This section will explain the use of the oxy-acetylene torch for cutting steel. You should know something about cutting and shaping metals in order to use the arc welding process to its fullest extent and to take advantage of its great flexibility.

The most common way of cutting steel is by “burning” it with an oxy-acetylene flame. Although steel is usually considered a “fireproof” material, it “burns” (or oxidizes) rapidly under an intense flame and when other conditions are just right.

AMAZON multi-meters discounts AMAZON oscilloscope discounts

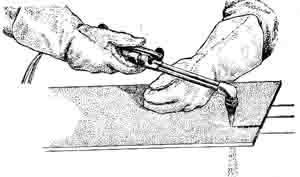

ill. 21—The oxy-acetylene torch cuts a piece of steel by removing a small

strip of metal (in the form of ‘ashes” or slag) just as a saw cuts a plank

(by re moving a small strip of wood.)

With an oxy-acetylene torch the “burning” can be confined to a narrow strip ( ill. 21), with little effect on adjoining metal. Just as a saw cuts a plank by removing a small strip of wood (in the form of sawdust), so the oxy-acetylene flame cuts a piece of steel by removing a small strip of metal (in the form of “ashes” or slag). The method is an ingenious one, yet simple to under stand. An area of steel is heated to the pasty range (over 2700 F) with a combined oxygen and acetylene flame. At the same time a jet of pure oxygen is blown into this heated area causing the rapid oxidation that “burns” the steel. The two operations are done simultaneously with a single torch.

If the torch is moved at the proper rate of travel, a smooth cut is made. This cut may be a straight line or may follow any pattern desired. It may be used to cut the steel square to the face or at an angle to get any degree of bevel.

The Torch

As shown in ill. 22, the cutting torch is a not too complex yet functional tool. It burns acetylene combined with oxygen in a series of small flames to preheat a small area of the steel, and delivers pure oxygen in the center of this area to cause the rapid oxidation that results in the “burning” of a hole through the steel.

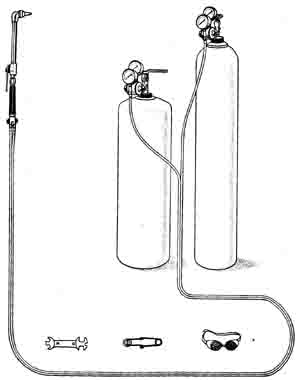

ill. 22—Oxy-acetylene equipment for cutting steel:

a tank of oxygen, a tank of acetylene, regulators and hoses for each tank, the acetylene cutting torch, goggles, a lighter and a special wrench.

The oxy-acetylene mixture is delivered at a low velocity through a series of openings spaced equally around the edge of the torch tip. The pure oxygen is delivered at a relatively high velocity through an opening in the center of the tip.

Lighting the Torch

The steps in lighting the torch are as follows:

(1) Open the main valves on the two cylinders and adjust them to the pressures recommended by the manufacturers of the equipment you are using.

(2) Crack (that is, open slightly) the acetylene valve on the torch and light the flame with a spark lighter.

(3) Slowly open the oxygen valve which controls the oxygen to the preheat outlets, turning it just enough to get a neutral flame.

(4) With both gases burning, re-check the regulator valves on the two cylinders to make sure you are still getting the recommended pressures.

(5) Then press the trigger or lever on the torch to allow the oxygen cutting jet to flow. This action will rob the preheat outlets of some oxygen, causing a slight feather edge on the flame. So with the oxygen jet still open re-adjust the flow of oxygen to again get a neutral flame.

(6) Now turn off the oxygen jet by releasing the trigger or lever. Remember, the preheat flames are just the same as small welding flames.

They should be adjusted to be “neutral” with complete combustion, having no excess of acetylene or oxygen. Remember, the sole purpose of these flames is to preheat the steel.

Using the Torch

The steps in using the torch are as follows:

(1) Hold the torch, with only the preheat flames burning, pointed directly into the metal to be cut and with the sharp tips of the preheat flames just barely touching the metal.

(2) Hold the torch steady in this position until the metal just barely begins to melt under the flames.

(3) Slowly and gradually press the lever opening the oxygen jet until it’s wide open. At the same time begin moving the torch slowly and steadily in the direction the cut is to progress.

(4) Now move as fast as the cut will hold its heat. Don’t point the torch forward or backward. It should be directed straight into the cut.

(5) At the end of the cut, turn off the oxygen jet, then turn off the acetylene and oxygen to the preheat flames.

Remember, the sharp points of the inner cones of the preheat flame should just barely touch the plate. When the plate is hot enough to cut (just barely mushy or pasty) the trigger or lever that releases the oxygen jet should be gradually and steadily opened at the same time that you begin to move the torch in the direction of cutting.

The oxygen jet should be kept full open as long as the cut is progressing. Don’t try to adjust it with the trigger or lever on the torch.

Your movement should be steady and regular and the forward motion should be as fast as possible without running away from the preheat. This speed is judged by the way the cut is progressing, and you will learn to recognize it only with practice.

It’s usually best to use the smallest tip that will produce a good cut. The heavier or thicker the plate to be cut, the larger the tip and the higher the oxygen cutting pressure. But in any case, the best cut will be obtained by using the smallest tip that produces the desired result.

The amount of metal that's burned away in oxy acetylene cutting is usually about twice the width of the center hole of the cutting tip. This burned metal is blown out of the cut in the form of small particles of slag, or adheres in the same form to the underside of the plate.

Beveling

If a bevel or scarf cut is desired, as in end preparation for butt welds, the torch is leaned on an angle. The resultant cut will be the same angle as the torch because the torch cuts straight in the direction it’s pointed.

The average beveled edge is 30° to 40° from square, so to get that much bevel simply angle the torch tip that much.

Safety

Where oxygen, acetylene and open flames are concerned, a few more safety suggestions are in order.

Acetylene is a highly combustible material. It will burn with explosive speed and force. It should be handled carefully.

Oxygen itself is not combustible, but it’s the element that makes possible all combustion. Almost anything will burn in the presence of pure oxygen. So it, too, should be handled carefully. Be particularly cautious with oils and greases—they may ignite spontaneously in the presence of pure oxygen.

Both acetylene and oxygen are compressed to high pressures in their cylinders. This is added reason why they should be handled carefully.

Never strike an arc on either cylinder. Never drop either cylinder. Tie them securely in place so that they can't be knocked over.

The flame on the end of your cutting torch should never be pointed toward anyone and should never be brought into contact with combustible materials. Many men have spent their whole lives in the welding business and have never been hurt. They were sensible and careful. Stay on the safe side. Be an adult and be a safe one. Remember the Biblical admonition, “When I was a child I behaved as a child, but when I became a man I put away childish things.”

Prev: Heat Measurement,

Whipping and Weaving

Next: Fillet Welds