AMAZON multi-meters discounts AMAZON oscilloscope discounts

Goals:

- Understand a brief history of the engine

- List job opportunities in the power equipment engine industry

INTRODUCTION

Engines have a long history that dates back hundreds of years, and the power equipment engine is a major factor in that history. But first try to imagine a world without lawn mowers, snow blowers, tractors, cars, cell phones, iPods, electricity, or computers. That is the way it was 200 years ago. All work was done by hand and with the help of animals and water or wind power.

Over the years, engines were developed to help us with various types of work, and over time, constant breakthroughs in engine and electronics technology have greatly changed how engines are developed and marketed to today's consumer.

With millions of power equipment engines being sold every year, trained engine technicians will remain in high demand throughout the country. This guide has been designed to discuss the various types of engines and engine components that a power equipment technician is likely to work with. This Guide was written for the high school, community college, or trade school level. It can be a valuable addition to the library of the seasoned technician as well as the casual consumer wanting to know more about how an engine operates. The content of this guide is the result of input from technicians, instructors, and owners of power equipment shops.

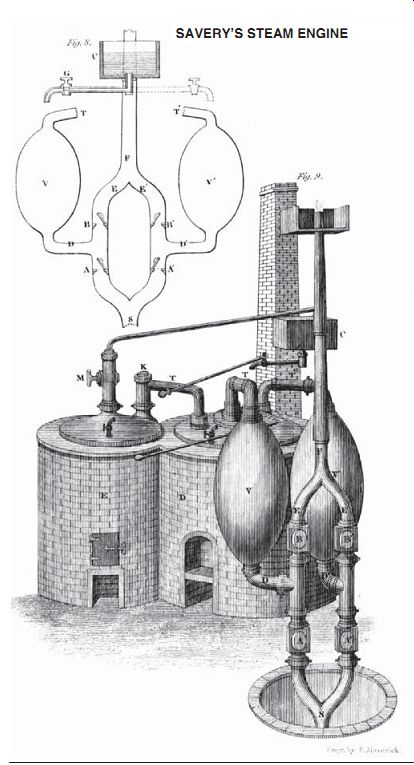

FIG. 1 Thomas Savery's steam engine (circa 1698) that was used to pump

water out of coal mines.

A BRIEF HISTORY OF THE INTERNAL COMBUSTION ENGINE

According to Merriam Webster's dictionary, the term "internal combustion engine" is defined as "a heat engine in which the combustion that generates the heat takes place inside the engine proper instead of in a furnace." Of course, engines are a bit more complex than this simple explanation suggests.

Internal combustion engines have been in existence for over 200 years and are a direct descendent of the external combustion, steam powered engine. Steam engines convert potential energy that exists as pressure into mechanical force. An example of a steam engine would be the steam-powered locomotive. Steam engines were designed in many different types but most utilized a reciprocal piston or a turbine device to convert the raw heat built up by the steam into mechanical work. It's argued that the Industrial Revolution came about primarily because of the steam engine. In 1698, Thomas Savery, an English military engineer and inventor, patented the first crude steam engine (FIG. 1), based on a pressure cooker.

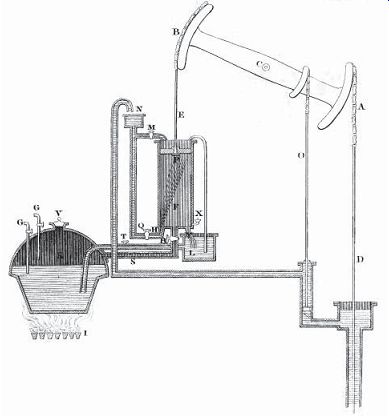

Savery worked on this design as a means to solving the problem of pumping water out of coal mines. Thomas Newcomen, an English blacksmith, improved upon Savery's design and, in 1712, built an engine (FIG. 2) on top of a water-filled mine to pump water out more

efficiently. Newcomen's engine used the force of atmospheric pressure to pump steam into a cylinder that was condensed by cold water, which in turn created a vacuum inside the cylinder.

This resulted in the operation of a piston that created strokes up and down that would allow the pumping of water.

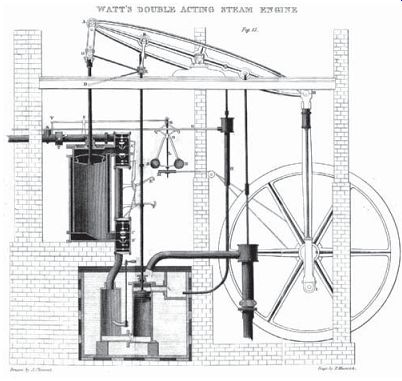

The first truly practical steam engine was patented by inventor James Watt in 1769 (FIG. 3). Watt's design was able to save a lot of physical work, like pumping water from mines, and led the way to power steamboats and locomotives.

