AMAZON multi-meters discounts AMAZON oscilloscope discounts

Predictive maintenance is perhaps the most misunderstood and misused of all the plant improvement programs. Most users define it as a means to prevent catastrophic failure of critical rotating machinery. Others define predictive maintenance as a maintenance scheduling tool that uses vibration and infrared or lubricating oil analysis data to determine the need for corrective maintenance actions. A few share the belief, precipitated by vendors of predictive maintenance systems, that predictive maintenance is the panacea for our critically ill plants. One common theme of these definitions is that it is solely a maintenance management tool.

Because of these misconceptions, the majority of established predictive maintenance programs have not been able to achieve a marked decrease in maintenance costs or a measurable improvement in overall plant performance. In fact, the reverse is too often true. In many cases, the annual costs of repairs, repair parts, product quality, and production have dramatically increased as a direct result of the program.

Predictive maintenance is much more than a maintenance scheduling tool and should not be restricted to maintenance management. As part of an integrated, total plant performance management program, it can provide the means to improve the production capacity, product quality, and overall effectiveness of our manufacturing and production plants.

DEFINITION OF PREDICTIVE MAINTENANCE

Predictive maintenance is not a panacea for all the factors that limit total plant performance. In fact, it cannot directly affect plant performance. Predictive maintenance is a management technique that, simply stated, uses regular evaluation of the actual operating condition of plant equipment, production systems, and plant management functions to optimize total plant operation.

The output of a predictive maintenance program is data. Until action is taken to resolve the deviations or problems revealed by the program, plant performance cannot be improved. Therefore, a management philosophy that is committed to plant improvement must exist before any meaningful benefit can be derived. Without the absolute commitment and support of senior management and the full cooperation of all plant functions, a predictive maintenance program cannot provide the means to resolve poor plant performance.

Predictive technology can be used for much more than just measuring the operating condition of critical plant machinery. The technology permits accurate evaluation of all functional groups, such as maintenance, within the company. Properly used, predictive maintenance can identify most, if not all, factors that limit effectiveness and efficiency of the total plant.

TOTAL PLANT MANAGEMENT

One factor that limits the effective management of plants is the lack of timely, factual data that defines operating condition of critical production systems and the effectiveness of critical plant functions, such as purchasing, engineering, and production. Properly used, predictive maintenance can provide the means to eliminate all factors that limit plant performance. Many of these problems are outside the purview of maintenance and must be corrected by the appropriate plant function.

High maintenance costs are the direct result of inherent problems throughout the plant, not just ineffective maintenance management. Poor design standards and purchasing practices, improper operation, and outdated management methods contribute more to high production and maintenance costs than do delays caused by catastrophic failure of critical plant machinery. Because of the break down mentality and myopic view of the root cause of ineffective plant performance, too many plants restrict predictive maintenance to the maintenance function. Expansion of the program to include regular evaluation of all factors that limit plant performance will greatly enhance the benefits that can be derived.

In a total plant performance mode, predictive technology can be used to accurately measure the effectiveness and efficiency of all plant functions, not just machinery. The data generated by regular evaluation can isolate specific limitations in skill levels, inadequate procedures, and poor management methods as well as incipient machine or process system problems.

MAINTENANCE MANAGEMENT

As a maintenance management tool, predictive maintenance can provide the data required to schedule both preventive and corrective maintenance tasks on an as-needed basis. Instead of relying on industrial average-life statistics, such as mean-time-to-failure, to schedule maintenance activities, predictive maintenance uses direct monitoring of the operating condition, system efficiency, and other indicators to determine the actual mean-time-to-failure or loss of efficiency for each machine train and system within the plant.

At best, traditional time-driven methods provide a guideline to normal machine-train life spans.

The final decision, in preventive or run-to-failure programs, on when to repair or rebuild a machine must be made on the basis of intuition and the personal experience of the maintenance manager. The addition of a comprehensive predictive maintenance program can and will provide factual data that define the actual mechanical condition of each machine train and operating efficiency of each process system. These data provide the maintenance manager with factual data that can be used to schedule maintenance activities.

A predictive maintenance program can minimize unscheduled breakdowns of all mechanical equipment in the plant and ensure that repaired equipment is in acceptable mechanical condition. The program can also identify machine-train problems before they become serious. Most problems can be minimized if they are detected and repaired early. Normal mechanical failure modes degrade at a speed directly proportional to their severity. If the problem is detected early, major repairs, in most instances, can be prevented.

To achieve these goals, the predictive maintenance program must correctly identify the root cause of incipient problems. Many of the established programs do not meet this fundamental requirement.

Precipitated by the claims of predictive maintenance system vendors, many programs are established on simplistic monitoring methods that identify the symptom rather than the real cause of problems.

In these instances, the derived benefits that are achieved are greatly diminished. In fact, many of these programs fail because maintenance managers lose confidence in the program's ability to accurately detect incipient problems.

Predictive maintenance cannot function in a void. To be an effective maintenance management tool, it must be combined with a viable maintenance planning function that will use the data to plan and schedule appropriate repairs. In addition, it is dependent on the skill and knowledge of maintenance craftsmen. Unless proper repairs or corrective actions are made, the data provided by the predictive maintenance program cannot be effective. Both ineffective planning and improper repairs will severely restrict the benefits of predictive maintenance.

Predictive maintenance utilizing vibration signature analysis is predicated on two basic facts:

(1) all common failure modes have distinct vibration frequency components that can be isolated and identified, and (2) the amplitude of each distinct vibration component will remain constant unless there is a change in the operating dynamics of the machine train. Predictive maintenance utilizing process efficiency, heat loss, or other nondestructive techniques can quantify the operating efficiency of nonmechanical plant equipment or systems. These techniques used in conjunction with vibration analysis can provide the maintenance manager or plant engineer with factual information that will enable them to achieve optimum reliability and availability from their plant.

