AMAZON multi-meters discounts AMAZON oscilloscope discounts

It was stated in Section 1 that the most basic or underlying premise of Lean Operations is the elimination of waste. As a basic premise, or basis of operations, it is also a governing principle, or ideal of Lean Operations.

Governing principles are the applied standards for defining policy, direction and objectives for the lean enterprise. There are three governing principles behind Lean Manufacturing:

Waste Elimination--Actively seek to identify and eliminate waste, which is anything (any part, practice, process, design element, work environment, organization element or policy) that does not add value to or for the customer.

Focus on Customer--The operation is focused on what the customer values, which in general are related to low cost, product quality and reliability, timeliness and demand for a product/function.

Quality Generated at the Source--Quality is built in, not inspected and/or tested in. That is, the production equipment and manufacturing processes generate first quality components and products the first time through; rejects, rework and work-arounds do not exist.

If these are the governing principles of a Lean Manufacturing plant, what are the governing principles of the Maintenance Organization in the Lean Manufacturing Plant? Since the function of maintenance is to support operations, do the same underlying standards apply?

1. LEAN MAINTENANCE GOVERNING PRINCIPLES AND CONCEPTS

The governing principles of every organizational element must be the same as those of the parent organization or corporation. In diversified enterprises that include, for example, manufacturing, service operations (e.g., financial services), facility operations (e.g., hospitals) and similarly diverse business units, individual organizational elements will have as their governing principles a subset of the parent organization's governing principles. Divergent principles create divergent policies and organizational elements risk opposing the goals and objectives of other interrelated, even interdependent elements. Thus, the governing principles of the maintenance operation, although focused somewhat differently, remain the same as those of the plant itself. To reflect the different focus, the governing principles of maintenance can be restated as:

Waste Elimination--Actively seek to identify and eliminate waste, which is anything (any part, practice, maintenance process, tools or instruments, "bench" spare, waiting time, travel time (e.g., walking from one job to the next at opposite ends of the plant), work environment, organization element or policy) that does not add value to or for the customer. The maintenance worker's customer is most often operations but also still includes the buying customer of the plant output.

Focus on Customer--The maintenance operation is focused on what his or her customer (operations) values, which is primarily equipment reliability. The operations customer also values timely completion of scheduled maintenance, restoration of equipment to "ready-to-produce" condition at completion of maintenance and similar production specific needs from maintenance activities. This principle also provides value to the end customer buying the products output by the plant through support of the production process.

Quality Generated at the Source--The quality of maintenance activities translates to correctly performing the right maintenance at the right time and the first time (no repeats of maintenance tasks because the tasks are performed correctly the first time). Maintenance tasks are performed using the correct parts, materials and consumables in the correct quantity.

Maintenance activities yield production equipment that manufactures first quality components and products the first time through; rejects, rework and work-arounds do not exist.

As these restated governing principles show, the emphasis is the same but the focus is placed on the immediate maintenance customer--operations.

Successful maintenance functions are built upon a foundation of governing principles and a layer of support concepts--concepts of how the Lean Maintenance Operation functions. Ten concept statements follow, which are considered essential for support of the Lean Maintenance Operation.

Individual Maintenance Operations may have additional concepts of how maintenance is performed in their plant, however they must still support the corporate mission and vision as well as the maintenance mission.

==========

1. Management has developed and communicated a clear statement of the maintenance mission to ensure that departmental activities are consistent with and supportive of the facilities' operating plan and associated operating strategies.

2. The concept of operating custodianship is basic to facility philosophy.

3. Responsibility for determining how best to satisfy maintenance needs rests with the maintenance department through technically qualified knowledge and advice.

4. Maintenance of processes, equipment and facilities is a responsibility shared by all units of the organization.

5. Maintenance is a cornerstone of the operation. Policy statements are issued by the management to ensure that the maintenance program is an integral part of the operating strategy. Thus, common understanding of the maintenance effort is assured and its procedures are rooted to these facility-wide practices.

6. Maintenance philosophies and functions supporting facility strategies are written within a procedures manual and effectively communicated to all concerned departments.

7. Effective maintenance is proactive, not reactive. When failures occur, preventive measures are sought to preclude recurrence.

8. There is a clear definition and understanding of responsibilities (primary and supportive) between the operating (production) and maintenance departments.

9. Mutual understanding and cooperation is excellent. Important procedures, such as the work order system are followed with reasonable uniformity.

10. The proactive nature of the Total Productive Maintenance (TPM) program is not overlooked when the plant is under pressure to meet output targets.

