AMAZON multi-meters discounts AMAZON oscilloscope discounts

Computerization of any management function has become possible and in some cases relatively common. Computerization has yielded significant benefits, but it has also yielded disasters. Thus, if we are to be successful in computerizing maintenance management, it is necessary to know the components of the function.

The components described here are appropriate for the various types or levels of maintenance work including routine, preventive, corrective, shutdown, facility, etc.

Work Order. A document that instructs the maintenance person in what is to be done. It identifies crafts, if appropriate; materials; special tools; critical times; and provides other necessary information to accomplish the job. If complete information is not provided, the document is a work request.

Prioritizing. The act of determining which jobs have precedence. Since the function of maintenance has limited resources available at any given time, this act is always performed in a formal or informal manner.

Material Availability. A majority of the jobs performed by maintenance involve the use of materials. The material may range from a simple fastener to a sophisticated microprocessor and is necessary to provide the service that is requested.

Work Plan. The asking of why, what, who, where, when, and how the maintenance group will respond to a work request. It provides logical answers to these questions.

Job Sequence. Frequently called scheduling. It recognizes priorities and resource availability and can be done at several levels.

Backlog. A listing of work that is yet to be done.

Control Reports. An after-the-fact record, or accounting, or what has been done and some form of measurement.

Computerization inherently means organization. In the case of maintenance management it means an organized database. The components of the maintenance management function determine what the elements of the database are and include:

Assignment of Costs. This usually follows the patterns established by accounting procedures used at a particular facility. It generally recognizes cost centers, departments, divisions, etc., and frequently, but not necessarily, is geographically oriented. Although a variety of approaches can be used to develop sort levels or to accumulate costs, a clear definition of the approach is critical at the start of a program to computerize maintenance management.

Equipment Identification. This normally takes the form of equipment numbering and includes physical assets or functions on which maintenance resources will be expended. Careful consideration should be given here as to how finely equipment should be identified. For example, should each door in a facility be numbered or should all doors of a certain type be grouped together as one equipment? A case can be made for both approaches depending upon the type of facility and its needs.

Employee Lists. Those people who will be charging time to maintenance work have to be identified. In many cases this will involve the development of a trades or crafts list. In the case of multi craft facilities it may include the several levels within the maintenance multicraft category. Trades or crafts are then associated with employee lists for time and cost analysis. Employee lists should be reconcilable to payroll but not necessarily generate or drive payroll.

Priorities. The type of priority approach must be agreed upon when building the database for a computerized maintenance management system.

Work Orders. The format for the work order must be agreed upon at the beginning of the computerization process. It is the key to accumulating and distributing cost, plus developing histories for future analysis. Although no database is preloaded, one is rapidly generated.

Parts Lists. In a complete maintenance planning and management control system, materials play an important role. Thus, a parts list or catalog for stocked material is necessary. These should be numbered, categorized, quantified, located, and priced when loading the database. In addition, pro visions should be made for purchased parts that are not stocked.

Depending on the sophistication and needs of the system, several other items are recommended when loading the database.

Cause Codes. Standardized identification of the basic causes of the work generated. This may be the basis for preventive maintenance programs or schedules that are part of the system. Cause codes provide a means for analyzing work and developing a corrective maintenance program.

Action Codes. Standardized identifications of what was done to respond to a work request. This is basically used to identify what level of "fix" was done and again can initiate a corrective maintenance program.

It should be noted here that a computerized maintenance management program does not, by itself, truly plan maintenance work. It cannot:

_ Determine if the work request provides adequate information so that maintenance people under stand what is to be done.

_ Make a sketch to illustrate what is to be done.

_ Decide what materials to use.

_ Ascertain what time constraints exist because of production or other needs.

In short, a computerized maintenance management program cannot ask the six questions of:

Why? What? Who? Where? When? How?

It is, however, a fine and powerful tool for assisting in maintenance planning. A well-conceived computerized maintenance management system should provide manpower backlogs, equipment hiries, equipment parts lists; determine material availability; provide preventive maintenance schedules; and track costs.

WHY COMPUTERIZE MAINTENANCE MANAGEMENT? It has become commonly accepted that maintenance represents a significant portion of the cost of doing business or providing a service. The portion of cost that maintenance represents will continue to increase as the various forms of automation increase. It therefore behooves us to make optimum use of that resource called maintenance.

Planning and scheduling of maintenance is one of the ways of optimizing the use of this resource.

Normally, however, one of the problems is the amount of clerical work, or "paper shuffling," associated with such planning and scheduling. Computerization, if properly conceived, can minimize this problem.