PRODUCTION MANAGEMENT

Predictive maintenance can be an invaluable production management tool. The data derived from a comprehensive program can provide the information needed to increase production capacity, product quality, and the overall effectiveness of the production function.

Production efficiency is directly dependent on a number of machine-related factors. Predictive maintenance can provide the data needed to achieve optimum, consistent reliability, capacity, and efficiency from critical production systems. While these factors are viewed as maintenance responsibilities, many of the factors that directly affect them are outside of the maintenance function. For example, standard operating procedures or operator errors can directly influence these variables.

Unless production management uses regular evaluation methods, i.e., predictive maintenance, to determine the effects of these production influences, optimum production performance cannot be achieved.

Product quality and total production costs is another area where predictive maintenance can benefit production management. Regular evaluation of critical production systems can anticipate potential problems that would result in reduced product quality and an increase in overall production costs.

While the only output of the predictive maintenance program is data, this information can be used to correct a myriad of production problems that directly affect the effectiveness and efficiency of the production department.

QUALITY IMPROVEMENT

Most product quality problems are the direct result of (1) production systems with inherent problems, (2) poor operating procedures, (3) improper maintenance, or (4) defective raw materials.

Predictive maintenance can isolate this type of problem and provide the data required to correct many of the problems that result in reduced product quality.

A comprehensive program will use a combination of data, such as vibration, thermography, tribology (the science of friction, wear, and lubrication of interacting surfaces), process parameters, and operating dynamics, to anticipate deviations from optimum operating condition of critical plant systems before they can affect product quality, production capacity, or total production costs.

PREDICTIVE MAINTENANCE TECHNIQUES

There are a variety of technologies that can and should be used as part of a comprehensive predictive maintenance program. Since mechanical systems or machines account for the majority of plant equipment, vibration monitoring is generally the key component of most predictive maintenance programs. However, vibration monitoring cannot provide all of the information that will be required for a successful predictive maintenance program. This technique is limited to monitoring the mechanical condition and not other critical parameters required to maintain reliability and efficiency of machinery. It is a very limited tool for monitoring critical process and machinery efficiencies and other parameters that can severely limit productivity and product quality.

Hence, as previously noted, it must be iterated that a comprehensive predictive maintenance pro gram must include other monitoring and diagnostic techniques. These techniques include (1) vibration monitoring, (2) thermography, (3) tribology, (4) process parameters, (5) visual inspection, and (5) other nondestructive testing techniques.

VIBRATION MONITORING

Vibration analysis is the dominant technique used for predictive maintenance management. Since the greatest population of typical plant equipment is mechanical, this technique has the widest application and benefits in a total plant program. This technique uses the noise or vibration created by mechanical equipment and in some cases by plant systems to determine their actual condition. Using vibration analysis to detect machine problems is not new. During the 1960s and 1970s, the U.S. Navy and petrochemical and nuclear electric power generating industries invested heavily in the development of analysis techniques based on noise or vibration that could be used to detect and identify incipient mechanical problems in critical machinery. By the early 1980s, the instrumentation and analytical skills required for noise-based predictive maintenance were fully developed. These techniques and instrumentation had proved to be extremely reliable and accurate in detecting abnormal machine behavior. However, the capital cost of instrumentation and the expertise required to acquire and analyze noise data precluded general application of this type of predictive maintenance. As a result, only the most critical equipment in a few select industries could justify the expense required to implement a noise-based predictive maintenance program.

Recent advancements in microprocessor technology coupled with the expertise of companies that specialize in machinery diagnostics and analysis technology have evolved the means to provide vibration-based predictive maintenance that can be cost-effectively used in most manufacturing and process applications. These microprocessor-based systems have simplified the data acquisition, auto mated data management, and minimized the need for vibration experts to interpret data.

Commercially available systems are capable of routine monitoring, trending, and evaluation of the mechanical condition of all mechanical equipment in a typical plant. This type of program can be used to schedule maintenance on all rotating and reciprocating and most continuous process mechanical equipment. Monitoring the vibration from plant machinery can provide direct correlation between the mechanical condition and recorded vibration data of each machine in the plant. Any degradation of the mechanical condition within plant machinery can be detected using vibration monitoring techniques. Used properly, vibration analysis can identify specific degrading machine components or the failure mode of plant machinery before serious damage occurs.

Most vibration-based predictive maintenance programs rely on one or more trending and analysis techniques. These techniques include broadband trending, narrowband trending, and signature analysis.

Broadband Trending

This technique acquires overall or broadband vibration readings from select points on a machine train. These data are compared with either a baseline reading taken from a new machine or vibration severity charts to determine the relative condition of the machine. Normally an unfiltered broadband measurement that provides the total vibration energy between 10 and 10,000 Hz is used for this type of analysis. Broadband or overall rms data are strictly a gross value or number that represents the total vibration of the machine at the specific measurement point where the data were acquired. It does not provide any information pertaining to the actual machine problem or failure mode. Ideally broadband trending can be used as a simple indication that there has been a change in either the mechanical condition or the operating dynamics of the machine or system.

At best, this technique can be used as a gross scan of the operating condition of critical process machinery. However, broadband values must be adjusted to the actual production parameters, such as load and speed, to be effective even in this reduced role. Changes in both the speed and load of machinery will have a direct effect on the overall vibration levels of the machine.

