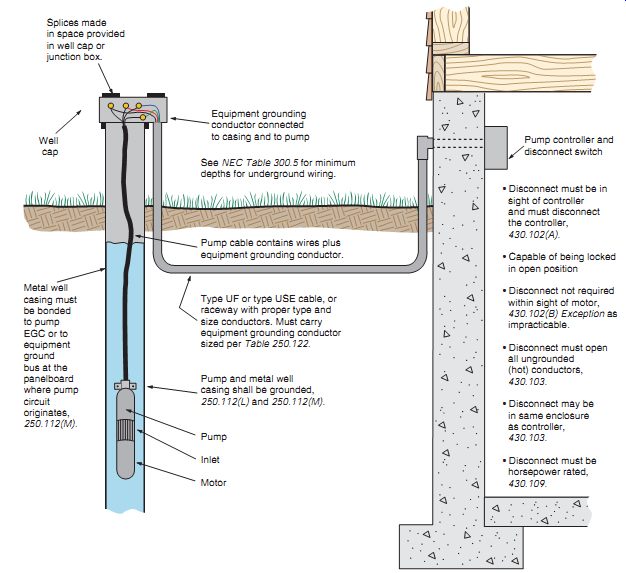

FGR. 4 below illustrates how to provide proper grounding of a submersible water pump and the well casing. Proper grounding of the well casing and submersible pump motor will minimize or eliminate stray voltage problems that could occur if the pump motor is not grounded.

Key Code sections that relate to grounding water-pumping equipment:

• NEC 250.4(A)(5): The last sentence states that: The earth shall not be considered as an effective ground-fault current path.

• NEC 250.86: Metal enclosures for circuit conductors shall be grounded, other than short sections of metal enclosures that provide support or physical protection.

• NEC 250.112(L): Motor-operated water pumps, including submersible pumps, must be grounded.

• NEC 250.112(M): Bond metal well casing to the pump circuit's equipment grounding conductor.

• NEC 250.134(B): Equipment fastened in place or connected by permanent wiring must have the equipment grounding conductor run with the circuit conductors.

• NEC 430.241: Grounding of motors-general.

• NEC 430.242: Grounding of motors- stationary motors.

• NEC 430.244: Grounding of controllers.

• NEC 430.245: Acceptable methods of grounding.

Because so much nonmetallic (PVC) water piping is used today, some local electrical codes or interpretations require that a grounding electrode conductor be installed between the neutral bar of the main service disconnecting means and the metal well casing. The interpretation often related to the proximity of the well casing to the main building or structure. The NEC does not provide a distance beyond which a connection to the well casing is no longer required. Connecting to the metal well casing would satisfy the requirements of 250.104 (bonding), 250.50 (grounding electrode system), 250.52 (grounding electrode descriptions), and 250.53 (installation of grounding electrodes). If installed, the grounding electrode conductor would be sized in compliance with Table 250.66 of the Code. At the metal casing, the grounding electrode conductor is attached to a lug termination, or by means of exothermic (Cadweld) welding.