AMAZON multi-meters discounts AMAZON oscilloscope discounts

THE DESIGNER OF TODAY'S BUILDINGS will add or reshape spaces on a planet that has, for eons, evolved by using renewable energy arriving from the sun at a generally fixed and limited rate.

Suddenly (in geologic time) our planet is experiencing population growth, nonrenewable resource depletion, and apparently global warming. Today's designers have available a vast, yet declining, reservoir of material resources, fossil fuel energy, and water. The building design professions thrive on a rapidly increasing population, each person consuming more resources than did her/his grandparents. Eventually, our planet must live within a fixed budget of renewable energy, water, and material resources. The question is: How can our present building designs best move toward this necessary accommodation with sustainability? How can building designers be environmentally proactive instead of simply reactive?

Population growth is both the source of much of our work as buildings professionals and the underlying source of our greatest problems. Our planet did not support a human population of 1 billion until about 1830, at which time the United States depended almost entirely upon the renew able energy sources of fuel wood and work animals; interior lighting was provided by burning oil or gas.

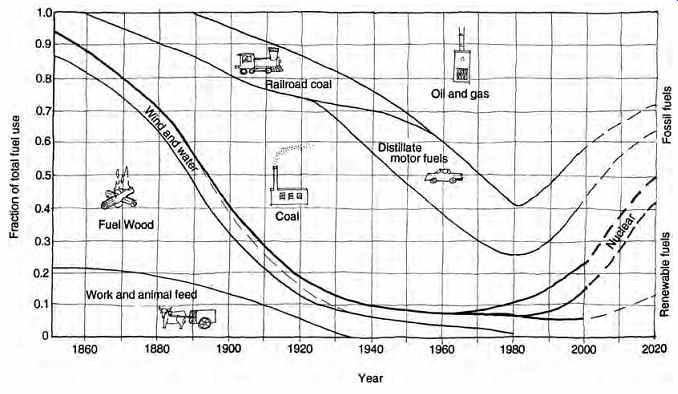

In less than 200 years, 4 billion more people were added to our planet, and the United States shifted to almost total dependence upon nonrenewable fuels: coal, oil, and natural gas (FIG. 1). Another 1 billion in population is expected around the year 2010.

The building design process plays an active role in deciding where these people will live and work and how much of what kinds of resources they will use.

The mechanical and electrical systems that support our new buildings can be part of a growing problem or an important start to a solution.

1. INTRODUCTION

Buildings depend upon energy and matter for their very existence and must pay heed to several fundamental rules of science. The First Law of Thermodynamics establishes the conservation of energy and matter (energy/matter can neither be created nor destroyed) and essentially states that you cannot get something for nothing. The Second Law of Thermo dynamics expresses the tendency toward disorder that is part of the normal nature of things. Entropy is a measure of such disorder; as disorder increases, so does entropy. The Second Law is a declaration against perpetual motion, and essentially states that not only can't you get something for nothing, you can't even break even, due to unavoidable losses (disorder) that contribute to increased entropy.

The construction and operation of buildings are fundamentally ordering processes. Materials are mined or harvested, refined or shaped, placed in manufactured products, transported to a building site, and assembled. All of these processes consume energy and materials as the various building systems are established. The operation and maintenance of a building consume further resources, as conditions (temperatures, light levels, flows of water) are established that would not otherwise occur under less-ordered natural conditions. Maintaining building materials and systems over time against the forces of nature requires additional inputs of energy and materials. Buildings are inherently antientropic. This is not necessarily bad (learning and evolving are also antientropic), but it should be considered during the design process.

As will be seen later in this section, buildings have a substantial collective impact on our patterns of energy, water, and materials consumption.