Narrowband Trending

Narrowband trending, like broadband, monitors the total energy for a specific bandwidth of vibration frequencies. Unlike broadband, narrowband analysis uses vibration frequencies that represent specific machine components or failure modes. This method provides the means to quickly monitor the mechanical condition of critical machine components, not just the overall machine condition.

This technique provides the ability to monitor the condition of gear sets, bearings, and other machine components without manual analysis of vibration signatures.

As in the case of broadband trending, changes in speed, load, and other process parameters will have a direct, often dramatic, impact on the vibration energy produced by each machine component or narrowband. To be meaningful, narrowband values must be adjusted to the actual production parameters.

Signature Analysis

Unlike the two trending techniques, signature analysis provides visual representation of each frequency component generated by a machine train. With training, plant staff can use vibration signatures to determine the specific maintenance required by plant machinery. Most vibration-based predictive maintenance programs use some form of signature analysis in their program. However, the majority of these programs rely on comparative analysis rather than full root-cause techniques. This failure limits the benefits that can be derived from this type of program.

THERMOGRAPHY

Thermography is a predictive maintenance technique that can be used to monitor the condition of plant machinery, structures, and systems. It uses instrumentation designed to monitor the emission of infrared energy, i.e., temperature, to determine their operating condition. By detecting thermal anomalies, i.e., areas that are hotter or colder than they should be, an experienced surveyor can locate and define incipient problems within the plant.

Infrared technology is predicated on the fact that all objects having a temperature above absolute zero emit energy or radiation. Infrared radiation is one form of this emitted energy. Infrared emissions, or below red, are the shortest wavelengths of all radiated energy and are invisible without special instrumentation. The intensity of infrared radiation from an object is a function of its surface temperature. However, temperature measurement using infrared methods is complicated because there are three sources of thermal energy that can be detected from any object: energy emitted from the object itself, energy reflected from the object, and energy transmitted by the object. Only the emitted energy is important in a predictive maintenance program. Reflected and transmitted energies will distort raw infrared data. Therefore, the reflected and transmitted energies must be filtered out of acquired data before a meaningful analysis can be made.

The surface of an object influences the amount of emitted or reflected energy. A perfect emitting surface is called a blackbody and has an emissivity equal to 1.0. These surfaces do not reflect.

Instead, they absorb all external energy and reemit as infrared energy. Surfaces that reflect infrared energy are called graybodies and have an emissivity less than 1.0. Most plant equipment falls into this classification. Careful consideration of the actual emissivity of an object improves the accuracy of temperature measurements used for predictive maintenance. To help users determine emissivity, tables have been developed to serve as guidelines for most common materials. However, these guide lines are not absolute emissivity values for all machines or plant equipment.

Variations in surface condition, paint, or other protective coatings and many other variables can affect the actual emissivity factor for plant equipment. In addition to reflected and transmitted energy, the user of thermographic techniques must also consider the atmosphere between the object and the measurement instrument. Water vapor and other gases absorb infrared radiation. Airborne dust, some lighting, and other variables in the surrounding atmosphere can distort measured infrared radiation. Since the atmospheric environment is constantly changing, using thermographic techniques requires extreme care each time infrared data are acquired.

Most infrared monitoring systems or instruments provide special filters that can be used to avoid the negative effects of atmospheric attenuation of infrared data. However, the plant user must recognize the specific factors that will affect the accuracy of the infrared data and apply the correct filters or other signal conditioning required to negate that specific attenuating factor or factors.

Collecting optics, radiation detectors, and some form of indicator comprise the basic elements of an industrial infrared instrument. The optical system collects radiant energy and focuses it upon a detector, which converts it into an electrical signal. The instrument's electronics amplifies the output signal and processes it into a form which can be displayed. There are three general types of instruments that can be used for predictive maintenance: infrared thermometers or spot radiometers, line scanners, and imaging systems.

Infrared Thermometers

Infrared thermometers or spot radiometers are designed to provide the actual surface temperature at a single, relatively small point on a machine or surface. Within a predictive maintenance program, the point-of-use infrared thermometer can be used in conjunction with many of the microprocessor based vibration instruments to monitor the temperature at critical points on plant machinery or equipment. This technique is typically used to monitor bearing cap temperatures, motor winding temperatures, spot checks of process piping temperatures, and similar applications. It is limited in that the temperature represents a single point on the machine or structure. However, when used in conjunction with vibration data, point-of-use infrared data can be a valuable tool.

Line Scanners

This type of infrared instrument provides a single-dimensional scan or line of comparative radiation.

While this type of instrument provides a somewhat larger field of view, i.e., area of machine surface, it is limited in predictive maintenance applications.

Infrared Imaging

Unlike other infrared techniques, thermal or infrared imaging provides the means to scan the infrared emissions of complete machines, process, or equipment in a very short time. Most of the imaging systems function much like a video camera. The user can view the thermal emission profile of a wide area by simply looking through the instrument's optics. A variety of thermal imaging instruments are on the market, ranging from relatively inexpensive black-and-white scanners to full-color, micro processor-based systems. Many of the less expensive units are designed strictly as scanners and do not provide the capability of store-and-recall thermal images. The inability to store and recall previous thermal data will limit a long-term predictive maintenance program.

Inclusion of thermography into a predictive maintenance program will enable you to monitor the thermal efficiency of critical process systems that rely on heat transfer or retention, electrical equipment, and other parameters that will improve both the reliability and efficiency of plant systems.

Infrared techniques can be used to detect problems in a variety of plant systems and equipment, including electrical switchgear, gearboxes, electrical substations, transmissions, circuit breaker panels, motors, building envelopes, bearings, steam lines, and process systems that rely on heat retention or transfer.

