Photovoltaic (PV) systems are highly versatile modular electrical power generation systems Every PV system requires components to conduct, control, convert, distribute, and store the energy produced by the array The specific components required depend on the type of system and functional requirements, but major components such as inverters, batteries, charge controllers, as well as wiring, switch gear and overcurrent protection are typically included PV systems are broadly categorized by how they are or are hot integrated with other electrical systems.

Objectives:

- Describe the purposes and functions of the major components in PV systems.

- Identify the common types of energy storage systems.

- Compare the functions of various power conditioning devices.

- Describe various energy sources that can be interfaced with PV systems.

- Compare the features, requirements, and applications of various system configurations.

- List various electrical and mechanical balance-of-system components

COMPONENTS

In addition to an array, all PV systems require electrical equipment to conduct, control, convert, distribute, store, and utilize the energy produced by an array. The specific components required depend on the application and operational requirements of the system.

Modules and Arrays

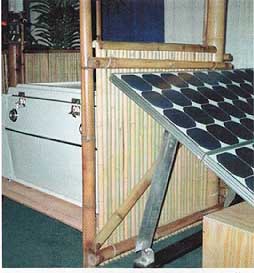

The primary component common to all PV systems is the PV array. An array consists of individual PV modules that are electrically connected to produce a desired voltage, current, and power output. See Ill. 4-1. Modules and arrays produce DC power, which can be used to charge batteries, directly power DC loads, or be converted to AC power by inverters to power AC loads or interface with the electric utility grid.

The voltage of PV modules varies somewhat with temperature, and the current varies proportionately to solar irradiance, so power output is rarely constant. PV systems usually require means to store or condition power so that it can be used effectively by electrical loads.

Energy Storage Systems

Any power-generating system, including a PV system, faces the problem of matching energy supply with demand. Demand can fluctuate considerably and changes occur within minutes or seconds. However, the output of most power generation technologies tends to be steadier or limited to certain times of the day. Matching electricity production to demand is either impossible or impractical, which means that an electricity supply does not always coincide with when it is needed. See Ill. 4-2. Excess energy must be stored for later use, and then recovered when it is needed at high demand. Energy storage systems balance energy production and demand.

There are many types of energy storage systems, though not all are suitable for PV systems. Batteries, particularly lead-acid types, are by far the most common means of energy storage in PV systems. However, other types of energy storage systems can be used, and advanced energy storage technologies are expected to compete with battery systems in the future. Energy storage systems are characterized by the form of energy they store and how it is utilized or converted into other forms.

Modules and Arrays:

Ill. 4-1. PV modules are connected together to form an array,

which is the primary DC power-generating source and principal component

in any PV system.

The term panel typically refers to a small group of modules, often three or four, physically and electrically connected together as an installation unit. Panelization is sometimes used for quickly installing many small modules.

Batteries are by far the most common type of energy storage

device used in PV systems.

Energy Storage systems

Any power-generating system, including a PV system, faces the problem of matching energy supply with demand. Demand can fluctuate considerably and changes occur within minutes or seconds. However, the output of most power generation technologies tends to be steadier or limited to certain times of the day. Matching electricity production to demand is either impossible or impractical, which means that an electricity supply does not always coincide with when it is needed. See Ill. 4-2. Excess energy must be stored for later use, and then recovered when it is needed at high demand. Energy storage systems balance energy production and demand.

There are many types of energy storage systems, though not all are suitable for PV systems. Batteries, particularly lead-acid types, are by far the most common means of energy storage in PV systems. However, other types of energy storage systems can be used, and advanced energy storage technologies are expected to compete with battery systems in the future. Energy storage systems are characterized by the form of energy they store and how it is utilized or converted into other forms.

Batteries. Batteries convert electrical energy into chemical energy when charging and vice versa when discharging. Batteries vary greatly in size, cost, and performance. Although a number of rechargeable battery types can be used in PV systems, lead-acid batteries are most common. Other types, including nickel-cadmium, nickel-metal hydride, and other advanced battery technologies, can also be used in PV systems but are considerably more expensive.

