Tools of the Trade / Care and Maintenance

The acceptance and increased emphasis by the industry on IPM (integrated-pest management) programs have prompted the development of hundreds of new industry tools as well us changes to many items that have been industry-standards for years. Most of the new products have focused on nonchemical approaches to pest management, typically in the areas of exclusion, mechanical, and biological control.

Pesticide application equipment has undergone major revamping with the development of baits and application devices, sprayers designed for application of small amounts of product deep into harborage, and changes in dusters and aerosol generation equipment. Regardless of why these changes have occurred, the current trend within pest management is to reduce the risk of pesticide exposure.

EXCLUSION STRATEGIES

Caulk is widely used by techs to keep pests out of a structure.

Products designed to prevent pest entry and eliminate harborage sites are used more frequently in IPM programs than any other nonchemical products.

Many companies have realized that most pest problems within the structural environment originate outdoors and that it is easier and more environmentally responsible to stop them before they enter structures, thus, avoiding the use of pesticides indoors. Caulk is one of the most widely-used exclusion materials within the industry. It is used indoors in order to eliminate harborage sites and outdoors to eliminate points of entry around pipes, wires, windows, siding, doors and other wall and roof penetrations. There is a vast choice of caulking materials with different formulations (e.g., silicone, la tex, etc.), expandability, slow and fast-drying, colors, adhesive qualities, and paintability properties.

Products selected for use must adhere to the application surfaces and have the customer’s approval regarding application, color and paintability.

Under most circumstances, caulk should be used to fill small gaps and holes that are about ½-inch or smaller in size. If larger gaps require repair a filler material, expandable caulk, and other exclusion material should be used.

Screen, wire gauze, sheet metal, hardware cloth, and similar materials are used when more permanent repairs are necessary. The type of product used depends on the size of the pest (e.g., small mesh screening is effective for flying insects but does little to stop rats and mice; likewise, ¼-inch hardware cloth prevents rodent entry but is ineffective in stopping insects.). The composition of metal products is particularly important outside where these products can rust if exposed to adverse weather conditions such as rain, snow, freezing temperatures, etc.

The most commonly used materials include galvanized metal, aluminum, and stainless steel. Because it does not rust, copper wool should be used instead of steel wool. Screens typically are manufactured from aluminum and nylon which are very durable; however some insects are able to chew through plastic screens. Cement can be used to seal larger gaps and holes in structures. Regardless of the material used to seal an opening, it should be permanently installed in a manner that forms a tight pest-proof seal.

Seals, door sweeps, and chimney caps are specifically designed to prevent pests from entering structures through fabricated openings. Seals of various composition are used around doors, garage doors, and windows to keep wind and moisture out of the structure. Some products offer the additional protection of preventing the entry of rodent and insect pests.

Door sweeps look like a long brush installed on the bottom of exterior doors. They allow the door to swing freely, yet, when installed correctly, form a tight pest-proof seal. Chimney caps are designed to fit over the top of the chimney in order to exclude birds and other animals such as raccoons, and squirrels, which might attempt to use it as a nesting site.

MECHANICAL CONTROL

This pest management technique utilizes a variety of devices to trap, remove, and/or kill pests. These products use baits, light, and pheromones (i.e., chemicals used by insects to communicate between the species) to attract the pest to the device.

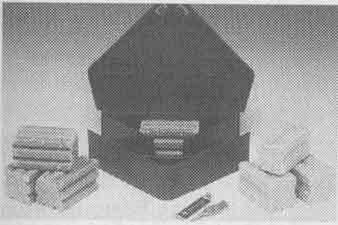

Sticky traps are designed to monitor pest infestations; in some situations, they ire used for limited control. Small cockroach infestations inside vending machines, computers, and other sensitive equipment and areas may be handled using sticky traps. Traps may also be used around doorways and entry points in order to capture pests crawling in from out side until permanent repairs can be made. Sticky traps come in a variety of sizes and some contain food attractants and/or pheromones. Sticky traps frequently are used by pest management professionals for flies, stored product pests, occasional invaders, and cockroaches.

Sticky traps come in a variety of models and styles.

Glue boards, with much larger surface areas,

are primarily designed to capture rats and mice and other rodents; however,

they may also be effective in capturing certain insects. Some traps incorporate

a food attractant in the glue; others leave the option of baiting up to the

technician.

The major limitations to sticky traps and glue-boards are correct placement, (i.e., along lines where the pest is expected to travel), and dust and moisture which can destroy the adhesive properties of the trap. Glue boards must be inspected frequently for trapped rats and mice; trapped animals must be quickly removed and destroyed.

