AMAZON multi-meters discounts AMAZON oscilloscope discounts

__3.1 Small centrifugal pumps for domestic water/ heating/sanitation applications

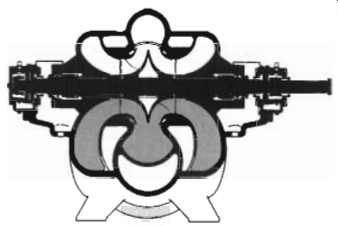

Fig. 2 Heating circulation pump of the twin design.

There are specially developed pumps, so-called heating, water and sanitation pumps for the different pumping requirements in buildings. One of their general characteristics is a low noise and vibration level, the requirements varying in accordance with the size of the building from a noise level of approximately 25dB(A) for a private house, to approximately 65 dB(A) for pumps placed in a well insulated machine room in a larger building.

These different pump requirements are covered by:

--Heating circulation pumps for circulating water in a central heating system. Smaller sizes up to a power requirement of normally 100W are of the wet type, i.e. wet rotor motors, Fig. 1. All the rotating parts, including the motor rotor are sealed inside a stainless steel can. The stator windings are placed around the outside of the can and the rotating magnetic field passes through the can wall. No seals are necessary; the bearings are usually ceramic lubricated by the hot water. Pump casings are usually cast iron or aluminum alloy with bronze or stainless steel impellers. The pumps are mass produced with fixed performance, but in order to match the circulator to the system and avoid noise in the piping system, they are supplied with a two or three speed motor.

So-called twin pump packages, i.e. a pump casing with two pumps built as a unit ready for installation in one suction and discharge pipe. The pumps can be operated together for parallel operation, see Fig. 2, or series operation. The unit includes a non-return valve system, controlled by the flow of liquid so that either pump can be operated independently or together with the other pump.

Hot water pumps for circulating domestic hot water in larger buildings so that the hot water is almost immediately available when the tap is turned on. In contrast to central heating pumps the parts in contact with the fluid are made of bronze or stainless steel instead of cast iron. Wet motors are available, as well as dry motors using special designs for motor and shaft seals in order to avoid blockages due to furring or deposition of the natural salts.

--Other pumps in buildings are pressure boosting pumps, (see multi-stage pumps, ground-water pumps and to some extent also standard water pumps for fire systems).

--Complete pump packages are supplied in buildings with water central heating systems, to maintain the static pressure in the heating circuit and make up any leaks.

Most of these pumps are of the inline design. The pump and motor form an integral package and the suction and discharge connections are inline so that the package can be fitted into a straight pipe run. Most pumps don’t require external support but rely entirely on the rigidity of the pipework. Pumps can be mounted with the motors vertically or horizontally. In most designs the pump cannot be mounted vertically above the motor.

BS 1394 should be reviewed for relevant requirements. EN 1151 specifies the European requirements for circulating pumps. Electrical safety requirements are given in Section 17, sub-sections 1.4.

Fig. 3 Automatic water supply packages a selection of models (Top right

hand illustration: AquaTech Ltd)

__3.2 Domestic water supply pump packages

Automatic water packages are used for supplying drinking water to households and properties which are not connected to the national water distribution network. The water is normally taken from a well with a suction lift for the pump of 3 to 7 m. The pump's flow and head are suitable for 1 to 3 outlets connected to the pump by relatively short pipes or hoses.

The package consists a self-priming pump, (centrifugal or liquid ring type), an electric motor, an accumulator (pressurized holding tank) and usually a pressure switch. The pressure switch ensures that the pump starts when the pressure falls due to water being drawn off and stops when the accumulator has filled up due to the corresponding increase in pressure.

There are many different makes and models available as illustrated in Fig. 3. When purchasing, account should be taken of the noise level as well as the fact that the water package should fulfill current electrical, hygienic, and legal requirements.

__3.3 Small centrifugal pumps for machine tool cutting oil applications

Special pumps are used for pumping coolant/cutting oil, or White Water, for machine tools, lathes, grinding machines, etc.

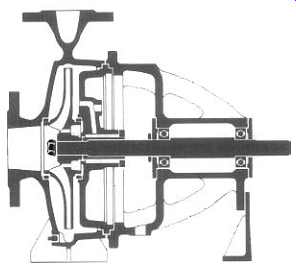

The liquid can be a specially blended oil or an emulsion of it in water, the oil content being from 2% to 15%. The flow usually varies between 0.3 and 20 m^3/h with heads varying between 2 and 20m. This type of pump is standardized in Germany in accordance with DIN 5440. This standard indicates both performance and those dimensions which have an influence on interchangeability. The pump unit is constructed so that the pump casing is submerged in the liquid with the motor placed outside the tank, Fig. 4. The immersed depth is up to 500 mm. Due to this construction, no shaft seal is required.