Most PV systems that employ batteries require more capacity than can be supplied by a single battery. A battery bank is a group of batteries connected together with series and parallel connections to provide a specific voltage and capacity. See Ill. 4-3. Batteries in a PV system are charged by the array when sunny and discharged by loads when cloudy or at night.

In addition to energy storage, batteries provide short surge currents for loads with special starting requirements, which PV modules (as current-limited power sources) can't provide. Most importantly, batteries establish a stable system operating voltage, at which the array and loads both operate. A stable system voltage allows the array to be optimized for maximum power and electrical loads or inverters to operate at their rated voltages, avoiding damage from high voltages or reduced performance from low voltages.

Batteries are characterized by their chemistry, nominal voltage, and energy storage capacity in ampere-hours or kilowatt-hours. They can also be evaluated in terms of their specific energy (kWh/kg), specific power (kW/kg), or cost (s/kwh), when comparing various battery types and other forms of energy storage.

Ill. 4-2. Energy Supply and Demand: Since the supply

of energy from a PV array rarely matches the energy demand at a given time,

some type of energy storage is usually required. TYPICAL PV ARRAY ENERGY

SUPPLY; TYPICAL ENERGY DEMAND; EXCESS ENERGY TO BE STORED; ADDITIONAL ENERGY

TO BE RECLAIMED FROM STORAGE

Ill. 4-3. Battery Banks . PV systems with battery storage

usually require more than one battery. A battery bank is a group of batteries

connected together to provide a specific voltage and capacity.

Sealed lead acid batteries although more costly than open vent lead acid batteries, are the most common type of battery in small- to medium size stand-alone PV systems This is because they are generally easier to transport install, and maintain than open-vent batteries.

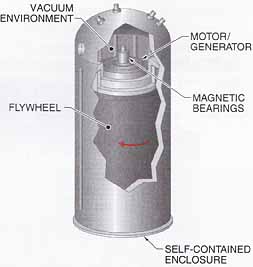

Flywheels. Flywheels are being developed as a practical energy storage solution. Flywheels are large, spinning rotors and are commonly used to transfer power from motor and engines to pumps and other rotational loads. Because flywheels resist changes in rotation speed, they help steady the rotation from uneven power sources like piston engines. Flywheels can also be used to store large amounts of kinetic (motion) energy and release it in a short amount of time.

Excess energy is stored by powering an electric motor that spins the flywheel to high speeds. The flywheel can remain spinning for quite some time with very little loss of speed (kinetic energy). To recover the energy, the motor is switched from a power source to a load becomes a generator and produces electricity from the stored kinetic energy. See Ill. 4-4. The amount of energy stored depends on the mass, shape, and speed of the flywheel. Flywheel energy storage systems are highly reliable and require little or no maintenance. Small-scale systems can store 2 kWh to 25 kWh of power with an efficiency of up to 90%.

Ill. 4-4. Flywheel energy storage systems convert and store electrical

energy as kinetic (motion) energy in the rotation of a heavy rotor.

Flywheel Energy Storage components: VACUUM ENVIRONMENT; MOTOR/GENERATOR;

MAGNETIC BEARINGS; FLYWHEEL; SELF-CONTAINED ENCLOSURE

Supercapacitors. Capacitors store energy in an electrical field developed by two oppositely charged parallel conductive plates separated by a dielectric (insulating) material. When charging, an accumulation of charge on one plate builds up a voltage between the plates. Capacitance is the ability to store an electrical charge and is measured in farads. Conventional capacitors are common in electronics circuits, although the amount of energy stored is extremely small (corresponding to capacitances of microfarads and milli-farads) and is released quickly. Supercapacitors build on basic capacitor technology by using advanced materials to increase capacitance to hundreds or thousands of farads per cell, resulting in significantly greater energy capacity. See Ill. 4-5.

