A storage shed in your yard makes good sense. It may even be a necessity if you don’t have a garage or if you have only a small, single-car garage. A simple shed with 2x4 stud walls and rafters is a relatively easy construction project for the above-average do-it-yourselfer. Starting from the ground up is a good way for a beginner to gain experience in carpentry. If you aren’t seeking carpentry experience, numerous easy-to- assemble prefabricated shed kits are available on the market.

Prefabricated sheds include traditional wood models, metal units, and high-impact

vinyl. The kits come with materials precut and ready to assemble. With basic

skills, a tape measure, level, hammer, screwdriver, and a helper, you can

erect one in no time.

The kits come with detailed instructions specific

to the model, so the steps shown here are general in nature to give you

an idea of just how easy it is to put a kit shed together.

PREPARE A FOUNDATION AND FLOOR:

Most shed kits do not include floors; they can be purchased as an option, or it’s easy to build your own. A solid floor and foundation beneath a shed will prolong its life.

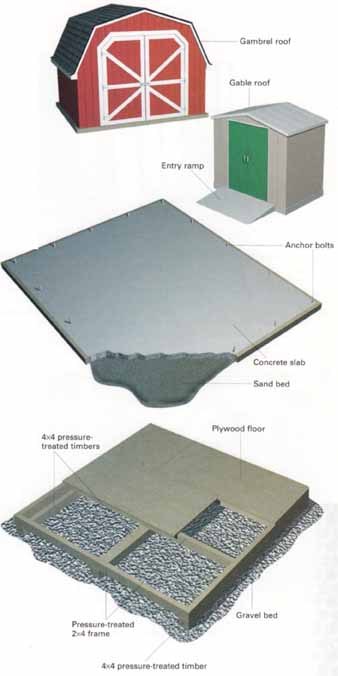

There are two basic options for floors: a concrete slab or a plywood floor constructed on top of 4x4 treated timbers, which in turn rest on a gravel base. In either case, lay out the area with batter boards and mason’s lines. Remove the sod from the area, taking about 4 inches around the perimeter of the shed.

If you’re going to pour a concrete slab floor, add a 3-inch sand base on the earth. If the shed is extremely large, check with local building codes for foundation and footing requirements. Pour the concrete into 2x4 forms so the top of the slab is 3 - 4 inches above ground level. You may have to place anchor bolts in the concrete for the shed walls, depending on the manufacturer’s instructions,

For a plywood floor, excavate an additional 4 inches and place 4 inches of gravel on the earth. Set three or more (depending on the size of the shed) 4x4 pressure-treated timbers on the gravel, making sure they are level in all directions, Using pressure-treated 2x4s, build a floor frame on top of the timbers with joists spaced 16 - 24 inches on center, depending on the size of the shed.

Nail / pressure-treated plywood on top of the floor frame.

Gambrel roof; Gable roof; Entry ramp; Anchor

bolts; Concrete slab; Sand bed; Plywood floor; 4x4 pressure-treated timbers;

Gravel bed; Pressure-treated 2x4 frame

(left) Raise the walls: Raise one of the

wall units, nailing it to the plywood floor or bolting it onto the anchor

bolts in the concrete. Set it vertical and brace it. Install the adjacent

wall in the same manner, then connect the walls according to the manufacturer’s

instructions. Depending on the style of the shed, you may have to install

the gable ends on top of the end walls, or they may be a part of the end

walls. If you’re building a metal shed, wear gloves to protect yourself

from sharp edges. (right) Install rafters and roof: Roof installation varies

by manufacturer and style. With a typical gable roof, rafters may come as

truss units, or you may have to tie them into a ridge beam that connects

the two gables. Install the rafters, then cover the roof with shingles over

a plywood sheathing. Or attach metal roofing panels with special sheet-metal

roofing screws that have rubber washers to prevent leaks.

(left) Install doors: door styles vary by

shed style; you also may have a choice of door type with individual models.

Single or double doors can be mounted on hinges to swing open or on tracks

to slide open. Some models also have roll-up doors similar to garage

doors, but these limit your access to storage space in the gable area

of the shed when the door is open. Hinged doors are the easiest to install.

With most kits, you simply install the hinges on the door jams and hang

the doors. (right) Add a ramp: Whether you use a concrete or a plywood

floor, the shed will sit 3 - 6 inches off the ground. This ensures the

items in the shed will remain dry. To make access easier, add a ramp in

front of the door. Extend the ramp out from the shed 2-3 feet, depending

on the slope you want. Use pressure-treated 2x6s, ripped to the appropriate

angle and covered with pressure-treated plywood. Set the ramp on a gravel

bed so water drains away from the wood.