The design process should consider various scales of concern relative to the impacts of buildings upon the environment. One such scale is geo graphic. Geographic scales of concern include the micro scale, the site scale, and the macro scale, with design focus historically being at the site scale. The terms micro (small) and macro (large) are not absolutely defined but are often referenced to a particular site. Thus, the area of influence of a microclimate is smaller than that of a macroclimate--but is usually also smaller than that of the site scale, often applying to one part of a site (perhaps with a steeper slope, lower elevation, or greater shading than other parts). The site scale is normally self-explanatory, running from property line to property line. Energy efficiency issues are typically and historically addressed at the site scale and often ignore (unfortunately) energy consumption off-site (such as electric power plant losses or natural gas transportation losses). Renewable/passive energy systems must consider microscale effects (such as orientation) in order to be successful. Nonrenewable/active systems often are oblivious to any scale of concern.

FIG. 1 U.S. fuel sources since 1850, showing a progression from dependence

on renewable fuels (wood and work animals) to fossil fuels (coal, then oil

and gas). Wind and water power were shifted from mills to electricity generation

between 1890 and the present. Although not shown here, much fossil fuel is

now converted to electricity before use. (Data 1850-1970 are from Fisher, 1974;

data 1970-1980 are from Meyers, 1983; future projections are from Brower, 1990.

Drawing by Michael Cockram; © 1998 by John S. Reynolds, A.I.A.; all rights

reserved.)

Time is another, and very interesting, scale of concern to building design. The scales typically addressed include now and the future-although the past is sometimes of concern with adaptive reuse and historic preservation projects. The concept of the future is usually left quite nebulous unless life cycle costing is undertaken for a project, in which case the expected lifetimes of systems and equipment are explicitly estimated. It is clear that most buildings have a useful life of 25, 50, perhaps 100 years (or more). Stuart Brand provides an interesting look at buildings over time in How Buildings Learn: What Happens After They're Built. The problem with design for the future is that we don't know precisely what it holds. Nevertheless, design for sustainability requires the design team and the design process to consider the needs of future generations.

This makes sustainability a very challenging concept and highly objective-but no less important than design for today.

2. ENERGY

Energy resources are broadly classified as renew able or nonrenewable. Renewable resources are those that are available indefinitely but are generally diffuse and arrive at a rate controlled by nature.

For example, the influx of solar energy varies from day to day, but on average it should be available for ever and at a generally predictable rate. Likewise, a woodlot produces a limited amount of wood per year but can do so for centuries if properly man aged. An analogy for using renewable fuel sources is living on a fixed annual salary-with no hope for spectacular annual raises or unexpected bonuses but with long-term stability if wisely managed.

Nonrenewable energy resources are those that, once exhausted, cannot be replaced in a time frame that is meaningful to the human race. Coal, oil, and natural gas are examples of nonrenewable energy resources. Using nonrenewable fuel sources is analogous to living off a one-time lottery win that can be spent in 1 year or over 50 years, depending upon needs and planning, but that is gone for good when all spent.

The United States, like other industrialized countries, has spent the time since the mid-1800s in an energy transition (FIG. 1). This transition began with renewable energy sources, obtained locally, that did relatively low-grade work: animals pulled or pushed, and wood was burned to provide heated air, water, or steam. Buildings and people were directly affected by energy sources; work animals were fed, tended, and housed; fuel wood was cut nearby and stacked in large sheds (FIG. 2); fireplaces were social centers of buildings; and smoke from chimneys indicated activity inside. The side effects of energy use were also directly sensed-animal wastes, deforestation, and polluted air. Fuel use depended upon human labor. Architects of the era responded to the visual and spatial organization potentials of fireplaces and chimneys (FIG. 3).

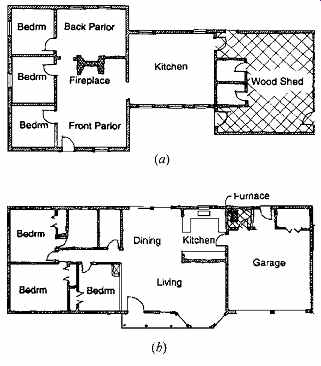

FIG. 2 Residential heating: past and present. (a) The house dependent on

fireplaces or wood stoves also depends on someone to tend the fire. The warmer

area near the fire in this early Oregon farmhouse was used for social purposes;

the colder extremities served as sleeping areas and for storage of food and

fuel. (Based upon a plan drawn by Philip Dole.) (b) The contemporary suburban

home has either a small furnace area or electric heat built into each room.