Supercapacitors are a suitable replacement for batteries in many low-power applications. They have fast response times, nearly infinite cycle life without loss of performance, and do not release heat during discharge. They can also smooth out power fluctuations in electrical systems, improving power quality.

Ill. 4-5. Supercapacitors store energy by ac cumulating a charge on pairs

of thin foil plates. The plates are usually wrapped into a cylinder shape.

Components: INSULATING COVERING; INSULATED CORE; POROUS ELECTRODE MATERIAL;

SEPARATOR / ELECTROLYTE LAYERS

Power Conditioning Equipment

Power conditioning equipment converts, controls, or otherwise processes the DC power produced by a PV array to make the power compatible with other equipment or loads. Power conditioning equipment includes inverters, charge controllers, rectifiers, chargers, DC-DC converters, maximum power point trackers, and power quality equipment. These components may be individual devices or may be combined into a single power unit. A power conditioning Unit (PCU) is a device that includes more than one power conditioning function. However, since an inverter is commonly the major component in a multifunction PCU, the unit is still often called an “inverter.”

Large-Scale Energy Storage There are many ways to store electrical energy, though some are only practical for large- scale applications. However, innovative system designers have been able to adapt some principles used for large-scale energy storage for use in smaller systems. Additionally, new technologies are continuously being developed for possible use in PV applications. Pumped Water Pumped water systems use off-peak electricity (when demand is low, usually during the night) to pump water up to elevated reservoirs, in effect storing electricity in the form of potential energy. Potential energy is a source of future energy due to position. Water in an elevated reservoir has potential energy because energy was required to pump it up to an elevation and , if allowed, the water would flow back down. Potential energy is converted back into electrical energy when it is needed (when demand is high, usually during the day) by releasing water and directing its flow through turbine generators. The energy capacity of water storage systems is determined by the volume of water stored, the maximum flow rate, and the vertical height that the water falls. Efficiencies in these systems are approximately 70% to 85%. That is, about 70% to 85% of the energy used to pump the water can be reclaimed when the water is released. These systems can store many megawatts of power for very long periods, though the energy is generally reclaimed within hours. The disadvantage of this technology is that it requires a specific set of circumstances to be feasible, such as a significant source of water and optimal geography. Compressed air Compressed air systems are another form of large-scale energy storage. Similar to the principle of pumped water energy storage, off-peak power is used to compress air into sealed containers, storing potential energy. In large systems, underground caverns can serve as the container. The compressed air is later released to drive turbine-generators. Because typical gas turbine generators use as much as two-thirds of the energy produced to drive the compressor, compressed air systems can also be used to improve the performance of gas turbines. The heated compressed air is mixed with oil or gas, burned, and the expanding mixture is used to drive turbine generators and produce electricity. |

Inverters. An inverter is a device that converts DC power to AC power. In PV systems, inverters convert DC power from battery banks or PV arrays to AC power for AC loads or export to the utility grid. See Ill. 4-6. Inverters are characterized by power source, power ratings, input and output voltages, waveform, power quality, and power conversion efficiency. Inverters used in PV systems are further classified as either battery-based or utility-interactive types.

Battery-based inverters are used in stand alone PV systems and operate directly from battery banks as their input source. The DC input corresponds to nominal battery bank voltages, usually 12 V, 24 V, or 48 V. Higher voltages are used for higher output power requirements. The AC output is typically 120 V or 240 V single-phase power, with power ratings from a few hundred watts to over 10 kW. The actual output is determined by the power demand from the loads. Some models may be combined in parallel to produce greater output power levels. Most battery-based inverters also include built-in battery chargers and some may control system loads or other energy sources such as engine generators.

+++

Resistive lighting loads such as incandescent or halogen lamps, can be powered by either DC or AC, but are less efficient and do not last as long as fluorescent and LED lighting LEDs can be operated directly by DC power, while fluorescent lighting requires a DC ballast.