Computerization can provide backlog information for various types of work; availability of materials; costs by job, facility, or type of work, etc., easily. It can increase effectiveness of planning, scheduling, and cost tracking by as much as 50 percent. In addition, it can frequently provide types of information not normally available, at no additional cost.

ORGANIZING FOR COMPUTERIZATION

This first step in computerization of maintenance management is program definition. This is necessary whether buying a software package in the marketplace or developing programs in-house. The question of what you want done is paramount.

The ability to track costs is an obvious requirement. What costs? The computerized program should give information on material availability. What information? Location? Quantity on hand? Vendor? Should the program generate purchase orders and when? What type of equipment histories should be generated? Is the program to be maintenance management oriented? Should the program provide information to corporate headquarters and between other facilities within the corporate structure? These and many other questions must be addressed in order to define the program.

Normally the definition cannot be achieved by the plant engineer, maintenance manager, or any other single individual. In addition, it is not normally practical for a single individual to implement a computerized maintenance management program. An interdisciplinary team provides the most workable approach for defining the program and implementing it. Heading up or coordinating such a group should be a high-level person responsible for the maintenance function.

Disciplines represented on the project team include maintenance, data processing, and accounting. Other disciplines that are frequently helpful are industrial engineering, purchasing or material control, payroll, and production. The use of the latter depends upon the personality of a particular organization. The team should be kept to a workable size, three to six people.

After establishing a project team and developing the program definition, technical evaluation takes place. Answers to questions in the technical evaluation may modify program definition, but the definition must be made first. Technical evaluations include hardware evaluation and make-or-buy software considerations.

IMPLEMENTATION OF A COMPUTERIZED MAINTENANCE MAN AGEMENT PROGRAM

Organizing for implementation of a computerized maintenance management program is one of the jobs of the project team. At this time of implementation, definitions of the following items should have been made:

_ Who is going to perform the function of maintenance planning and/or scheduling?

_ Who is going to front-end load semi-permanent information such as cost centers, employee lists, parts lists, equipment lists, cause codes, action codes, budgets, or other information that is not changed on a daily or weekly basis? Included in this is the definition of the sequence necessary for the loading of these data.

_ Who is going to maintain the files on a daily and weekly basis? Several persons may be involved, such as a planner to load work orders, a time clerk to load employee time sheets, a storeroom clerk to load material requisitions, or any other appropriate combination. It is advisable to have individual information flowcharts for each of the information flows of the system.

_ What type of security is going to be part of the system? That is, definitions and procedures should be established as to who can enter and/or modify information in each of the systems' various segments, who can view information, and who can call for reports.

_ Forms for data entry should be designed for data entry. They should be compatible with the computer's entry format and include work orders, time sheets, and material requisitions.

Orientation of the various people concerned with the new computerized maintenance management program is the next step after organization. This may take place as part of organizing.

Orientation will be necessary from the highest levels of the facilities organization to the lowest and includes production and staff as well as maintenance people. The details of the orientation appropriate for the various groups is of course different. It is also appropriate to have concise progress review sessions as the implementation takes place.

Orientation and training are similar, but there is a difference. Orientation is informing people what is going to be done or what is being done, while training is instructing people in how to do something.

Training of people is a critical aspect of the implementation of a computerized maintenance management program. Training minimally should include:

_ All users as to how to write a work request.

_ All users as to how to exercise the priority system.

_ All data-entry people as to the necessary procedures for correct data entry.

_ Appropriate maintenance people (planners, supervisors, etc.) on how to retrieve information.

_ Maintenance management and supervision, and appropriate production management as to how to read and interpret reports and other available information.

In summary, although computerizing maintenance management is a demanding task, the benefits are normally significant:

Better labor utilization 5 to 25 percent

Equipment utilization 1 to 5 percent

Stores inventory reduction 10 to 20 percent

OPERATING CHARACTERISTICS OF A GOOD SYSTEM

On-Line Inquiry. A typical complaint made about computerized systems is that they must generate too much paper. Thus one of the prime characteristics of a good computerized maintenance management system is that it has on-line inquiry and provides screen viewing for the areas of work orders, material, and equipment.

Work Orders. The work order is the controlling document in any maintenance management control program. When viewing a work order on a screen in a computerized program, the following information should be readily available:

_ What equipment the work is to be done on.

_ A description of the work to be done.

_ The kind of priority the work has.

_ What charging centers should be assigned the costs incurred.

