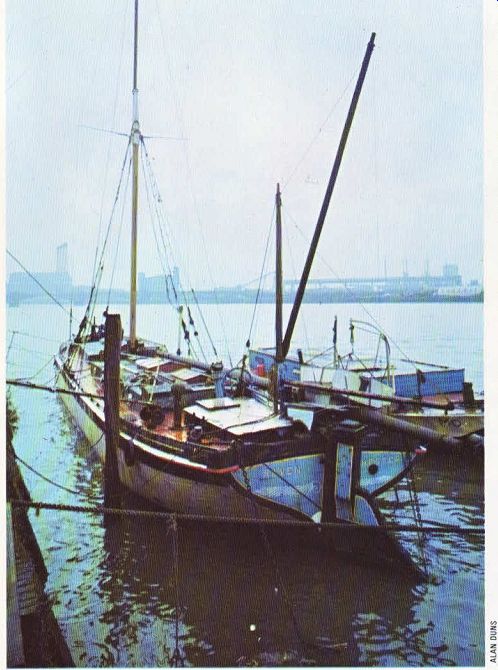

The Thames sailing barge has suffered a ad demise in recent years. At the beginning of the century it was a common, and magnificent, sight on the East Coast of England and River Thames estuary. Now, most Thames barges have been broken up, or are rotting in derelict wharves.

When artist-designer Allan Chidgey bought a disused barge to use as a studio he took on more than he expected, because he decided not only to convert it into a home but also to restore he hull. The result is an elegant sailing barge, fully rigged, which serves as a permanent home and studio. Its Thames-side mooring in front of

distinctive Georgian church makes it an idyllic retreat.

The Raven was built in 1904 as a traditional Thames sailing barge. It was used for carrying wheat and general cargo from the East Coast to London up to 1965. Long before that (in about 1948) the mast had been cut down and it had been converted to a motor barge.

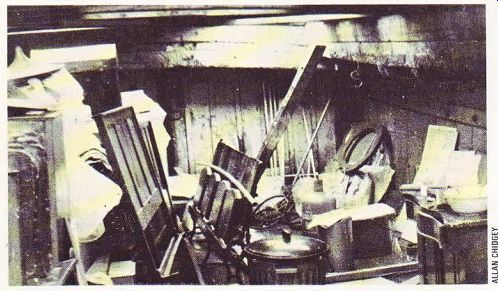

The raw material the designer had to work on was a wooden hull 80ft by 1 8ft, two open holds surrounded by decks, an engine room in the stern, and a fore-cabin, The barge leaked badly, and the hull was in very bad condition.

The transformation involved a great deal of forethought and hard work, and a solution to he problems inherent in such a venture demanded a certain amount of ingenuity.

First, the whole existing structure had to be made good, which involved stripping it down completely and burning off all the paint and tar.

All internal steel was treated with rust sealer.

The longest and most arduous task was the re-caulking of the decks (filling between the planks with waterproof jointing) to prevent leakage. This involved stripping out nearly a mile of 3in. seams and refilling them with oakum, tar and pitch. The decks were then re-bolted to strengthen them.

A temporary wooden roof was erected over the exposed area to protect the interior while work was in progress. Even at this stage it was important to allow adequate ventilation to prevent rot.

One of the worst problems was the damage that had been caused by steel plates which were fixed to the exposed woodwork to protect it from the steel grabs used for unloading cargo. These had corroded and eaten into the wood, leaving severe gashes and rents when they were removed. This was overcome by putting a Jin. layer of a plastic-based filler over the wood. This gives it a smooth surface while retaining its texture and appearance.

The floor had also suffered considerable damage. A new floor was laid directly on to the old one, using old floorboards bought from demolition sites. Once they were cleaned and scraped and the nails had been knocked out, they provided a good, solid floor at minimal expense. They were sanded down with an industrial sander, then polished and coated with a polyurethane varnish to give extra durability Electricity on a houseboat is essential, as gas or oil lights are not bright enough for working or reading. However, a connection from the nearest power source involves a considerable voltage drop, so that only lighting, a refrigerator and ‘light' appliances such as record players can be run off electricity.