Snap traps are among the oldest items still in use by the industry and have remained relatively unchanged over the years. Traps consist of a wood or plastic base with a spring-loaded lever and trigger mechanism. The small trap is used for mice; the large one is used for rats. Those models with an enlarged trigger mechanism often are used without bait. Typically, small trigger traps are baited with food or nesting material. Although traps should be clean, they do not need to be sterile for continued use. Damaged or heavily soiled traps should be discarded and replaced. Traps should be placed in rodent runs perpendicular to the route of travel with the trigger positioned in the run, and they should be located out of the reach of children and non-target animals.

Live traps are used to trap mice, birds and larger animals which, under most circumstances, will be released at a distant location following capture. The most notable exception are mice which usually are destroyed. Repeating mouse traps consist of a wind-up mechanism and sweep bar activated by a trigger mechanism as the mouse enters the trap. Once activated, the sweep bar quickly pushes the mouse into a holding chamber. The holding chamber can accommodate a number of mice. Live traps for other animals include wire cages with spring doors connected to a treadle which closes the door once the animal is inside. These traps are usually baited with food and placed inside animal runs and feeding sites.

Light traps come in all sizes and shapes but share two basic characteristics: they use light to attract flying insects (and jumping insects, in the case of fleas) and either electrocution or sticky boards to kill or entrap the in sects, respectively. Light traps vary in the intensity and frequency of the light emitted which leads to many manufacturer claims regarding which is the better light trap.

Light traps are designed to control flying insects.

If installed correctly, i.e., away from entry ways and at the appropriate height for the target pest, light traps are an effective means of eliminating populations of flying insects in doors. Light traps are not recommended for use outdoors because they tend to attract undesirable insects, such as mosquitoes, into the area being protected. Light traps must be serviced on a regular basis to remove the accumulation of dead insects and replace glue boards. Failure to do so can lead to secondary pest infestations such as dermestid beetles which feed on dead insects.

Jar traps (also available with bags) are used to capture flies and yellow jackets. To attract insects, the traps are baited with food materials specific to the insect pest. The traps are designed with entry ports to permit the insect to enter at the top of the trap and pass through a “funnel”, thus, preventing the insect from flying or crawling out of the trap. Trapped insects either succumb to exhaustion or drown in fluid at the bottom of the jar. Because spoiled food attractants and dead insects cause foul odors, it is important to inspect the traps frequently, Vacuums are used to physically remove pests, such as cockroaches, spiders, and other occasional invaders, from structures. They vary significantly in size and shape, and some are outfitted with HEPA filters designed to remove the smallest particulate matter from the air. Consideration must be given to the method of handling the pests that have been vacuumed into the bag or other filtering device. Disposable bags are easily handled by removing the bog, placing tape over the opening, and discarding it in the trash. Pests collected in reusable bags can be killed by spraying a small amount of pyrethrin into the vacuum while it is operating or taping the opening and placing the bag in a freezer for several days.

Vacuums can be used to physically remove pests, like cockroaches,

dangerous spiders and other pests, from an account.

BIOLOGICAL CONTROL

Biological organisms, by-products of biological organisms, and products which affect the growth and development of pests have been used to manage pest populations since the beginning of time. Several of these natural organisms have been isolated and harnessed for use in order to control a variety of agricultural pests Unfortunately this technology has limited use in structural pest management.

Predators and parasites are the most commonly recognized biological control organisms. Unfortunately they do not play a major role in the management of structural pests. Several parasitic wasp species which attack fly pupae and cockroach egg capsules have been identified and cultured. A lack of customer acceptability is the major limitation to their use indoors because hundreds of thousands of parasites are often necessary to effect control, and they are not self sustaining in the absence of their host insect.

Nematodes are unsegmented, soil-inhabiting worms which are parasitic on plants and animals. Several species have been identified and cultured for use against termites, cockroaches, fleas, and mosquitoes. The greatest success with these organisms has been in controlling fleas and mosquitoes.

Bacteria, single celled organisms, ore the oldest commercially-marketed biological pesticide. Bacteria must be ingested in order to cause toxicological affects on the insect. Most pathogenic bacteria contain a crystalline spore and toxin. When the spore enters the insect gut, it dissolves, thus, releasing the toxin which then causes the insect’s digestive enzymes to eat holes in its gut, thereby releasing the bacteria and gut contents into the blood. These events lead to on infection which eventually kills the insect. Bacteria in structural pest control is limited to mosquitoes, black flies, and fungus gnats.

Avermectin, a bacterial derivative, recently has been developed as a very effective bait for cockroaches and ants.

Fungi are multicellular organisms closely related to plants which cause diseases in a variety of insects. They infect the insect through spores which require moisture and humidity in order to germinate and penetrate the cuticle (hard outer skeleton) of the insect. Infected insects die from toxins produced by the fungus. A fungus, Metarhizium anisopliae, has been developed for use on cockroaches and termites.

Some termite baits use insect growth regulator (IGR) technology

to control termites in structures.

