All home insulating materials have certain features in common. Light for their bulk, they are fluffy or foamy — even rigid insulation boards have the feel of congealed foam. They have these qualities because they consist mainly of tiny pockets of trapped air.

The air pockets resist the flow of heat out of or into a house. Heating engineers rate the resistance on a scale of R-values, based on the amount of heat that will pass through a square foot of a material in one hour when the temperature on one side is 10 higher than on the other. The R-value depends on both the composition and thickness of the material.

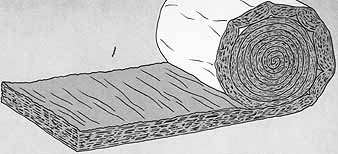

By far the most common material used for insulation consists of fibers — fibers of glass; rock-wool fibers, made by blowing steam through molten rock; and cellulose, or plant fibers. There are two common ways of packaging this material: in long rolls that are called blankets, or pre-cut flexible rectangles called batts.

Fibers can also be used as loose-fill insulation, poured or blown onto attic floors or into hollow walls. Besides fibers, loose fill may consist of pellets or granules, usually made of vermiculite (a form of mica) or perlite (volcanic ash).

The remaining insulating materials are man-made synthetics. One type comes in rigid boards or sheets and is widely used to insulate masonry walls. Another, called foamed-in-place, consists of a plastic foam that flows around obstructions to fill a space completely, then hardens to a rigid mass.

By blocking heat flow, insulation solves one problem but introduces another. It increases the temperature difference between inside and outside wall surfaces. and temperature determines how much vapor air can hold; moisture that is vapor at the interior temperature turns to liquid at the lower exterior temperature. The water makes insulation worthless, and damages paint and wood.

The solution to the problem is a vapor barrier—a layer of impervious material that prevents water vapor from reaching a section cold enough to make it condense. Most blankets and batts are sold with a vapor barrier already installed. With loose fill you can install a separate barrier or cover the interior of an insulated wall with oil-base enamel paint and a top coat of alkyd paint.

Comparing insulation materials. Although insulation is marketed under a bewildering variety of trade names, almost all of it uses one of the basic materials listed by their generic names on this chart. Fiberglass and rock wool account for more than 90% of all insulation sold in the United States and Canada, but the others have distinctive forms or properties, listed in the last three columns, that make them preferable to fibers in some applications.

The materials are ranked in an ascending order of resistance to heat flow, or R-value. The R numbers, given here as R-value per inch, can not be simply added or multiplied for greater thicknesses—a glass fiber batt 6 inches thick, for example, does not have exactly six times the R value of a 1-inch batt. The exact rating, however, is printed on all blankets, batts and boards (the 6-inch fiber batt will be rated R-19—the value recommended for exterior walls in most of the United States and Canada). When you buy loose fill, look for bags that indicate the R-value of the insulation at different thicknesses.

Table of Insulation Types

Material |

Approximate R-value per inch of thickness |

Form |

Advantages |

Disadvantages |

Vermiculite Perlite Fiberglass Rock wool Polystyrene Cellulose Urea formaldehyde Urethane |

2.08 2.70 3.33 3.33 3.45 3.70 4.48 5.30 |

Loose fill Loose fill Blankets, batts, loose fill Blankets, batts, loose fill Rigid boards Blankets, batts, loose fill Foamed-in-place Foamed-in-place |

Especially suitable for the spaces in hollow-core blocks Easily poured into hollow spaces Relatively inexpensive; fire-resistant Comparable to fiberglass Moisture-resistant; useful for below-grade floors and exterior walls Fine consistency permits loose-fill installation through small access holes; does not irritate skin Excellent fire resistance; high insulation efficiency; good for exterior walls Highest insulation efficiency |

