AMAZON multi-meters discounts AMAZON oscilloscope discounts

The material selected when creating a particular tool normally is determined by the mechanical properties necessary for that tool's proper operation. These materials should be selected only after a careful study and evaluation of the function and requirements of the proposed tool.

For most applications, more than one type of material will be satisfactory, and a final choice normally will be governed by material availability and economic considerations.

The principal materials used for tools can be divided into three major categories: ferrous metals, nonferrous metals, and nonmetallic materials. Ferrous tool materials have iron as a base metal and include tool steel, alloy steel, carbon steel, and cast iron. Nonferrous materials have a base metal other than iron and include aluminum, magnesium, zinc, lead, bismuth, copper, and a variety of other metals and their alloys. Nonmetallic materials include woods, plastics, rubbers, epoxy resins, ceramics, and diamonds that do not have a metallic base.

To properly select a material, several physical and mechanical properties should be understood to determine how they affect a tool's function and operation.

PHYSICAL PROPERTIES

The physical properties of a material control how it will react under certain conditions.

Physical properties are natural in the material and cannot be permanently altered without changing the material itself. These properties include: density, color, thermal and electrical conductivity, coefficient of thermal expansion, and melting point.

Density

The density of a material is a measure of its mass per unit volume, typically measured in units of lb/in. 3 (g/mm^3 ). Density is important to consider when the weight of a tool needs to be minimized.

Color

Color is the natural tint contained throughout the material. For example, steels are normally a silver-gray color and copper is usually a reddish brown.

Thermal and Electrical Conductivity

Thermal conductivity and electrical conductivity measure how quickly or slowly a specific material conducts heat or electricity. Aluminum and copper, for example, have a high rate of thermal and electrical conductivity, while nickel and chromium have a comparatively low rate.

Coefficient Of Thermal Expansion

The coefficient of thermal expansion is a mea sure of how a material expands when exposed to heat. Materials such as aluminum, zinc, and lead have a high rate of expansion, while carbon and silicon expand very little when heated. Using materials with low coefficients of thermal expansion is important when dimensional accuracy is critical. Specifying materials with differing rates of thermal expansion can cause problems in constructing and using tools.

Melting Point

The melting point is the temperature at which a material changes from a solid to a liquid state.

Materials such as tantalum and tungsten have a high melting point, while lead and bismuth have a comparatively low melting point. The melting point is a consideration when high temperatures are involved in the use of a tool.

MECHANICAL PROPERTIES

The mechanical properties of a material can be permanently altered by thermal or mechanical treatment. These properties include strength, hardness, toughness, plasticity, ductility, malleability, and modulus of elasticity.

Strength

Strength is the ability of a material to resist deformation. The most common units used to designate strength are pounds per square inch (psi)

and kiloPascals (kPa). When designing tools, the principal categories to be most concerned with are a material's ultimate tensile strength, compressive strength, shear strength, and yield strength.

Ultimate Tensile Strength

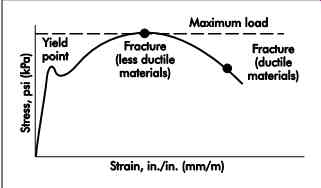

Ultimate tensile strength is the value obtained by dividing the maximum load observed during tensile testing by the specimen's cross-sectional area before testing. An example of a plot of a tensile test is shown in FIG. 1. This plot shows the yield point as well as fracture points for several different materials.

A material's ultimate tensile strength is an important property to consider when designing large fixtures or other tooling. It is of lesser importance in tools and dies except where soft- or medium hard ferrous or nonferrous materials are used.

The tensile tests successfully made on tool steel involve the use of tempering temperatures much higher than those typically used on tools.

Tool steels for hot work, fatigue, or impact applications are usually specified at lower hardness levels. The tensile properties of tool steels can be obtained from data books or vendor literature.

Compressive Strength

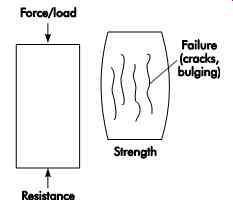

Compressive strength plays an important role in tool design. It is the maximum stress that a metal, subjected to compression, can withstand without fracture bending or bulging (see FIG. 2).