Heating equipment is no longer a major influence on building form.

FIG. 3 The fireplace and the more efficient wood stove can inspire architectural

form. This chimney symbolizes permanence as well as protection against the

cold. The major social space of the house is marked both by the arched window

and by the fireplace chimney. (Photo by William Johnston.)

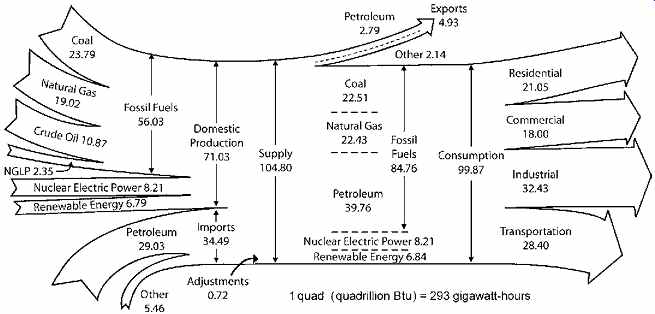

North America is now almost entirely dependent upon nonrenewable energy resources, an increasing proportion of which consists of imported oil and natural gas and electricity transported across substantial distances (FIG. 4). Buildings account for a good percentage of this energy demand. This trend is partly due to rapid growth in both population and per capita energy consumption. It is also due to the allure of highly concentrated energy available from fossil fuels, which encourages the use of high-quality energy sources such as electricity and natural gas for buildings and gasoline for transportation. People are now largely oblivious to their sources of energy: electricity is generated in far-off power plants; natural gas arrives through buried pipelines, and fuel oil via supertankers. The experiential impact of energy use on building design and operation tends to be diluted. Energy consumption is regulated by automatic controls, and heating and cooling equipment is hidden from sight. Building occupants/users-who often do not personally control a thermostat, see climate control equipment, or pay a utility bill-have no direct contact with or concern about energy resources. Clients hire architects to provide for function and comfort. Architects then pay engineers to design (and usually to successfully hide) mechanical and electrical equipment. Entropy, however, continues to increase.

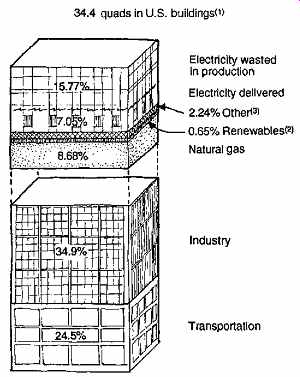

For several reasons, buildings designed for today are likely to rely heavily upon electricity (FIG. 5), a situation that carries serious implications for resource depletion and environmental quality:

1. Consumption of electricity is expected to rise about twice as fast as overall energy demand, and we are more often using electricity in place of other energy forms. Part of the reason for this is that, for some primary energy sources (such as coal, heavy fuel oil, or a nuclear reaction), generation of electricity for subsequent (secondary) distribution to buildings is the only convenient usage option.

2. Other than daylighting (unfortunately still rare in today's buildings), electricity is the only source for building illumination. Heat produced by electric lighting may reduce a building's need for space heating, but it increases its need for space cooling-and mechanical cooling is almost universally provided by electric air-conditioning equipment.

3. Electricity is a convenient and versatile energy form; it not only serves such high-quality and highly concentrated (or high-grade) tasks as lighting and providing drive power via electric motors, it can also serve such low-quality, low-temperature (or low-grade) tasks as cooking, water heating, and space heating (Table 1). All-electric buildings are commonplace, even though they are subject to paralysis in black outs-as any building dependent upon a single energy source is vulnerable to disruptions.

As shown in Table 1, of a total of 38 quads used for all building energy requirements, the primary energy used for electricity generation was 27 quads, equal to over two-thirds of the total.

