AMAZON multi-meters discounts AMAZON oscilloscope discounts

.Lubrication is one of the most important aspects of any rotating equipment reliability program.

Lubrication related failures are the most preventable type of machinery failures. With sufficient attention to details, they should be rare events. It is normally through the neglect of lubricants and lubrication systems that equipment fails prematurely. As a machinery operator your vigilance plays a central role in maximizing the useful life of a machine's lubrication system.

The lubricants and sealing methods available today have greatly improved the reliability of both pressurized, non-pressurized, sump and splash type lubrication systems. All machines require lubrication of their radial and axial bearings in order to maintain the rotor's position relative to the casing and to ensure reliable operation.

Lubrication serves the following critical functions:

• Reducing wear by separating moving surfaces

• Reducing friction between the rotating and stationary components

• Absorbing shock

• Dampening noise

• Carrying heat generated by friction within the bearing

• Removing heat transmitted down the shaft from the process end of the machine

• Minimizing corrosion

• Keeping contaminates away from the bearing components

• Flushing contaminants away from bearings

• Acting as a sealing medium

Lubrication Regimes

There are four basic fluid film lubrication regimes encountered in machinery, listed here from thinnest to thickest:

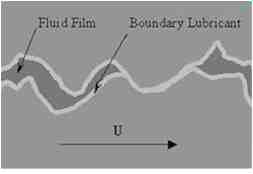

1. Boundary lubrication, where surfaces are in contact with each other even though a lubricant is present (see FIG. 1). This is generally an undesirable operating regime for a fluid film bearing since it leads to increasing friction, energy loss, wear, and material damage. If designed properly, most machines will experience boundary lubrication only during start-ups, shutdowns, and low speed operation. Special lubricants and additives have been developed to lessen the negative effects of this regime. When constant starts and stops create boundary lubrication the life of a machine is reduced.

2. Mixed lubrication, where surfaces are partially separated

3. Elastohydrodynamic lubrication, where two surfaces are separated by a very thin lubrication film. Elastohydrodynamic lubrication is employed in most rolling element bearings. Think of a balloon sitting on a table. As the balloon is pressed on the top the contact area on the table will increase, allowing the support of more load by reducing the unit loading. "Elasto" in the name means parts can deform elastically; "-hydro-" refers to a liquid such as oil, and "-dynamic" means it is moving.

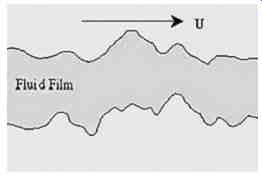

4. Full fluid lubrication, also called hydrodynamic lubrication, is where two surfaces are completely separated by a fluid film (see FIG. 2). Full fluid lubrication is essential for the long-term reliability of high-speed, fluid film bearings. A full fluid film is formed when the bearing geometry, shaft speed, and oil viscosity combine to generate sufficient pressure to support the full bearing load. This is self-generating pressure that results in the complete separation of the shaft from the bearing.

FIG. 1-Boundary Lubrication

FIG. 2-Full Fluid Lubrication

Types of Lubricants

Grease

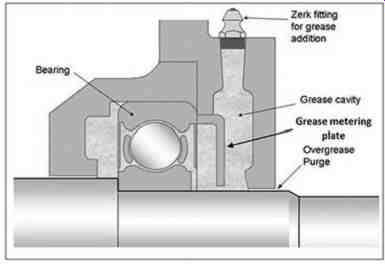

Grease is a solid to semi-fluid mixture of a thickening agent (such as a chemical soap) and liquid lubrication. Some commonly used soaps are polyurea for electric motor applications and lithium for pillow block bearings and similar rolling element applications. Thicknesses range from 000 (semi fluid grease) to 6 (block grease). It is typically used in lower speed applications (1800 rpm or less).

The price of grease ranges from $0.20 to $100 per ounce. Always refer to the manufacturer's recommendation when selecting grease for your specific application.

FIG. 3 shows a typical greased bearing with a "zerk"1 fitting for grease addition. Remember: You should never mix greases without first checking with your lubrication department Mixing grease types can be considered the same as contaminating the lubrication-the result is either softer grease that allows lubricant to flow away from the application at a lower temperature or harder grease that decreases its ability to lubricate and flow properly.

FIG. 3-Double-shielded bearing with grease-metering plate facing grease

reservoir

Greasing Tips

• Keep grease guns out of the weather (clean and dry).

• Clean the zerk fitting before adding grease; otherwise contaminants resting on the fitting could be pushed into the bearing with the fresh grease. Be sure no paint is on the zerk fitting, as it might prevent grease from getting to the bearing.

• Ensure the grease coupler is clean and free of hardened grease globs and dirt-before use. This can be done by capping the end or wiping excess grease off of the grease gun end and then operating the gun by pumping a small amount of grease out into a cloth to clean the grease passage way.

• Remove the vent plug to allow old grease to be expelled.

• Always follow re-greasing guidelines regarding the type, application interval, and amount of grease to apply during each application. Don't over grease!

