass surface should be darker-colored and free of rugs, wall hangings, etc. Light colored surfaces near glass reduce glare. Outdoor view and access to south are encouraged.

Quick to warm up in the morning; fast response to sun. Tendency to overheat at midday; large temperature swings. Much radiant loss to bare window by night; movable insulation encouraged (or triple glazing or selective film). Warmth spread throughout space along with thermal mass.

Needs to be on south wall of building.

Inner wall of TW or WW should be kept clear of hangings, furniture, etc., but rest of space is unrestricted. Not much solar impact beyond about 25 ft from TW or WW. Outdoor view and access to south are discouraged.

Unvented TW, WW are slow to warm up by day, slow to cool by night; small temperature swings. Most radiant heat arrives in evening; comfort is most likely near the TW or WW surface. (Behavior of vented TW is midway between those of unvented TW and DG systems.) Same influences as TW and WW above; or SS can be insulated from building, becoming a less-efficient heat source for a rock bed. Floor above rock bed should be kept free of rugs. SS becomes a special place with different characteristics from rest of building.

Access to SS thereby encouraged.