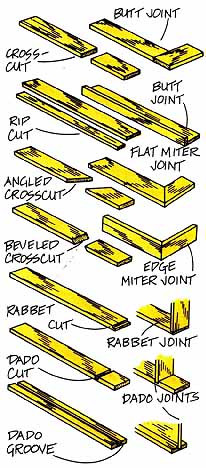

Cutting the material to size is a two-step process. The general rule of thumb is this: first, rip the materials to width, then cross-cut the pieces to length. To get the most out of the material, rip the widest pieces first; then rip the narrower pieces out of the remainder. Follow the same order for crosscutting, starting with the longest pieces.

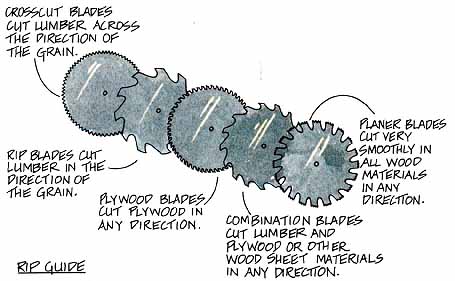

Saw Blades

Saw blades are specially designed to make specific types of cuts in different types of materials. Since using unsuitable blades can waste materials and put stress on your tools, you’ll want to choose the right blade for the job. Keep blades sharp: it’s a safer practice; and sharp blades are more likely to produce the clean cuts and good joints you want. And remember, whenever you change a blade, unplug the tool first.

Saws

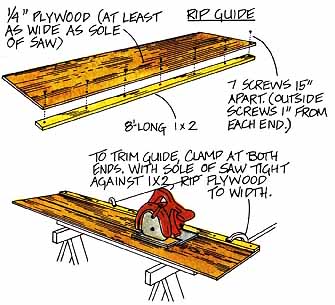

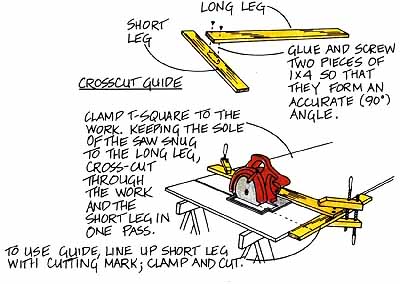

Accurate cuts produce tight, attractive joints. Stationary power tools like the radial arm saw and the table saw are highly prized shop tools because they yield the most precise cuts. But a portable circular saw, when you use it well, is also an accurate milling tool. It will make the most precise cuts when you suit the blade to the material, support the material on a cutting table or a portable work bench, and use rip and crosscut guides to cut your material to size. The illustrations below show how to make both of the cutting guides.

Prev.: Layout and Cutting List

Next: Detail Milling and Edging

ALL ARTICLES in this Guide:

DIY and Custom-Made Storage Solutions: Components You Can Build for Home, Office ... as a Hobby or for Sale (Profit, earn Income)