TRIBOLOGY

Tribology is the general term that refers to design and operating dynamics of the bearing-lubrication rotor support structure of machinery. Several tribology techniques can be used for predictive maintenance: lubricating oil analysis, spectrographic analysis, ferrography, and wear particle analysis.

Lubricating oil analysis, as the name implies, is an analysis technique that determines the condition of lubricating oils used in mechanical and electrical equipment. It is not a tool for determining the operating condition of machinery. Some forms of lubricating oil analysis will provide an accurate quantitative breakdown of individual chemical elements, both oil additive and contaminates, contained in the oil. A comparison of the amount of trace metals in successive oil samples can indicate wear patterns of oil-wetted parts in plant equipment and will provide an indication of impending machine failure.

Until recently, tribology analysis has been a relatively slow and expensive process. Analyses were conducted using traditional laboratory techniques and required extensive, skilled labor.

Microprocessor-based systems are now available which can automate most of the lubricating oil and spectrographic analysis, thus reducing the manual effort and cost of analysis.

The primary applications for spectrographic or lubricating oil are quality control, reduction of lubricating oil inventories, and determination of the most cost-effective interval for oil change.

Lubricating, hydraulic, and dielectric oils can be periodically analyzed, using these techniques, to determine their condition. The results of this analysis can be used to determine if the oil meets the lubricating requirements of the machine or application. Based on the results of the analysis, lubricants can be changed or upgraded to meet the specific operating requirements. In addition detailed analysis of the chemical and physical properties of different oils used in the plant can, in some cases, allow consolidation or reduction of the number and types of lubricants required to maintain plant equipment. Elimination of unnecessary duplication can reduce required inventory levels and there fore maintenance costs.

As a predictive maintenance tool, lubricating oil and spectrographic analysis can be used to schedule oil change intervals based on the actual condition of the oil. In middle-sized to large plants, a reduction in the number of oil changes can amount to a considerable annual reduction in maintenance costs. Relatively inexpensive sampling and testing can show when the oil in a machine has reached a point that warrants change. The full benefit of oil analysis can be achieved only by taking frequent samples trending the data for each machine in the plant. It can provide a wealth of information on which to base maintenance decisions. However, major payback is rarely possible without a consistent program of sampling.

Lubricating Oil Analysis

Oil analysis has become an important aid to preventive maintenance. Laboratories recommend that samples of machine lubricant be taken at scheduled intervals to determine the condition of the lubricating film that is critical to machine-train operation. Typically 10 tests are conducted on lube oil samples:

Viscosity. This is one of the most important properties of a lubricating oil. The actual viscosity of oil samples is compared with an unused sample to determine the thinning or thickening of the sample during use. Excessively low viscosity will reduce the oil film strength, weakening its ability to pre vent metal-to-metal contact. Excessively high viscosity may impede the flow of oil to vital locations in the bearing support structure, reducing its ability to lubricate.

Contamination. Oil contamination by water or coolant can cause major problems in a lubricating system. Many of the additives now used in formulating lubricants contain the same elements that are used in coolant additives. Therefore, the laboratory must have an accurate analysis of new oil for comparison.

Fuel Dilution. Oil dilution in an engine weakens the oil film strength, sealing ability, and detergency. It may be caused by improper operation, fuel system leaks, ignition problems, improper timing, or other deficiencies. Fuel dilution is considered excessive when it reaches a level of 2.5 to 5 percent.

Solids Content. This is a general test. All solid materials in the oil are measured as a percentage of the sample volume or weight. The presence of solids in a lubricating system can significantly increase the wear on lubricated parts. Any unexpected rise in reported solids is cause for concern.

Fuel Soot. An important indicator for oil used in diesel engines, fuel soot is always present to some extent. A test to measure fuel soot in diesel engine oil is important, since it indicates the fuel-burning efficiency of the engine. Most tests for fuel soot are conducted by infrared analysis.

Oxidation. Lubricating oil oxidation can result in lacquer deposits, metal corrosion, or thickening of the oil. Most lubricants contain oxidation inhibitors. However, when additives are used up, oxidation of the oil itself begins. The quantity of oxidation in an oil sample is measured by differential infrared analysis.

Nitration. Fuel combustion in engines results from nitration. The products formed are highly acidic and may leave deposits in combustion areas. Nitration will accelerate oil oxidation. Infrared analysis is used to detect and measure nitration products.

Total Acid Number (TAN)

This is a measure of the amount of acid or acidlike material in the oil sample. Because new oils contain additives that affect the TAN number, it is important to compare used oil samples with new, unused, oil of the same type. Regular analysis at specific intervals is important to this evaluation.

Total Base Number (TBN). This number indicates the ability of an oil to neutralize acidity. The higher the TBN the greater its ability to neutralize acidity. Typical causes of low TBN include using the improper oil for an application, waiting too long between oil changes, overheating, and using high sulfur fuel.

Particle Count. Tests of particle count are important to anticipating potential system or machine problems. This is especially true in hydraulic systems. Particle count analysis made a part of a normal lube oil analysis is quite different from wear particle analysis. In this test, high particle counts indicate that machinery may be wearing abnormally or that failures may occur as a result of temporarily or permanently blocked orifices. No attempt is made to determine the wear patterns, size, and other factors that would identify the failure mode within the machine.

Spectrographic Analysis

Spectrographic analysis allows accurate, rapid measurements of many of the elements present in lubricating oil. These elements are generally classified as wear metals, contaminates, or additives.