The compressive strength test is used on hardened tool steels, especially at high hardness levels.

For all ductile materials, the specimens flatten out under load, and there is no well-marked frac ture. For these materials, compressive strength is usually equal to tensile strength.

Shear Strength

The shear strength of a material is important to consider when designing tools that will be subjected to shear loads or torsion loads. Shear strength is defined as the stress necessary to cause failure in shear loading (or torsion loading). For most steels, the shear strength (see FIG. 3) is approximately 50-60% of the alloy's tensile yield strength. Shear strengths are measured in units of lb/in. 2 (psi) or kN/m^2 (kPa).

Yield Strength

The yield strength of a material is often the most important property to consider when selecting an alloy for a specific application. Measured in units of lb/in. 2 (psi) or kN/m^2 (kPa), yield strength is the stress level at which an alloy will show permanent elongation after the stress has been removed. A typical yield strength reported is 0.2%, which indicates that the stress produced 0.2% elongation in a 2-in. (50.8-mm) test specimen. Therefore, if permanent deformation is not acceptable for a given application, the stresses that a component is subjected to must be below the yield strength of the alloy. Heat treatments can be used to increase or decrease the yield strengths of alloys.

Hardness

Hardness is the ability of the material to resist penetration or withstand abrasion. It is an important property in selecting tool materials.

However, hardness alone does not determine the wear or abrasion resistance of a material. In alloy steels, especially tool steels, the resistance to wear or abrasion varies with alloy content.

Hardness scales have been developed, each covering a separate range of hardness for different materials.

Rockwell Hardness

Rockwell hardness is the most widely used method for measuring the hardness of steel. The Rockwell hardness test is conducted by using a dead weight that acts through a series of levers to force a penetrator into the surface of the metal being tested. The softer the metal being tested, the deeper it will be penetrated with a given load. The dial gage does not directly read the depth of penetration, but shows scales of Rockwell numbers instead. A variety of loads and penetrators can be used, each designated by a different letter and the relative hardness or softness measured.

Two types of penetrators are used in Rockwell hardness testing: a diamond cone, known as a brale, for hard materials such as tool steel, and a hardened steel ball for soft materials.

Brinell Hardness

The Brinell hardness method of measurement is much older than the Rockwell method. It operates similarly to the Rockwell ball-test principle.

In the Brinell machine, a 10 mm (.39 in.) steel ball is forced into the material being tested under a load of up to 3,000 kg (6,600 lb). Instead of measuring the penetration, the diameter of the impression in the test piece is measured using a small hand microscope with a lens calibrated in millimeters. The measured diameter is converted into a Brinell hardness number by using a table.

The Brinell hardness measurement is most useful on soft and medium-hard materials. On steels of high hardness, the impression is so small that it is difficult to read; therefore, the Rockwell test is used more commonly for such materials. A comparison of the designations for each system, as well as other hardness tests, is shown in Table 1.

Toughness

Toughness is the ability of a material to resist fracture when subjected to impact loads (sudden rapid loads). Materials that have high toughness must have a combination of high strength and high ductility. Those with high strength but little ductility have low toughness.

(coming soon) Table 1. Approximate relationships of various hardness scales for steel

Plasticity

Plasticity is the property of a material that allows it to be extensively deformed without fracture. Two general categories of plasticity are ductility and malleability.

• Ductility is the property of a material that allows it to be stretched or drawn with a tensional force without fracture or rupture.

• Malleability is the property of a material that permits it to be hammered or rolled without fracture or rupture.

Modulus of Elasticity

The modulus of elasticity is a measure of the elastic stiffness of a material. It is a ratio of the stress to the strain in the elastic region of a tensile test. The modulus of elasticity determines how much a material will elastically deflect under an applied load. For alloys within the same family, the modulus of elasticity does not vary (for example, the modulus of all steels is 30 × 10^6 psi; the modulus of all aluminum alloys is 10.5 × 10^6 psi). The modulus of elasticity is not affected by heat treatment.

FERROUS TOOL MATERIALS

Many ferrous materials can be used for tool construction. Typically, materials such as carbon steels, alloy steels, and cast irons are widely used for jigs, fixtures, and similar special tools. These materials are supplied in several different forms.

