AMAZON multi-meters discounts AMAZON oscilloscope discounts

.

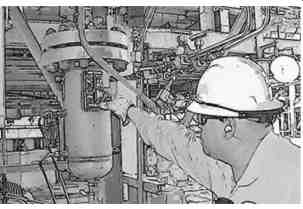

ABOVE: Operator Checking Seal Pot Level

The inspection methods described in this section are primarily limited to those used on centrifugal and positive displacement pumps, gear boxes, motors, heat exchanger and turbines. However, with some modifications, the inspection methods can be applied to all types of equipment, such as fans, compressors, extruders, turbines, motors, conveyers, elevators, etc.

You will notice a common pattern after studying the best inspection practices discussed below. In all cases, you are asked to look, listen, and feel. These simple methods can help locate basic machinery problems early. They will help you to determine when a piece of equipment is needed to quantify the magnitude of the problem and get help. With practice, these methods should become second nature.

Recommended Pump Inspection

1. LOOK at the pump as you walk up to it.

• Is it shaking?

• Is it smoking?

• Is the discharge pressure different today than yesterday? Is it steady or wiggling? A wiggling needle on a pressure gauge may be due to cavitation.

• Are all of the anchor bolts in place? Are they tight?

• Are there indications of leakage of fluids of any kind? (see FIG. 1)

• Have parts of the pump come loose?

• Look at the motor amps.

Pump capacity problems due to flow restrictions or internal wear can cause the motor to pull less or more than the normal amp load, depending on the pump design and the nature of the problem. This means it is important to regularly monitor amp loading and note any deviations, high or low, from normal values.

• Is the seal leaking? If this is a packed pump is the leakage rate excessive? (Note: Mechanical seals should not have any visible leakage, while pump packing requires visible leakage for cooling and lubrication. A packing leakage rate of about one drop per minute should be considered normal.)

• If the seal uses a seal pot, check to see if the sight glass is showing a correct fluid level? Is the line to the top of the seal gland connected to the upper fitting on the seal pot?

• Is there coupling spacer dust on the foundation? Pieces of shim pack?

• Is the oil level in the bearing housing correct (see FIG. 2)? Discolored?

• Is oil pressure correct for the pump?

• Is the P, pronounced delta P, (upstream pressure minus downstream pressure), on the oil filter gauge low? Is delta "p" on the oil filter high? If the P on the oil filter gauge is high, can you explain why?

• Is paint burned off in new places? Why? (Remember that paint discolors at around 400 to 450 degrees F.)

• If the pump is equipped with a permanent vibration monitor, check it on a regular basis, looking for any dramatic changes between inspections.

FIG. 1-An obvious indication of a leak.

FIG. 2-An oil level sight glass showing the full oil level .

2. LISTEN to the pump.

• Is it noisy? Can you detect a bearing noise? Can you hear any cavitation noise? The louder the cavitation noise the greater the potential for internal damage over time.

• Does it sound different today than yesterday? Is the noise from the motor or the pump?

• Is the noise constant or changing? (This may be an indication of a control valve opening and closing.)

• Does it sound like gravel inside of the pump casing? (This could possibly be a sign of cavitation.)

• Are there any steam, air, or gas leaks in or near the pump?

• Are the drive belts squealing? Are there any visual indications of loose belts?

3. FEEL-Touch the pump with finger tips.

• Is it warm, hot, cold?

• Is it different than it was yesterday? How and why is it different than yesterday?

• Is it shaking more than yesterday? Is it too much?

• Is the auxiliary oil pump running? Why?

• Is the oil relief valve dumping oil? Why?

• Is the pump vibrating? Is it the same as yesterday?

• Is the bearing housing hot? Touch the seal flush lines. Can you tell if there is a difference in temperature? No difference can indicate a loss of flow or a reduction of heat exchange?

Recommended Electric Motor Mechanical Inspection

Operator checking electric motor vibration

1. LOOK at the motor.

• Is it shaking?

• Is it smoking or are sparks flying?

• Is anything loose, shaking, or vibrating on the motor?

• Is the flex conduit in good condition?

• Has the dust cap come off the bearing on the coupling end of the motor?

• Is the fan on the TEFC (totally enclosed fan cooled) motor turning?

• Are the air filters or fins on a TEFC motor clear so air can circulate (see FIG. 3 and 4)?

• Is there any burned paint? This would be a clear indication of an abnormally high motor surface temperature. If yes, why and where?