4. Electricity generated by thermal processes (except for cogeneration) delivers to the end user less than one-third of the total energy that goes into its production; more than two-thirds is usually lost as waste heat at the generating plant (FIG. 6). (In Table 1, for every 1 quad of electricity delivered, 22 quads were assumed used in generation.)

Table 1 Energy End-Use in U.S. Buildings, by Fuel Type (Quads)

As we consume our planet's resources, including fossil fuels, many look to a return to renewable and sustainable energy. This vision will be partially implemented by solar energy converted directly to electricity (through photovoltaics [PV]) on or near the building requiring the electricity. Solar collectors (some for heating water, others for producing electricity) will shape the roofs and silhouettes of buildings. Building design professionals can choose to ignore or embrace such opportunities.

Hydrogen may be stored and distributed as a high-grade fuel, produced from water using electricity generated from renewable resources such as solar energy and wind. The lifetimes of mechanical and electrical equipment specified today will probably overlap such a future. In this near future, lower-tech processes such as biomass conversion (combustion of wood and waste products) may develop faster than higher-tech processes such as PV. PV is growing very rapidly, though; its growth curve is as steep as that during the first 15 years of computer technology. One major oil company's energy scenario (in the late 1990s) anticipated 50% of world energy demand being met by alternatives to fossil fuels by the year 2050.

Today's fossil-fueled economy seems so entrenched as to defy a transition to renewable energy. A common question is often heard: Is solar energy adequate for our energy needs? Table 2 compares the Earth's receipt of solar energy at the surface in a single day with other energy phenomena. There appears to be adequate resource avail ability-given the will to move toward renewable and site-based resources. Energy efficiency efforts will play a critical role in making such a transition feasible.

To date, societal focus has been primarily upon using less energy-energy efficiency. The oil embargo of the 1970s spurred the development of energy efficiency standards, which have remained a fixture of building design ever since. In general, such standards seek to reduce building energy consumption-not to shift energy resources from nonrenewable to renewable. The green building design movement has provided momentum for a serious look at both reduced energy use and the use of energy from renewable resources (see Appendix G).

FIG. 4 U.S. energy flow, 2005: sources and end uses. Fuel types and sources

are shown to the left and end use sectors to the right.

Note the importance of residential and commercial consumption to total U.S. consumption-and the currently minuscule contribution of renewable energy sources to the whole. (Drawing by Nathan Majeski using data from the Energy Information Administration, U.S. Department of Energy, Annual Energy Review, 2005. This data resource is updated on a regular basis, but the general patterns shown in this figure change slowly.)

FIG. 5 Energy resources as consumed by various end-use sectors in the United

States, 1996. Total: 94.0 quads (1 quad = 1015 Btu). Not included are raw materials

used in manufacturing.

(1) Both residential and commercial buildings are included.

(2) Renewables do not include passive solar energy use; hydroelectricity and PV are included in "electricity." (3) "Other" includes fuel oil, liquefied natural gas, coal, kerosene, and other petroleum products. (Data from U.S. Office of Building Technologies, Core Databook, 1998. Drawing by Michael Cockram; © 1998 by John S. Reynolds, A.I.A.; all rights reserved.)

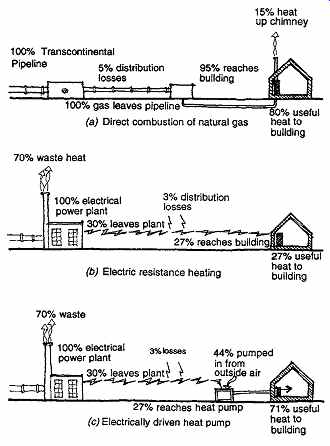

FIG. 6 Variations on higher-grade energy and lower-grade tasks. (a) Natural

gas (a fossil fuel) is often burned in furnaces to provide low-grade space

heating. With today's high-efficiency furnaces, well over 80% of the energy

in the gas is delivered to the building as space heat. (b) However, when that

natural gas is used instead to generate (higher-grade) electricity, and electric

resistance is used for space heating, the inefficiencies at the electric power

plant cut deeply into the available energy: only about 27% is delivered to

the space as heat. (c) However, when the electricity generated by natural gas

is used to drive a heat pump and the outdoor air is above freezing, about 71%

of the energy in the gas is delivered as space heat. (Drawing by Michael Cockram;

© 1998 by John S. Reynolds, A.I.A.; all rights reserved.)