The most common types used for tools are hot rolled, cold-rolled, and ground.

When steel is hot-rolled at a mill, a layer of decarburized slag, or scale/oxide, covers the en tire surface of the metal. This scale/oxide should be removed when the part being made is to be hardened. If, however, the metal is to be used in an unhardened condition, the scale/oxide may be left on. When ordering hot-rolled materials, the designer must make allowance for the removal of the scale/oxide.

Cold-rolled steels are generally used for applications where little or no machining or welding is required. Cold-rolled bars are reasonably ac curate and relatively close to size. When rolled, these steels develop internal stresses that could warp or distort the part if it were extensively machined or welded. A cold-rolled bar is distinguished from a hot-rolled bar by its bright, scale-free surface.

Steels are also available in a ground condition. These materials are held to close tolerances and are available commercially in many sizes and shapes. They are normally used where a finished surface is required without additional machining. The two standard types of ground materials are "to-size" and "oversize." To-size materials are ground to a specific size, such as .25 in. (6.4 mm), .50 in. (12.7 mm), or any similarly standard size.

Oversize materials are normally ground .015 in. (0.38 mm) over the standard size.

Carbon Steels

Carbon steels are used extensively in tool construction. They contain mostly iron and carbon with small amounts of other alloying elements, and are the most common and least expensive types of steel used for tools. The three principal types are low-carbon, medium-carbon, and high-carbon steels. Low-carbon steel contains 0.05-0.30% carbon; medium-carbon steel contains 0.30-0.70% carbon; and high-carbon steel contains 0.70-1.50% carbon. As the carbon con tent is increased in carbon steel, the maximum strength and hardness also increase when the metal is heat-treated.

Low-carbon steels are soft, tough steels that are easily machined and welded. Due to their low carbon content, these steels cannot be hardened except by case hardening. Low-carbon steels are well suited for tool bodies, handles, die shoes, and similar situations where strength and wear resistance are not critical.

Medium-carbon steels are used where greater strength and toughness are required. Since medium-carbon steels have higher carbon content, they can be heat-treated to make studs, pins, axles, and nuts. Steels in this group are more expensive as well as more difficult to machine and weld than low-carbon steels.

High-carbon steels are the most hardenable type of carbon steel. They are used frequently for parts with which wear resistance is an important factor. Other applications where high-carbon steels are well suited include drill bushings, locators, and wear pads. Since the carbon content of these steels is so high, parts made from them are normally difficult to machine and weld.

Alloy Steels

Alloy steels are basically carbon steels with additional elements added to alter their characteristics and bring about a predictable change in their mechanical properties. Not normally used for most tools due to their cost, some alloy steels have found favor for special applications. The alloying elements used most often in steels are manganese, nickel, molybdenum, and chromium.

Another type of alloy steel frequently used for tooling applications is stainless steel. Stainless steel is a term used to describe high-chromium and nickel-chromium steels. These steels are used for tools that must resist high temperatures and corrosive atmospheres. Some high-chromium steels can be hardened by heat-treatment and are used where resistance to wear, abrasion, and corrosion are required. Martensite stainless steel is sometimes preferred for plastic injection molds.

Here, the high chromium content allows the steel to be highly polished and prevents deterioration of the cavity from heat and corrosion.

Tool Steels

Tool steels are alloy steels produced primarily for use in cutting tools. Properly selecting tool steels is complicated by their many special properties. The five principal properties of tool steels are:

1. heat resistance,

2. abrasion resistance,

3. shock resistance,

4. resistance to movement or distortion in hardening, and

5. cutting ability.

Because no single steel can possess all of these properties to the optimum degree, hundreds of different tool steels have been developed to meet the total range of service demands.

The steels listed in Table 2 will adequately serve 95% of all metal-stamping operations. The list contains 31 steels, nine of which are widely applied and readily available. The other steels rep resent slight variations for improved performance in certain instances. Their use is sometimes justified because of special considerations.

Tool steels are identified by letter and number symbols. All the steels listed, except those in the S and H groups, can be heat-treated to a hardness greater than Rockwell C 62 and, accordingly, are hard, strong, wear-resistant materials. Frequently, hardness is proportional to wear resistance, but this is not always the case because wear resistance usually increases as the alloy content and, particularly the carbon content, increases.

