The Permanent Wood Foundation (PWF) foundation system, which used to be called the All Weather Wood Foundation (AWWF), has been around for many years, but only over the past decade or so has it started to gain widespread use. It is efficient, practical, effective, and relatively inexpensive, the materials are available almost anywhere, and the system is approved by all the model building codes. It is an excel lent system for the do-it-yourselfer, in that the entire foundation is made from dimension--stock lumber and plywood and is put together in just the same way as an ordinary platform-framed stud wall. No great amount of labor or expertise is required, and the materials are easily transported to sites where accessibility is a problem for large vehicles. In fact, this foundation can be put together in panels in a work shop or garage and then trucked to the site for erection, a decided advantage in cold or other wise inclement weather. And, not a bit of concrete or mortar is needed. The key to the PWF is that all the lumber and plywood is pressure-treated with special preservatives.

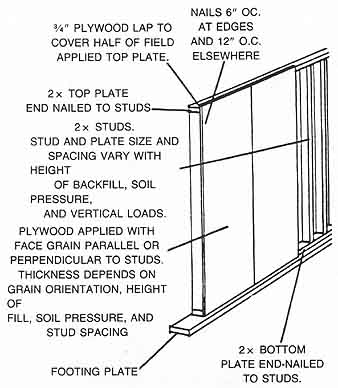

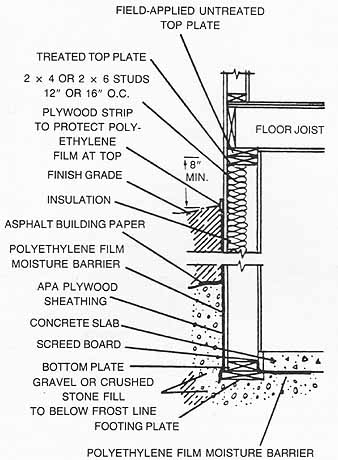

In a typical full-basement installation (Figs. 4-30 and 4-31) the walls

are made from 2- x -6 studs placed on 12- or 16-inch centers between a

sole plate and a top plate. The width of the studs and plates and the spacing

on centers can be varied to suit the amount of strength needed in the foundation

to support the structure adequately.

The exterior of the wall frame is covered first with a layer of plywood, the thickness of which depends upon the estimated backfill pressure and the stud spacing. The plywood is then completely covered with a damp-proofing layer of polyethylene film, glued on tight with a waterproof compound. The wall rests upon a wider footing plate of nominal 12-inch stock, which in turn rests upon a wide bed of gravel, compacted and leveled and extending below frost line.

Fastening is done with stainless steel or galvanized nails or staples, depending upon just what is being fastened and where. All the below-grade wood is pressure-treated with preservatives; the top plate is untreated. A drainage system can be added around the base of the foundation if desired, and the backfilling is handled in the usual manner, though with extra care so as not to damage the walls.

This foundation system can also be used for crawl-space foundations, or for perimeter foundations with a slab-on-grade poured within, as for a garage. In these situations the job is even easier, because the plastic film barrier need not be used and the gravel bed need not go below frost line. Crawl-space ventilation and moisture protection is handled in the normal way. A PWF foundation can't be satisfactorily used in Type IV soils (primarily organic silts and peat), but performs well in other soils, and its many advantages make it well worth investigating.

Further details—and there are a lot of them—can be obtained from the American Plywood Association.