Table 2 Daily Arrival of Solar Energy on Earth Compared to Other Energy Quantities

Table 3 Comparison of Regional Water Use versus Resources for the Continental United States

3. WATER

The building design profession's efforts toward a more resource-efficient product have, for the past 30-some years, focused primarily upon energy.

This focus has been warranted by the limits upon nonrenewable energy sources imposed by the laws of thermodynamics. There is no option for the reuse or recycling of fossil fuel energy (as may be done with water and materials). Water concerns, how ever, are at crisis level in many parts of the United States, and water may well be the emerging limit to growth and development-especially locally and regionally-rather than energy.

Concerns about a viable supply of potable water have dominated politics and civil engineering in the arid western United States for a century.

Surprisingly, Tampa, Florida, in the heavily rained upon Southeast, has a desalination plant to provide water for an otherwise under-resourced region.

Although water is a recyclable resource, it is not a renewable resource (no new daily supplies are being delivered to Earth). A quote generally attributed to National Geographic (October 1993) made this point succinctly: "All the water that will ever be is, right now" (UNH, 2004). In addition, where the water is, is not necessarily where it is wanted.

Periodic water rationing is an unpleasant fact in many areas. Table 3 compares regional water resources with sustainable water usage capacity; it is clear that some areas of the United States now have serious water shortages. Accelerated depletion of underground water stocks (from aquifers, which are analogous to fossil fuel reserves) and maxed-out imports (both hydrologically and politically) suggest more trouble on the way. On a global scale, the disparities become even greater. Mostafa Tolba, former executive director of the UN Environment Program, speaking of the international picture, notes: "We used to think that energy and water would be the critical issues for the next century. Now we think water will be the critical issue" (UNH, 2004).

As with energy, per capita use of water involves more than consumption within a building.

In the case of energy, transportation and industrial uses influence per capita consumption; with water, energy production and agricultural uses play a role. About half of all U.S. fresh and saline water withdrawals in 2000 were used in conjunction with thermoelectric power generation. Most of this was surface water used for once-through cooling at power plants. Withdrawals for this use have been relatively stable since 1985. (In a quirky turnabout, the California State Water Resources Control Board estimates that 6.5% of California's total electricity use is related to pumping and treating water.) Irrigation remains the largest use of freshwater. Since 1950, irrigation has accounted for about 65% of total water withdrawals, excluding those for power generation. Historically, more surface water than groundwater has been used for irrigation. The percentage of total irrigation withdrawals from groundwater has continued to increase, from 23% in 1950 to 42% in 2000. Irrigated acreage more than doubled between 1950 and 1980, then remained constant before increasing nearly 7% between 1995 and 2000 (USGS, 2004).

Public water supply withdrawals in 1950 were 14 Bgal/day (53 GL/day); in 2000, more than 43 Bgal/day (163 GL/day). During 2000, about 85% of the U.S. population obtained drinking water from public suppliers, compared to 62% during 1950. Surface water provided 63% of the total during 2000, compared to 74% during 1950. Potable water obtained from a surface source via a public supply system is becoming the norm; private well systems are less common than in the past. As with energy, population increases are increasing overall consumption, while efficiency efforts provide some counterbalancing effect.

Water efficiency standards are not nearly as extensive or ubiquitous as energy efficiency standards, although most building users are aware of low-flow toilet requirements, flow restrictors for showers, and self-closing bathroom faucets in public facilities. Surprisingly, given the few design restrictions that exist, per capita water use in the United States has remained flat for the past several years-and is currently 25% lower than in the late 1970s. This is partly because overall per capita use involves important sectors other than buildings (agriculture and power generation, for example) and partly due to increasing awareness of the value of water.