Insect growth regulators (IGRs) are synthetic chemicals similar to insect juvenile hormones which regulate growth and development of insects. Exposure to small concentrations of these products disrupts insect molting and development of the reproductive system. Some products cause death in the molting process; others cause only reproductive failure in the population These products do not affect insects in the pupal stage and adults; therefore, other control measures are needed in order to manage these life stages. These products are used to manage cockroach, flea, stored product pest, termite, and mosquito populations.

Chitin synthesis inhibitors are products which affect the formation of the insect cuticle (i.e., hard outer skeleton). Thus, because insects exposed to these products do not develop normally during the molting process, they die.

APPLICATION EQUIPMENT

These pest management tools are designed to apply specific pesticide formulations, e.g., liquids, dusts, and granules. Very few items of equipment are capable of dispersing more than one formulation. Thus, the selection of equipment is based on the formulation, site of application, and size of the area to be treated.

LIQUID DISPERSAL EQUIPMENT

Aerosol dispensers are pressurized cans with a push button nozzle or specialized equipment designed to generate small particles. In aerosol cans, the pesticide is dissolved in a solvent and then mixed with a gas; the pesticide is dispersed as a fine spray when the nozzle is depressed. Aerosols are ready-to-use products which require no further dilution. Because many of the solvents used in aerosols are petroleum-based, these products should not be dispersed near an open flame nor in confined spaces where electronic ignition pilot lights are used.

A mechanical aerosol generator.

Ultra-low volume (ULV) and ultra-low-dosage (ULD)generation equipment is capable of dispensing droplets which are even smaller than those produced by aerosol dispensers. This type of equipment is designed to disperse very small amounts of highly concentrated pesticides. These generators are either gasoline or electrically powered and range in size from hand-held units to vehicular mounted models. This equipment is used to control flying insects indoors and outdoors, exposed crawling insects, and to flush in sects out of deep harborages.

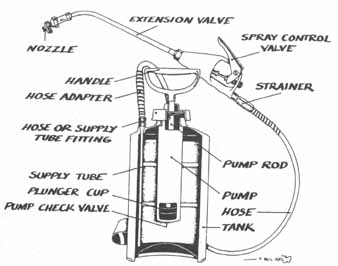

Compressed air sprayers have been the standard tool of the pest control industry for decades. However, in recent years, the industry has begun to wean itself from baseboard spraying and this type of pesticide application equipment in response to customer demands for more targeted pesticide applications.

These sprayers typically have a tank capacity of one to three gallons and are used to apply residual insecticides in and around structures and for treating areas outdoors such as foundations, around doors and windows, pet resting areas, etc. The ideal operating pressure for this sprayer is 25 to 50 psi; lower pressure causes the liquid to dribble out of the spray tip; and higher pressure causes the product to splash. There are several types of nozzles available for use with compressed air sprayers, and selection is based on the site of application.

The compressed air sprayer for indoor/outdoor use.

The solid stream tip and the plastic extension crack and crevice tip are designed to apply a fine stream of insecticide directly into cracks and crevices for crawling insect control. The flat spray tip produces a flat fan pattern and is used to make spot applications to floors, walls, and areas where pests are present. The hollow cone tip produces the largest volume of insecticide and is used for outdoor applications such as treating bushes, foundations, bodies of water, and other surfaces where higher volumes of product are needed.

Hydraulic sprayers are designed to allow technicians to deliver large volumes of pesticides at higher pressures. This equipment can be outfitted with either a boom or single nozzle. Only the latter piece of equipment is used in structural pest control operations. The nozzle sprayer is used to treat large surface areas around and on buildings, trees, ornamentals, turf, and to inject pesticides into the soil for the control of subterranean termites.

Hydraulic sprayers are used to treat large areas.

DUST AND GRANULAR DISPERSAL EQUIPMENT

Bulb dusters are commonly used indoors to dispense dusts for the control of cockroaches and other crawling insets in areas where liquids can not be used, e.g., electrical junction boxes and around equipment. The rubber bulb reservoir (four to eight ounces) capacity is fitted with either a screw cap or stopper, and has either a metal or plastic extension tip. Placing a marble or ball-bearing in the reservoir keeps the dust from caking and helps in dispensing fine puffs of dust. A modification of this duster which consists of a bulb duster at the end of a long pole permits the treatment of wasp nests in high places and from a safe distance.

A bulb duster being used for an exterior application

at a house.

Plunger dusters and foot-pump dusters are designed to apply dusts for the control of ticks, mites, and rodents in outbuildings and outdoor sites. The plunger duster has a smaller capacity than the foot duster which can hold one to five pounds of dust. Both dusters can be outfitted with a rubber hose to disperse dust deep into rodent burrows.

Compressed air dusters are adaptations of compressed air sprayers designed to apply only dusts. The dust is placed in the tank which is pressurized using a hand pump or compressed air source, and the dust is dispensed through a hose and nozzle modified for this formulation. One of the best uses for this type of equipment is to dust large void areas such as crawl spaces and attics.