Some elements can be listed in more than one of these classifications. Standard lubricating oil analyses do not attempt to determine the specific failure modes of developing machine-train problems.

Therefore, additional techniques must be used as part of a comprehensive predictive maintenance program.

Wear Particle Analysis

Wear particle analysis is related to oil analysis only in that the particles to be studied are collected through drawing a sample of lubricating oil. Where lubricating oil analysis determines the actual condition of the oil sample, wear particle analysis provides direct information about the wearing condition of the machine train. Particles in the lubricant of a machine can provide significant information about the condition of the machine. This information is derived from the study of particle shape, composition, size, and quantity. Wear particle analysis is normally conducted in two stages. The first method used for wear particle analysis is routine monitoring and trending of the solids content of machine lubricant. In simple terms the quantity, composition, and size of particulate matter in the lubricating oil are indicative of the mechanical condition of the machine. A normal machine will contain low levels of solids with a size less than 10 micrometers. As the machine's condition degrades, the number and size of particulate matter will increase.

The second wear particle method involves analysis of the particulate matter in each lubricating oil sample. Five basic types of wear can be identified according to the classification of particles: rubbing wear, cutting wear, rolling fatigue wear, combined rolling and sliding wear, and severe sliding wear (see Table 3.1). Only rubbing wear and early rolling fatigue mechanisms generate particles pre dominantly less than 15 micrometers in size.

======

Table 1 Five types of wear

Type | Description

Rubbing wear Result of normal wear in machine

Cutting wear Caused by one surface penetrating another machine surface

Rolling fatigue Primary result of rolling contact within bearings

=====

Combined rolling and sliding wear Results from moving of contact surfaces within a gear system Severe sliding wear Caused by excessive loads or heat in a gear system Rubbing Wear. This is the result of normal sliding wear in a machine. During a normal break-in of a wear surface, a unique layer is formed at the surface. As long as this layer is stable, the surface wears normally. If the layer is removed faster than it is generated, the wear rate increases and the maximum particle size increases.

Excessive quantities of contaminate in a lubrication system can increase rubbing wear by more than an order of magnitude without completely removing the shear mixed layer. Although catastrophic failure is unlikely, these machines can wear out rapidly. Impending trouble is indicated by a dramatic increase in wear particles.

Cutting Wear Particles. These are generated when one surface penetrates another. They are produced when a misaligned or fractured hard surface produces an edge that cuts into a softer surface, or when abrasive contaminate becomes embedded in a soft surface and cuts an opposing surface.

Cutting wear particles are abnormal and are always worthy of attention. If they are only a few micrometers long and a fraction of a micrometer wide, the cause is probably a contaminate.

Increasing quantities of longer particles signal a potentially imminent component failure.

Rolling Fatigue. This is associated primarily with rolling contact bearings and may produce three distinct particle types: fatigue spall particles, spherical particles, and laminar particles. Fatigue spall particles are the actual material removed when a pit or spall opens up on a bearing surface. An increase in the quantity or size of these particles is the first indication of an abnormality. Rolling fatigue does not always generate spherical particles, and they may be generated by other sources.

Their presence is important in that they are detectable before any actual spalling occurs. Laminar particles are very thin and are thought to be formed by the passage of a wear particle through a rolling contact. They frequently have holes in them. Laminar particles may be generated throughout the life of a bearing, but at the onset of fatigue spalling the quantity increases.

Combined Rolling and Sliding Wear. This results from the moving contact of surfaces in gear systems. These larger particles result from tensile stresses on the gear surface, causing the fatigue cracks to spread deeper into the gear tooth before pitting. Gear fatigue cracks do not generate spheres.

Scuffing of gears is caused by too high a load or speed. The excessive heat generated by this condition breaks down the lubricating film and causes adhesion of the mating gear teeth. As the wear surfaces become rougher, the wear rate increases. Once started, scuffing usually affects each gear tooth.

Severe Sliding Wear. This is caused by excessive loads or heat in a gear system. Under these conditions, large particles break away from the wear surfaces, causing an increase in the wear rate. If the stresses applied to the surface are increased further, a second transition point is reached. The surface breaks down and catastrophic wear ensues.

Normal spectrographic analysis is limited to particulate contamination with a size of 10 micrometers or less. Larger contaminants are ignored. This fact can limit the benefits that can be derived from the technique.

Ferrography

This technique is similar to spectrography, but there are two major exceptions. First, ferrography separates particulate contamination by using a magnetic field rather than burning a sample as in spectrographic analysis. Because a magnetic field is used to separate contaminants, this technique is primarily limited to ferrous or magnetic particles. The second difference is that particulate contamination larger than 10 micrometers can be separated and analyzed. Normal ferrographic analysis will capture particles up to 100 micrometers and provides a better representation of the total oil contamination than spectrographic techniques.

There are three major limitations with using tribology analysis in a predictive maintenance pro gram: equipment costs, acquiring accurate oil samples, and interpretation of data.

One factor that severely limits the benefits of tribology is the acquisition of accurate samples that represent the true lubricating oil inventory in a machine. Sampling is not a matter of opening a port somewhere in the oil line and catching a pint sample. Extreme care must be taken to acquire samples that truly represent the lubricant that will pass through the machine's bearings. One recent example is an attempt to acquire oil samples from a bullgear compressor. The lubricating oil filter had a sample port on the clean, i.e., downstream, side. However, comparison of samples taken at this point and one taken directly from the compressor's oil reservoir indicated that more contaminants existed down stream from the filter than in the reservoir. Which location actually represented the oil's condition? Neither sample was truly representative of the oil condition. The oil filter had removed most of the suspended solids, i.e., metals and other insolubles, and was therefore not representative of the actual condition. The reservoir sample was not representative since most of the suspended solids had settled out in the sump.

