Other electrical systems may be integrated with PV systems as additional sources of electrical energy, depending on the type of system and application requirements. Besides the PV array, an electric utility grid is the source of electricity that is by far most commonly connected to PV systems. Other electricity sources include engine generators, gas-turbine generators, uninterruptible power supplies, wind turbines, micro-hydroelectric turbines, and fuel cells.

Engine Generators

An engine generator is a combination of an internal combustion engine and a generator mounted together to produce electricity. A generator is a device that converts mechanical energy into electricity by means of electromagnetic induction. The arrangement is also sometimes called an engine generator set, or genset.

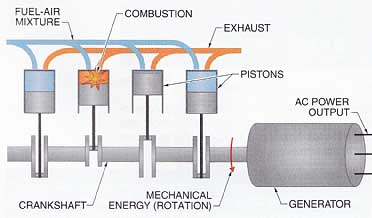

Generators are typically driven by internal combustion piston engines. These engines burn a compressed fuel-air mixture, which moves reciprocating pistons that drive a crankshaft. The crankshaft then transfers mechanical power to the generator shaft. The generator uses electromagnetic principles to convert the rotation of the shaft into electricity. See Ill. 4-10.

Ill. 4-10. Engines use reciprocating pistons to create mechanical

power, which is then converted to electrical power in the generator.

Engine generator components.

Generators can be designed to produce from a few hundred watts of single-phase power to several megawatts of three-phase power. Small portable engine generators are used for emergency residential power or on job sites for temporary power. Standby engine generators are permanent, medium to large systems used for larger back-up and temporary power applications, but are not run continuously as a primary power source. See Ill. 4-11. Prime-duty engine generators are also medium to large systems, but are designed to operate continually as a primary source of power.

Engines used with generators are typically fueled with gasoline, diesel, propane, or natural gas. Small systems typically run on gasoline because of its widespread availability, while larger systems can be designed for any of these fuels, though diesel is the most common. The type of fuel affects the load response of the engine generator. Diesel engines are well suited for constant loads, whereas gasoline engines can respond quickly to changing loads. However, diesel engines generally have better partial-load efficiency, run slower, are more robust, last longer, and require less maintenance, so they are predominately used for large stationary applications.

Ill. 4-11. (Standby) Engine generators are usually in stalled

as a complete, integrated package.

Engine generators are characterized by their output rating, engine type, fuel source, and fuel-to-power conversion efficiency. Engine generators also require auxiliary equipment to safely and successfully start, operate, and interface with other systems. Some PCUs can control engine generators for battery charging and powering certain AC loads.

===

Transfer Switches

A transfer switch allows an electrical system to be quickly and safely switched from a primary power source to an al ternate power source in order to keep critical loads operating. The most common configuration is an emergency engine generator to back up the utility power. Transfer switches may also be used with PV systems, typically those in off-grid residences or facilities that rely on alternate power from engine generators when insolation is low or the PV system can't charge the battery system.

Transfer switches are either manual or automatic. With a manual transfer switch, the transfer to alternate power is done by a person physically activating the switch. If the alternate power source is an engine generator, additional start-up procedures are required to bring the engine up to nor mal operating conditions before making the transfer.

Automatic transfer switches continually monitor the primary power source. When the voltage falls below a certain level, the switch automatically starts a power transfer, such as sending electronic commands to an engine generator to initiate its start-up sequence. When the switch detects the proper voltage and frequency on the alternate source, it completes the transfer. The switch can also manage an automatic and controlled transfer back to primary power when it becomes available again.

In all cases, the primary power source must be completely disconnected from the electrical system before the alternate power source is connected. This prevents the power from back-feeding into the primary system but results is a short power interruption. Depending on the system, the interruption may last from a fraction of a second to several seconds.

===

Gas Turbine Generators

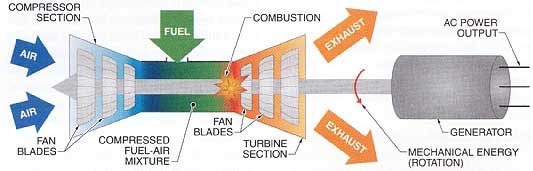

A gas turbine is a device that compresses and burns a fuel-air mixture, which expands and spins a turbine. A turbine is a bladed shaft that converts fluid flow into rotating mechanical energy. The shaft power from the turbine can be used to drive a generator to produce electricity. See Ill. 4-12. Gas turbines are essentially jet aircraft engines developed for stationary applications. Gas turbines are combined with generators to form electricity producing units similar to piston-driven engine generators.

Gas turbine generators produce up to several hundred megawatts of power and are used in large industrial plants, ships, and vehicles such as tanks. Gas turbines have a better power-to- weight ratio than internal combustion engines, which means that they can generate more power from smaller, lighter equipment. The main disadvantages of gas turbine generators are high cost and complexity. They typically run on natural gas, liquefied petroleum gas, diesel, or kerosene fuels. Gas turbine generators are best suited for constant loads.

Automatic transfer switches monitor utility power and engage auxiliary power sources, such as an engine generator, if the

power fails below preset limits.