Granular spreaders are of two designs — the push-type spreader which drops granules from a hopper onto a dispersal wheel which evenly distributes the granules in a six to eight foot swath and the granule spreader which is hand held and operates by turning a crank on the side. The capacity of the hand held unit is significantly less than the push-type which can disperse several hundred pounds of granules per hour. These spreaders are used to disperse pesticide granules outdoors to control pests which occasionally invade structures.

Backpack sprayer-dusters have dual capabilities, i.e., they can be used to disperse liquid and dry formulations. They have the additional utility of being carried on the applicator’s back and facilitate treatment of isolated areas for mosquitoes and areas around structures where it is often desirable to apply larger quantities of pesticides.

Backpack sprayers may be used to treat large areas.

BAITING TOOLS

Containerized baits are one of the most popular items in commercial pest management and the over-the-counter consumer market. Formulated primarily for the control of ants and cockroaches, the baits ore contained in child-resistant plastic containers. Some of the bait stations have a see through lid which permit visual inspections to determine the amount of bait remaining. To work effectively, containerized baits must be placed in the trails used by the target pest population.

Bait guns are designed to use either refillable cartridges or pre-filled bait cartridges, and dispense a variety of active ingredients. The gun is outfitted with a syringe-like needle which is used to place small amounts of bait, usually no larger than the size of on “o,” directly into cracks and crevices where cockroaches hide.

Bait guns are a common IPM tool.

It is much better to have numerous small placements than one large one, and the bait should never be applied like caulking material in a long bead.

Tamper-resistant rodent bait stations are designed to prevent children and

non-target animals from being exposed to rodenticides. These stations are

designed to dispense liquid, block, and/or loose bait formulations. In most

circumstances, it is preferable for the technician to secure the bait station

so that it can not be picked-up by children, pets or other non-target animals.

Technicians should always make sure the station is secured and locked.

Tamper-resistant rodent bait stations are designed to prevent children and

non-target animals from being exposed to rodenticides. These stations are

designed to dispense liquid, block, and/or loose bait formulations. In most

circumstances, it is preferable for the technician to secure the bait station

so that it can not be picked-up by children, pets or other non-target animals.

Technicians should always make sure the station is secured and locked.

CARE AND MAINTENANCE OF EQUIPMENT

Pesticides should not be stored within dispersal equipment for extended periods of time. A good rule-of-thumb: liquids can be stored overnight if they will be used the next day, and dry formulations should be stored for no more than a week. After each use, clean and repair pesticide application equipment as needed. Preventive maintenance will minimize problems on the job site. Liquid application equipment should be washed with soap and water after each use and when using different products.

Gaskets, strainers, and filters should be kept clean and serviced on a regular basis. Strainers and filters should be rinsed with water and cleaned with a soft bristle brush. If this does not remove the residue, the nozzle should be soaked in an appropriate solvent.

Equipment should be regularly cleaned and, also, inspected for proper opearation.

Nozzles which cannot be adequately cleaned or are damaged should be replaced. Valves should be inspected regularly for serviceability, i.e., they should open easily and rapidly, shut-off quickly and tightly, and be replaced if defective.

Plunger and piston cups should be inspected for wear and tightness of fit. Whenever pressurized equipment is cleaned, the leather cups should be lubricated with a light grease. Nozzles should be cleaned very carefully to avoid any damage to the opening in the tip. Rinsing with soap and water is usually sufficient, however, heavy residues can be removed with a soft bristle brush and by soaking in an appropriate solvent. If the nozzle opening is worn, it should be replaced.

Hoses should be inspected on a regular basis for cuts, cracks, bulges, and fraying and replaced if a defect is found. Couplings should be inspected for leaks and repaired. Dusters should be cleaned weekly by removing excess and caked dust from the chamber. The dust tube should be cleaned with a stiff brush and caked dust should be carefully removed from filter screens and small openings.

All electrically-powered equipment should be cleaned and inspected for any defects in the cord and extension cords. The grounding pin should not be removed, and all outlets used during normal operations should be grounded. Electric cords, when worn, should be replaced.

Gasoline powered equipment requires minor maintenance, i.e., the oil level should be checked, and the air filter should be cleaned monthly. Oil changes should be based on the hours of use and the manufacturer’s recommendations but no less than annually at the beginning of each season. At the end of the season, the remaining gas from the tank should be drained and the engine run until all the fuel in the carburetor is gone. Pumps, tanks, and hoses stored outdoors in freezing temperatures should be drained and antifreeze put in the pump. Equipment manuals, which are the sources of information for repair parts and care and maintenance instructions, should be stored in an accessible area.

A compressed air sprayer.

Prev: Identification and Control

Next: Safety