As with renewable energy sources, green building design efforts have also increased awareness of and design for water supply savings and alternatives. Part V, "Water and Waste," discusses many design alternatives that would likely be used in a green building. The role of water in the U.S. Green Building Council's Leadership in Energy and Environmental Design (LEED) rating system is outlined in Appendix G.

4. MATERIALS

A global or even countrywide perspective on materials resources is more difficult to obtain than is the case for energy and water. In the United States there appears to be a general upward trend in per capita consumption of materials. In the early 1900s, per capita consumption (in metric tons per person) was around 3.0, about 50% of which was construction materials; in 1950 about 6.0, with about 60% in construction materials; and from 1970 to 1990 about 10.0 (with ups and downs), with about 65% in construction materials.

Given the scarcity of quantitative data, a qualitative comparison with water must suffice. Many materials used in building construction and upkeep come from a generally fixed resource base. Like water, materials (at least many) may be recycled, but there is a fixed quantity of resources available on Earth. For many materials, what we have now is what we will have in the future, a marked exception being those organic materials (such as fiber products) that are renewable.

Finding adequate material resources for a building directly on the building site is rare: wood, straw, and earthen construction systems, for example, require large land areas to supply the materials for even a small building. The most commonly used construction systems involve materials brought to a site from some distance. A designer can generally select between imported renewable or nonrenewable materials and between imported virgin or recycled materials. The common thread is imported-not necessarily from overseas, but from a distance.

Reducing the transportation distance and finding local materials when available are emerging design strategies.

Wood is the only renewable construction material currently in wide use in North America. It is easily worked, supports a wide variety of finishes, has moderate structural strength, requires regular maintenance for long life, burns easily, and has only moderate value either as thermal mass or as insulation. This common building material illustrates the impact a rapidly increasing population can have on a fixed, even if renewable, resource base. As huge old trees are harvested to the point of disappearance, growing demand for wood outstrips the supply available from younger, smaller trees. New production methods are devised (such as laminates, particle board, and engineered lumber) to allow large wood members to be constructed from smaller timber. The value of salvaged older wood members increases.

Nonrenewable materials are by far the most commonly used materials in mechanical and electrical systems; metals and plastics predominate. Their advantages include strength, durability, fire resistance, and conductivity or resistivity as required.

Most such materials are obtained, however, at a significant energy cost to mine/manufacture, transport, and shape them for our use.

With rapidly increasing demand for both renewable and nonrenewable materials, how can a designer on a planet with fixed resources respond? What are the key materials issues for the design team to consider?

(a) Embodied Energy

One issue is embodied energy, a complex and there fore elusive indicator of how much energy must be invested to mine/harvest/produce, fabricate, and transport a unit of building material. Table 4 summarizes information on embodied energy for common units of today's prevalent construction materials. Such apparently simple numbers are complicated by variations in availability of the raw resource (more work needed to extract materials requires more energy), variations in distance from raw resource to manufacturing locations, and variations in the fuels used (and their efficiency of use) in the refining or fabricating processes.

Consider two alternatives for exterior wall cladding: wood siding and aluminum siding. Wood has embodied energy from a renewable resource- the sun. It takes the energy of human beings and chain saws to cut the trees and fuel to haul them, perhaps 100 miles (160 km), to a mill. At the mill, more energy is invested as logs become lumber, and still more energy is used as lumber becomes finished siding-which is then transported to a construction site. Aluminum begins as bauxite, which requires energy to mine, then more energy to ship great distances to smelters, which use large quantities of electricity in the refining process. Cheap electricity (as in the Pacific Northwest, with its once-surplus hydropower) attracts bauxite mined thousands of miles away. Once aluminum ingots are formed at the smelter, they are shipped-again, sometimes thousands of miles-to factories that make products such as siding; the products are then transported to a construction site. For a given surface area of finished siding, the aluminum alter native represents about 100 times as much embodied energy as the wood. This, however, is not the end of the story-as a designer must consider the impacts of these two siding materials on building energy consumption and envelope maintenance and replacement needs and schedules.