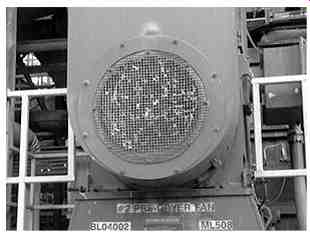

FIG. 3-Electric motor with debris beginning to block the air inlet screen.

This could lead to overheating and the eventual failure of the internal windings.

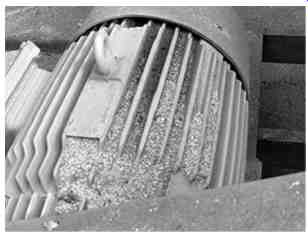

FIG. 4-A TEFC (totally enclosed fan cooled) electric motor with debris

resting between the cooling fins. This reduces the motor's ability to expel

internal heat, which could lead to overheating and the eventual failure of

the internal windings.

2. LISTEN to the motor.

• Does it sound different today than yesterday?

• Is the noise the motor or the driven piece of equipment?

• Is the noise constant or a rhythmic hum?

• Does the noise seem to coming from the bearings, the fan, or some other location on the motor?

• Are belts slipping on the drive end of the motor?

3. FEEL-Touch the motor.

• Is it different than it was yesterday? How and why is it different than yesterday? Is it warm, hot, cold?

• Is it vibrating?

• Is the fan turning and putting out air?

• Is the cooling system for the motor and/or lubrication system functioning properly based on your experience?

Recommended Gear Box Inspections

FIG. 5 Industrial Gearbox

1. LOOK at the gearbox as you walk up.

• Is it shaking?

• Smoking?

• Are all of the anchor bolts in place? Are they tight?

• Is there indication of leakage of fluids of any kind?

• Have vibrating parts come loose? (Check oil coolers, piping, base plate, bearing caps, etc.)

• Is there water in the oil?

• Is the auxiliary pump running? Why?

• Is the oil pressure correct?

• Is the oil cool enough?If the oil supply line has any type of temperature indicator, see if the temperature is in the normal range; if there is no indicator, touch the supply line to determine if it seems to be consistent with past inspections.

• Is the oil level correct in the sump?

• Are there coupling pieces on the pedestal under the coupling guard?

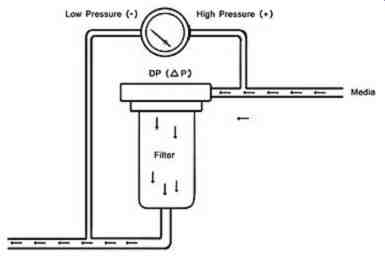

• Is the P on the oil filter gauge high (see FIG. 6)? Why?

• Check the vibration readings log if continuously monitored.

FIG. 6-A local differential pressure meter, if provided, can be used to

indicate the pressure difference between high (upstream) pressure and low

(downstream) pressure across an oil filter. This is an excellent means of

monitoring the condition of the filter.

2. LISTEN to the gear box.

• Is it noisy?

• Does it sound different today than yesterday?

• Is the noise constant or changing?

• Are there steam, air, or gas leaks in or near the gear box that could contaminate the lubrication?

3. FEEL-Touch the bearing housings with your fingertips.

• Is it different than it was yesterday? How and why is it different?

• Are they excessively hot?

• Is it shaking more than yesterday? Is it too much?

• Is the oil pressure relief valve bypassing oil? If so why?

• If there is an oil cooler is heat being exchanged? Touch the inlet and outlines to ensure heat is being removed.

Recommended Steam Turbine Inspection

FIG. 7-General Purpose Steam Turbine

1. LOOK at the turbine as you walk up.

• Is it shaking?

• Smoking? Any signs of smoke, which may be an indication of an oil leak, should be acted on immediately due to fire potential it represents.

• Are all of the anchor bolts in place? Are they tight?

• Are there any indications of fluid leakage?

• Are there vibrating parts on the turbine that have come loose? (Check coolers, piping, baseplate, bearing caps, etc.)

• Is excessive steam leaking out of the glands that seal the shaft to the casing? (Note: Normally, there should be no visible leakage exiting the turbine seal glands. Any significant gland leak has the potential of injecting steam into the bearing housings and contaminating the oil.

• Is there water in the oil? (Check level, is it rising?)

• Is the governor hunting? (This wears out valve packing and linkage.)

• Are the steam traps near the turbine working (see FIG. 8)?

• Is the auxiliary pump running? Why?

• Is the oil pressure correct?