_ When the work order was written, when it was last worked on, and when it was completed.

_ What the work's current backlog status is.

_ An estimate of how much time by craft will be needed to perform the work.

_ Costs, both labor and material, charged against the work order.

Other information may be desired but the foregoing are necessary for good maintenance management.

In addition, the program should be able to selectively bring up work orders for observation. The selection criteria should include:

_ Cost areas

_ Equipment numbers

_ Dates written, issued, completed, or last worked

_ Priority level

_ Backlog status

_ Cause or action taken

_ Trade

_ Supervisor

_ Planner

Through the use of any one or combination of the above selection criteria, file search time by the viewer is greatly reduced.

Material. A good storeroom is helpful in optimum equipment and manpower utilization. Screen viewing of material in that stockroom should include:

_ Parts catalog by part number

_ Parts catalog by location

_ Parts status summary

_ Open purchase orders

_ Parts issued and returned Included in this section should be the ability to view:

_ Vendors

_ Maximum and minimum quantities

_ Costs

_ Reorder quantities

_ Usage information on a periodic basis

Equipment. The third leg of a good maintenance management program concerns equipment.

Screen viewing for this section should include:

_ An equipment list

_ A work order list for the piece of equipment

_ A parts list for the piece of equipment

_ Maintenance expenditures (labor and materials) for the piece of equipment

Custom Report Generation. A second characteristic of a good computerized maintenance management system is the ability to generate specific reports on demand. The selection criteria should be similar to those for screen viewing and include the following reports:

Work Orders:

_ Work order status

_ Backlog status

_ Closed jobs

_ Equipment downtime

_ PM schedule

_ Time sheet transactions

_ PM compliance Materials

_ Parts catalog

_ Inventory status

_ Inventory usage

_ Reorder report

_ Physical inventory reports

_ Location catalog

_ Parts activity list

_ Vendor names and addresses

_ Purchase order lists Equipment

_ Equipment lists

_ Equipment status

_ Equipment parts list

_ Equipment parts usage

Performance Reports. The third characteristic that a good system should have is measured performance against some type of target or budget. These reports should be brief yet meaningful for maintenance management and include:

_ Hours analysis

_ Backlog summary

_ Closed job summary

_ Schedule compliance

_ PM compliance

The most important characteristic is that the program is "user-friendly." This means that users needing information can get it easily, usually by means of a series of menus and questions asked by the computer.

Teaching the user to respond to menus and questions is easier than teaching the user how to query the computer in its own language.

WORK ORDER SYSTEM

Purpose. A formal work order system provides an information network incorporating inputs and outputs for all the various phases of the maintenance program.

Scope. The work order system and its procedures provide a uniform means of information flow for requesting, planning, scheduling, controlling, recording, and analyzing the performance of all the work done by the maintenance department. The work order form serves as the vehicle for communicating information related to specific work requested of maintenance.

More specifically, the work order system provides:

_ A single common means of transmitting requests for services by the maintenance department that increases the probability that the information needed by the maintenance department to perform the work will be included in the order.

_ A means whereby all work requested may be screened and analyzed to ensure that it is needed.

_ A means whereby most work can be preplanned and estimated as to time, methods, and materials to further ensure optimum performance.

_ A means of controlling the work going to the various maintenance groups through the scheduling procedure, to assure that the most important work is performed first.

_ A means whereby management can track performance relative to time, cost, and materials used for specific work that was requested.

All too often verbal work orders result in performance of unimportant, unauthorized, unnecessary, and even unwanted work. To reduce the possibility of this happening, it is essential that all requests for maintenance services be submitted in writing on the work order form. Requests for ser vice may be initiated by maintenance or production personnel desiring to have work performed.

The work order is the basic authorization for performance of maintenance work and, together with the "planning package," will produce an accurate account of individual maintenance jobs. It may be used as a reference for similar jobs in the future.

RIME PRIORITY SYSTEM

Purpose. In general, it can be said that there is never enough time, money, or manpower to perform all of the maintenance work that is needed and/or desired.

The decision as to what maintenance work is performed and when, if not systematized, will be made on the subjective judgment of any one or a combination of several persons.

If the intent, as it generally is, is to perform the most badly needed and important work first, then it is desirable to have a reasonably objective system to identify priorities for maintenance work that can serve as a guide for the maintenance department.

The intent, therefore, is to develop a relative priority ranking system for maintenance work based on the collective judgment of those responsible for the operation of the facility.

The best method of achieving this is one which produces a quantitative index of the relative importance of a job at the time that the need for the job occurs. Thus personal judgments are less likely to influence the resultant ranking of jobs by priority.