==========

1.1 Vision and Mission

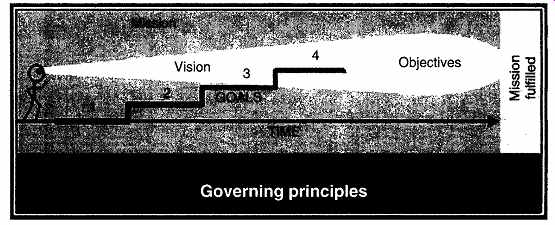

FIG. 1 Relationships: Mission-Vision-Objectives-Goals

It is important to understand the relationships between governing principles, objectives and goals as well as an operation's vision and its mission (FIG. 1). The underlying drive for the way you do things, whether in life or in business, are your particular set of principles and concepts. Everything else grows from these roots. A vision is a portrait of what you would like ultimately to become, or in business, where the organization would like to be in the future. Your mission is the purpose of your existence or of the Maintenance Operation's existence. Mission is the reason you do what you do. Goals are the measurable steps toward fulfilling the mission while objectives are the conditions that must be met in order to fulfill the mission.

Section 1 listed eight objectives of the Lean Maintenance Operation. These are the minimum required objectives. Depending on the Mission Statement of the Maintenance Department, additional objectives may be required.

A Maintenance Mission Statement will clearly state the reasons, or purpose, for the maintenance department's existence as it supports the company's vision and its strategic and operations (production) plan. Vision statements are normally generated only at the top level of the company. They become, by force of policy, the vision of every element within the organization. Maintenance objectives and goals are synchronized with the maintenance department mission statement and will be consistent with the company's strategic plan and operations/production plans, which in turn, are formulated to realize the company's vision. The maintenance mission statement must support the company's stated mission and vision. The following is one example of a maintenance mission statement:

"Our maintenance mission is the provision of timely, high quality, cost-effective service and technical guidance to support short-range and long-range operating/production plans. We will ensure, through proactive practices rather than reactive, that assets are maintained to required levels of reliability, availability, output capacity, quality and customer service. The maintenance mission seeks to continuously improve work practices and maintenance effectiveness and will actively seek out and eliminate waste.

Our mission is to be fulfilled within a working environment that fosters the highest levels of safety, morale and job fulfillment for all members of the maintenance team while protecting the surrounding environment." 3.1.2 Strategic Plans, Goals and Targets Strategic planning is the weighing of and choosing among long-term alternatives to develop a timeline of action, milestones and goals necessary for a company to achieve elements of its vision. Strategic plans are more focused on marketing, sales, product development, production and profitability aspects of the company vision statement. Strategic plans emanate from the top level of corporations. They often require subsidiary elements of the company to develop a strategic plan of their own detailing their action requirements to support the corporate level strategic plan. At a minimum, a set of time-lined goals and targets necessary to support and achieve the short- and long-term milestones and/or goals of the corporate level or immediate client support strategic plan are required. At the level of the Maintenance Department, the latter requirement of goals and targets in support of the Operations Department's strategic plan is normally applicable.

In the Lean Environment, the Maintenance Department will define specific goals for achievement in relation to the Operations Department's strategic plan. Additionally, targets are set for maintenance performance in terms of equipment up time, maintenance costs, overtime, work-force productivity, supervisor's time at job-sites and similar measures. Such specific targets as these enable management to monitor progress and the effectiveness of the maintenance management program and to control activities by focusing corrective attention on performances or levels that consistently fall short of the targets.

Superficial goals lead to superficial results. A clear understanding of the mission is critical to success. Similarly, unachievable goals will frustrate maintenance supervisors and workers and ultimately lead them to abandon the pursuit of goals and targets. In the Lean Environment, maintenance staff members participate in defining the department's goals and targets. A positive and productive mind-set results in positive and productive performance. The Lean Environment builds a climate that promotes self-motivation.

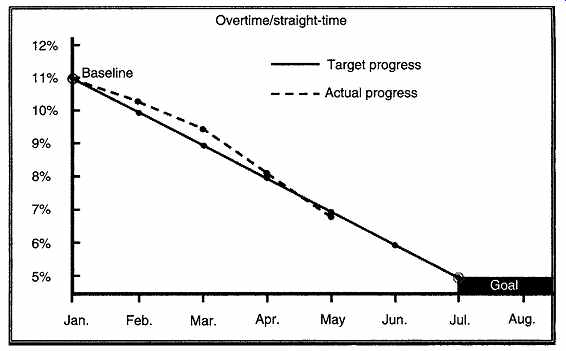

Most targets are merely mile-markers for goal attainment. For example, existing overtime hours are 11% of straight-time hours. The goal is to reduce overtime to 5% or less within 6 months. Targets are established at 1-month intervals of 10%, 9%, 8%, etc. Once defined, performance measurement strategies are defined, the goals and targets are published and measured performance is tracked against target values in a visual, public display (FIG. 2). Nearly as important as goals and time-targeted achievement levels are the metrics, or measurement processes, necessary to determine progress towards performance goals. Without the measure of progress, course adjustments cannot be made in a timely fashion to correct deviations from targeted paths. Rewards for meeting target performance levels are just as difficult to meter out without the benefit of performance metrics. The Information Technology (IT) department has an important role in identification of data sources and creation of performance indicator reporting formats.

