Making a good die begins with the die designer. If the die is designed and made correctly, it will work properly and require infrequent, simple repairs at most. This section progresses from the basics to more advanced concepts that all diemakers and designers use frequently. Thus it serves as a source of information to solve problems for the apprentice and trainee, as well as those with decades in the trade.

Systems of Length, Area, and Force measurement

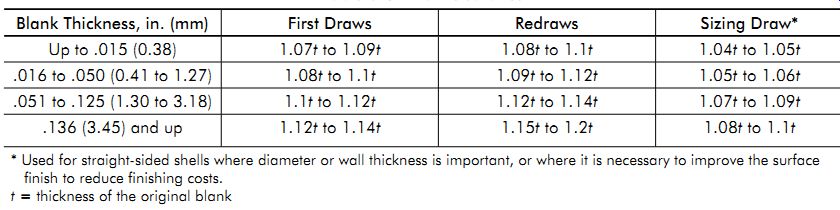

In North America, many shops still carry out engineering calculations for stampings using measurements based on the inch for length and thickness. Shear or yield strengths are based on pounds per square inch (psi). Usually, the press force in short tons is based on 2,000 lb.

The metric system is in standard use through out most of the world. Metric pressworking linear and area measurements are in terms of the meter, centimeter, and millimeter. Pressworking forces in metric tons based on 1,000 kilograms are common in Asia. However, most of the metric world uses the kilo-Newton (kN) or mega-Newton (MN). The preferred metric unit for material strength is the kilo-Pascal (kPa) or mega-Pascal (MPa).

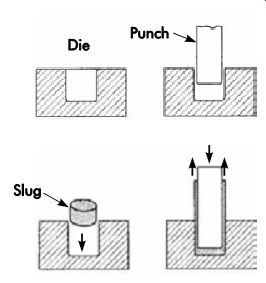

Simple die piercing

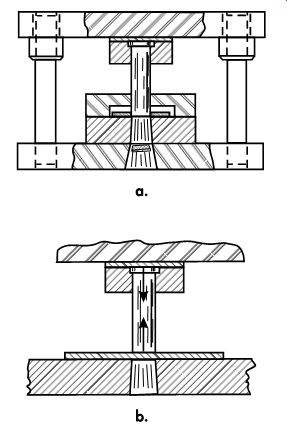

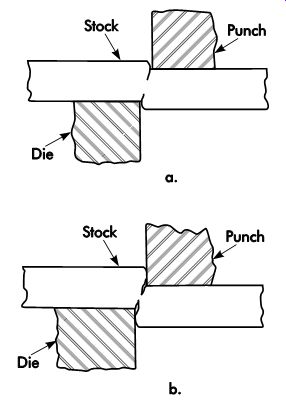

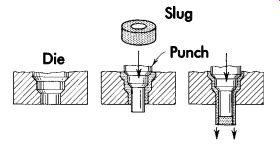

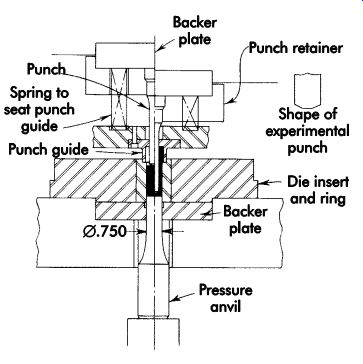

FIG. 1 illustrates a sectional view of a simple die for piercing a hole in a part. Such dies may have several punches. In addition, a cut-off shearing operation may be included if the die is fed with strip or coil stock. On contact with the stock, the punch compresses slightly, as shown in FIG. 1b. The punch is fastened to the upper die shoe by means of a retainer with a hardened backing plate. A slug can be seen falling through the lower die shoe. On the upstroke of the press, the stock is stripped from the punch by a simple fixed or tunnel stripper.

Die-cutting operations

Cutting, which includes shearing, is one of the most common pressworking operations. A single formed stamping, such as a sieve or automobile inner door, has many holes, all of which are produced by cutting operations.

FIG. 1. (a) Sectional view of a cutting die for producing round holes; (b) the

punch is compressed after making initial contact with the stock.

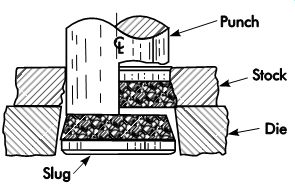

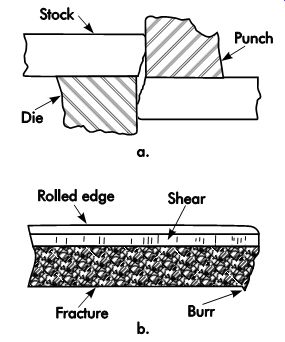

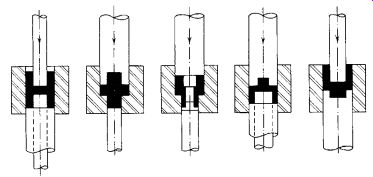

Cutting operations essentially are a controlled process of plastic deformation or yielding of the material, leading to fracture. Both tensile and compressive strains are involved. Bending or distortion of the scrap metal trimmed away and metal cut out by the punch may occur. Stretching beyond the elastic limit occurs, then plastic deformation, reduction in area and, finally, fracturing starts through cleavage planes in the reduced area and becomes complete. FIG. 2 illustrates a sectional view of a successful hole cutting operation.

The cutting of metal between die components is a shearing process in which metal is stressed in shear between two cutting edges to the point of fracture, or beyond its ultimate strength.

Clearance

There are general rules governing the amount of clearance between the punch and die. The clearance amount varies as the type of material and thickness varies. Clearance normally is expressed as a percentage of stock thickness per side. Once a clearance has been determined, it is critical that it be maintained when the punch and die are made.

For mild steel, the clearance per side varies between 5-12% of stock thickness. Soft material such as aluminum, brass, and draw-quality, cold rolled steels generally run best between 9-11% per side. Low-carbon, cold-rolled and hot-rolled, pickled and oiled steels, CDA 110 copper, and hardened brass tend to run best at 12 or 13% per side. Higher-carbon steel and annealed stainless steel run best at 14% per side. Hardened materials require additional punch-to-die clearance.

Optimizing the amount of die clearance to best suit the material being cut may require some experimentation to minimize an uneven fractured edge condition. By increasing clearance, within reasonable limits, cutting force is lowered. This extends tool life and increases the number of parts produced before the tool requires sharpening. A limiting factor is burr height and taper permitted, as the size may be out of tolerance.

Insufficient Clearance

FIG. 2. Section view of a successful hole-cutting operation involving normal

clearances. Note that both the cut edge and slug have one-third of metal

thickness as a sheared edge shear and two-thirds fracture typical of common

die stamping operations.

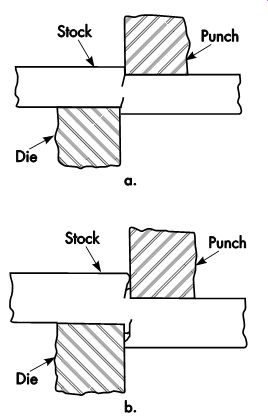

FIG. 3. (a) Cutting with insufficient clearance. (b) As fracture continues,

rough tearing occurs and the fracture paths will not meet.

FIG. 4. (a) Insufficient clearance results in a double fracture or breakage

condition. (b) Appearance of a cut edge with a double-breakage condition.

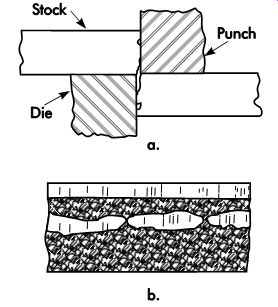

FIG. 5. (a) Start of punch penetration and fracture with a relatively large

punch-to-die clearance. (b) The fracture paths will meet evenly.

In general, tight clearances will result in holes having a high ratio of shear or burnish to fracture, and less taper at the expense of accelerated tooling wear. The fracture, which starts from each side, may not meet evenly and may leave a ragged edge, as shown in FIGs. 3 and 4. One or more sharp projections may result. Essential indicators for the diemaker are secondary shiny areas on the inside of the hole and/or slug and a rough, torn fracture. The die may burnish the torn peaks of the fracture.

Generally, tight clearances in the 3-5% per side range result in:

• parts with less taper on the cut edge;

• fewer tendencies for the slug to be pulled from the die opening;

• higher cutting forces, and

• a tendency to have double breakage problems, especially with thick materials.

As larger clearances in the 7-25% range are used, the result is often:

• longer punch and die life between resharpening;

• a need to use a means to ensure against slug pulling;

• lower cutting forces;

• avoidance of double breakage, and

• greater edge taper and more burr height.

Double-Breakage Solutions

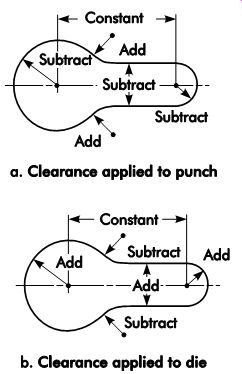

Double breakage sometimes occurs when too little clearance is used. The solution usually requires increasing the punch-to-die clearance. Making the punch smaller is frequently the solution. This will maintain both the size of the hole and part. There will be an increase in the taper of the fracture. The cutting action is shown in FIG. 5.

Clearances of 12-15% per side may be required to eliminate double-breakage problems in soft steels.

In some thick blanks, 25% per side is occasionally necessary. The cut edges may have a pronounced taper in the fractured portion of the cut edge. Die roll and burr height also may be more pronounced.

These edge conditions, shown in FIG. 5b, may be acceptable for many applications.

If the clearance is large, higher than normal forces may be required. The hole's cut edge may have a pronounced die roll, taper, and burr height (see FIG. 6). Large clearances also result in high lateral forces on the punch and die, which can shorten tool life.

Applying Clearances to Irregularly Shaped Blanks

FIG. 7 illustrates how to apply clearances to obtain the correct sizes of holes or blanks.

When the metal punched out is the functional part, and the metal around the opening is scrap, the die is made to the desired part size and the clearance is subtracted from (applied to) the punch size as shown in FIG. 7a. Another simple example would be the outside diameter of a common flat washer. When the slug is discarded and the punched opening is functional, the required clearance is applied (added) to the die opening as shown in FIG. 7b.

Center of pressure

If the contour to be blanked is irregularly shaped, the summation of shearing forces on one side of the center of the ram may greatly exceed the forces on the other side. Such irregularity results in a bending moment in the press ram and undesirable deflections and misalignment.

For critical work, such as fine blanking, it is necessary to find a point about which the summation of shearing forces will be symmetrical.

This point is called the center of pressure, and is the center of gravity of the line that is the perimeter of the blank. Note that this is not the center of gravity of the area. The press tool is designed so that its center of pressure will be on the central axis of the press ram when the tool is mounted. If this is not possible, it may be feasible to offset the tool in the press to achieve the same goal.