• Is the oil cool enough, based on your experience with this steam turbine? Is the cooler working?

• Look at the vibration readings for the turbine; are they steady and low? Is the oil level correct in the sump? Is the oil level correct in the bearing boxes? Is the oil level rising or falling?

• Are the ring oilers turning or hung up?

• Is there steam leaking out of the stem of the control valve?

• If installed, is the bearing housing air purge turned on to prevent steam from contaminating the oil?

• Are there coupling pieces on the pedestal under the coupling guard?

• Is the trip mechanism resting on its knife edge?

• Is the delta P on the oil filter gauge high?

• Look at piping support springs to insure that blocks were not left in after maintenance, especially if a hydrostatic, i.e. "hydro", test was performed on the piping system during any construction work.

• Look at the coupling area and see if there are shims from the spacer or dust if an elastomeric type of coupling is used.

FIG. 8-Condensate or free water in a steam turbine's inlet will lead to

the rapid erosion of the steam path components, which is why steam traps

are always installed in steam turbine inlet piping. A steam trap is used

to remove condensate and non-condensable gases from steam piping, with a

negligible consumption or loss of live steam.

2. LISTEN to the turbine.

• Is it noisy? Steam leaking?

• Does it sound different today than yesterday?

• Is the noise constant or changing? Is the governor steady or hunting?

3. FEEL-Touch the turbine bearing housings with your fingertips.

• Are they excessively hot?

• Is the temperature different than it was yesterday? How and why is it different than yesterday?

• Is it shaking more than yesterday? Is it too much?

• Is the oil pressure relief valve bypassing oil? Touch the inlet to the valve and the outlet from the valve. Under normal conditions, the outlet line should be noticeably cooler that the inlet line. If the relief valve is leaking, the outlet line will feel warm.

• If it is bypassing oil, try to determine if this is normal or not.

• Check oil cooler to ensure it is removing heat from the oil.

Recommended Heat Exchanger Inspection

FIG. 9-Heat Exchanger

1. LOOK at the heat exchanger as you walk up.

• Is it shaking?

• Are all of the anchor bolts in place? Are they tight?

• Are there any indications of leakage of fluids of any kind?

• Is the differential pressure correct?

• Is heat being exchanged in the cooler? Touch the inlet and outlet and insure there is a difference in temperatures.

• Is the delta temperature for the exchanger normal?

• If the exchanger operates hot, is the mechanism that allows controlled expansion clean, rust free and functioning? Are slides, flex legs, or bolts left loose on one end to allow movement of one end of the exchanger?

2. LISTEN to the exchanger

• Is it noisy?

• Does it sound different today than yesterday?

• Is the noise constant or changing?

• Is there the sound of gas or boiling going on inside?

3. FEEL-Touch the exchanger your fingertips.

• Is it excessively hot?

• Is it different than it was yesterday? How and why is it different than yesterday?

• Is it shaking more than yesterday? Is it too much?

• Touch or test the inlets and outlets of the exchanger to see if an exchange is taking place.

General Machine Start-ups

During the start-up of a process machine, it is prudent to be extra vigilant in order to detect problems related to how a machine is lined-up, whether it may be subjected to adverse process conditions or equipment deterioration, etc. Extra attentiveness should be given to machines that have recently been repaired or idled for extended periods of time.

Keep in mind that the instructions provided here are very general and should be performed on the driver and the driven equipment before and during start-ups. More specific start-up procedures may be required for more complex or critical machines. Furthermore, before attempting to start-up a critical machine, verify the locations of all key field instruments, such as flow meters, pressure gauges, and temperature gauges and know what are considered normal indications for all these devices (see FIG. 10).

FIG. 10-Always locate all key field instruments before starting rotating

equipment. The figures shown here are of an oil pressure gauge (upper left),

differential pressure gauge (lower left), level glass on a reservoir (center),

and a rotameter (right) Inspection:

• Check and start all auxiliary system, including lubrication, seal, and cooling systems, depending on what your specific machine has installed

• Ensure there are adequate levels in all components that have liquids, including sumps, lubricators, greasers, and barrier or buffer systems, etc.

• Look at the condition of the lubricant. Color changes, especially if they happen rapidly or are not normal for this piece of equipment, should be investigated prior to starting.

• If this equipment operates hot, allowances must be made for warm up to allow all parts to come to normal operating temperatures.

• If there is a device such as a guided slide or flex plate, as on steam turbines, it must be free to allow movement or flexing as temperatures approach normal from ambient. The same is true for equipment operating at extreme cold temperatures.