The primary source of maintenance performance data is the Computerized Maintenance Management System (CMMS). The accounting system is also an important source of cost and labor data. In those companies utilizing a fully integrated Enterprise Asset Management (EAM) system, the acquisition of data as well as creation of performance indicators and reports is greatly simplified. An EAM system is a plant-wide (or multisite wide) information management system that encompasses data management for all departments in the organization. The most common maintenance performance indicators can be classified into three categories:

FIG. 2 Typical Display of Goal and Performance

1. measures of equipment performance, such as availability, reliability and overall equipment effectiveness;

2. measures of cost performance such as labor and material costs of maintenance;

3. measures of process performance such as schedule compliance and the ratio of planned and unplanned work.

-------

2. OPERATIONS AND MAINTENANCE

In the pre-Lean world, there was not much integration between maintenance and operations functions, and most of what existed was between maintenance planning and scheduling, and production scheduling. The other primary interfacing was initiated through trouble and failure reports, and work requests initiated predominantly by production line operators.

In the Lean Environment, the integration of maintenance and operations is much tighter. The tighter integration begins with the formation of empowered action teams consisting of both operators and maintenance technicians and sometimes includes a maintenance engineering representative. Depending on plant size, layout and other factors, teams are organized by plant area, production line, process or stage, or facility zones. Each team is accorded stewardship of the plant assets within their area assignment. (Stewardship: the conducting, supervising or managing of something," especially: the careful and responsible management of something entrusted to one's care.)

2.1 Operations, Maintenance--A Partnership with Two-Way Responsibilities

Along with the formation of the Lean action teams comes a new (although it should have always existed) set of responsibilities between team members. The strict separation of production work and maintenance work no longer exists, although the new functions and responsibilities must be well defined. In the Lean Environment, new functions include:

-- operators performing equipment cleaning;

-- operators being a part of "early warning" system-in order to perform daily equipment checks;

-- team members pitching in to restore equipment when they spot any problem;

-- operators performing routine (autonomous) maintenance;

-- training and certification of operators performing autonomous maintenance to perform designated routine maintenance tasks;

-- maintenance personnel assisting in set-up following maintenance work;

-- considering action team members as qualified personnel, and not as castoffs;

-- operations and maintenance supervisors spending more time at the job site;

-- performance of major maintenance work requiring highly skilled crafts, by centralized (non-team) maintenance forces and

-- effective communication between team members: communicate, communicate, communicate!

In addition to these new functions and relationships between members of Lean action team, there is a new (although always existing) set of responsibilities, both shared and to each other, for operations and maintenance departments in the Lean Environment. These responsibilities should be formalized through inclusion in departmental standard operating procedures (SOPs).

Shared Responsibilities:

-- Both must work cooperatively to reduce emergencies---converting costly breakdown to proactive maintenance.

-- Both must actively pursue the identification of waste and then jointly seek ways to eliminate it.

Responsibilities of Operations to Maintenance:

-- Operate machinery and equipment properly.

-- Know the conditions and performance of equipment assets. Maintain surveillance and establish awareness of system and equipment in order to detect unsatisfactory or anomalous conditions and anticipate essential work. Report such conditions to maintenance for diagnosis and action.

-- Request and authorize repairs, replacements and alterations and describe them clearly in writing.

-- Avoid unnecessary work and fictitious priority. Help to control the volume variance within maintenance budgets.

-- Accept equipment ownership (stewardship).

-- Participate in performance of equipment maintenance work to the degree specified, authorized and trained.

-- Plan for and provide adequate equipment access for timely performance of programmed and scheduled maintenance.

-- Communicate capacity needs.

-- Responsibilities of Maintenance to Operations.

-- Based on authorized orders for maintenance or repair service, define and execute the required work in a timely fashion, with quality workmanship, knowing what is to be done, when and how best to do it. Then do it right.

-- Assist operations in establishing a practical level of maintenance so that long- and short-term production plans can be met and repairs can be anticipated, planned and scheduled.

-- Maintain facilities at specified levels of operating condition, at lowest possible cost consistent with the goals of producing quality products as economically as possible.

-- Actively participate with operations to execute and continuously improve a comprehensive preventive maintenance program.

-- Convert emergency work to planned work by anticipating it.

-- Make repairs and replacements at intervals required for optimal operating efficiency and in a manner creating as little production loss as possible.

-- Constantly strive to improve maintenance work methods, completeness and neatness with the goal of quality work at minimal cost.

-- Effectively plan, schedule and coordinate maintenance work with operations in advance, to permit them to plan for out-of-service equipment and to minimize nonproductive time and production stoppage.

-- Prior to execution, thoroughly review all shutdown work with key operations personnel so their first-hand operating knowledge can be fully utilized.

-- Provide regular feedback regarding status of work requests and completion promises.

-- Advise operations as to the levels of risk and the potential costs related to operating equipment believed to be close to failure. Develop techniques for predicting failure of critical facilities with reasonable accuracy.

-- Inform operations of systems or equipment requiring excessive maintenance and take appropriate action to reduce it.

-- Account for the level of cost incurred in the performance of requested maintenance (standard vs. actual -- the performance variance).

-- Regard operations as a customer (internal).

PREV. | NEXT | Article Index | HOME