The use of CAD provides many methods for locating the center of an irregular area. If it is used when designing the part, the center of pressure (not center of area) can be easily located.

FIG. 6. (a) Completion of punch penetration and fracture with a generous

punch-to-die clearance. (b) View of a cut edge with large punch-to-die clearances.

FIG. 7. How to apply clearances to irregularly shaped holes.

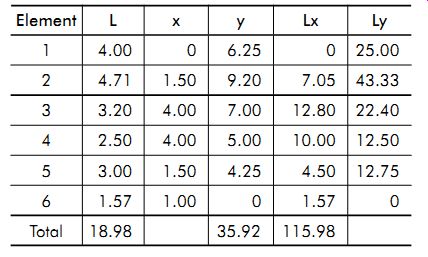

Mathematical Calculation

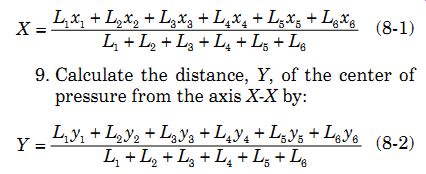

The center of pressure may be precisely deter mined by the following procedure:

1. Draw an outline of the actual cutting edges, as indicated in FIG. 8.

2. Draw axes X-X and Y-Y at right angles in a convenient position. If the figure is sym metrical about a line, let this line be one of the axes. The center of pressure will, in this case, be somewhere on the latter axis.

3. Divide the cutting edges into line elements, straight lines, arcs, etc., and number each as 1, 2, 3, etc.

4. Find the length, L1, L2, L3, etc., of these elements.

5. Find the center of gravity of these elements.

Do not confuse the center of gravity of the lines with the center of gravity of the area enclosed by the lines.

6. Find the distance, x1, of the center of gravity of the first element from the axis Y-Y, x2 of the second, etc.

7. Find the distance, x1, of the center of gravity of the first element from the axis X-X, y2 of the second, etc.

8. Calculate the distance, X, of the center of pressure, C, from the axis Y-Y by:

(1)

9. Calculate the distance, Y, of the center of pressure from the axis X-X by:

(2)

In FIG. 8, the elements are shown and numbered 1, 2, 3, etc. The length of 1 is obtained directly from the dimensions. It has a value of

4. The center of gravity is evidently at the geo metrical center of the line. Therefore:

x1

= 0 and y1

= 4.25 + 4/2

For the second element, x2 is 1.5. The value of y2 is found from:

CG = 2r/p (8-3) where:

CG = center of gravity

r = radius of the element, in. (mm)

To find the requirements for line 3 in FIG. 8, it is necessary to solve the hypotenuse of the right triangle. The requirements of the other elements are found in a similar manner. All values are entered in TBL. 1. These values then are substituted in Equations 1 and 2.

The center of pressure, C, is therefore located as indicated in FIG. 8.

It should be noted that most computer-aided design (CAD) software can determine feature characteristics of mass, weight, perimeter, and centroids, as well as rectangular and polar moments of inertia. This process can be accomplished within seconds when material density is specified.

TBL. 1. Values for elements shown in FIG. 8

Wire Method of Location

The center of pressure of a blank contour may be located mathematically, but it is a tedious computation. Normally, locating the center of pressure to within .50 in. (12.7 mm) of the true mathematical location is sufficient.

One simple procedure accurate within such limits is to bend a soft wire to the blank con tour. By balancing this frame across a pencil, in two coordinates, the intersection of the two axes of balance will locate the desired point. The calculated offset should be made in the die design for critical work.

Forces

The force required to cut through stock in creases with the ultimate tensile strength of the material. Die cutting requires less energy than parting metal by tensile failure. There is no absolute relationship between tensile strength and shear strength. Typically, shear strength is 60-80% of ultimate tensile strength.

Generally, the ultimate tensile strength of the material, which is used to calculate the cutting forces based on the area of material cut, provides a substantial safety factor. For example, AISI SAE 1010 cold-rolled steel has an approximate ultimate tensile strength of 56,000 psi (386 MPa) and shear strength of 42,000 psi (290 MPa). The shear strength of the material increases due to the fast strain rates encountered in high-speed pressworking. The ultimate strength provides the safety factor in such cases.

The die designer or engineer must calculate force requirements to determine the size and type of press required. An assumption that the pressroom can somehow fit a new job into an existing press can be a foolish blunder.

The length of cut, material thickness, and shear strength are calculation entry items in CAD software. Most can automatically calculate tonnage if all of the correct data is entered.

Determining Length of Cut

To calculate the force required for cutting or shearing materials, the actual total length of cut is required. The dimensions printed on the part provide a starting point. For progressive die work, all pilot holes and work done to cut the carrier strip must be included.

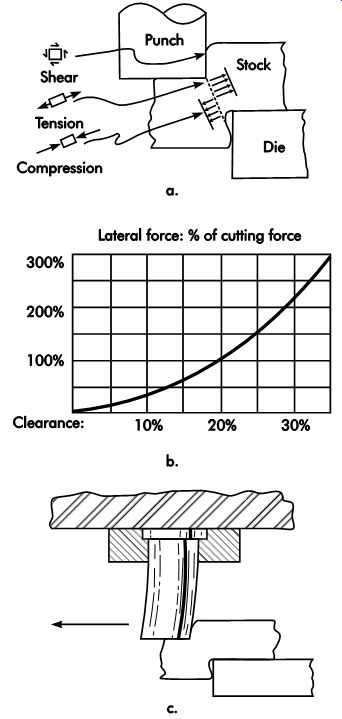

FIG. 9. (a) Shear, tensile, and compressive forces occur during the cutting

process; (b) as punch-to-die clearance increases, the lateral force, or the

side thrust, rapidly increases; (c) as side thrust increases, the cutting

clearance may increase, leading to greater side thrust or lateral forces,

and potential tool failure.

Determining Theoretical Peak Cutting Force

To determine the theoretical peak cutting force, multiply the total length of cut by the stock thickness to obtain the area of material cut. Then, multiply the total area of cut by the shear strength of the material. Equation 8-4 is useful for calculating cutting forces. Making no allowance for shear angles or timing of entry provides a safety factor.

Fs

= L × t × Ss

( 4) where:

Fs = force required to shear in the same sys tem of units as L, t, and S, lbf (kN) L = length of cut, in. (mm) t = thickness of material, in. (mm) Ss

= shear strength of the material as defined by ASTM tests

Stripping Forces

A properly designed tool needs to have a method for holding the work while the punch is pulled back through the material. This strip ping process can be by either a fixed-bridge or spring-loaded stripper. Thinner material requires a spring-loaded stripper because the material lacks the strength to prevent deformation when the punch is withdrawn from a hole.

The force required to strip the stock from a punch is difficult to determine with accuracy since it is influenced by the type of metal being cut, area of metal in contact with the punch, punch-to-die clearance, punch sharpness of the stripper spring position with respect to the punch, and numerous other factors. The following rough empirical equation is used for approximations:

F = L × T × 1.5 (8-5) where:

F = stripping force, ton L = length of cut, in.

T = material thickness, in.

When using metric units:

F × L × T × 20,600 (6)

where:

F = stripping force, kN

L = length of cut, mm

T = material thickness, mm

Press Tonnage

Press tonnage is determined by the sum of all the forces required to cut and form the part.

Practical experience with presses equipped with tonnage monitors shows close agreement between calculated versus measured values. In many cases, the stripping force must be added to the cutting force if a spring-loaded stripper is used because the springs must be compressed while cutting the material. Likewise, any spring pressure for forming, draw pads, etc., will have to be added. Using fixed (or tunnel) strippers will keep the press load to a minimum, but these devices will not control the stock as well as spring-loaded strippers.

Side-thrust or Lateral Forces

FIG. 9a illustrates the shear, tensile, and compressive forces that occur during the cutting process. The amount of lateral force varies with the cutting clearance and material.

For round and symmetrical holes, the lateral forces balance out. However, the die must be sufficiently strong to withstand high spreading forces. For notching, shearing, and other unbalanced operations, the alignment system of the die must not allow excessive deflections to occur.

Side-thrust or lateral force can result in excessive deflections of die components, such as punches, heel blocks, and guide pins. As lateral deflection occurs, clearances increase.

The lateral pressure can exceed the press force by a factor of three or more, due to a wedge-like, mechanical advantage. If not carefully controlled, the resulting misalignment can damage the tooling and produce scrap parts.

Effect of Die Clearance on Lateral Forces

Equation 7 gives an approximation of the side-thrust or lateral force generated when cut ting or shearing. When applying this equation, adjustments for the type of material and die conditions must be made. FIG. 9a shows that cutting operations involve some bending. The graph in FIG. 9b is based on Equation 7.

( 7)

where:

C = clearance, in. (mm)

FH = side thrust, lbf (kN)

T = material thickness, in. (mm)

P = penetration, typically 0.33 × T

FV = cutting force, lbf (kN)

Excessive clearances and dull die steels can result in extraordinarily large side thrusts. In severe cases, the side-thrust or lateral force can be so great that the die may shatter due to extreme pressures and interference of die components.

The function of die alignment system components, such as guide pins and heel blocks, is to limit deflections due to side thrusts to acceptable values. FIGs. 9b and c illustrate how side thrusts can cause punch deflection. Punch deflection increases the die clearance, thus leading to greater lateral forces.

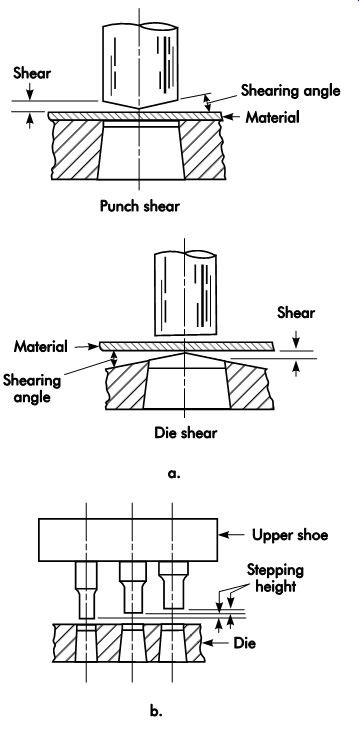

Reducing Cutting Forces

By their nature, cutting operations are characterized by high forces exerted for short periods. Sometimes it is desirable to reduce the magnitude of the force and spread it over a longer portion of the press stroke. Punch contours of large perimeter or many smaller punches frequently will result in tonnage requirements beyond the capacity of an available press. In addition, whenever abnormally high tonnage requirements are concentrated in a small area, the likelihood of design difficulties and outright tool failure increases.

Two methods generally reduce cutting forces and smooth the shock impact of heavy loads.