Proper methods and frequency of sampling lubricating oil are critical to all predictive maintenance techniques that use lubricant samples. Sample points that are consistent with the objective of detecting large particles should be chosen. In a recirculating system, samples should be drawn as the lubricant returns to the reservoir and before any filtration. Do not draw oil from the bottom of a sump where large quantities of material build up over time. Return lines are preferable to the reservoir as the sample source, but good reservoir samples can be obtained if careful, consistent practices are used. Even equipment with high levels of filtration can be effectively monitored as long as samples are drawn before oil enters the filters. Sampling techniques involve taking samples under uniform operating conditions. Samples should not be taken more than 30 min after the equipment has been shut down. Sample frequency is a function of the mean time to failure from the onset of an abnormal wear mode to catastrophic failure. For machines in critical service, sampling every 25 hr of operation is appropriate. However, for most industrial equipment in continuous service, monthly sampling is adequate. The exception to monthly sampling is machines with extreme loads. In this instance, weekly sampling is recommended.

Understanding the meaning of analysis results is perhaps the most serious limiting factor. Most often results are expressed in terms that are totally alien to plant engineers or technicians. Therefore, it is difficult for them to understand the true meaning, in terms of oil or machine condition. A good background in quantitative and qualitative chemistry is beneficial. As a minimum requirement, plant staff will require training in basic chemistry and specific instruction on interpreting tribology results.

PROCESS PARAMETERS

Many plants do not consider machine or systems efficiency to be part of the maintenance responsibility. However, machinery that is not operating within acceptable efficiency parameters severely limits the productivity of many plants. Therefore, a comprehensive predictive maintenance program should include routine monitoring of process parameters. As an example of the importance of process parameters monitoring, consider a process pump that may be critical to plant operation.

Vibration-based predictive maintenance will provide the mechanical condition of the pump and infrared imaging will provide the condition of the electric motor and bearings. Neither provides any indication of the operating efficiency of the pump. Therefore, the pump could be operating at less than 50 percent efficiency and the predictive maintenance program would not detect the problem.

Process inefficiencies, like the example cited, are often the most serious limiting factor in a plant.

Their negative impact on plant productivity and profitability is often greater than the total cost of the maintenance operation. However, without regular monitoring of process parameters, many plants do not recognize this unfortunate fact. If your program included monitoring of the suction and discharge pressures and ampere load of the pump, you could determine the operating efficiency. The brake horsepower

bhp _

gpm _ TDH _ sp. gr.

___ 3960 _ efficiency

could be used to calculate operating efficiency of any pump in the program. By measuring the suction and discharge pressure, the total dynamic head (TDH) can be determined. A flow curve, used in conjunction with the actual total dynamic head, would define the actual flow (gpm) and an ammeter reading would define the horsepower. With these measured data, the efficiency can be calculated.

Process parameters monitoring should include all machinery and systems in the plant process that can affect its production capacity. Typical systems include heat exchangers, pumps, filtration, boilers, fans, blowers, and other critical systems. Inclusion of process parameters in predictive maintenance can be accomplished in two ways: manual or microprocessor-based systems. However, both methods will normally require installing instrumentation to measure the parameters that indicate the actual operating condition of plant systems. Even though most plants have installed pressure gages, thermometers, and other instruments that should provide the information required for this type of pro gram, many of them are no longer functioning. Therefore, including process parameters in your program will require an initial capital cost to install calibrated instrumentation. Data from the installed instrumentation can be periodically recorded using either manual logging or a microprocessor-based data logger. If the latter is selected, many vibration-based microprocessor systems can also provide the means of acquiring process data. This should be considered when selecting the vibration monitoring system that will be used in your program. In addition, some microprocessor-based predictive maintenance systems provide the ability to calculate unknown process variables. For example, they can calculate the pump efficiency used in the example. This ability to calculate unknowns based on measured variables will enhance a total plant predictive maintenance program without increasing the manual effort required. In addition, some of these systems include nonintrusive transducers that can measure temperatures, flows, and other process data without the necessity of installing permanent instrumentation. This further reduces the initial cost of including process parameters in your program.

ELECTRIC MOTOR ANALYSIS

Evaluation of electric motors and other electrical equipment is critical to a total plant predictive maintenance program. To an extent, vibration data isolate some of the mechanical and electrical problems that can develop in critical drive motors. However, vibration cannot provide the comprehensive coverage required to achieve optimum plant performance. Therefore, a total plant predictive maintenance program must include data acquisition and evaluation methods that are specifically designed to identify problems within motors and other electrical equipment.

Insulation Resistance Insulation resistance tests are important, although they may not be conclusive, in that they can reveal flaws in insulation, poor insulating material, the presence of moisture, and a number of other problems. Such tests can be applied to the insulation of electrical machinery from the windings to the frame, to underground cables, insulators, capacitors, and a number of other auxiliary electrical components. Normally these tests are conducted using (1) megger, (2) Wheatstone bridge, (3) Kelvin double bridge, or (4) a number of other instruments.

A megger provides the means to directly measure the condition of motor insulation. This method uses a device which generates a known output, usually 500 V, and directly measures the resistance of the insulation within the motor. When the insulation resistance falls below the prescribed value, it can be brought to required standards by cleaning and drying the stator and rotor.

The accuracy of meggering and most insulation resistance tests varies widely with temperature, humidity, and cleanliness of the parts. Therefore, they may not be absolutely conclusive.

