Building stairs requires careful planning, the right tools, and some installation know-how. Good rules of thumb are: when you add the height of a stair riser and tread width, the result should be to 17 - 18 in (430 - 460 mm). Risers usually rise 7 - 7-3/4 inches (180—200 mm) and treads usually run 10 in (255 mm). And once the stringers are installed they should sit at about a 35-degree angle. These measurements are somewhat adjustable, to make the stair assembly fit in an opening, for example.

1. Layout

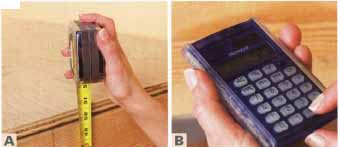

A. Measure the height (called “rise”) from

the floor to the landing, where the top of the stairs will

go. B. Divide the measurement by 7 or 7.5

to determine the number of risers the stringer needs. Round

this to the closest whole number. Re-divide the total rise

by this number.

C. With riser height determined and tread

run known (10 in/255 mm) fasten brass stair gauges to your

framing square. D. Check your stringer stock.

Make sure it is straight. If there is a crown, place the crown

facing up.

E. Place the square on the stringer stock.

Apply pressure with your thumb to keep it flat and scribe the

riser height. F. Without moving the square,

mark the tread run. Keep gentle, even pressure on the square

to keep it stable.

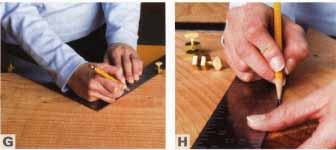

G. Step the square down the stringer stock

by placing it next to the previous mark. Repeat the process

until all stairs are marked. H. Remove the

stair gauges for the last mark so you can mark all the way

across the board.

2. Cutting Out

A. A circular saw is the ideal tool for cutting

most of the stringer, however, do not over cut the stringer.

Instead, use a hand saw to finish cuts. This ensures the stringer

stock (usually 2 x 12 in/50 x 300 mm) remains as strong as

possible for heavy use.

B. Using a sharp handsaw to finish circular

saw cuts ensures accuracy and ensures the stringer will be

as sturdy as possible. C. Clamp the pattern

piece to new stock and trace it. This ensures accuracy between

stringers, and speeds up the process.

D. Cut carefully. Make sure you always keep

the saw blade on the same side of the line during every cut. E.

When cutting the bottom riser, be sure to cut it one-tread-thickness

shorter than all the other risers.

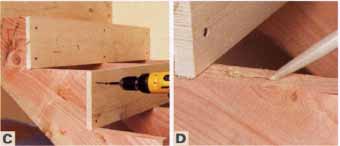

3. ATTACHING THE STAIRS

A. At the location where the stairs will contact

the landing, place riser stock (plywood) to create a connection

point for the stringers. B. Place the stringers

in place and on your layout marks. Fasten from behind the riser

stock.

C. Install riser material on the stringers.

Cut each one exactly the same so the stair is the same width

at all points. D. To really fasten the treads,

glue and screw them down. This prevents squeaks and makes a

permanent bond.

E. Use screws, rather than nails, to fasten

tread stock to the stringers. Screws will form a tighter bond

with the glue. F. Sink screws from behind

the riser stock into the edge of the tread. This binds everything

together into a unit.

4. ATTACHING THE RAIL

A. A sturdy rail is an important safety feature

of any stair. It is vital that they are built properly and

to local building code, to prevent accidents. The newel post

should be set plumb and fastened with screws while the rails

should follow the exact rise- angle of the stairs.

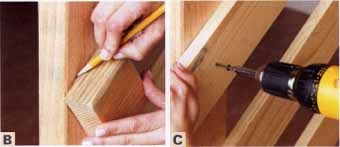

B. After running the bottom rail along the

stair nosings and fastening securely, use a block to transfer

the measurement up to the next rail piece. C.

Once you’ve marked where the next rail segment goes, fasten

it to the newel post with screws.

D. Run rail segments long and cut them off,

once fastened in place, with a handsaw. This saves you from

having to calculate angles and lengths. E.

Above the last rail, install a handrail. Install all handrail

hardware the same distance from the last rail section to maintain

the proper angle.

F. Pre-miter and fasten the railing returns.

Doing this prior to installation makes installation much easier.

Pre-drill each side of the miter and set nails to fasten. G.

Set the railing on the railing hardware and fasten from the

bottom side. It often helps to pre-drill holes to prevent splitting

the wood. H. Fastening all parts of the stair

together with screws and installing a sturdy railing are the

key to safe, sturdy stairs.

PREV: Staircase Maintenance

Home • •