(Keep in mind that during a piercing operation with proper clearance, complete fracture occurs when the punch has penetrated one-third of the material's thickness.)

1. By adjusting the height of the punches so they differ in length by one-third of the material's thickness, they can cut in sequence rather than all at once. Using three punches of the same diameter and stepped properly, only one-third of the tonnage required to punch all three simultaneously is used.

2. Adding shear to the die or punch equal to one-third of the material's thickness reduces the tonnage required by 50% for the area being cut with shear applied. Note that shear should be applied to the die member (punch or die) that contacts the scrap. As a result, the deformation due to the shear angles will have little effect on the part (FIG. 10).

In piercing, the tool is designed so the direction of shear angles is generally such that the cut proceeds from the outer extremities of the contour to ward the center. This avoids stretching the material before it is cut free. Timing can be important to re duce the snap-through that can damage the press.

Limiting factors in how much timing can be used to reduce tonnage requirements include:

• the allowable tonnage as a function of the distance above the bottom of the press stroke, and

• the allowable loss of flywheel energy per stroke.

FIG. 10. Three methods to reduce cutting forces.

Analysis of Snap-through Forces

The loud boom that characterizes a snap through problem when cutting metal directly results from the sudden release of potential energy stored in press and die members as strains or deflection occur. The deflection is a normal result of the pressure required to cut through the material. In extreme cases, the energy released can damage the press. The press connection (the attachment point of the pitman to the slide) is easily damaged by the reverse load generated by snap-through. As a rule, presses are not designed to withstand reverse loading of more than 10%, and the shock may result in die components working loose.

In timing punch entry or die shear, care must be taken to provide a gradual release of developed tonnage. The shock normally is not generated by the impact of the punches on the stock. In fact, when the punches first contact the stock, the initial work is done by the kinetic energy of the slide. To complete the cut, energy must be supplied by the flywheel. As this occurs, the press members deflect. An analysis of the quantity of energy involved will show why a gradual reduction in cutting pressure before snap-through is important.

The magnitude of actual energy released increases as the square of the actual tonnage developed at the instant of final breakthrough.

The actual energy is given by:

( 8) where:

E × 166.7 = energy, ft-lbf (1 ft-lbf = 1.356 J)

F = pressure at moment of breakthrough, tons

D = amount of total deflection, in.

or

E × 9.807 = energy, J (1 J = .738 ft-lbf)

F = pressure at moment of breakthrough, metric tons (kgf × 1,000)

D = amount of total deflection, mm

For example, if 400 tons (362.8 t), which resulted in .080 in. (2.03 mm) total deflection, were required to cut through a thick steel blank, the energy released at snap-through would be 2,667 ft-lbf (3,616 J).

If careful timing of the cutting sequence results in a gradual reduction of tonnage at the instant of snap-through so that only 200 tons (181.4 t) are released, the reduction in shock and noise is dramatic. Half the tonnage would produce half as much deflection, or .04 in. (1.0 mm). The resultant snap-through energy is only 667 ft-lbf (904 J), or one-fourth of the former value.

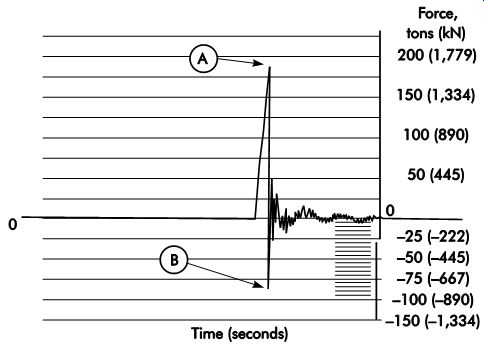

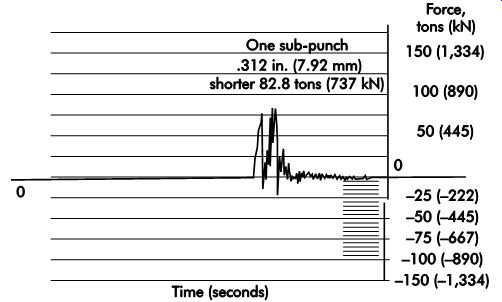

Example: snap-through reduction by die timing. FIG. 11 illustrates a waveform resulting from an operation to punch two 1.625-in. (41.28-mm) holes and parting a chain side bar from fine-grained AISI-SAE 1039 steel. The steel was .50 in. (12.7 mm) thick by 3.00 in. (76.2 mm) wide. A 300-ton (2.7-N) straight-side press was used for this operation. The allowable reverse load is 30 tons (267 kN). Point A on FIG. 11 illustrates a peak load of 191 tons (1.7 N), which was also displayed on the tonnage meter. This is well within press capacity. In this case, the reverse load, B, was 87 tons (774 kN), which is nearly three times the allowable amount. The die was immediately taken to the repair bench and one punch was shortened .312 in. (7.92 mm). FIG. 12 illustrates the improvement achieved by modifying the tool. The peak tonnage was reduced to 82.8 tons (737 kN), which is less than half the initial value. The reverse load was reduced to 22 tons (196 kN), or about one-fourth of the former value. This is keeping with the square law formula for the energy suddenly released.

FIG. 11. Actual waveform signature of a combined piercing and cut-off operation

having excessive snap-through or reverse load.

FIG. 12. Waveform signature after adding timing and balanced shear.

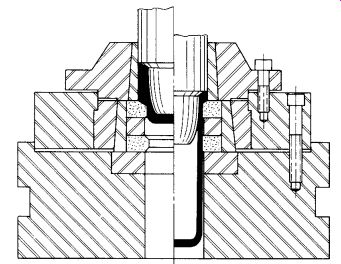

Ball-Lock punches

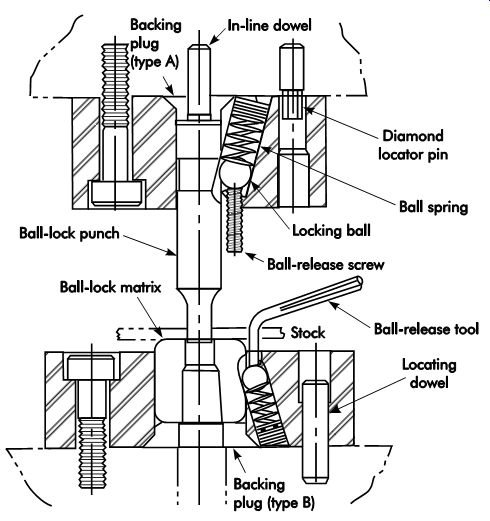

The ball-lock concept of retention and quick punch replacement has been in use for many years. Style changes on a stamping can be made quickly, without removing the die from the press, simply by pulling or adding punches. In the event that a fragile punch needs replacement during the run, the ball-lock system of punch retention makes this operation quick and easy. FIG. 13 illustrates the ball-lock retention system used to positively lock both a punch and die button (matrix) in a die. The ball-lock retention is an adaptation of the wedge principle. Once correctly seated, the ball locks the punch in position both vertically and radially, while permitting rapid replacement of the punches in the die assembly.

To install a ball-lock punch, it is inserted into the retainer and twisted until the spring-loaded ball drops into position, locking the punch. The punch is removed by depressing the ball with a ball-release tool inserted into the hole in the retainer provided for this purpose. This action frees the punch so it can be pulled out of the retainer.

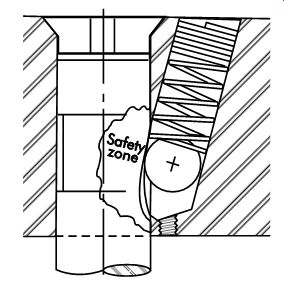

Some retainers use a ball-release screw, as illustrated in FIG. 13. To ensure correct location and certain retention, it is important that the ball-locking condition be correct. There can be a problem if the ball is either too low or high in the teardrop-shaped ball seat. This problem can be avoided by always using the correct retainer specified for a given punch and the proper size replacement ball, as shown in FIG. 14.

FIG. 13. The ball-lock retention system used to positively lock both a punch

and die button (matrix) while permit ting rapid replacement of these components

in the die assembly.

FIG. 14. The ball must be properly seated in the teardrop-shaped pocket

in the punch.

FIG. 15. A metal beam supported at two points, with a load applied at the

midpoint, resulting in bending or deflection.

Bending

Bending frequently is used to increase the rigidity of shaped parts in pressworking operations. The simplest bending operation is air bending, so called because the die does not touch the outside of the bend radius. The part to be bent is supported on each side of the bend and force is applied to a forming punch in the center.

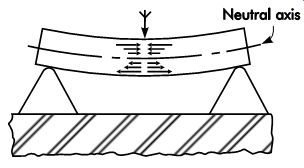

FIG. 15 illustrates a metal beam supported at two points, with a load applied at the midpoint.

The load produces compressive stresses in the material on the inside of the bend (above the neutral axis) as it is forced into compression. Tensile stress or stretching occurs on the outside of the bend (below the neutral axis). To produce a bend in a finished part, the yield point of the material must be exceeded. If the bending force applied does not exceed the yield strength of the material, the beam will return to its original shape on removal of the load, as shown in FIG. 16. However, if the stress exceeds the material's yield strength, the beam will retain a permanent set or bend when the load is removed, as illustrated in FIG. 17.

The goal of the process is to bend the material the correct amount. Springback, or elastic recovery, will occur until residual stresses in the bend are equal to the stiffness of the material. This concept is illustrated in FIG. 18.

Not all of the material in the bend zone is stressed equally. The material in the inner and outer surfaces is stressed the most, and the stress gradually diminishes toward a neutral axis be tween the two surfaces. At that point, the stress is zero and there is no length change.

FIG. 16. If the applied force does not exceed the material's yield strength,

the beam returns to its undeflected shape.

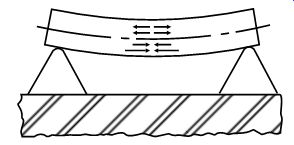

FIG. 17. Simple beam deflection occurs in air bending. If the applied force

exceeds the material's yield strength, the beam retains a permanent set or

bend when the load is removed.

FIG. 18. Springback occurs until the residual stress forces are balanced

by the stiffness of the material.

Bend Allowances

The exact length of a bend is determined by trial and error. The assumed neutral axis varies depending on the bending method used, location in the bend, and type of stock to be bent.

The direction of grain in a steel strip relative to the bend radius has a slight effect on the length of metal required to make a bend. Bending with the grain allows the metal to stretch more easily than bending against the grain. However, this results in a weaker stamping.

Bend allowances depend on the physical properties of the metal, such as its tensile and yield strength and ductility.

The exact bend allowance is the arc length of the true-neutral axis of the bend (metal is stretched above the neutral axis; below it, metal is compressed). The neutral axis only can be approximated. Many manufacturers assume the neutral axis is 1/3-stock thickness from the inside radius of the bend for inside radii of less than twice the stock thickness. For an inside radii of two times the stock thickness or greater, the neutral axis is assumed to be 1/2-stock thickness from the inside radii. One reason for the requirement of relatively less metal to make a tight bend is that the sharp radius tends to be drawn or stretched slightly.