BS 3766:1990 specifies ten sizes in the form of dimensions and minimum performance characteristics for vertical top and side mounted units. DIN 5440 specifies six pump sizes in submerged and external forms. The French Standard, NF E44-301 incorporates DIN 5440 requirements. Normally coolant pumps are manufactured in cast iron or aluminum alloy but there are special types available in plastic. EN 12157, includes six sizes of pumps, from 1.5m^3/h to 15 m^3/h, for depths from 90 mm to 550 mm.

Fig. 4 Coolant pump for machine tools

__3.4 Horizontal single-stage end-suction overhung impeller centrifugal pumps (for general purposes includes fixed irrigation pumps, EN 733 pumps)

Standard water pumps

These are pumps designed to operate with clean water, at temperatures up to 80/120 degr. They are used for clean liquids compatible with cast iron and in some special cases bronze. Impellers may be cast iron, bronze or plastic. Small pumps will generally not have wear rings. A wide range of styles and designs is available, nevertheless, a classification into main categories can be made in accordance with Fig. 5.

Compact pumps with the impeller mounted directly on the motor shaft end, close-coupled, are suitable for flows up to a maximum of approximately 300 m^3/h and for differential heads of up to 100m. Casing pressure ratings can be up to 10 barg. Motor output can be over 100 kW however, motors exceeding 20 kW will require lifting facilities. Close coupled pumps rely on the motor bearings to absorb axial thrust and radial loads. Suction pressure may be restricted. Most of the hydraulics specified in Part. 3.4 for EN 733 pumps are also available in close coupled units which don’t comply with the dimensional part of the Standard.

====

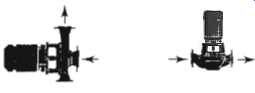

Fig. 5 Various designs of standard pumps

Horizontal compact pump with impeller mounted on the motor shaft (close coupled). End suction, top discharge; central or tangential.

Vertical compact pump with impeller mounted on the end of the motor shaft (close-coupled). Inline connections.

Horizontal pump with bearing bracket mounted with motor on baseplate. End suction, top discharge; central or tangential.

Vertical pump with support feet, bearing bracket and extended motor stool for spacer coupling. Inline connections.

====

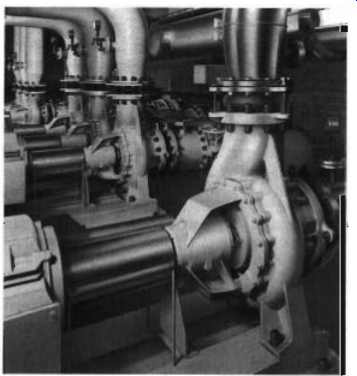

Fig. 6 A pump in accordance with EN 733

Fig. 7 A small pressed/fabricated stainless steel pump

===

Smaller vertical compact pumps can often be mounted directly in pipework without supports, this of course assumes that the pipework has sufficient rigidity. Larger vertical compact pumps have a foot to rest on a support. Normally the pump can be mounted at any angle, with the exception that the motor must not be located under the pump because of the risk of motor damage in the event of seal leakage. Mounting, other than vertical, can cause maintenance problems. Small pumps may have female screwed connections as an alternative to flanges.

Space around the stuffing box is restricted and the choice of packing and seal arrangements will be limited.

Pumps with bearing brackets, housing their own radial and axial bearings, are available to cover most of the operational range of close coupled pumps. Pumps with bearing brackets won’t have the same restrictions on suction pressure and sealing arrangements. Somewhat larger pumps are produced in this configuration. A coupling is required between pump and motor as is a baseplate for horizontal units. These units are slightly longer than the equivalent compact close coupled pump but more versatile. Some pumps are designed to be back-pull-out; the complete rotating assembly plus the bearing bracket can be removed leaving the casing connected to the pipework. If a spacer coupling to the motor is used, the pump can be maintained without disturbing the pipework or the motor. These pumps are capable of 2000 m^3/h at differential heads of 160 m and pressure ratings up to 16 barg.