+++

Ill. 4-6. Inverters convert DC power from batteries or arrays

into AC power to serve local loads or for export to the utility grid.

A power conditioning unit is the most complex electronic

device in a PV system because it must manage many functions simultaneously,

such as inverting, monitoring, and switching.

Utility-interactive inverters draw power directly from PV arrays and operate in parallel with the utility grid. Modem interactive inverters adapt to a wide range of DC input voltages and match AC output to the utility system. Typical AC output voltages are 120 V or 240V single-phase units with power outputs up to 10 kW, while 208 V and 480 V three-phase units are available from around 10 kW up to a few hundred kW. Utility-interactive inverter output is determined by the DC input from the array, unlike the output from battery-based inverters, which is determined by the load. The output of interactive inverters is supplemental to utility-supplied power, so it must be matched and synchronized to the utility power in order to be combined. Excess power can be fed back to the utility grid if not needed by local loads. In this situation, the utility functions as an infinitely large battery bank for excess electricity storage and additional electricity retrieval, as needed.

Charge Controllers. Nearly every PV system that uses a battery requires a charge controller. See Ill. 4-7. A charge controller is a device that regulates battery charge by controlling the charging voltage and /or current from a DC power source, such as a PV array. Charge controllers protect the battery from overcharge and over-discharge, improving system performance and prolonging battery life.

Charge controllers regulate battery charging by terminating or limiting the charging current when the battery reaches a full state of charge. Charge controllers may also protect batteries from extreme discharges by disconnecting electrical loads when the battery reaches a low state of charge. Charge controllers are characterized by their method of charge regulation, voltage and current ratings, and other features and functions.

Rectifiers and Chargers. A rectifier is a de vice that converts AC power to DC power. A charger is a device that combines a rectifier with filters, transformers, and other components to condition DC power for the purpose of battery charging. See Ill. 4-8. Battery chargers are used in PV systems with an AC power source available, such as the utility grid or an engine generator, to provide supplemental battery charging. A battery charger can be an independent component or an integral part of a battery-based inverter. Battery chargers are characterized by their AC input and DC output ratings, methods of charge regulation, and efficiency.

DC-DC Converters. A DC-DC converter is a device that converts DC power from one volt age to another. For example, a power input of 48 V at 10 A can be converted to an output of 24 V at almost 20 A (some losses from conversion). These devices are sometimes used in battery-based PV systems to power loads at voltages higher or lower than the nominal battery voltage. Some are capable of providing more than one output voltage simultaneously. They can also convert high voltage from an array to a lower battery-charging voltage at higher current. DC-DC converters are characterized by power rating, input and output voltages, and power conversion efficiency.

Maximum Power Point Trackers. The voltage and current output from an array can vary with temperature, irradiance, and load. Various combinations of these factors produce power out puts anywhere between the rated (maximum) power level and zero. For any combination of temperature and irradiance, there is a maximum possible power output that corresponds to a certain voltage and current. A maximum power point tracker (MPPT) is a device or circuit that uses electronics to continually adjust the load on a PV device under changing temperature and irradiance conditions to keep it operating at its maximum power point.

An MPPT circuit monitors array conditions and dynamically changes its resistance or input voltage to maximize power from an array. The rest of the MPPT works like a DC-DC converter and delivers power at any output voltage required by the load. MPPT functions are included with inverters and some charge controllers.

Charge controllers with MPPT and DC- DC conversion circuits can be beneficial for systems with large arrays or arrays located far from the battery bank. The array is configured at a higher voltage, which lowers the current. Lower current reduces voltage drop and the size and cost of conductors and switchgear needed. The system then converts the voltage to the required charging level.

+++

Simple interactive inverters are not suitable for providing back up power because they must be shutdown during utility outages for safety reasons. Bimodal inverters are required to provide battery backup during utility outages.

