You’ve caulked the cracks and weather-stripped the windows. The coldest air can’t crawl across your threshold. At every window, panes of glass combine their strength to beat back infiltration. If yours is a typical American house, your heating and cooling bill has already plummeted—10, 15, maybe even 20 percent. and yet, as you sit before your energy-efficient wood stove (see our “Wood and Other Alternatives” section), you feel … cold air.

It’s coming through the walls!

Your house itself needs insulation. How much depends on where you live, the structure and site of your building, and other factors. But even if you already have insulation, the odds are great that it isn’t enough to keep out the winter cold and summer heat.

Until very recently, it cost so little to heat and cool our homes that it hardly made sense to maintain efficient insulation, and houses were therefore constructed with little of it. However, for the present and the foreseeable future, insulation is one of the best investments you can make. You might say it’s a hot item.

It would be self-defeating to insulate without first caulking, stripping, and protecting your windows and doors. If you neglect these crucial steps, insulation alone won’t keep whatever heat or cooling might be saved from slipping away into the great outdoors However, once you have sealed the various seams and edges of your house, you can save an additional 20 to 25 percent on your space-conditioning bill by bringing its shell up to the same effective standards.

Thickness of Various Insulating and Building Materials Required to Reach R-19 |

|

Material |

Required Thickness (approximate) |

1/2” Plywood Plasterboard Concrete cinder blocks Common brick Sand Fiberglass batts Cellulose fiber batts Urethane foam |

18” (1½’) 24” (2’) 72” (6’) 96” (8’) 156” (13’)

6” 5” 3” |

Making Your Own Vapor Barrier

• Insulating materials: What constitutes a good insulator? Wood, brick, plaster, masonry, and glass—all materials that are commonly used to build a house—are not particularly effective insulators, although they store heat well. Rock wool, fiberglass, polystyrene, and urethane do the job much better.

An effective housing insulation should have these characteristics: it should be moisture, fire, and rot resistant; it should not attract feeding or nesting mice or other vermin; it should not emit unpleasant odors; and it should not be so heavy that it strains the structure of the building. But the most important quality of all is: it should have the ability to resist the conduction of heat.

The ability of any material to resist heat conduction is known as its R-value. The greater a material’s R-value, the more efficient its heat-resisting qualities; therefore, the better it can insulate.

Because air itself is such a good insulator, the best housing insulation materials generally trap many minute pockets of air in a compact space. As a result, housing insulation tends to be bulky without being very heavy.

A material’s R-value (and therefore its quality as an insulator) is calculated on the basis of its thickness as well as its composition. R-value is the criterion by which housing insulation is sold and applied, rather than according to its weight, density, thickness, or other qualities. For example, R-1 9 is the insulation recommended by the Federal Housing Administration, the American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and other insulation research and manufacturing organizations for the outside walls of most houses in the United States.

The chart below indicates what R-19 insulation means in terms of several common insulators and several common building materials.

• Vapor barriers: The air in your heated, insulated house contains a surprising amount of water in the form of vapor. As the warm air attempts to pass through your ceilings, walls, and floors to the cold outside, it carries this water with it.

When the water starts to penetrate your building’s shell and reaches cooler air, it condenses. Then it collects in your insulation and other nearby materials, such as wallboard and structural timber. This makes the insulation ineffective; and , along with the other affected materials, it begins to deteriorate.

To protect your building, as well as your insulation, from moisture, a vapor barrier is recommended with virtually all insulation. This is a layer of water-repellent material—for example, aluminum foil or thick plastic sheeting—taped at all seams with a water-repellent tape.

It lies on the warm side of the insulation (toward the inside of the house, not away from it), between the warmth of an inner wall and the cold temperature just beyond it.

Most insulation sold in the form of blankets or batts comes with an attached vapor barrier. and some of the extruded insulations act as their own vapor barriers. But if you are installing loose fill, rigid boards, or some sort of blanket or batt that has no vapor barrier, you need to create your own. Aluminum foil or plastic sheeting and waterproof tape work well. So does painting at least two coats of an oil-based enamel paint on the inside walls in front of the insulation (or on the floor above it, or on the ceiling below it).

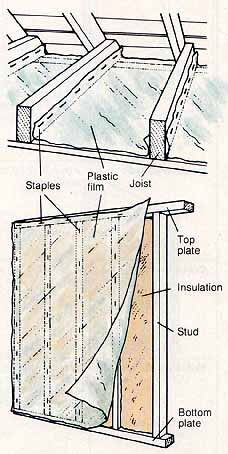

• Installing a vapor barrier: If you plan to install your own vapor barrier, consider polyethylene sheeting—it’s easier to buy and use than large rolls of aluminum foil. The plastic should be at least 2 mils thick.

For an unfinished wall, drape a sheet of polyethylene around the entire wall, on the inside of both insulation and studs. For an unfinished floor or ceiling, follow the same procedure or, cut strips of plastic to fit between joists, allowing about 4 inches extra width to lap up the sides of the joists. Staple these in place as smoothly as possible, then tape any gashes in the plastic with waterproof tape.