++

Some engine generators can operate on more than one fuel type. For example, a large back up power system may be connected to a gas line and operate from natural gas under normal outage conditions However if the gas supply is interrupted such as during a natural disaster the engine may run using an on-site reserve of diesel fuel

++

Ill. 4-12. Gas turbines have separate compressor and turbine

sections that work together to send mechanical power to a generator.

Components: COMPRESSED FUEL-AIR MIXTURE; FAN BLADES; TURBINE SECTION;

MECHANICAL ENERGY (ROTATION); AC POWER OUTPUT.

Microturbines are small gas turbine generators that produce up to a few hundred kilo watts of power. These have been adapted for portable or distributed power for demand-side applications, as opposed to primary generation. Microturbines are installed at industrial or commercial facilities to supplement the utility during peak loads or provide back up power. Combined heat and power (CHP) microturbines produce both thermal energy and electricity, improving the overall efficiency of the process.

Uninterruptible Power Supplies

An uninterruptible power supply (UPS) is a battery-based system that includes all the additional power conditioning equipment, such as inverters and chargers, to make a complete, self-contained power source. In standby mode, a UPS system keeps its batteries at a full state of charge from utility power. When a utility disturbance occurs, an automatic transfer circuit isolates critical loads from the utility, and supplies AC power inverted from DC power from the battery.

Small UPS systems are commonly used by businesses and homeowners to back up computers, security systems, office equipment, and other critical loads for short periods (minutes) in the event of utility outages. Large systems can be used to power large equipment or entire facilities for extended periods (hours). The size of the battery bank determines the magnitude and duration of critical load operation.

UPS systems are often used to supply power during the transition from utility power to a back-up power source, such as engine generators. UPS systems rely on an external power source to charge the batteries. A PV array can charge the batteries when the primary source of power is lost, extending the time that loads can be supplied with power.

Wind Turbines

A wind turbine is a device that harnesses wind power to produce electricity. The wind rotates aerodynamic surfaces and the resulting mechanical energy drives a generator to produce electricity. See Ill. 4-13. Wind power increases significantly with wind speed and wind turbines are viable in areas with an average wind speed greater than about 12 mph. Small wind turbines from 1 kW to 20 kW peak output are often used in conjunction with PV systems as an alternative energy supply. Large commercial wind turbines can produce up to a few megawatts and have rotor diameters up to a few hundred feet.

++

Depending on wind speed, wind turbines turn at variable speeds, which normally produces AC power with variable frequency. Some wind turbines are designed to match utility frequency by using utility power in the generators exciter circuit. Others convert the AC power to DC and then back to AC, matching the frequency of the utility grid.

++

Ill. 4-13. Wind turbines convert the power of the wind into

electrical energy.

Wind turbines are generally classified by size, output, turbine blade type, axis of rotation, and electrical generation, control, and regulation characteristics. Most wind turbines use horizontal-axis rotors with variable yaw and pitch, and electronic clutch mechanisms to load and unload the machine and for stowing during excessive winds.

Wind turbines can be integrated with other electrical systems and equipment in very similar ways to PV systems. They can operate in parallel with the utility grid, and supply supplementary power to site loads. In addition, they may be used to charge batteries that are used to power system loads as required.

Micro-Hydroelectric Turbines

A micro-hydroelectric turbine is a device that produces electricity from the flow and pressure of water. Moving water acts against turbine blades, rotating a shaft that operates an electrical generator. The principles are the same as for large-scale hydroelectric plants, such as the Hoover Dam, but on a much smaller scale. Micro-hydroelectric systems are those with electrical outputs less than 100kw. Many rural and off-grid consumers have successfully implemented micro-hydroelectric turbines in nearby streams and rivers as an auxiliary power source. A significant advantage to these systems is a very steady supply of power.

Fuel Cells

A fuel cell is an electrochemical device that uses hydrogen and oxygen to produce DC electricity, with water and heat as byproducts. Although similar to batteries, fuel cells are different in that they require a continual replenishment of the fuel and oxidizer reactants (such as hydrogen and oxygen).

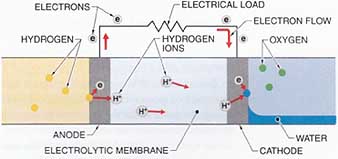

A typical fuel cell element consists of a cathode and anode separated by an electrolytic membrane material. See Ill. 4-14. As hydrogen gas flows across the anode, electrons are stripped from the hydrogen and flow through an external circuit, re-entering the fuel cell at the cathode. At the same time, positively charged hydrogen ions migrate across the membrane to the cathode, where they combine with oxygen and the returning electrons to form water and heat. Typical fuel cell efficiency is about 50% to 70%, though it may be higher if the heat byproduct is also utilized, such as for water heating.

Ill. 4-14. Fuel cells use reactants such as hydrogen and oxygen in a process that transfers electrons, with only water and heat

as byproducts.

An electrolyzer is an electrochemical device that uses electricity to split water into hydrogen and oxygen. This is the opposite process as is used in a fuel cell and is analogous to charging a battery. An electrolyzer may be coupled to a PV system to produce hydrogen and oxygen, which can be stored and later used in fuel cells to generate electricity. Hydrogen can also be generated from traditional fuels, such as oil and natural gas products, using a device called a reformer.

Next: Photovoltaic System Configurations

Prev: Components