Cooking is done with bottled gas, which is economical and convenient, as the containers are delivered by van. Water, which comes from the mains, is run off a large tank and pumped to a header tank to give adequate pressure to the kitchen and bathroom supply. The basin and sink had to be raised higher than is usual to allow outlets above the water line.

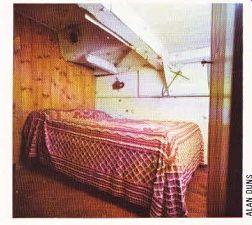

The layout of the interior was determined by the need to use the low areas (maximum height 5ft 6in.) under the sailing beams. This was done by building a cabin on one side and a bathroom on the other, and placing the ends of both the bed and the bath under the lowest beam in each case, Tongued and grooved planking was used for the partition walls. To allow for the flexing of the vessel (iin.-1in.) with the movement of the tide, these walls had either to be hung from the ceiling and left clear of the floor, or fixed to the floor and left clear of the ceiling. The remaining gaps at the top or bottom were then disguised with beading.

The space between this area and the existing forecabin-11ft x 18ft-was made into a kitchen/dining room. Cupboards and shelves were built on the partition walls and a bench seat was fixed against the side walls of the dining area. The floor beam running along the centre of the boat creates a natural division between the kitchen and the dining area.

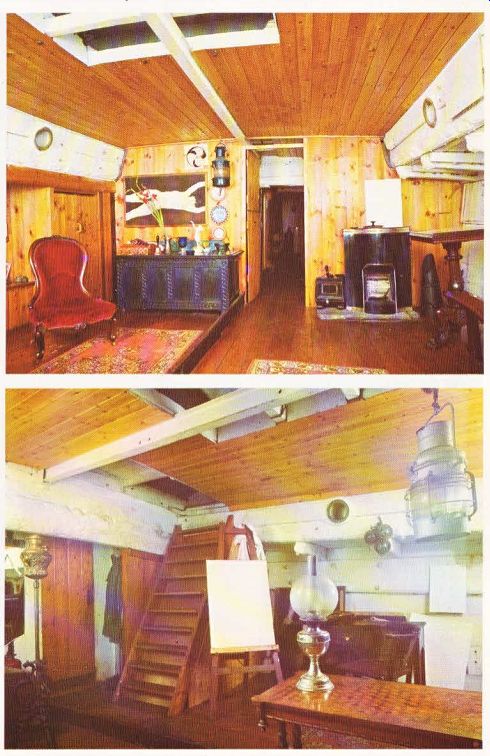

The forecabin is used as the main bedroom, and the remaining space (32ft x 18ft) in the rear of the boat is the sitting room/studio.

The walls were painted white, and the wood work was treated with varnish to give color, Skylights in the roof give a generous amount of daylight, and a skyline view of a church. These skylights were recovered from other boats which were being broken up.

When the new roof was built, the old curved hatch covers were forced down over a centre beam, leaving maximum headroom and giving a more pronounced and attractive curve to the ceiling. To give sufficient circulation of air, two hatches were built into the roof, one at each end.

These also give access to the interior via ladders. Portholes were fitted into the sides of the roof to provide additional ventilation. This does not spoil the boat's exterior appearance or affect its sailing qualities.

Heating is provided by slow-burning an thracite fires, which are both elegant and efficient. They heat the water and also help prevent condensation. A gas water heater is used in hot weather.

Cupboards and bookshelves are built in, and free-standing furniture has been kept to a minimum. This is because the sloping floor makes it stand at a slight angle.

'The Raven' was built in Rochester in 1904, as a traditional Thames sailing

barge.

--------------TOP. The outside of the barge was scarcely altered by the conversion, but the interior, above below, was transformed.

--- TOP. The sitting room studio in the rear of the barge was left

its original size (32ft x 18ft). Skylights in the roof let in plenty of light.

---- Above. The ladder leads to a hatch which is used for access. Another hatch was built in the roof above the kitchen dining room.

ABOVE. A cabin under the sailing beam on one side. The maximum height is 5ft

6in., so the bed is fitted underneath the lowest part, with the water tank

underneath it.

--------------