Low insulation efficiency; moisture-absorbent Comparable to vermiculite Particles can irritate skin; gives off odor when damp Particles can irritate skin Highly combustible; easily dented Flammable unless chemically treated Requires professional installation Requires professional installation; gives off noxious gases if ignited |

|

|

|

|

|

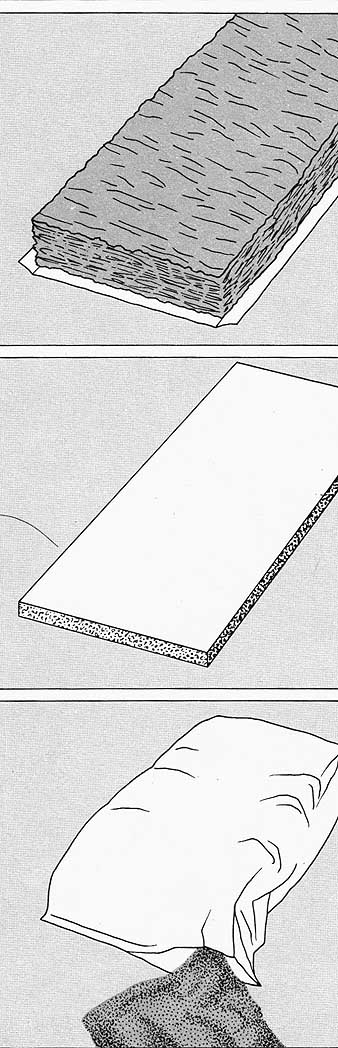

above: How Insulation is Packaged

Blankets. These rolls of insulation are sold in thicknesses of 1 to 7 inches, lengths of 16 to 64 feet, and widths designed to fit snugly between standard stud spacings. Blankets usually have thin marginal strips, called flanges, for stapling, and a vapor barrier of paper or foil, but they also come without a barrier. Blankets are difficult to cut and are best for long runs of unobstructed space: between floor joists in an unfinished at tic or between rafters in a roof.

Batts. These are simply short blankets, cut into uniform lengths of 4 or 8 feet for easier handling—the 8-foot length fills the space between studs in a standard wall; an 8-foot ball plus a 4-foot one completes a common joist run of 12 feet. Balls without attached vapor barriers can be squeezed between joints without fasteners.

Rigid boards. Constructed from lightweight plastic foam, rigid insulation is supplied in sizes from 8-inch squares to 4-by-12-foot sheets. They provide relatively high insulation in thick nesses of ½ to 1 inch, and are often used as sheathing beneath aluminum or plastic siding. Be cause the plastic boards are flammable, they should not be left exposed or covered with wood paneling—on a basement wall, for e but should be protected with gypsum wallboard, which resists fire.

Loose fill. This type is easy to spread into open, flat spaces, such as unfloored attics, or to blow inside covered walls and floors through access holes. But it requires a separate vapor barrier, and unlike other forms of insulation, it settles, especially in walls or sloping areas. This can result in a loss of heat resistance over the years unless the fill is replenished occasionally.

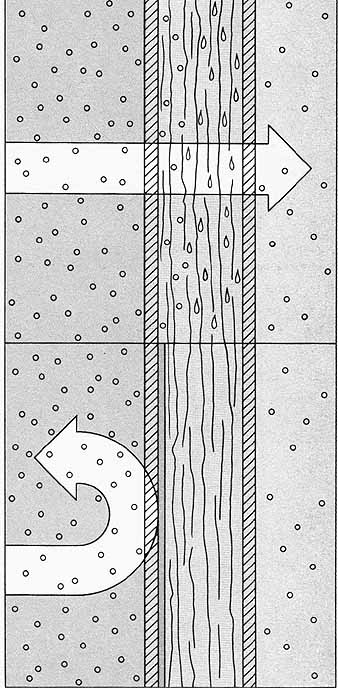

How a Vapor Barrier Works:

How a vapor barrier works. In winter, when the interior temperature of an insulated building is much higher than that of the air outside, warm, moist interior air releases its moisture as it passes through the insulation, condensing into water inside the insulation and on the cold inner surface of the exterior wall.

A vapor barrier of aluminum foil, heavy plastic sheeting or waterproof paint prevents water vapor from passing beyond the interior surface of the insulation—it never reaches a cold region and can't condense.

- Intro

- A Guide to the Complexities of Insulation

- Where to Insulate a House

- How Much Insulation Do You Have?

- Getting insulation into Finished Walls

- Some Pros and Cons of Insulated Siding

Next: Where to Insulate a House

Prev: Intro