Scope. The system for establishing priority values is called RIME (Ranking Index for Maintenance Expenditures). This system, which provides a wide range of priority numbers, will best provide a true ranking of all the varied jobs which maintenance must perform.

To establish a sound priority system, the following three elements are essential. Without them, the system will function improperly.

1. The priority system must encompass everything within the plant.

2. All production and maintenance personnel involved must understand and respect the priority system.

3. The priority system must be based on profit.

The computing of job priority indexes considers the equipment and facilities (equipment code) in conjunction with the importance of the work (work class). These two considerations provide multiples which establish the value of the work requested. The higher this value, the more important the request.

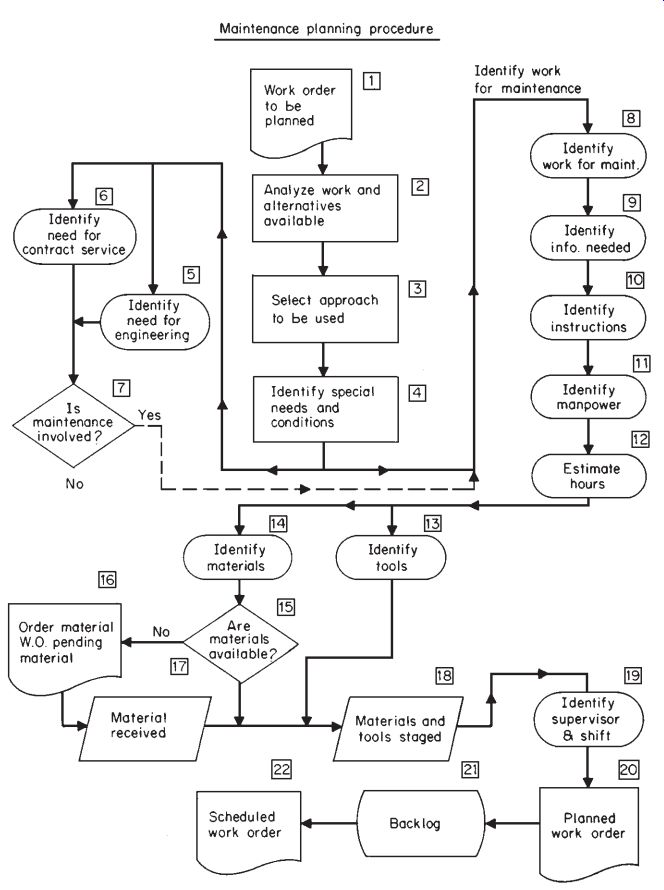

FIGURE 1 Flowchart showing how the maintenance procedure moves along in

logical sequential stages.

PLANNING PROCEDURE DEFINED

The following outline describes the procedure for work order planning in detail. (See Fig. 1.) 1 Decision has been made that the work order requires planning.

2. Analyze the work requested:

a. Is the information complete and adequate?

b. Is the work needed?

c. Why is the work needed?

d. Can anything be done to avoid recurrence in the future?

e. Visit the job site, if appropriate.

3. Determine the basic approach to be followed:

a. What is the priority of the work?

b. What effect will it have on operating?

c. What are the future plans for the equipment?

d. Is the equipment scheduled to be overhauled, replaced, or phased out?

e. Can repair provide the same reliability as a replacement at a lower cost?

f. Make sketches as required.

4. Identify special considerations, needs, and conditions: Is production assistance required? 5 Identify need for engineering:

a. If required, notify engineering or have the appropriate person do so.

b. If maintenance is involved, identify work for maintenance.

6 Identify need for contract service: If required, contact contractor or have the appropriate person do so.

7. Is maintenance involved? If maintenance is involved, coordinate job.

8. Identify work for the maintenance department.

9. Identify information needed.

10. Identify instructions required: If description of work does not clearly state what work is to be done, provide instructions.

11. Identify manpower required.

12. Estimate man-hours required.

13. Identify any special tools or permits required:

a. Is work overhead?

b. If welding is required, is a welding permit needed?

c. List any special tools.

14. Identify material/parts required: Are any special materials/parts needed? If so, list them.

15. Determine if materials/parts are stock items; if so, list location.

16 If materials/parts are non-stock or out-of-stock items:

a. Order.

b. Record the work order number on the purchase order and the purchase-order number on the work order.

c. Change the status of the work order to delayed materials in the backlog file.