Other Electrical Testing

A complete predictive maintenance program should include all testing and evaluation methods required to regularly evaluate all critical plant systems. As a minimum, a total plant program should also include (1) dielectric loss analysis, (2) gas-in-oil analysis, (3) stray field monitoring, (4) high voltage, switchgear discharge testing, (5) resistance measurements, (6) Rogowski coils, and (7) rotor bar current harmonics.

VISUAL INSPECTION

Regular visual inspection of the machinery and systems in a plant is a necessary part of any predictive maintenance program. In many cases, visual inspection will detect potential problems that will be missed using the other predictive maintenance techniques. Even with the predictive techniques discussed, many potentially serious problems can remain undetected. Routine visual inspection of all critical plant systems will augment the other techniques and ensure that potential problems are detected before serious damage can occur. Most of the vibration-based predictive maintenance systems include the capability of recording visual observations as part of the routine data-acquisition process.

Since the incremental costs of these visual observations are small, this technique should be incorporated in all predictive maintenance programs. All equipment and systems in the plant should be visually inspected on a regular basis. The additional information provided by visual inspection will augment the predictive maintenance program regardless of the primary techniques used.

ULTRASONIC MONITORING

This predictive maintenance technique uses principles similar to vibration analysis. Both techniques monitor the noise generated by plant machinery or systems to determine their actual operating condition. Unlike vibration monitoring, ultrasonics monitors the higher frequencies, i.e., ultrasound, produced by unique dynamics in process systems or machines. The normal monitoring range for vibration analysis is from less than 1 to 20,000 Hz. Ultrasonics techniques monitor the frequency range between 20,000 and 100 kHz. The principal application for ultrasonic monitoring is in leak detection. The turbulent flow of liquids and gases through a restricted orifice, i.e., leak, will produce a high-frequency signature that can easily be identified using ultrasonic techniques. Therefore, this technique is ideal for detecting leaks in valves, steam traps, piping, and other process systems.

Two types of ultrasonic systems are available that can be used for predictive maintenance: structural and airborne. Both provide fast, accurate diagnoses of abnormal operation and leaks. Airborne ultrasonic detectors can be used in either a scanning or a contact mode. As scanners, they are most often used to detect gas pressure leaks. Because these instruments are sensitive only to ultrasound, they are not limited to specific gases as are most other gas leak detectors. In addition, they are often used to locate various forms of vacuum leaks. In the contact mode, a metal rod acts as a waveguide.

When it touches a surface, it is stimulated by the high frequencies (ultrasound) on the opposite side of the surface.

This technique is used to locate turbulent flow and/or flow restriction in process piping. Some of the ultrasonic systems include ultrasonic transmitters that can be placed inside plant piping or vessels. In this mode, ultrasonic monitors can be used to detect areas of sonic penetration along the container's surface. This ultrasonic transmission method is useful in quick checks of tank seams, hatches, seals, caulking, gaskets, or building wall joints.

In a typical machine, many other machine dynamics will also generate frequencies within the bandwidth covered by an ultrasonic instrument. Gear meshing frequencies, blade pass, and other machine components will also create energy or noise that cannot be separate from the bearing frequencies monitored by this type of instrument. The only reliable method of determining the condition of specific machine components, including bearings, is vibration analysis. The use of ultrasonics to monitor bearing condition is not recommended.

OPERATING DYNAMICS ANALYSIS

This analysis method is driven by machine or system design and is not limited to traditional analysis techniques. The diagnostic logic is derived from the specific design and operating characteristics of the machine-train or production system. Based on the unique dynamics of each machine train or system, all parameters that define optimum operating condition are routinely measured and evaluated.

Using the logic of normal operating condition, operating dynamics can detect, isolate, and provide cost-effective corrective action for any deviation from optimum.

Operating dynamics analysis combines traditional predictive maintenance techniques into a holistic evaluation technique that will isolate any deviation from optimum condition of critical plant systems. This concept uses raw data derived from vibration, infrared, ultrasonics, process parameters, and visual inspection but applies a unique diagnostic logic to evaluate plant systems.

OTHER TECHNIQUES

Numerous other nondestructive techniques can be used to identify incipient problems in plant equipment or systems. However, these techniques either do not provide a broad enough application or are too expensive to support a predictive maintenance program. Therefore, these techniques are used as the means of confirming failure modes identified by the predictive maintenance techniques identified in this section. Other techniques that can support predictive maintenance include acoustic emissions, eddy-current, magnetic particle, residual stress, and most of the traditional nondestructive methods.

PROGRAM COSTS

The initial and recurring costs required to establish and maintain a comprehensive predictive maintenance program will vary with the technology and type of system selected for plant use. While the initial or capital cost is the more visible, the real cost of a program is the recurring labor, training, and technical support that is required to maintain a total plant program.

VIBRATION MONITORING

The capital cost for implementing a vibration-based predictive maintenance program will range from about $8000 to more than $50,000. Your costs will depend on the specific techniques desired.

Training is critical for predictive maintenance programs based on vibration monitoring and analysis. Even programs that rely strictly on the simplified trending or comparison techniques require a practical knowledge of vibration theory so that meaningful interpretation of machine condition can be derived. More advanced techniques, i.e., signature and root-cause failure analysis, require a working knowledge of machine dynamics and failure modes.

THERMOGRAPHY

Point-of-use infrared thermometers are commercially available and relatively inexpensive. The typical cost for this type of infrared instrument is less than $1000. Infrared imaging systems will have a price range between $8000 for a black-and-white scanner without storage capability and over $60,000 for a microprocessor-based, color-imaging system.