Oil

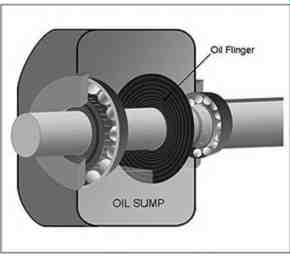

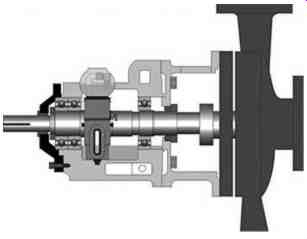

Oil is a liquid lubricant frequently used in critical process machinery operating at speeds greater than 1500 rpm. Oil can be splashed onto rolling element bearings by either slingers/flinger rings (see FIG. 4a) or oil rings. For splash lubrication to work properly, the correct oil level must be maintained in the bearing housing. The most common means of maintaining this level is through the use of a constant level oiler (see Figure below). Oil can also be used to lubricate journal bearings by means of slinger rings or pressure feed lubrication.

FIG. 4a-Oil Flinger Ring

FIG. 4b Centrifugal Pump with a Constant Level oiler

Oils fall into three main categories:

1. Animal/vegetable oils which are not commonly used in industrial machines. Many of these are food grade and used in food applications.

2. Mineral oils are the most commonly used industrial lubricants due to their relatively low cost.

They have moderate oxidation and viscosity stability, and cost $12 per gallon or more.

3. Synthetic (man-made) oils are used in the more demanding machine applications, cost $32 per gallon or more, and have very good oxidation and viscosity stability.

Types of lubrication systems

Machinery lubrication can be applied in a variety of ways depending on the equipment design, speed, and operating conditions. The machine's manufacturer normally determines the type and quantity of lubrication required. As stewards of equipment, it is your job to follow the manufacturer's lubrication recommendations closely to ensure reliable operation.

The most common ways lubrication is supplied to process machinery are:

Splash Lubrication--This type of lubrication system usually consists of a reservoir of oil and some part of the spinning shaft and attachment or the rolling elements of the bearing that touches the oil causing it to splash, allowing lubrication to take place. There is normally a place on the machine to check the oil level while it is in operation. Ensuring oil is always at the correct level is critical.

Ring Lubrication--This is a form of splash lubrication, accomplished by use of a large ring, usually brass, that rides on a turning shaft. The ring dips down into the oil reservoir and, by viscous drag, brings oil up onto the shaft where it is distributed along the shaft to the bearing. As stated above, there should be a place on the machine to check the oil level. During inspections, it is critical for operators to verify that bearing housing oil levels are at the correct level. There is also usually an inspection port (see FIG. 5) that can be opened or a plug that can be removed in order to look at the oil ring while the piece of equipment is running. Inspection of the oil ring in service should be viewed often to ensure the ring is turning; if the ring is not turning, lubrication has ceased.

FIG. 5-An Opened Ring oil Inspection Port

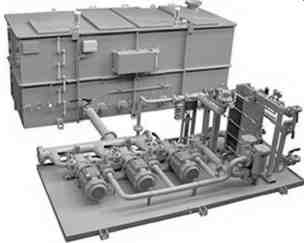

Circulating oil Systems--This type of lubricating system usually contains a reservoir, a pump, a filter, and may or may not have a heat exchanger (see FIG. 6). This type of system supplies oil to the lubricated item at very low (essentially zero) pressure. It is used when a controlled flow of clean lubricant is necessary in one or more places which may or may not be at the same level as the reservoir. This is very similar to a forced-feed lubrication system, but uses its pump to simply circulate oil. Frequently check the level in the reservoir and the color of the lubricant. If there are changes, the question "Why?" should always be asked.

FIG. 6-Circulating oil System

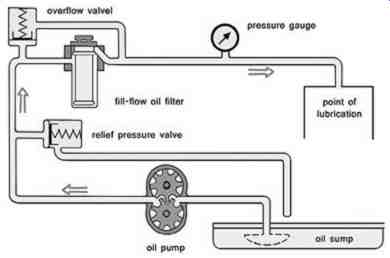

Forced oil Lubrication-This system is similar to a circulating system, but operates at an elevated lubrication supply pressure. It usually has a regulating valve to maintain pressure on the system, and utilizes coolers, multiple pumps, a pressure regulator, auto-start of the stand by pump, filters, and a reservoir (see FIG. 7 below).

FIG. 7-Basic Forced Lubrication System

This type of system is designed to remain at or above the design pressure continuously or the equipment it is lubricating will fail prematurely. There are usually safety switches that will cause the lubricated equipment to shut down if the level in the tank falls below a set amount, or if the pressure in the system becomes too low. In addition to checks of the circulating system, additional checks should be made, such as "Are both the main and auxiliary oil pumps running?" If they are both running, ask yourself some additional questions: "Why? What is the system pressure? Is it normal?" Touch the discharge side of the relief valve on the discharge of the pump. Is it relieving? It should not be.