EN ISO 9908 could be useful for both horizontal and vertical pump requirements. BS 4082 could be useful for vertical pump requirements. Stuffing box and seal cavities should comply with ISO 3069.

Standard pumps to EN 733 In Germany and a few other European countries for many years, there were standardized pumps for non-hazardous liquids. The German Standard DIN 24255 was probably the most popular. The German Standard has been replaced by a very similar European Standard, EN 733. The Standard relates to foot mounted horizontal pumps with a bearing bracket, see Fig. 6, and a back-pull-out facility when driven via a spacer coupling.

The Standard does not define materials of construction, only performance and physical dimensions. The Standard comprises a total of 29 sizes with discharge connections from 32 up to 150 mm. The nominal performance at BEP specifies flow of 6 to 315 m^3/h and the differential head of 5 to 80 m. The pump casing must have a pressure rating of 10 barg. The pump's design, Fig. 6, consists of a system of units based on three basic shaft sizes.

The pumps are generally built with cast iron casings, cast iron or bronze impellers and stainless steel shafts. Some manufacturers have bronze and steel casings available, as well as plastic impellers. The space, allocated for soft packing and mechanical seals, is small, limiting the use of the pumps to non-hazardous liquids. The intent of the Standard was to allow interchangeability between manufacturers, equipment and provide the user with greater choice. EN 735 lists the tolerances on pump dimensions to ensure interchangeability.

Fig. 7 shows a small pressed/fabricated stainless steel pump. This style of construction allows very thin walls to be used and hence minimizing material costs. Exotic materials can be used providing suitable rolled sheet is available. Of course, initial production costs are high because press tools are very expensive. Many pumps must be produced to recover the tooling costs. Hydraulics from popular standards, such as EN 733, are used to ensure sales into existing markets.

Fixed irrigation pumps

Irrigation and other agricultural applications make use of different pumps depending upon the location and what power sources are available. Permanent surface installations normally have single-stage pumps in accordance with Part. 3.4 or multi-stage pumps in accordance with Sections 3.12 and 3.21. When wells have been sunk, submersible deep-well pumps in accordance with Sections 3.13, 3.18 and 6.3 are used. The drive is generally an electric motor although diesel or LPG operation are alternatives. Some large installations in very remote locations use crude oil burning engines or natural gas. The required pump performance depends upon the type and size of the installation. Normal duties lie within the range 10 to 100 m^3/h with heads of the order of 50 to 120m.

__3.5 Horizontal single-stage end-suction overhung impeller centrifugal pumps (for chemical applications includes ISO 2858, ISO 3069, ISO 3661, ASMEIANSI B73.1 designs)

ANSI, the American National Standards Institute, has a philosophy more similar to DIN than ISO in that it specifies materials and mechanical seal options. B73.1 is a standard for single stage centrifugal pumps, with back pull-out, intended for chemical and corrosive duties. Construction is similar to Part. 3.21. The Standard specifies bare shaft pump dimensions, also installation dimensions for complete packages with motor and baseplate. The Standard does not specify hydraulic duties.

Mechanical seal arrangements, with various piping plans, are detailed to cover most applications.

Depending upon materials and cooling arrangements pumps must be suitable for at least 260 degrees. The Standard specifies material columns with casings in:

--Cast iron

--Ductile iron (spheroidal graphite iron)

--Carbon steel

--Alloy steel

--18-8 stainless steel

-- 18-10-2 stainless steel

Many manufacturers can supply pumps in more exotic materials such as; Carpenter 20, Hastelloy B & C, duplex stainless steels; as well as non-metallic materials like glass reinforced polymer. The Standard requires a corrosion allowance of 0.125", 3 mm.

Pump sizes vary from 11/2 to 10 suction connections with flanges to ANSI B16.1, B16.5 or B16.42. Impeller diameters range from 6" to 15". At 3600 rpm, pumps are capable of 1680m^3/h at heads up to 300m. At 3000 rpm the performance falls off slightly to 1400 m^3/h at 208 m. ANSI does specify pressure ratings for the pumps; 125LB/150LB flange rating, 12 barg and 20 barg. An option for 250LB/300LB flanges is given.

The Standard specifies a minimum bearing life of 17500 hours at maximum load conditions. On test, with a speed of + 10% of operating speed, the peak velocity of vibration shall not exceed 0.25 in/s, 6.35 mm/s.

End-suction pumps can suffer high axial thrust due to high suction pressure. Shortened bearing life may result. Manufacturers should confirm the bearing life if it’s less than the standard requirement.