Many experts believe that the location of the true-neutral axis from the inside radius varies from 0.2-0.5 times the stock thickness. An important factor that determines the neutral axis is how the bend is accomplished. Less metal is required for a bend made by a tightly wiped flange than for an air bend on a press brake. Wiping the flange tends to stretch the metal.

Equations

For 90° bends, the coefficient of 1.57 (the number of radians in 90°) determines the assumed amount of metal necessary to make a bend, which is multiplied by the assumed neutral axis. For bends that are not exactly 90°, it is necessary to multiply the number of degrees of bend by 0.0175 (the number of radians in 1°), and to substitute the result for the coefficient 1.57. The actual neutral axis will vary from the stock centerline to 20% from the inside of the bend for sharp bends.

Springback or elastic recovery

Stiffness is a function of the material's modulus of elasticity. This explains why some materials, such as mild steel with a high modulus of elasticity (as compared to tensile strength), spring back less than materials with a lower modulus. How ever, some materials do have comparable tensile strength, such as hard aluminum alloys.

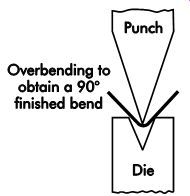

Some springback occurs whenever metals are formed. Springback is caused by the residual stress that is a result of cold-working metals. For example, in a simple bend, residual compressive stress remains on the inside of the bend, while residual tensile stress is present on the outside radius of the bend. When bending pressure is re leased, metal springs back until residual-stress forces are balanced by the material's stiffness, which resists further strain. The most common method used to compensate for springback is overbending, in which material is bent a sufficient amount beyond the desired angle and allowed to spring back to the desired angle after elastic recovery occurs. Because of the uncertainty of the exact location of the neutral axis, it is best to use trial-and-error methods when developing close-tolerance stampings.

Many complex factors determine the amount of springback that will occur in a given operation. Because the exact amount of springback is difficult to predict, data for a specific material and forming method is often developed under actual production conditions to aid process control and future product development. If the die designer and builder fail to include correct springback compensation in the die, correction will need to be done by the repair facility of the press shop that uses the tool.

Factors Affecting Springback

Some factors that increase springback are:

• higher material strength;

• thinner material;

• lower modulus of elasticity;

• larger die radius;

• greater wipe-steel clearance;

• less irregularity in part outline, and

• flatter surface contour of the part.

If a flanged part is irregular compared with either the outline or surface contour, the spring back will be slight. The springback for large wipe steel clearances can be several degrees or more.

Air Bending

Press-brake tooling for air bending (FIG. 19) is quite simple. Air bending is one of the most common press-brake operations. It requires minimum tonnage for the work performed. Exact repeatability of ram travel is required to maintain close repeatability of the bend angle. The amount of over-travel is determined experimentally to compensate for springback.

causes of Bend-angle Variation There are several causes of bend-angle variation when bending materials in pressworking operations. These include:

• changes in stock yield strength;

• variation in stock thickness;

• machine variations due to temperate changes; and

• machine deflection, especially in long press brake-bending operations.

Compensation for change of any condition that affects the bend angle may require adjustment of the ram travel. With press-brake-bed deflection, shimming also may be required. In addition, shims may be required to correct for additional machine deflection. Some press-brake designs have automatic deflection-compensating devices, such as hydraulic cylinders built into the bed. If high force is required in press-brake bending because of an increase in stock thickness or hardness, a simple ram adjustment may not be enough to correct the problem.

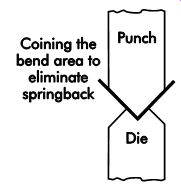

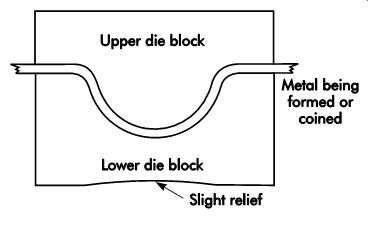

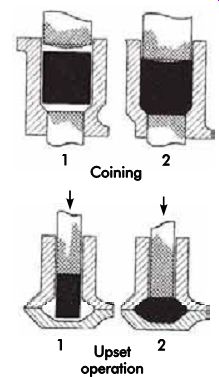

Coining

Coining, or bottom bending, has the advantage of producing sharp, accurate bends with less sensitivity to material conditions than air bending. The disadvantages of coining compared to air bending are high force requirements and accelerated die wear.

FIG. 20 illustrates a press-brake die de signed to coin the bend for a precise angle. This coining action eliminates the root causes of springback, including the tensile and compressive residual stresses on opposite sides of the bend. Coining action is accomplished with pres sure sufficient to subject the metal to the yield point in the bend area.

FIG. 19. Simple tooling of the type used to air bend sheet-metal parts in

press brakes. The upper die is lowered a little and a hit is made until the

desired bend angle is obtained.

FIG. 20. Coining the bend requires high tonnage to obtain a sharp, accurate

bend.

FIG. 21. Sectional view of a wipe-flanging die.

FIG. 22. Close-up view of the point of flange steel contact on the bend

radius in a wipe-flanging die.

The tonnage required for coining might be five to 10 times that required for simple air bending. Higher forces increase machine deflection.

Air-bending jobs that produce acceptable bend angles throughout the entire length of the bend may need shimming if coining is required. The amount of machine deflection increases approximately in proportion to the developed tonnage.

Wipe Bending

It is often not feasible to use V-bending tooling for bending. V-bending is popular for press-brake work. The tooling is simple and can accomplish a variety of work. Usually, only a single bend occurs per stroke. Accurate work requires that each previous step be accurate. Skilled and experienced operators are required. A limiting factor is the cost of press-brake work, because of low throughput and the high skill required for accuracy.

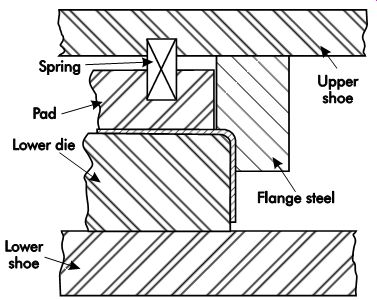

Wipe Flanging and Springback Control

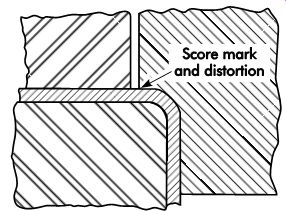

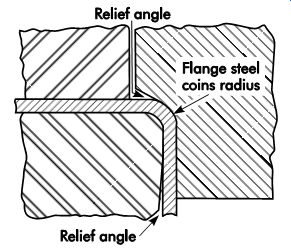

FIG. 21 illustrates a sectional view through a wipe-flanging die. In this design, the flange steel attached to the upper die wipes the metal around the lower die. A popular method for controlling springback is to coin the top of the bend with the flange steel. A disadvantage is the limited spring back compensation that can result in a distorted bend-angle condition. A close-up view of this is shown in FIG. 22. The top thickness of the bend can be squeezed beyond the material's yield point by careful adjustment of the die's shut height. Only the top portion of the bend is coined. This can result in a score mark that might weaken the stamping and extrusion of the metal being coined.

If excessive coining pressures are applied, the metal at the top of the bend will extrude and result in a weak and distorted bend condition. An improved flanging method relieves the radius in flange steel so it does not contact the top of the bend radius. One way to do this is to relieve the flange steel at an angle approximately 20° tangent to the radius. Another method is to machine the flange steel to a radius that is larger than the out side of the bend. The flange steel is positioned so the tightest point is 45-60° beyond the top of the radius. The side of the form steel is relieved 5° or more to permit the material to be overbent (FIG. 23). This method is more effective than coining the top of the bend. In addition, the improved bending process is not as sensitive to variation from press adjustments and material conditions.

FIG. 23. The side of the radius is coined and a relief angle is provided

in the lower die steel in this improved springback control method.

FIG. 24. A Ready bender makes initial contact with the stock. As the die

closes, the bender clamps and bends the stock.

FIG. 25. A Ready bender bends the stock through rotary action of the circular

member.

FIG. 26. A Ready bender overbends the stock at the bottom of the stroke

to provide for springback.

Rotary-action die Bending

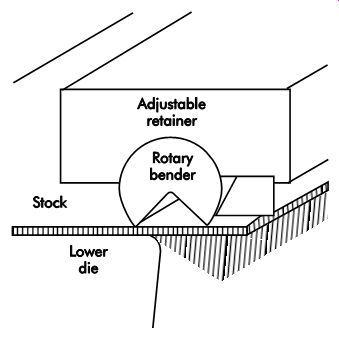

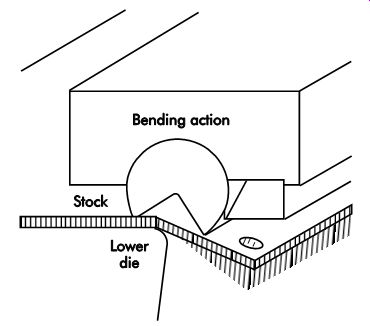

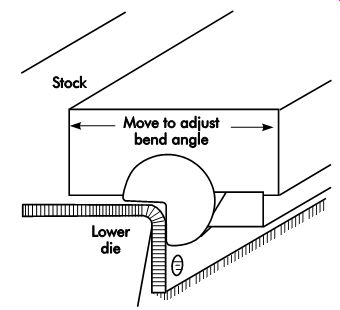

A patented rotary-action bender known as the Ready™ bender combines the low tonnage requirements of air bending with the accuracy and multiple-bend capabilities of wipe-flange tooling. FIG. 24 illustrates a Ready bender making initial contact with the stock. As the up per die travels down, the stock is clamped and bent by the rotating bender. As the die closes, the rotary-bending action progresses (FIG. 25). An optional relief angle in the lower die permits the rotary member to overbend the stock at the bottom of the stroke to provide springback control (FIG. 26).

Rotary-action benders can bend angles up to 120°. The rotary member usually is made of heat-treated tool steel for long wear. The bending pressure is typically 50-80% less than that required for conventional wipe bending. The lower pressure permits many types of pre-painted materials to be fabricated without damaging the finish. Rotary benders also can be constructed of nonmetallic materials, such as hard thermoplastics, for work with prefinished materials.

Fine Adjustment of Bend Angle

On conventional wipe-flange tooling, bend-angle adjustment is usually made by adjusting the flange steel up or down with shimming. In the case of rotary-action benders, the bend angle is adjusted by moving the assembly containing the bender along the horizontal plane relative to the lower-die member or anvil. Attempts to obtain a tighter bend by excessive lowering of the press shut-height can result in tooling damage.