• On motors, ensure ventilation openings are clear of obstructions that could restrict airflow.

• Ensure the area around the equipment is clean and free of hazards.

• For motors, verify there are no loose conduit or cable connections or broken conduit. Ensure all foundation bolts are tight.

• If there are site-specific or manufacturer's specific instructions, they must be incorporated in your operating procedures.

• Start the equipment.

• If the unit is motor driven and does not start the first time, look for all the reasons why it didn't start. These could include the activation of one or more permissives that have been installed to protect the motor from starting before conditions are safe. (A permissive is a particular type of safety interlock designed to prevent actions from taking place until pre-defined criteria have been satisfied. A permissive may prevent machine start-ups if there is a condition of low oil pressure, high suction drum level, high winding temperatures, etc.) Most large motors will allow only three (3) starts then they lock out for hours before they can be started again.

Machine Shut-downs:

Operating procedures should also be developed and followed for equipment shutdowns. Some auxiliary systems, such as lubrication to protect bearings from overheating and seal oil systems to maintain pressure differentials, may need to be kept running. The manufacturer is an excellent source for shutdown guidelines.

Keep in mind that the instructions provided here are very general and should be performed on the driver and the driven equipment after machine shut-downs. More specific shut-down procedures may be required for more complex or critical machines.

Inspection:

• Prior to shut down, look at the condition of the lubricant while it is still circulating. Color changes, especially if they happen rapidly or are not normal for this piece of equipment, should be investigated.

• If this equipment operates hot, allowances must be made for cool down to allow all parts to come to ambient temperature.

• Ensure there are adequate lubricant levels in all areas that require it, i.e. sumps, lubricators, greasers, etc.

• If there are site-specific or manufacturer's specifications, they must be followed.

• Stop the equipment.

• Stop the auxiliary systems, which include lubrication, seal systems, and cooling. If rotors are extremely hot (Above 250 F) allow the lubricating system to circulate to cool the shaft and bearings. This is especially necessary if the bearings are made of babbited material.

• If the equipment has a cooler to regulate temperatures it is ideal to have a method of back flushing the cooler and this should be done at each opportunity such as shutdown or equipment swaps.

• Ensure ventilation openings on motors are clear of obstructions that could restrict airflow.

• Verify there are no loose conduit or cable connections or broken conduit on motors.

• Ensure all foundation bolts are tight.

• Perform a visual inspection for leaks after shutdown.

For turbines make sure steam traps are working to ensure the turbine does not fill with water during shut down.

Quiz

1. What are the three senses you can utilize during a machinery walk-though inspection?

2. List three things to look for during a pump inspection.

3. List three things to listen for during an electric motor inspection.

4. List three things to feel for during a steam turbine inspection.

5. The one secret to detecting problems early is to know what is.

Answers

1. What are the three senses you can utilize during a machinery walk-though inspection?

• Sight

• Hearing

• Touch

2. List three things to look for during a pump inspection.

• Is it shaking?

• Smoking?

• Is the discharge pressure different today than yesterday?

• Are all of the anchor bolts in place? Are they tight?

• Are there any indications of leakage of fluids of any kind?

• Are there vibrating parts on the pump that have come loose?

• Are the motor amps normal? Pump capacity problems do not cause the motor to pull excessive power or higher amps.

• Is the seal leaking?

• Is there proper level in the seal pot if used?

• Is there coupling spacer dust on the foundation? Pieces of shim pack?

• Is the discharge pressure gauge steady? (If not there may be cavitation)

• Is the oil level in the bearing housing correct? Discolored?

• Is oil pressure correct for the pump?

• Is the ΔP indication on the oil filter gauge low? High? Why?

• Is paint burned off in new places? Why? (Paint discolors around 400 to 450 F.)

• Look at the vibration monitor on a regular basis.

3. List three things to listen for during an electric motor inspection

• Is it noisy? Bearings? Fan?

• Does it sound different today than yesterday?

• Is the noise the motor or the driven piece of equipment?

• Is the noise constant or a rhythmic hum?

• Are the belts slipping on the drive end of the motor?

4. List three things to feel for during a steam turbine inspection.

• Are they excessively hot?

• Is it different than it was yesterday? How and why is it different than yesterday?

• Is it shaking more than yesterday? Is it too much?

• Is the oil pressure relief valve bypassing oil? If so why?

• Check oil cooler to insure it is removing heat from the oil.

5. The one secret to detecting problems early is to know what normal is.