ISO has prepared a standard recommendation, ISO 2858 for end-suction centrifugal pumps, pressure rating PN 16 (maximum pressure 1.6 MPa = 16 barg). This is included in British Standard EN 22858 and equivalent to the German Standard DIN 24256. The Standard specifies the principal dimensions and nominal duty point. Fig. 8 shows typical standard pumps.

General note on ASME/ANSI Standards

The ANSI B73 Standards were produced in response to requests by users to standardize manufacturers products for the chemical industries. The end-suction pump Standard was introduced in 1974 and the vertical inline in 1975. The standards were based on recommendations by users but compiled by a committee of mostly manufacturers. There are many American chemical installations worldwide and manufacturers and users should be aware of these standards.

General note on ISO 13709 and API 610

API is the American Petroleum Institute which is predominantly a trade association of pump users concerned with oil and gas production and refining. Pump manufacturers are represented on the API committees but are outnumbered by the users.

For example, API 610 specifications have a complete section for Vendor's Data; they don’t have a section for Purchaser's Data. API is a long established organization and has a large catalogue of specifications, publications and recommended practices. Since American technology is used worldwide in oil and gas related sectors, it’s logical to use proven methodology where appropriate.

API 610 is a mature specification currently up to the eighth edition published in August 1995. API is unlike the majority of DIN, and EN pump standards in that it’s more a philosophy to achieve results rather than instructions. It’s not a dimensional standard which would allow interchangeability between manufacturers. It does contain requirements but also many by agreements which are frowned upon by European standards authorities because of the lack of control and uniformity. However API 610 does specify materials of construction. API and ISO have collaborated on a new ISO Standard, ISO 13709.

The first two requirements are a 20 year service life and the capability of three years uninterrupted operation. API does follow these requirements with a statement that these are design criteria. From a European viewpoint both are not verifiable and are application specific. Bearing this in mind, API 610 pumps are heavier and more robust than most other pump designs, no pressure or temperature limitations are specified, and are suitable for the most arduous duties. Drain rim baseplates are standard and most pumps are center-line mounted to reduce alignment problems caused by thermal growth. Allowable forces and moments on process nozzles are large necessitating substantial baseplates. Pump selection is guided by a requirement to have BEP between the normal operating point and the rated duty point.

API 610 specifies the size of seal cavities and the distance to the closest obstruction and specifies mechanical seals, single balanced, as a minimum. The space available allows for complex double or tandem seal arrangements. The Standard requirement is for mechanical seals and systems to comply with ISO 21049/API 682. Arrangements for other auxiliary piping, cooling water for seals, bearing housings, jackets and pedestals, are also shown in API 610.

Spacer couplings are standard with a minimum spacer length of 127mm. Bearings, seal(s) and rotor must be removable without disturbing the driver or the casing.

API 610 specifies 11 material columns covering the following range of casing materials:

--Cast iron

--Carbon steel

--12% chrome steel

--18-8 stainless steel

-- 18-10-2 stainless steel

Although cast iron is specified as an acceptable material the lowest specification applied in practice is carbon steel. It’s very unlikely that cast iron casings could support the nozzle load requirements.

__3.6 Horizontal single-stage end-suction overhung impeller centrifugal pumps (for heavy-duty applications includes ISO 13709, API 610 designs)

Fig. 8 Typical standard ISO 2858 pumps

Fig. 9 Double suction axially-split pump with sleeve bearings and tilting

pad thrust

These are the most popular style of process pumps. Basic pump design is similar to EN 733, Part. 3.4 and ISO 2858, Part. 3.21, with a back pull-out feature. In practice, the minimum material readily available is carbon steel. Some manufacturers will make specials in bronze when commercially attractive. Standard flanges are inch to ANSI standards, B16.1, B16.5 or B16.42. Both suction and discharge flanges must be the same pressure rating. Rolling bearings, typically ring oiled, are supported in a cast housing bolted to the stuffing box or casing. Bearing housings are steel for hazardous liquids.

Pumps are available with flows over 2000 m^3/h at differential heads of 300 m. Operating temperatures from -30 to 425 degr. are common, down to -180 degr. is possible. Popular pumps range from suction branch sizes of 2" to 12". Pressure ratings of smaller pumps are up to 100 barg reducing to 40 barg for the larger sizes. Pressure/temperature rating variations with materials are important, so check flange specifications.