Table 4 Approximate Total Embodied Energy in Building Materials

(b) Recycled or Virgin Material

It seems paradoxical that, while the world's population is increasing and its raw materials are decreasing, labor costs are growing so much faster than the costs of raw materials. One consequence is that labor-intensive practices become less economically attractive. Recycling is one such labor-intensive practice (see examples in Section 23), whether at the scale of a household, an office building, or an entire industry.

Building construction, renovation, and demolition involve many opportunities for recycling, but at present these activities represent a major source of waste. The U.S. Environmental Protection Agency's 1998 report Characterization of Building-Related Construction and Demolition Debris in the United States estimated that 136 million tons per year (123 Mg) of such material are produced in the United States and that 65% to 85% of that total ends up in landfills.

Consider building demolition. If more of a demolished building can be recycled, more of the energy embodied in its material can be recovered, and fewer virgin materials will be required for some other project. At present, the recovery of usable materials from demolition is limited because the cost of labor is high and the cost of energy and new products is relatively low. It is currently easier, quicker, and cheaper to reduce a building to rubble and haul it to a landfill than to recycle. As landfill capacity becomes scarce, design regulations concerning recycled material use can be expected.

An Atlantic City, New Jersey, project was able to recycle 90% of its demolition waste. Of a total of 1583 tons (1400 Mg) of demolition waste, only 152 tons (140 Mg) were non-recyclable. Concrete and masonry became crushed aggregate for road building. Glass became "glasphalt" embedded in road surfaces as reflectors. Wood waste became mulch. At Fort Ord in California, four buildings totaling about 11,000 ft 2 (1022 m2) were dismantled rather than demolished, saving roofing boards, framing lumber, and tongue-and-groove wood flooring. Unpainted drywall was reclaimed for composting.

Construction recycling opportunities include crushed wallboard as a replacement for lime in agriculture, carpet ground up for attic insulation, plate glass crushed for use in glass fiber insulation, and pulverized wood as a composting aid at sew age sludge treatment facilities. Used acoustic ceiling tiles can become part of the slurry from which new acoustic tiles are made. Building materials are now increasingly being made from recycled materials: reinforcing bars from ferrous scrap metal; cellulose insulation from newsprint; parking lot bumper strips, fence posts, and park benches from recycled plastics; and nonstructural concrete from incinerator ash. Even plastic yogurt containers, complete with scraps of aluminum foil, are made into a terrazzo-like floor tile.

Architect Pliny Fisk, co-director of the Austin, Texas-based Center fr Maximum Potential Building Systems, has developed a wide array of such applications. His "Advanced Green Builder" home near Austin displays several applications of "ashcrete," made with coal fly ash and bottom ash, producing a 97% recycled-content concrete. This is used as ferro-cement for columns and beams and is foamed for hollow wall infill. Numerous other innovative recycled-material applications are show cased as well.

The most effective form of recycling involves reuse of a building or building shell. Audubon House in New York City is an excellent and well-publicized example of this level of reuse. The next most effective form of recycling involves the reuse of a building component as is. A residential demolition by-hand salvage project in Portland, Oregon, recovered doors, windows, bathroom fixtures, framing lumber, plywood, siding, flooring, and bricks. The energy and economic summary for this project is shown in Table 5.

Table 5 Residential Salvage for Reuse

As with water and renewable energy sources, much of the current interest in lowering the embodied energy content of construction materials and increasing the recycling and reuse of products is attributable to green design efforts. The role of LEED in promoting a change in thinking about materials is outlined in Appendix G. The impact of building materials on occupant health and well-being is also an emerging area of concern and interest. There is a direct link between the selection and maintenance of building materials and indoor air quality (see Section 5). Although beyond the scope of this guide, LEED also looks at this aspect of materials use, and several reference texts provide fundamental information on design for healthy buildings. Many building products with substantially reduced heath impacts have been developed and marketed during the past 10 years.