+++

Ill. 4-7. Charge controllers protect batteries in PV systems

from overcharge or excessive discharge.

Power Quality Equipment. Although power quality management is inherent to most inverters, additional equipment may be required in some systems to improve the power quality of the inverter output. Power quality equipment may also be used to address poor power quality of utility power or other sources.

Electrical Loads

An electrical load is any type of device, equipment, or appliance that consumes electricity. They are characterized by purpose, operating voltage, and power demand, and vary widely in performance and other characteristics. Electrical loads typically require either DC or AC power, though some may operate from either, such as resistive loads or universal motors.

Stand-alone PV systems are designed as the sole power source for loads, so the energy consumed by the load determines the size and cost of the required array and battery. In interactive PV systems, the PV power is only supplemental to other power sources, so the size of the loads has little influence on the size, operation, or performance of the PV system. However, in either circumstance, the efficiency of the loads is vital to designing the most practical, efficient, and cost-effective system.

Some loads have special characteristics that affect their energy use. For example, most motors require a high starting current. Electrical loads may also be categorized by importance. When power is limited, less critical loads can be disconnected from the system to preserve remaining power for more critical loads.

Small stand-alone PV systems are often used to power medical

refrigerators in remote areas. To avoid losing energy in the inverting

process, some refrigerators are designed to run on DC power.

Ill. 4-8. Rectifiers and chargers make AC power from sources

such as the utility or engine generators available for charging batteries

or other DC loads.

DC Loads. Since a PV array produces DC power, DC loads are used in many PV applications to avoid having to invert the power to AC. This simplifies the design and installation and eliminates the cost of an inverter. DC loads may be powered directly from arrays or batteries. The most common DC loads used in PV systems are lighting fixtures and motors for fans and pumps. Most DC loads operate at 12V, 24V, or 48V.

Most DC loads and appliances are produced for the marine and RV markets and are readily available from retailers specializing in those areas. However, because they are not intended for use in buildings, they may not meet applicable building codes and regulations. DC appliances should be carefully checked for listing to applicable safety standards.

AC Loads. AC loads are powered from inverters, generators, or the utility grid. AC loads operate at normal service voltages and at a specific frequency. Most residential and commercial loads are AC loads, including refrigerators, air conditioners, televisions, lighting, and motors. AC loads are more widely available and usually less expensive than comparable DC loads. AC loads may require single-phase or three-phase power at voltages from 120V to 480 V.

Balance-of-System Components

Balance-of-system (BOS) components are all the remaining electrical and mechanical components needed to integrate and assemble the major components in a PV system. See Ill. 4-9. BOS components are also an important part of safety management.

Mechanical BOS Components. Mechanical BOS components include fasteners, brackets, enclosures, racks, and other structural support for the safe and reliable installation of PV system components. Additional mechanical BOS components, such as fencing, handrails, access ladders, and building or architectural components associated with the PV system, depend upon the particular PV installation. For PV water delivery systems, storage tanks, pumps, and distribution equipment are considered mechanical BOS components.

Electrical BOS Components. Electrical BOS components include conductors, cables, conduits, junction boxes, enclosures, connectors, and terminations needed to make circuit connections between modules, controllers, batteries, inverters, and other electrical systems and equipment. Electrical BOS hardware also includes switchgear, overcurrent protection devices, and grounding equipment needed to safely isolate and protect major components and conductors from overload and fault conditions. Instrumentation and monitoring equipment may also be considered BOS components, as would any special surge protection devices, power quality equipment, related control systems, or dedicated electrical loads.

Ill. 4-9. Balance-of-system (BOS) components include all the

additional mechanical and electrical parts needed to connect and secure the major components.

+++

DC loads are no more efficient than comparable AC loads. However, using DC power instead of AC power whenever possible avoids the power losses inherent with the inverting process, increasing overall system efficiency.

+++

Next: Electrical Energy Sources

Prev: Site Surveys and Pre-planning