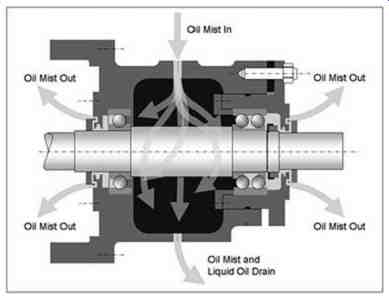

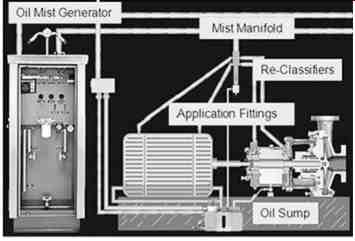

Oil Mist Lubrication--A type of lubrication that is formed of oil particles 1.0 to 3.0 microns in diameter suspended in a current of air, consisting of 1 part oil to 200,000 parts air. This mixture is not a volatile organic compound (VOC); therefore, there is no risk of explosion or combustion. When the oil mist arrives at the bearing housing, it must pass through a reclassifier which, producing turbulence, causes the mist to coalesce into larger oil particles that are capable of "wetting" and lubricating the bearings.

Typical oil mist lubrication systems consist of a tank, tubing to each item being lubricated, an atomizer, and various safety devices relating to flow and the level in the reservoir. There are two general types of systems: One is pure mist, where there is no lubricant in a reservoir in each piece of equipment. The other type is a purge mist system, where there is a level in the lubricated piece of equipment and oil mist fills the space above the reservoir. Bearings lubricated with pure mist tend to run cooler and have longer service lives.

FIG. 8 shows a bearing housing with pure mist lubrication and FIG. 9 shows a complete oil mist system.

FIG. 9- Oil Mist Lubrication System

Automatic grease lubricators-These are often used to grease inaccessible machine locations. They have a built-in timing mechanism that can be electronic, chemical, or mechanical (see FIG. 10).

They may or may not put out much pressure, so in some instances they can be prevented from delivering lubricant. It is important for these lubricators to be marked on their reservoirs with a permanent marker line showing the lubricant level and the date that the lubricant was at that level. It is one of the few ways to know that lubricant is being supplied to the intended locations. This technique provides the operator with a visual indication if lubricant is being provided. If the lubricant is being delivered slowly, it should be remarked every few months with a new line and dated to ensure lubricant is being delivered continuously.

FIG. 10-Auto Grease Lubricator

Lubrication inspections:

Have the following recommendations regarding lubricant properties and oil levels in mind when inspecting lubrication systems:

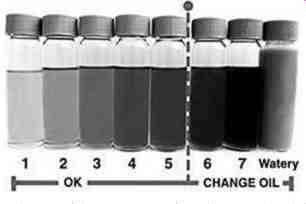

• Pay close attention to any changes in the lubricant's smell, color, and level. A dramatic change in color may indicate contamination with water (see FIG. 11). ("The Nose Knows-Using Odor as a Test for Your oils" in SECTION 6 describes how to use your sense of smell to spot lubrication problems.)

• If the reservoir is small and an oil leak is detected, check the level immediately since not much leakage can be tolerated before the level is dangerously low.

• If the color has changed significantly from your last inspection or from what you know to be normal, find out why.

• Ensure lubricant levels are maintained as recommended. Inadequate oil levels can cause equipment to fail catastrophically in a relatively short period of time.

• If the level is found to be increasing, water may be entering the system in some way. Tip: A simple test for water contamination is to drain some of the lubricant out onto a napkin or paper towel. The oil will be absorbed into the towel but the water beads will stand on the oil-soaked towel.

FIG. 11-How oil appearance can change as i t become contaminated. Remember

look for changes from newly installed oil.

1. Sample #1 shows ideal oil that is golden and fully transparent.

2. Sample #5 shows a sample that is discolored.

3. Sample #6 shows oil that is no longer transparent and has darkened.

4. Sample #7 is now completely dark due to oxidation.

5. The "Watery" sample (on the far right) is seriously contaminated with water.

QUIZ:

1. List at least 3 critical functions that lubrication provides.

2. is a mixture of a semi-fluid thickening agent and liquid lubrication.

3. List 3 elements of circulating oil systems.

4. List at least 3 ways that lubrication is applied to bearings.

5. List at least 3 things to be looked for during oil inspections.

6. lubrication, also called hydrodynamic lubrication, is where two surfaces are completely separated by a fluid film.

Answers:

1. List at least 3 critical functions that lubrication provides.

• Reduce friction between the rotating and stationary components

• Reduce wear

• Absorb shock

• Dampen noise

• Carry heat generated by friction within the bearing

• Remove heat transmitted down the shaft from the process end of the machine

• Minimize corrosion

• Keep contaminates away from the bearing components

2. Grease is a mixture of a semi-fluid thickening agent and liquid lubrication.

3. List 3 elements of circulating oil systems.

• Reservoir

• Pump or pumps

• Filter or filters

• Heat exchanger

4. List at least 3 ways that lubrication is applied to bearings.

• Splash

• Ring

• Circulating

• Forced

• Oil mist

• Automatic grease lubrication

5. List at least 3 things to be looked for during oil inspections.

• Oil level

• Unusual smells

• Oil appearance

• Oil color

6. Full fluid lubrication, also called hydrodynamic lubrication, is where two surfaces are completely separated by a fluid film.