Forming

A large percentage of stampings used in the manufacturing of products require some forming operations. Some are simple forms that require tools of low cost and conventional design. Others may have complicated forms, which require dies that produce multiple forms in one stroke of the press. Some stampings may require several dies to produce the shapes and forms required.

Forming dies, often considered in the same class with bending, are tools that form or bend the blank along a curved, instead of straight, axis.

There is little stretching or compressing of the material. The internal movement or plastic flow of the material is localized and has little or no effect on the total area or thickness of material.

A first consideration in analyzing a stamping is to select the class of die to perform the work. Next, determine the number of stampings required, which will help identify the forming process to be used.

A forming die may be designed in many ways and produce the same results. The tool that is cheapest and has the simplest design may not always be best because it may not produce the stamping to the drawing specifications. Where limited production is required, press-brake tooling often can be used.

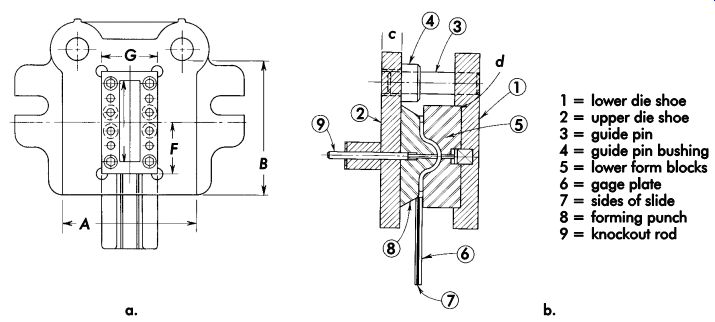

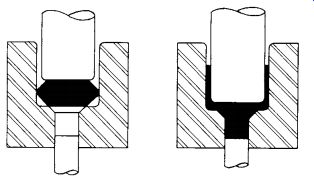

Solid forming dies

The solid forming die is of simple construction and design. A forming die of this kind need not be mounted on a die set as shown in FIG. 27. A die set can be considered because the repeatability of the setup reduces the chances for misalignment. A great deal of side pressure is exerted on the female die block, which must be considered in the design.

One option is to make the female block out of two pieces of tool steel held together by pre stressed tie rods. This is used as a safety measure in case the operator should feed a double blank or if metal of a thicker gage is used. The use of a computer-aided stress analysis program is advised to determine the areas of high tensile stress so the die blocks can be proportioned accordingly.

In some cases, a relief under the center of the female die will transfer much of the tensile strain to the more robust bottom of the female die-this is the same mechanical principle as a bridge with truss work under the roadway. Operating dies of this type in a hydraulic press is advised to limit the pressure applied to the die, especially if coining pressures are achieved.

Coining dies

FIG. 27. A set of forming blocks used without a die set.

Coining dies are useful for achieving precise forms by coining-a process for bringing the entire thickness of the metal up to the yield strength of the material. Applications for coining may include sizing bearing shell halves, but any curved stamping requiring accurate form dimensions is a candidate for coining.

Flat coining often is done to produce parts with high flatness requirements. Another application for flat coining blocks is the production of medal lions of materials varying from stainless steels to sterling silver and gold alloys. Surprisingly high forces are required to bring up all of the detail in some medallion work. Forces of 325 ksi (2,240 MPa) or higher are achieved.

Forming die design

FIG. 28. Pressure-pad-type form dies.

FIG. 28 is an example of a two-piece forming die mounted in a die set and equipped with a positive knockout. A close-fitting cutout is machined into the lower die shoe to limit shifting of the lower form detail. The form blocks are made wider than the workpiece and their height by an approximate ratio of 1:1.5. The radius being formed should be at least twice the metal thickness to avoid excessive stress concentration. A good polish on the form blocks will ensure against marring the stamping.

The punch is made of a good grade of tool steel, which is heat-treated for toughness. Grade S5 or S7 are good choices for severe work.

Consideration is given to stripping the formed part from the punch. This is accomplished by means of a knockout rod application, stripper hooks, or stripper-pin (spring) construction. It is important to consider and plan for removing the formed part. FIG. 28b shows these details and illustrates the gages necessary for locating the stamping.

The shoe is thick enough to withstand the pressure required for the forming operation. In selecting its thickness, the size, shape of the bolster, and plate of the press are considered. The A and B dimensions of the shoe, when placed over the hole of the bolster plate, should be long and wide enough to allow ample space for clamping it to the bolster plate. A die shoe made of steel will give good service and costs only a little more than cast iron. Select the diameter of the guide pins according to the working area of the shoe, or by consulting a die set manufacturer's catalog. The length of the pins should be at least .25 in. (6.4 mm) shorter than the shut height of the die, as listed on the drawing. The guide bushings may be of the shoulder type. Ball-bearing pins and bushings can be used if better accuracy and longer life than plain bushings are desired.

The upper die shoe is made to the same outer dimensions as the lower shoe. If a shank is to be used, Occupational Safety and Health Administration (OSHA) rules require toe clamps or some other means other than the shank alone to retain the die in the press.

Locate the screw and dowel holes so they will not mar the stamping. Dowel pins should be large enough in diameter to ensure correct alignment of the sections. The screws should be large enough to clamp the die-steel details to the shoes by friction. The screw- and dowel-hole locations also should locate the gage plate. Designing the gage-plate shape when designing the die blocks and then placing the screw and dowel holes accordingly accomplishes a dual purpose. It helps eliminate some of the holes required in the die blocks, as well as the work of drilling and tapping the holes and the cost of the extra screws. The blank should be fed the long way to ensure easy loading and accurate location. When blanks are fed the short way, they have a chance to twist, and the operator loses control over them. This causes a loss of time in locating the blank in the die, and can cause mis-location of the blank.

Make the gage plate so the blank will slide into the proper location for forming. When the blanks are wide and flat, provide ribs or wires to help slide the blank into the die and reduce some of the friction caused by the oil on the blank's surfaces. Design the slide long enough to prevent the operator from placing his or her fingers under the punch.

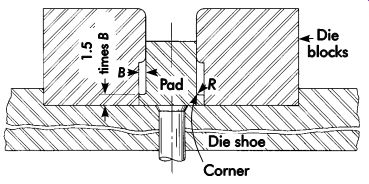

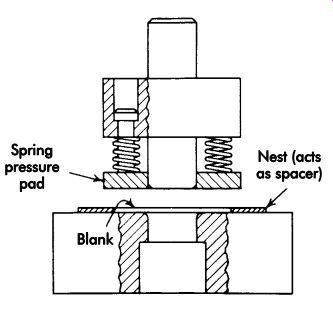

Pressure Pads

When the forming of stampings requires accuracy, dies employing pressure pads often are designed. A pressure pad helps hold the stock securely during forming and eliminates shifting of the blank. The pressure can be applied to the pad by springs or the use of an air cushion or nitrogen springs. When springs are used, they can be located directly under the pad and confined in the die shoe. They also may be located in or under the bolster plate of the press. By the use of pressure pins, which are located under the pad, and through the die shoe, pressure is applied to the pressure plate.

Pressure pins also are used with an air cushion. The construction of the pressure plate and pressure pins would be the same, except that an air cushion is substituted for the springs. When an air cushion is used, the proper amount of pressure on the pressure pad is ensured as long as the air supply is set properly. It is important that the die-setter use the correct pressure in the die setup procedure, as well as proper pin placement. A consistent pressure ensures repeatable stamping quality.

When springs are used to apply pressure to a pressure pad, spring pressure increases with the pad travel. Each fraction of an inch or millimeter of travel increases the pressure on the pad. This may cause some trouble when stamping light gage material because too much pressure may cause the metal to stretch. Care must be used to not over-compress the springs used, which can lead to loss of pressure and spring break age. Increasingly, nitrogen manifold systems or self-contained nitrogen cylinders are used as pad pressure sources.

The pressure pad is controlled in its travel be tween die blocks by retaining ledges or shoulder screws. When using the retaining ledge construction, a recess is machined into the form blocks and a corresponding shoulder is machined on the pad. The ledge shoulder should always be made strong enough to withstand the pressure applied by either springs or an air cushion. The size of the shoulder to be used varies according to the size and metal thickness of the stamping.

A good rule is to have the height of the ledge 1.5 times the width, as shown in FIG. 29. Always design pad ledges with a radius in the corner.

When using shoulder screws to control the travel of the pad, the die shoe must be thick enough to permit sufficient travel.

The pressure pad should always travel so that it extends slightly above the die blocks.

This will ensure uniform parts because pres sure locks the part between the punch and pad faces before the actual forming takes place.

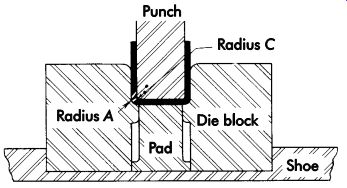

The amount of travel in the pad depends on the height of the form die. It is not always necessary to travel the full height; in many cases, half of the die's form height is sufficient. For accurate work, allow the punch to give the part a definite set at the bottom of the stroke. When a stamping must have sides square with the bottom after forming, the corner radius should be set.

This is done by designing the die blocks with the correct radius, A, shown in FIG. 30. The pres sure pad is made to match the height of the die block's radius edge. The punch radius, C, is made slightly smaller, approximately 10% less than the die-block radius.

It may be necessary to machine a slight relief angle on the side of the punch to allow slight over bending of the side being formed. This ensures that the sides of the formed part will be square with the base after forming.

FIG. 29. Pressure-pad design.

FIG. 30. Radii considerations for forming die design.

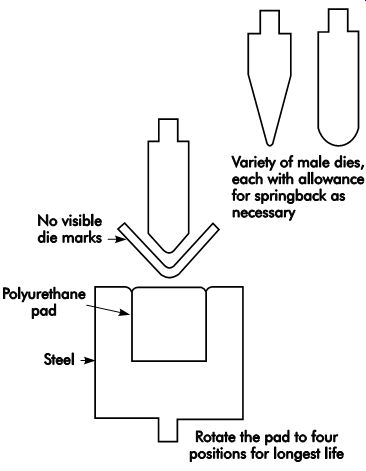

Rubber and Polyurethane

Often, a rubber or polyurethane forming die is used in press-brake operations, as illustrated in FIG. 31. This reduces tooling costs, as only the male forming punch has to be made.

This method is well adapted to forming angles channels, and radii. Another advantage is that the rubber die leaves no visible marks on the part, which is especially important when bending prefinished material.

FIG. 31. Rubber or polyurethane forming die and punches.

Embossing

In an embossing operation, a shallow surface detail is formed by displacing metal between two opposing mated tool surfaces. One surface has the depression, the other the projection. The metal is stretched slightly, rather than being compressed.

