Essentially, all wood-burning stoves are either airtight or non-airtight. The airtight type is much more efficient because it lets the user control the air supply. As a result, you can restrict both the rate of combustion and the amount of heat lost in the burning process. Controlling these factors minimizes the expenditure of heat through the stack, which slows the chimney effect and lowers the amount of heat lost from the heated space. As a result, much less wood is consumed to produce a greater and more constant heat—the very definition of “efficiency” for a wood-burning unit.

An airtight stove is also efficient in terms of how it distributes heat to the surrounding area. When a stove is not airtight (when it has cracks, loose joints, or other openings), heat is drawn back into the wood-burning unit and is lost up the stack. With an airtight unit, however, such drawback is minimal.

When all is working right—that is, when your airtight stove doesn’t have to battle with infiltration from a poorly insulated house—it may take only minutes to begin heating your house in the morning. Then, once the air is hot, the convection cycle will keep it warm for as long as the stove is burning wood. and the convection cycle tends to create very even heat throughout your house.

Airtight stoves come in many forms, ranging from simple box-heaters and contemporary Franklin-type stoves to unique shapes that defy categorization. Most are made of steel. In stoves that are designed for maximum efficiency, gases from the burning wood are directed in specific patterns (draft configurations) to the hottest part of the stove where they are ignited, increasing the amount of heat.

• Combination stove: One variation of an airtight stove is called a combination stove. With this type, the units can be either left open, providing a homey view of the fire that’s burning inside, or closed for airtightness. This flexibility allows the rate at which wood is burned to be determined by air intake alone. As with ordinary airtight stoves, there is no need for a chimney damper.

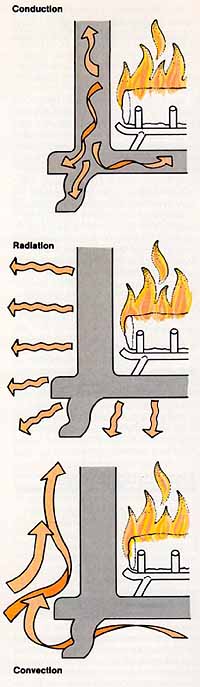

Conduction; Radiation; Convection: When wood burns in a

stove, heat is conducted through the metal firebox, and radiates into the

air around the stove. The warmed room air begins to rise up off the stove

in the process of convection, heating further and further reaches of the

surrounding area; as the warmed air rises, it is replaced by cooler air,

which in turn is warmed. and so the cycle continues.

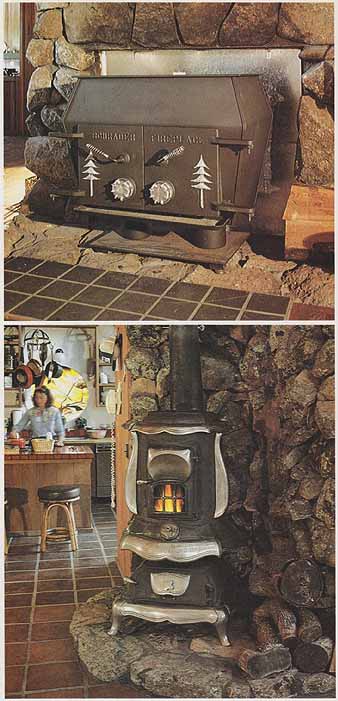

The airtight stove (top) allows you to control the influx

of air to the firebox, and thereby to control the rate at which your fire

burns. It allows for far greater efficiency in burning wood for heat than

does the non-airtight stove (below), which will burn with a merry

blaze until it consumes its fuel.

Non-Airtight Stoves

The most popular non-airtight stoves are made of cast iron. The traditional parlor stove and potbelly stove have been manufactured for many years with small regard for air-tightness.

Baffles, similar to those used in air tight stoves, have been introduced into some modern non-airtight designs. Al though a few of the older non-airtight stoves were also built with baffles, many were not. If you want to use one of these older, nostalgia-producing artifacts today, try adding a damper to the duct carrying air to the fire—it will give you some measure of control over the wood’s combustion (although you’ll never have as much control as with an airtight stove). Fires in non-airtight stoves almost never keep their coals alive overnight, requiring a new fire and a new warm-up time each morning.

Further, the room housing the stove may be hot while the other rooms are only moderately warm, If this is your situation, you can remedy it to some extent by using a forced-air fan (with the in take near the heat source), or a series of fans between rooms.

Next: Buying a Wood-Burning Stove

Prev: Wood-Burning Stoves