Remember to keep the vapor barrier toward the warm side of the insulation—the in side of the house.

Forms of Insulation:

Insulation materials are packaged and sold under many brand names, sometimes with minor variations in composition. However, only nine materials are currently used for housing insulation, and these materials come in only five basic forms. This chart tells you how these five forms are generally used, what materials they are made of, and how easy or difficult they are to handle.

You will also want to know the R-value of the insulation. This depends on the material it is composed of, and details about each of the materials listed here are included in the chart below. The R-value is usually printed on the face of the insulation or, in the case of loose fill, on the bag.

Form |

Materials |

Principal Use |

Remarks |

|

Perlite/Vermiculite Fiberglass Rock wool Polystyrene Cellulose fiber |

Floors, walls |

Very easy to apply, and fairly commonly used by people doing their own insulating. Has a tendency to settle, particularly if installation is high or slanted, which diminishes its effectiveness by leaving top portions of till empty or packed far too loosely. Vapor barrier should be installed separately. |

|

Fiberglass Rock wool Cellulose fiber |

Floors, attics, roofs |

The form most commonly used by people insulating their own homes. Usually sold with flanges designed for easy stapling, and sold with or without vapor barrier attached. |

|

Fiberglass Rock wool Cellulose fiber |

Floors, attics, roots |

Easier to handle than blankets, but otherwise identical. |

|

Fiberglass Polystyrene Urethane Isocyanurate |

Unfinished walls |

Plastic boards are common, and are highly flammable; they should be covered with fire-retardant wallboard. Some are not water resistant, and some are sold with a bonded aluminum vapor barrier; but the absence of a vapor barrier does not imply that the board is water-resistant. Ask your sales person. |

|

Urea formaldehyde Urethane |

Finished walls |

Very effective, but very difficult to install satisfactorily. Should be in stalled only by a reputable, qualified contractor. May stink, emit toxic fumes, or even swell and burst through walls. |

Insulation Materials

As we’ve said, there are nine materials currently in use for housing insulation. These materials are described in the chart below. But you should not be discouraged by this diversity. You will not have to choose among them all. First of all, unless you are a professional in the building trades, you probably won’t even be able to find several of the materials listed. Second, if you do find them, you might well decide they are too expensive, or too complicated to install, for your purposes. We have provided more complete information than you are likely to need simply to let you know the lay of the land. If you know that isocyanurate exists, you may decide that it suits your needs perfectly.

The materials you are most likely to encounter when you go to your friendly-neighborhood home improvement center are, in general, the least expensive, easiest, and safest materials to handle. You will almost always find fiberglass in batts and blankets; you will usually find cellulose fiber as loose fill; and you will often find rock wool, particularly as loose fill. If you are seriously looking for it, you can also track down polystyrene as rigid boards. You can locate perlite and vermiculite easily in plant and garden centers, since both materials are used to lighten plant soil. and if you arrange to have a contractor blow foam into your walls, he will normally use urea formaldehyde.

The R-value for each of the materials varies from form to form. It also varies in another way: A three-inch fiberglass board does not yield three times the insulation provided by a one-inch fiberglass board. However, these numbers, representing the R-values per inch, provide you with the relative qualities of the materials. As we’ve noted, the actual B-value will be printed on the insulation, so you will know exactly what you are getting.

Material |

Forms |

R-value Per Inch |

Remarks |

Perlite Vermiculite |

Loose fill Loose fill |

2.3 2.3 |

Easy to use, but least efficient of all standard materials; moisture retentive. |

Fiberglass |

Loose fill Blankets Batts Rigid boards |

2.7 3.0 3.0 4.0 |

Fiberglass blankets and batts are the forms of insulation most commonly installed without contractor assistance. Easy to handle; both fiber- and moisture-resistant. Wear gloves, long-sleeved shirt, respirator and eye protection when handling, to keep material from irritating skin, lungs and eyes. |

Rock wool |

Loose fill Blankets Batts |

2.7 3.6 3.6 |

Similar to fiberglass. |

Polystyrene |

Loose fill Rigid boards |

3.0 3.5 |

Polystyrene boards are commonly used to insulate unfinished walls. Should be faced with gypsum or similar wallboard since polystyrene is highly flammable. Moisture-resistant. |

Cellulose fiber |

Loose till Blankets Batts |

3.7 4.0 4.0 |

The most common loose fill insulation sold. Basically, it is shredded paper, and is flammable and not moisture-resistant. Therefore, buy only those brands that have been treated with a fire retardant. Install with a separate vapor barrier. |

Urea formaldehyde |

Foam-in- place |

5.0 |

Should be installed only by a qualified and reputable contractor. Moisture-retentive; fire-resistant, Formaldehyde gas, released during curing process, may be harmful. |

Urethane |

Rigid boards Foam-in-place |

6.2 |

Excellent insulation but highly flammable, emitting cyanide gas when burning. Foam should be installed only by a qualified and reputable contractor. |

Isocyanurate |

Rigid boards |

9.0 |

Most effective insulation available, but very expensive and , like urethane, very flammable, emitting cyanide gas when burning. Moisture-resistant. |

Next: Where to Insulate