Embossing is used for various purposes, the most common being the stiffening of the bottom of a pan or container. The embossing is designed to follow the outside profile of the part. A round canister may have an embossed circle or raised grooves of various widths or panels. When a can or box is square or rectangular, embossments follow the contours. Embossments often are ribs or crosses stamped in the metal to help make a section of a blank stronger by stiffening. An embossing die can be a male and female set of lettering dies or a profile of one of various shapes.

The construction of die blocks for an embossing operation depends on the size and shape of the form, and the accuracy and flatness required. When embossing simple shapes, such as stiffening ribs, it is not necessary to strike the bottom of the relief.

The metal stretches over the punch and across the two radius edges of the die's clearance.

The female die opening has the same width of the rib or embossing punch, and a slight radius is added to the edges of the opening to allow metal to flow freely. The punch is made slightly smaller than the required metal thickness per side so that it does not strike along this area. By avoiding coining or hard marks, the pressure required to stamp the embossing is reduced and die wear is much less.

A small embossment often is used as a spot weld projection nib. Spot-welding is a process where metal is electrically welded together under controlled pressure and current. These nibs are helpful to ensure highly uniform current flow and sound spot-welds.

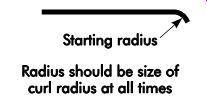

Beading and Curling

In beading and curling operations, the edges of the metal are formed into a roll or curl. This is done to strengthen the part or to produce a better looking product with a protective edge. Curls are used in the manufacturing of hinges, pots, pans, and other items. The size of the curl should be governed by the thickness of the metal; it should have a radius of at least twice the metal's thickness. To make good curls and beads, the material must be ductile; otherwise, it will not roll and will cause flaws in the metal. If the metal is too hard, the curls will become flat instead of round. If possible, the burr edge of the blank should be the inside edge of the curl. This location facilitates metal flow and helps keep the die radius from wearing or galling. In making curls and beads, a starting radius is always helpful. A starting radius is shown in FIG. 32.

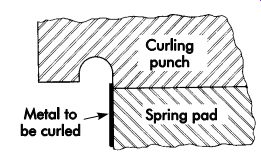

The curling radius of the die always must be smoothly polished and free of tool marks. Any groove or roughness will tend to back up the metal while it is rolling and cause defective curls.

The inside surface of the blank must be held positively in line with the inside curling radius of the punch (FIG. 33).

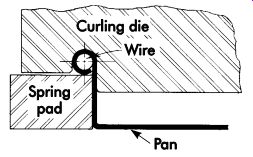

When curling or beading pots, pans, cans, or pails, wires may be rolled inside the curls. This will make them stronger. The wire is made to the contour of the pan and placed on a spring pad.

When the curling die closes, the edge of the pan is forced to curl around the wire, as shown in FIG. 34. If the wire is omitted, the tooling is much the same, except the curled edge is termed a false wire curl.

Twisters and Benders

The successful manufacturing of fans requires uniform blades formed alike and of equal weight.

A hub spider must provide a precise location for the blade attachment holes in relationship to the hub shaft insert. Steel sheeting, by the very nature of the rolling process, cannot be made with out slight variations in the way it bends with and across the rolling direction or grain of the sheet.

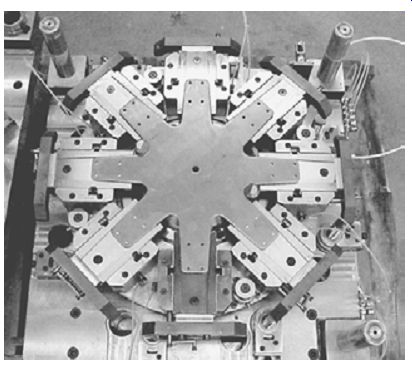

Since the spider has a critical role in the balance and overall performance of the assembled fan, it must be made with precise bend angles in spite of the variation across the steel sheet and even larger differences from coil to coil. An example of a hub spider press is shown in FIG. 35.

FIG. 32. Starting curl radius.

FIG. 33. Curling punch design.

FIG. 34. Curling die design.

FIG. 35. Plan view of lower die with fan hub to be formed in place. Note

the two locating pins that hold the part on location. Each of the spider

legs rest on one-half of a cam-actuated bending device.

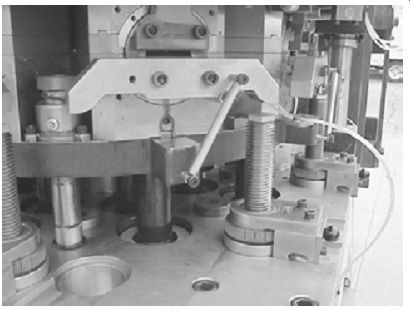

Rotary Bender operation

FIG. 36. A view of an individual spider bending station. The die is on the

bench and held partly open by eight self-contained nitrogen cylinders. (Modern

Die Systems, Inc.)

When the die closes with the flat spider in place (FIG. 36), the rotary motion of the lower and upper die begins forming. All eight of the forming stations ride on a circular plate supported by eight nitrogen cylinders and guided by four guide pins and bushings. FIG. 36 is a view of an individual spider bending station. As the die closes, the cam lever arm contacts the fine adjustment screw resulting in the rotary motion of the lower and upper die halves.

The die is operated in a hydraulic press, ensuring smooth, controlled closing. As the die closes, the plate, floating on nitrogen cylinders, descends until the lever arms meet the round contact pads on each adjustment screw. Thus, the adjustment of each screw controls the angle to which each corresponding spider leg is bent. The amount of adjustment needed for variations in material is determined by a gaging station, which feeds the output of precision dial indicators to a computer.

The computer provides a statistical process control (SPC) record and tells the operator how much adjustment is required to stay in the middle of the upper and lower statistical process control (SPC) limits.

Once a computer interface has been attached, it can be used to measure parts and adjust the tool during production using servomotors to ad just the screws. One such computerized gage with .00005-in. (1.3-um) resolution digital indicators can measure the angles of each spider leg to five decimal places faster than the operator can load and cycle the next part. This makes 100% inspection possible. The computer interface for the gage and die displays X-bar charts of the angle data for true "real-time" quality control. Thus quality discrepancies can be dealt with quickly.

Hole flanging or extruding

Hole flanging or extruding is the forming or stretching of a flange around a hole in sheet metal. The shape of the flange can vary according to part requirements. Flanges are made as countersunk, burred, or dimpled holes.

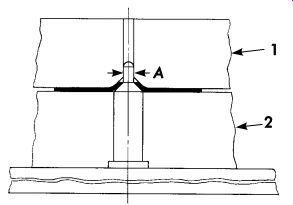

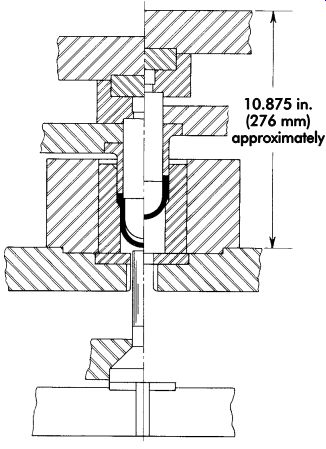

When countersunk, shaped, extruded holes are made in steel, it is necessary to coin the metal around the upper face and beveled sides to set the material. The holes also are made about .005 in. (0.13 mm) deeper than the required height of the rivet or screw head to allow for metal compression, which occurs when squeezing the rivet in place. A section of a die for this purpose is shown in FIG. 37. The hole can be pierced before it is placed in the countersinking die, or it can be formed and pierced in a single operation, depending on the required size.

As shown in FIG. 37, the sheet is placed over the pilot diameter, A, which locates it centrally in the die. The die body, 1, descends and forces the metal down around the flange surface of the punch. Spring pressure strips the part from the punch and releases the formed part from the die.

FIG. 37. A forming die used to produce countersunk holes.

FIG. 38. A die for punching and countersinking a hole.

FIG. 38 shows a two-step punch. A hole, 1, is punched in the part and metal is forced around to the countersunk shape of the die block, 2. A hole punched by this method is always somewhat smaller than the size of the hole in the finished part. Spring pressure is used to strip the finished part from the punch. A shedder pin should be provided in the piercing point of the punch to remove the slug.

Although FIGs. 37 and 8-38 show counter sunk holes formed from the bottom up, the holes can be just as easily formed from the top down, depending on the part's design requirements.

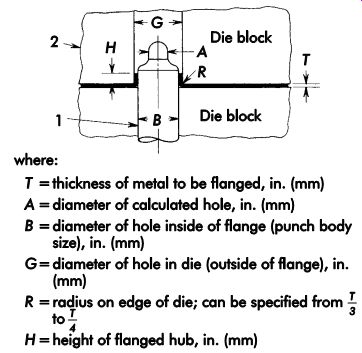

FIG. 39. Hole flange design.

90° hole flanging

The size of the pierced hole for a 90° hole flange can be calculated, but should never be used until it has been proven correct by using the same tools that will be employed in the die. To calculate the hole size, the same principles are employed as when finding a 90° bend.

When flanges are stretched more than 2-1/2 times the metal thickness in height, the wall can split. This can be prevented to some extent by burring the edge around the hole before the extruding operation. In this situation, the side of the hole with the burr is important. Coining the hole's edge is a good way to strengthen it for flanging. This is an especially attractive option in progressive die operations.

Forming a flange around a previously pierced hole at a bend angle of 90° (the most common operation) is nothing more than the formation of a stretch flange at that angle.

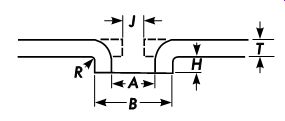

One manufacturer offers standardized flange widths (FIG. 39, dimension H) and starting hole diameters (FIG. 39, dimension J) for holes that are to be threaded. Using taps that form the metal by displacement rather than cutting the threads will result in a much stronger female thread. Following are the equations for low-carbon steel stamping stock:

when T < .045 in. (1.14 mm)

where:

B = diameter of hole inside of flange (punch body size), in. (mm)

A = diameter of calculated hole, in. (mm)

T = thickness of metal to be flanged, in. (mm)

H = height of flanged hub, in. (mm)

R = radius on edge of die, which can be specified,

J = starting hole diameter, in. (mm)

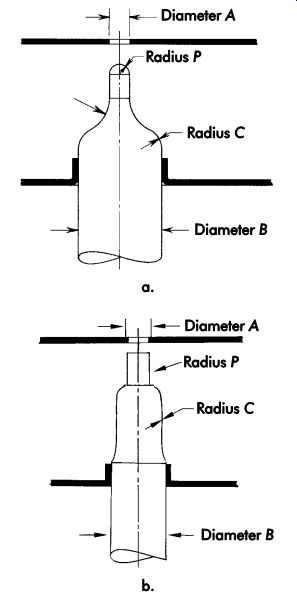

The radius, P, on the nose of the punch should be blended into the body diameter, eliminating any sharpness that could cause the metal to score as it passes over it. The radius on the body, B, or hole-sizing portion of the punch, must be as large as possible and smooth. The portion between the A and B diameters of the punch should have a radius, C, as large as possible (FIG. 40a). When using the single-station method (FIG. 40b), controlling the length of the flange is more difficult (FIG. 39, H).