Training is critical with any of the imaging systems. The variables that can destroy the accuracy and repeatability of thermal data must be compensated for each time infrared data are acquired. In addition, interpretation of infrared data requires extensive training and experience.

TRIBOLOGY

The capital cost of spectrographic analysis instrumentation is normally too high to justify in-plant testing. Typical cost for a microprocessor-based spectrographic system is between $30,000 and $60,000.

Because of this, most predictive maintenance programs rely on third-party analysis of oil samples.

Simple lubricating oil analysis by a testing laboratory will range from about $20 to $50 per sample.

Standard analysis will normally include viscosity, flash point, total insolubles, total acid number (TAN), total base number (TBN), fuel content, and water content. More detailed analysis, using spectrographic or ferrographic techniques, including metal scans, particle distribution (size), and other data, range to well over $150 per sample.

ULTRASONICS

Most ultrasonic monitoring systems are strictly scanners that do not provide any long-term trending or storage of data. They are in effect a point-of-use instrument that provides an indication of the overall amplitude of noise within the bandwidth of the instrument. Therefore, the cost of this type of instrument is relatively low. Normal cost of ultrasonic instruments ranges from less than $1000 to about $8000. Used strictly for leak detection, ultrasonic techniques require little training to utilize. The combination of low capital cost, minimum training required to use the technique, and potential impact of leaks on plant availability provides a positive cost benefit for including ultrasonic techniques in a total plant predictive maintenance program. However, care should be exercised in applying this technique in your program. Many ultrasonic systems are sold as a bearing condition monitor. Even though the natural frequencies of rolling-element bearings will fall within the bandwidth of ultrasonic instruments, this is not a valid technique for determining the condition of rolling-element bearings.

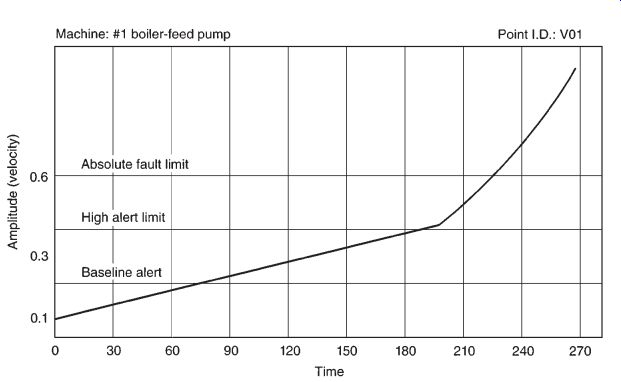

FIGURE 1 Broadband trend.

BENEFITS

Properly implemented predictive maintenance can do much more than just schedule maintenance tasks. Typical results of predictive maintenance, based on operating dynamics, can be substantial.

Using the four major loss classifications, first-year results from a maintenance improvement program based on a comprehensive predictive maintenance program include the following.

Breakdown Losses In the first year at a large, integrated steel mill, plant delays as a result of machine and system break downs were reduced by more than 15.4 percent as a direct result of a comprehensive predictive maintenance program. As Fig. 1 illustrates, all divisions of the mill reflected a marked reduction in total delays. The key to reduction in delays is not limiting the scope to unscheduled delays. A focused effort must be made to reduce scheduled maintenance as well.

Arbitrary acceptance of planned delays for maintenance severely limits available production time. Too many plants accept historical data as the only reason for planned maintenance downtime.

A comprehensive predictive maintenance program must include specific methods to evaluate all delays and downtime. The objective of predictive maintenance is to achieve 100 percent availability. The 15.4 percent improvement does not include the added production capacity that resulted from elimination of scheduled downtime. This classification added an additional 5 percent to the avail ability of the mill.

Quality Defects

Rejects, diversions, and retreats were reduced by more than 1 percent across the integrated mill. This reduction reduced the negative costs of poor quality by more than $5 per ton of product produced, or a reduction of 13 percent. After 2 years, the total costs associated with poor quality had been reduced by more than 24 percent, or $10 per ton.

Capacity Factor Setup and adjustment, reduced speed, and start-up losses as well as operating efficiency of plant processes directly affect the overall capacity factor of a plant. Reduction of these major losses, in conjunction with the reduction in delays and rejects, resulted in an overall increase of 2.5 percent in net production capacity. The net result, in prime quality product, was an additional 477,000 tons produced by the end of the first year.

Predictive maintenance, when implemented as an integral part of a total plant improvement pro gram, can dramatically improve the net operating profit of the company.

Maintenance Costs

Traditional maintenance costs, i.e., labor and material, are not included in the TPM indexes recommended by the Japanese. However, they are a major factor that should be addressed by any plant improvement program. Traditional applications of predictive maintenance will do little to decrease the overall maintenance costs within a plant. In most cases, the only reduction will result from an incremental reduction in overtime costs. Material costs, such as bearings and couplings, will increase and the net overall effect will be a slight increase in the overall costs.

Predictive maintenance, based on operating dynamics, will dramatically reduce both the labor and material, i.e., maintenance, costs. After 2 years, the example steel mill reduced its total labor costs by more than 15 percent, or $45,000,000 per year. In addition, their material costs were reduced by more than $6,000,000 per year. One simple example of this reduction in material cost is rolling element bearings. In the years preceding implementation of the program, the client purchased an average of $9,100,000 of bearings each year. During the first year after the operating dynamics pro gram was implemented, the total expenditure for bearings dropped to $4,000,000 and was further reduced to less than $2,000,000 in the second year. In this one line item, the client was able to eliminate more than $7,000,000 per year in repair parts costs.

PREV | NEXT | Article Index | HOME