17. Material/parts received:

a. As the material/parts are received they are charged to the work order.

b. When all the parts are received, the work order status is changed from pending material/parts in the backlog file.

18. All material/parts and tools are staged.

19. Identify the supervisor that will be responsible for the work.

20. The work order is now planned.

21. Backlog file: Planned work order's status is changed to the appropriate ready-to-run category, and it is placed into the backlog file.

22. Planned work orders are scheduled: The work order is pulled from the backlog file and given to the supervisor with the weekly schedule.

PLANNING FOLLOW-UP

Effective planning requires observing preplanned job progress to eliminate potential delays or problems that may arise. The planner should occasionally observe planned work in progress with the intention of improving his preplanning expertise.

During the follow-up process, the planner may address problem areas which are common to planning functions. These areas are:

_ Were the communications clear and adequate for all personnel involved on the job?

_ Was the planner's time properly utilized?

_ Was translation of the job plan in clear and understandable terms?

Remember, the goal of planning is to eliminate the cause of the job and to eliminate this job in the future. To repair quickly is not the basic goal. The reason for maintenance planning is to eliminate the cause while overcoming the effects efficiently.

ANALYSES AND DISPLAYS

Work Orders

The work order section contains information pertaining to specific work for a piece of equipment or facility. This work could be corrective or preventive maintenance, emergency, routine, or standing orders. The data collected provide answers to the standard questions of what, when, where, why, who, how much, and how often. Output from the system consists of two types of reporting.

1. Planning function data and specific information about job orders are provided on request by the following reports:

_ Work order status--CRT display screen

_ Work order recording and update--CRT display screen

_ Backlog status report-hard copy

_ Closed job status report-hard copy

_ PM master schedule-hard copy

_ Equipment downtime report-hard copy

Backlog and completed job reports can be created based on a multitude of selection criteria, including:

_ Customer organization (three levels)

_ Equipment number or range of numbers

_ Work order priority

_ Key dates (written, issued, completed)

_ Component codes/action codes

_ Backlog status

_ Cause codes

_ Craft

2. The second type of output data provides management with performance control data on a weekly and monthly basis through the following listed reports.

_ Hours analysis

_ Backlog job summary

_ Closed job summary

_ Report of schedule compliance

_ PM compliance report

The control reports provide summaries by operating organization and maintenance craft.

Work Order Module

Examples of the following selected screens and reports are included.

Screens:

_ Time sheet entry

_ Work order report selection

_ Data selection

_ Sort/total selection

_ Work order list

_ Work order status summary

Reports. The following informational reports can be generated using the report data selection screens.

_ Work order status report

_ Backlog status report

_ Closed job status report

_ Work order craft list

_ Preventive maintenance master schedule

_ Preventive maintenance compliance report

_ Equipment downtime report (not included)

_ Work order cost report

_ Hours analysis

_ Report of scheduled compliance (not included)

_ Backlog job summary

_ Closed job summary

_ Time sheet transaction list

Parts Inventory:

The parts inventory section provides control over the second key element in an effective maintenance system, the first key element being what has to be done, i.e., work orders. The primary functions of the inventory system are:

_ To identify and locate spare parts in the storeroom

_ To determine the availability, status, and levels of inventory

_ To maintain purchase order status and vendor information

_ To provide cost and usage history on parts issued from and returned to inventory

_ To record cost and usage data against work orders written and equipment repaired

Examples of the following selected screens and reports are included.

Screens:

_ Parts catalog by part no.

_ Parts catalog by location

_ Parts status summary

_ All purchase orders

_ Parts issued and returned

Reports:

_ Inventory status report

_ Inventory reorder report

_ Vendor name and address list

_ Physical inventory listing

_ Parts activity transaction list (report not included)

_ Purchase order listing

Equipment:

The equipment section contains data used to identify individual pieces of equipment or physical locations and to track history on labor and material costs. The accumulation of data retained in the system provides the means for:

_ Evaluating changes needed in preventive and corrective maintenance programs

_ Analyzing the history of work performed through work orders

_ Comparing for trends in parts issued through the inventory

_ Assisting in the decision to repair or replace equipment

_ Determining what parts are common between different pieces of equipment

Examples of the following selected screens and reports are included.

Screens:

_ Equipment list

_ Equipment master and status

_ Parts list

_ Work order list

Reports:

_ Equipment listing

_ Equipment status report

_ Equipment parts catalog listing (by equipment no.)

_ Equipment parts catalog listing (by part no.)

_ Equipment status summary (report not included)

PREV | NEXT | Article Index | HOME