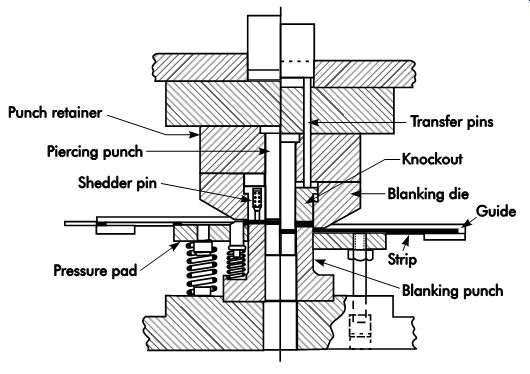

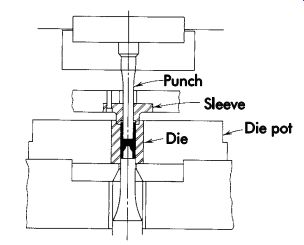

Compound dies

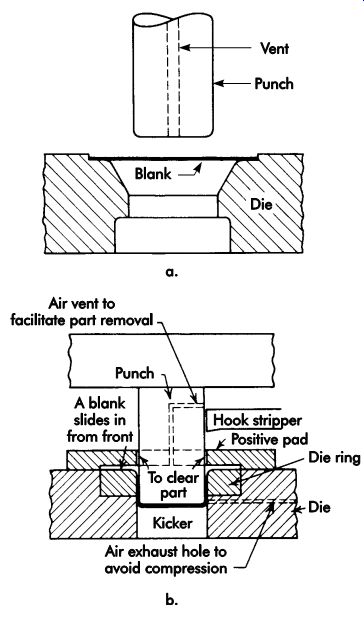

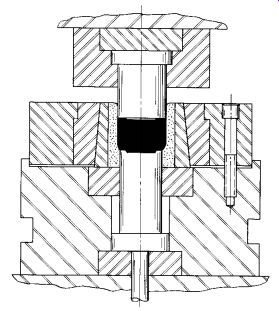

A compound die usually refers to a one-station die designed around a common vertical centerline where two or more operations are completed during a single press stroke. Usually, only cutting operations are done, such as combined blanking and piercing.

A common characteristic of compound die design is inverted construction, with the blanking die on the upper die shoe and the blanking punch on the lower die shoe. The pierced slugs fall out through the lower die shoe. The part or finished blank is retained in the female die, which is mounted on the upper shoe.

Compound Blank and Piercing Dies

Compound dies are widely used to produce pierced blanks to close dimensional and flatness tolerances. Generally, the sheet material is lifted off the blanking punch by a spring-actuated strip per, which may be provided with guides to feed the material. If hand-fed, a stop is provided to position the strip for the next stroke.

The blank normally remains in the upper die, and is usually removed by a positive knockout at the top of the press stroke. Ejection of the blank from the die by spring-loaded or positive knock out occurs at the top of the stroke. Because of this feature, the die does not require angular die clearance. Not providing angular die clearance simplifies die construction and ensures constant blank size throughout the life of the die.

A compound die for making a washer is shown in FIG. 41. The center hole is cut and outer diameter trimmed in a single die station in one press stroke. The material is .015-in. (0.38-mm) cold-rolled steel strip. A piercing punch is attached to an upper die shoe. The blanking punch is attached to a lower die shoe. In this design, the piercing punch contacts the material slightly ahead of the blanking die. The part is stripped from both the blanking die and piercing punch by a positive knockout. The blanked strip is lifted off the blanking punch by a spring-loaded pressure pad.

FIG. 40. (a) Two-station and (b) single-station flanging punch design.

FIG. 41. A compound blanking and piercing die used to produce a washer.

Dies of this type are widely used to produce accurate flat blanks.

Part removal

FIG. 42. A complex stamping is produced by a variety of forming operations,

each of which may be analyzed separately.

A potential disadvantage of compound dies is that the part must be removed from the upper die at the top of each stroke. The part usually is knocked out at the top of the stroke by means of a press-actuated knockout bar.

In the case of small parts, once knocked out of the upper die, they may be ejected by a timed blast of air. Larger parts can be removed by means of a shuttle unloader that enters the die opening as the ram ascends. The press ram normally drives the unloader; although air, hydraulic, or servomotor-driven units may be used.

Accomplishing part removal during each press stroke may limit the speed of the operation. For low-volume production jobs, manual removal with appropriate safeguarding precautions may suffice.

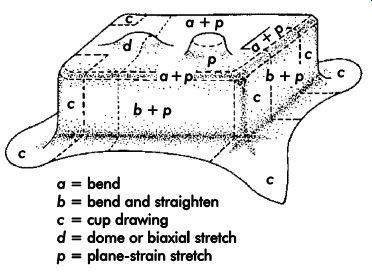

Stamping Analysis

Forming flat sheet metal into complex, radically deformed stampings may appear to involve skills and processes that are more art than science.

Modern stamping design and development techniques permit the product designer to work with manufacturing and tooling engineers to design parts that can be manufactured with certainty. A complex stamping is shown in FIG. 42.

Stamping designs should be based on the data of successful prior designs and analytical form ability methods. Uncertainty concerning the manufacturability of complex stampings often results in added expense and delays, such as:

• trial production on temporary tooling to prove process feasibility;

• delays in marketing the product while the process or product design is changed;

• specifying more operations than needed as a safety factor; and

• choosing alternative processes and materials such as molded plastics.

Computerized techniques

Simple computer software programs are avail able to ensure that proposed stamping designs can be manufactured with certainty. Using these programs avoids costly trial-and-error guess work. Software is available to analyze the amount and type of deformation in a stamping design.

Computer-aided analysis ties in nicely with computer-aided design (CAD) design of stampings. The analysis should be applied early in the product design process. The CAD math data, which describes the part, is used for computerized formability analysis. Computerized analysis falls into several categories, such as:

• simple sectional analysis programs;

• general analysis programs that fully model the part, which are typically based on finite element analysis; and

• programs that analyze the stamping based on the type of deformation occurring in an individual area.

Sectional Analysis Programs

Sectional analysis is good for identifying and troubleshooting a number of simple forming conditions. Computer programs are useful for determining the amount of strain present in a specific area of a stamping so that anticipated design problems can be checked easily.

A moderately priced personal computer has sufficient computational capacity to run sectional analysis programs to determine strain conditions.

Estimating the effect of surface friction on metal movement is a useful feature of nearly all computerized formability analysis programs.

General Analysis Programs

General analysis programs are required to completely model a part using the finite-element or finite-difference methods. Stamping the whole part is simulated in three dimensions with a single computer program. Many complex inter actions occur during the stamping simulation.

General analysis programs require the calculation and interaction of many complex variables occurring throughout the forming process.

Simplifying Analysis

A simplified approach breaks down complete stampings into local regions for individual analysis. Following this approach, a stamping is analyzed as individual zones that interact in a predictable manner as they are formed. Some good programs include an expert systems approach based on a library of successful designs.

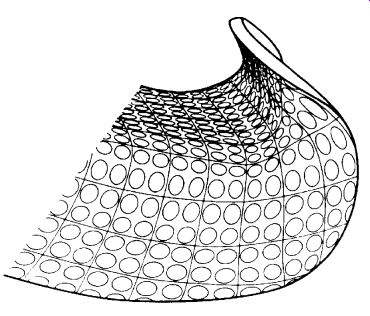

Circle Grid Analysis

Circle grid analysis (CGA) is a powerful process control tool. Data on essential areas of the stamping near the forming limit should be checked periodically to determine the effect of die wear on formability. Should a production stamping process start to experience problems, a blank of the material can be quickly gridded and analyzed. The CGA results can be compared with historical data for the part and steel formability specifications.

Measuring Deformation

The CGA technique permits measurement of the deformation that occurs when forming stampings. First, a grid is stenciled on the surface of the blank by dye transfer or electrochemical etching.

This grid deforms with the blank and allows ac curate calculations of the strain or deformation that occurred during the stamping operation.

Press Shop Applications

If a part always runs well within the safety zone, often a less costly steel or lubricant can be used. If only a few areas on the stamping are close to failure, a blank-holder improvement or minor product change often will ensure manufacturability of the product.

The CGA system is excellent for training apprentices. By making tooling, lubricant, and material changes, and then observing the metal deformation changes, cause-and-effect patterns can be readily discerned.

FIG. 43 illustrates a bumper jack hook. The grid of circles placed on the blank shows different types of deformation on the stamping. Note that most of the circles are deformed very little, while a few circles, especially one near the lip, show pronounced elliptical patterns. A stamping of this type will often fracture at the location where the edge is most severely stretched.

Measuring Forming Severity

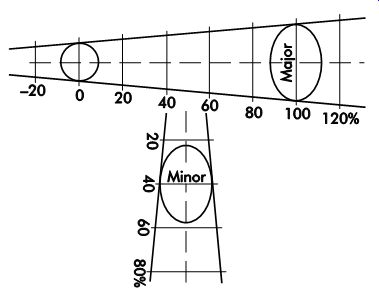

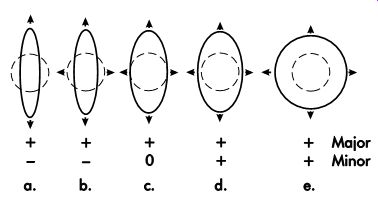

The distribution of stretch is useful information by itself. Knowing the location of high stretch concentrations and direction of the maximum stretch often is sufficient to suggest solutions to forming problems. However, CGA uses a numerical rating system for the deformation of the circles.

The system of rating forming severity is based on measuring the deformation of the circles and plotting the measurements on a graph. Grid measurements are easily made with transparent Mylar tape imprinted with a calibrated scale (FIG. 44). The tape is flexible and can be laid around a radius or tucked into a tight corner.

The calibration of the tape eliminates any need to calculate stretch. The tape is used to measure the major (length) axis of the ellipse first, then rotated to measure the minor (width) axis.

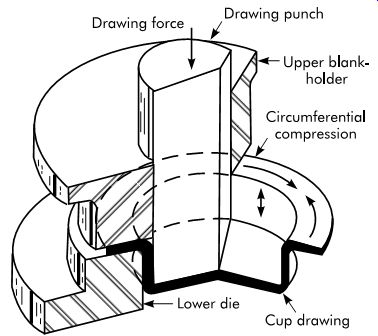

Many combinations of major and minor circle deformations can be found on different stampings. FIG. 45 illustrates five different types of deformation. FIGs. 45a and 45b detail large major elongation, while the minor stretch is negative. These types of circle deformations are observed in the sidewalls of drawn cups and the corner sidewalls of rectangular drawn shells. This combined compression and elongation indicates that the metal has been subjected to circumferential compression and tensile stretching as it is pulled toward and over the draw radius.