The toughness of steels, on the other hand, is inversely proportional to their hardness, and increases markedly as the alloy or carbon content is lowered. Table 3 lists basic characteristics of steels used for press tools; Table 4 lists the hardening and tempering treatments; and Table 5 lists typical applications of various steels.

Table 2. American Iron and Steel Institute (AISI) identification and classification of tool steels

Classes

The general nature and application of the various standard tool steel classes are as follows.

W: water-hardening tool steels. This group includes plain carbon (W1) and carbon vanadium (W2). These were the original tool steels. Because of their low cost, abrasion- and shock-resisting qualities, ease of machinability, and ability to take a keen cutting edge, the carbon grades are widely applied. Both W1 and W2 steels are shallow hardening and are readily available.

O: oil-hardening tool steels. Types O1 and O2 are manganese oil-hardening tool steels. They are readily available and inexpensive. These steels have better stability than water-hardening steels, and are of equal toughness with water hardening steels when the latter are hardened throughout. Wear resistance is slightly better than that of water-hardening steels of equal carbon con tent. Steel O7 has greater wear resistance because of its increased carbon and tungsten content.

A: air-hardening die steels. Type A2 is the principal air-hardening tool steel. It has minimum movement in hardening and higher toughness than the oil-hardening die steels, with equal or greater wear resistance. Steels A4, A5, and A6 can be hardened from lower temperatures. How ever, they have lower wear resistance and higher resistance against distortion.

D: high-carbon, high-chromium die steels.

Type D2 is the principal steel in this class. It finds wide application for long-run dies. It is deep-hardening, fairly tough, and has good resistance to wear. Steels D3, D4, and D6, containing additional carbon, have very high wear resistance and lower toughness. Steels D2 and D4 are air hardened.

S: shock-resisting tool steels. These steels contain less carbon and have higher toughness.

They are applied where heavy cutting or forming operations are required, and where breakage is a serious problem. Steels S1, S4, and S5 are readily available. Steels S4 and S5 are more economical than S1.

H: hot-work die steels. These steels combine red hardness with good wear resistance and shock resistance. Air-hardening, they are used on occasion for cold-work applications. They have relatively low carbon content and intermediate to high alloy content.

(coming soon) Table 3. Comparison of basic characteristics of steels used for press tools

(coming soon) Table 4. Hardening and tempering treatments for press tools

(coming soon) Table 5. Applications of tool steels

T and M: tungsten and molybdenum high speed steels. Steels T1 and M2 are equivalent in performance and have good red hardness and abrasion resistance. They have higher toughness than many of the other die steels and may be hardened by conventional methods or surface-hardened by carburizing. Steels M3, M4, and T15 have greater cutting ability and resistance to wear. They are more difficult to machine and grind because of their increased carbon and alloy contents.

L: low-alloy tool steels. Steels L3 and L6 are used for special die applications. Other L steels find application where fatigue and toughness are important considerations, such as in coining or impression dies.

F: finishing steels. Steel F2 has limited use, but is occasionally applied where extremely high wear resistance in a shallow-hardening steel is desired.

Cast Iron

Cast iron is essentially an alloy of iron and car bon, containing from 2-4% carbon, 0.5 to about 3% silicon, 0.4 to approximately 1% manganese, plus phosphorus and sulfur. Other alloys may be added depending on the properties desired.

The high compressive strength and ease of casting gray irons are utilized in large forming and drawing dies to produce such items as auto mobile panels, refrigerator cabinets, bathtubs, and other large articles. Conventional methods of hardening result in little distortion.

Alloying elements are added to promote graphitization and improve mechanical properties or develop special characteristics.

Invar

Invar is an iron-nickel alloy with 35-36% nickel and smaller amounts of other elements added for machinability. It is strong, tough, and ductile, with a fair amount of corrosion resistance. The main feature of Invar is that it has a coefficient of thermal expansion of almost zero, thus providing the dimensional stability required for length standards and optical platforms. How ever, one problem with Invar is that it is difficult to machine.