FIG. 45c is special. Here the minor stretch component is zero. This is called plane strain.

This stretch condition is found over edge radii or across character lines. Another special case is shown in FIG. 45e, where both the major and minor axes of the ellipse are equal-the circle becomes a larger circle. This is called balanced biaxial stretch.

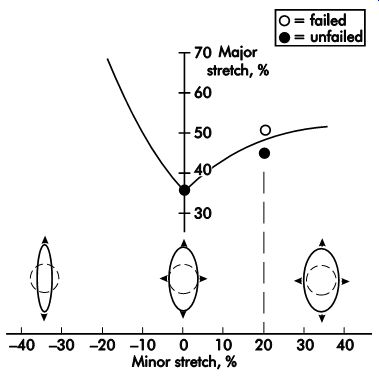

Plotting the Measurements

Due to the variety of combinations, a method for plotting them on a single graph is necessary.

The plotting technique used in FIG. 46 allows both the major and minor stretch for each circle to be plotted as a single point. The major stretch is plotted on the vertical axis, while the minor stretch is plotted on the horizontal axis.

Circles that plot on the left side of the diagram have negative minor stretch, while circles that plot on the right side of the diagram have positive minor stretch.

FIG. 43. A bumper jack hook formed from a circle gridded blank.

FIG. 44. Circle deformation is measured with a Mylar tape overlay.

FIG. 45. Examples of deformed circles.

FIG. 46. Measurements are plotted on the forming limit diagram (FLD).

FIG. 47. Different steels move the FLDo point.

Three of the ellipses from FIG. 45 are plotted in FIG. 46. Note that the case of plane stretch (FIG. 45c) is plotted on the vertical axis.

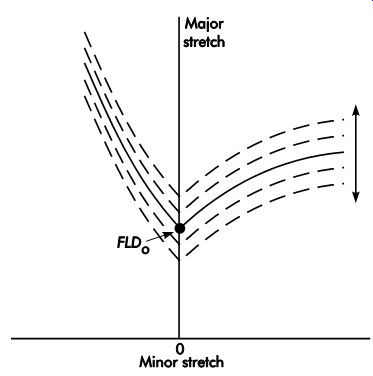

FIG. 47 illustrates an asymmetrical V shaped curve, which is the forming limit. Circles plotted below this curve show no evidence of necking or fracture, while those above it fail. A graph developed in this way is called a forming limit diagram (FLD). The point where the FLD intersects the major stretch axis is called FLDo. Here, only plane strain deformation is occurring.

To initially develop this diagram, many samples of failed versus not failed circles from the same material must be plotted.

The shape of the FLD (FIG. 47) is constant for most low-alloy sheet steel used in automotive, appliance, agricultural, container, and similar industries. It illustrates how the FLD curve can raise or lower for different steel sheets. The level of the FLD-as specified by FLDo-is a characteristic of the sheet steel. For example, a thinner sheet of steel would have a lower FLD than a thicker sheet of steel. In addition, higher-strength steel would have a lower FLD than lower-strength steel. Thus, the location of the curve can be described by specifying the intersection of the curve's FLDo with the minor stretch axis.

FIG. 48. A simple drawing die.

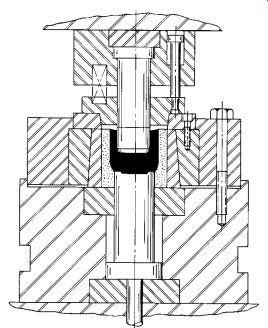

Deep drawing of cups

FIG. 48 illustrates the forces involved in deep drawing a metal cup. It is important to note that all of the force required for drawing is trans mitted by the draw punch to the bottom of the cup. Very little deformation occurs over the bottom of the punch. Nearly all deformation occurs in the metal restrained by the blank-holder.

The cup-drawing process starts with a flat round blank. The blank is subjected to radial tension and circumferential compression. The metal thickens as it flows toward the draw radius. Deep drawing is unique because of the deformation state of the metal restrained by the blank-holder.

Metal flow

In general, metal flow in deep-cup drawing may be summarized as:

• little or no metal deformation takes place in the blank area that forms the bottom of the cup;

• the metal flow occurring during the forming of the cup wall uniformly increases with cup depth; and

• the metal flow at the periphery of the blank involves an increase in metal thickness caused by circumferential compression.

Success factors The success of a drawing operation depends on several factors, including:

• the formability of the material being drawn;

• limiting the drawing punch force to a lower value than that which will fracture the shell wall; and

• adjustment of the blank-holder force to pre vent wrinkles without excessively retarding metal flow.

Causes of Failure

The maximum force requirement for the drawing process is limited by the tensile failure of the material in the sidewall. As this limit is approached, the metal will neck or thin excessively in a localized area near the punch radius.

Many complex interactions occur during the cup-drawing process. The actual force required depends on the cross-sectional area of the cup wall and the yield strength of the material as it is worked. Should the process fail, some or all of the following factors may be the root causes:

• the ductility or drawability of the stock may be too low;

• the blank-holder force may be too high;

• scoring or galling may be present on the die surfaces;

• the blank-holder geometry and draw radius may not provide for metal thickening and smooth flow into the die cavity;

• there may be an incorrect or insufficient amount of drawing lubricant;

• the depth of draw or percentage of blank reduction may be too great; and/or

• one or more redrawing operations may be necessary to obtain the desired depth of draw.

Annealing may be required between redrawing operations, especially when using materials that work-harden rapidly.

Draw Radius

The blank-holder draw radius should be approximately four to six times the metal thickness for most applications. It has a large effect on the punch force required to pull the metal into the draw cavity. As the metal passes over the radius, it is bent and then straightened to form the sidewall of the drawn cup. If the radius is too small, this can lead to fracture because more force is required to pull the metal over a small radius than a larger one. Also, it will more severely strain the metal, increasing work hardening. This, in turn, requires more force to draw the part.

There is little reduction of drawing force achieved by making the draw radius larger than six times the metal thickness. Approaching a draw radius of 10 times the metal thickness may result in puckering deformation of the metal as it flows over the draw radius. Severe deformation can result in folded metal, which can lock up metal movement and result in fractures.

In cases where all of the metal on the blank holder is to be drawn into the cavity to form a straight-walled shell without a flange, a large radius may result in folded metal as blank-holder control ceases.

FIG. 49. Localized thinning (necking) at the punch radius indicates a failure

of the drawing process.

Measuring Thickness

Necking failures, such as those shown in FIG. 49, are preceded by localized thinning, which may not be visible in the part. However, the onset of a necking failure can be detected by measuring the metal thickness with an ultrasonic thickness-measuring device.

Application of an ultrasonic thickness gage. The ultrasonic thickness gage is a stamping analysis tool that is useful for online process tracking, troubleshooting, and control. It features a portable control box, which provides thickness readout, and a probe with an ultrasonic transducer.

The principle of operation is much like that of a sonic or sonar depth finder used as a navigational aid by boaters. In its simplest form, a sonic depth finder measures the time between a sonic pulse sent out by a transducer attached to the boat's hull and the arrival of the return echo. The speed of sound in water is a known constant. The delay time between sending the sonic pulse and return echo can be easily converted and displayed in units of depth such as feet, meters, or fathoms. Ultrasonic metal thickness gages work in much the same way.

An ultrasonic pulse is sent out by a handheld transducer, which attaches to the control unit.

The return echo time is short, since the speed of sound in steel is in excess of 16,000 ft/sec (4,877 m/sec). For stamping thickness measurements, the operating frequency is approximately 15 MHz.

A plastic delay line is used between the transducer and the point of contact, with the workpiece being measured so a faint return echo can be detected.

Manufacturer-supplied compliant media is placed between the transducer and plastic delay line.

This media requires periodic renewal to ensure accuracy.

A .125-in. (3.18-mm) diameter transducer is considered better than larger sizes (for example, .250 in. [6.35 mm]), especially for use on curved surfaces. A compliant media is needed between the transducer face and metal workpiece. The best readily available material meeting this requirement is common surgical jelly-a product made to strict quality requirements for uniformity and purity. Be sure to wipe this substance off the part after measurement because it can cause rust.

Tracking thinning. Stampings that are severely drawn or formed usually have one or more areas where thinning is apt to occur. These areas are spots that should undergo regular thickness checks. The areas where a necking failure or fracture is apt to occur on a stamping can be predicted with CGA during the development and die tryout period for new stampings. The failure locations on an existing stamping become well known to pressroom personnel.

Regular checks should be made with an ultra sonic thickness gage. It is helpful to chart the thinning trends in each area. This permits corrective action to be taken before a necking failure becomes visible. Causal factors for a pronounced increase in thinning include:

• excessive blank-holder force;

• material problems such as a lack of ductility or drawability;

• material too thin; and

• scored die surfaces.

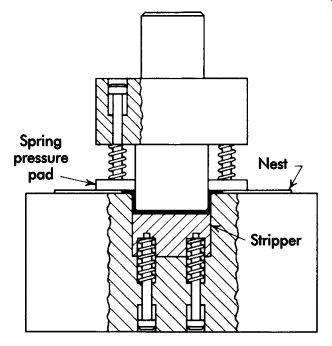

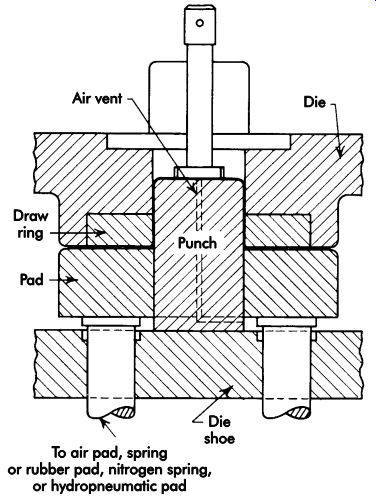

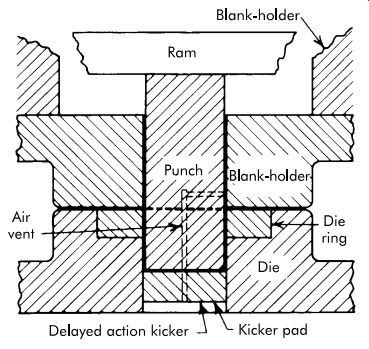

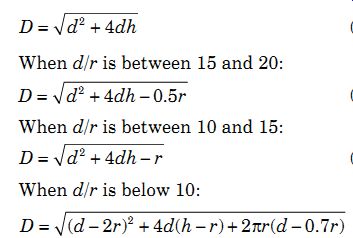

Single-action draw dies