A unit of electrical power, the watt (W), named after James Watt, is equal to 1/746 of a horse power, expressed as follows:

One volt times (×) one amp equals (=) one watt

The steam engine, however, had its draw backs. It was a large machine requiring constant monitoring by men who became known as engineers. A fire had to be built and maintained in a boiler, and there was always the chance of a boiler explosion.

FIG. 3 James Watt patented the first practical steam engine in 1769 and

his design led the way to engines that were used to power boats and locomotives.

FIG. 2 The steam engine designed by Thomas Newcomen in 1712 used a piston

and was a more efficient design as compared with Savery's steam engine.

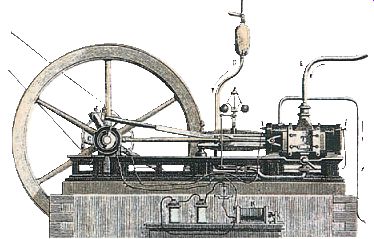

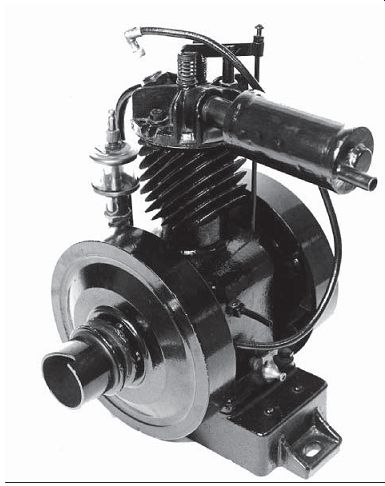

FIG. 4 The first successful gas-powered engine was built by Etienne Lenoir

in France.

This design was used as stationary power plants in engineering setups such as printing presses, water pumps, and machine tools.

The Birth of the Internal Combustion Engine

The internal combustion engine emerged in the 19th century as a result of a search for a substitute for steam power. In an internal combustion engine, the fuel is burned inside the engine. A cannon, for example, can provide us with an image of a primitive, single-stroke engine. In fact, people had experimented with gunpowder as a means of driving a piston in a cylinder. Their efforts failed mainly because of their inability to find a suitable fuel and then ignite that fuel in an enclosed space to produce an action that could be easily and quickly repeated.

The first problem was solved in the mid-19th century by the introduction of gasoline, which was a by-product of oil wasted during the manufacture of kerosene. The second problem proved to be more difficult to solve because ignition could not be maintained evenly.

FIG. 5 German inventor Nikolas Otto designed this engine that allowed

gas-powered engines to be a commercial success in 1878. Owls Head Transportation

Museum.

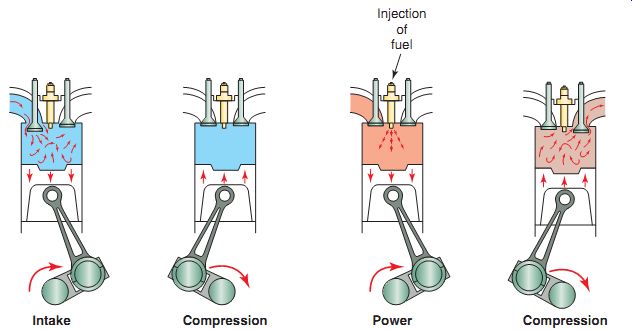

FIG. 6 The "Otto cycle" was the introduction of the four-stroke

engine design of intake compression-power-exhaust.

The first successful gas engine was invented by Etienne Lenoir in Paris, France, in 1859 (FIG. 4). It was a two-stroke design resembling a horizontal steam engine, with its mixture of gas and air ignited by an electric spark on al ternate sides of the piston when it was in the mid stroke position. Most applications of the Lenoir engine were as a stationary power plant, powering printing presses, water pumps, or machine tools. They, however, proved to be rough and noisy after prolonged use. Although technically satisfactory, the engine was expensive to operate.

It was not until a major refinement was introduced by the German inventor Nikolas Otto in 1878 that the gas engine became a commercial success (FIG. 5). Otto adopted a four-stroke cycle of intake-compression-power-exhaust that has been known as the Otto cycle ever since (FIG. 6). Gas engines came to be used extensively for small industrial factories, which could thus dispense with the upkeep of a boiler necessary in any steam plant, however small. These engines were also of great benefit to farmers.

With the purchase of just one small engine, a farmer could run his cream separator, wood saw, butter churn, feed grinder, and gristmill, and pump water too. Everything from small shops to factories could be run on engines now. These engines could usually be started in just a few minutes, without waiting for a head of steam to build up before operating machinery.

So, why is this important? As time passed, companies in the United States, such as Briggs & Stratton, Tecumseh, and Kohler began producing small, lightweight, high-speed, air-cooled engines (Figures 7 through 8) for portable machinery. Today's power equipment engines use the same basic principles established by these pioneers of the internal combustion engine.

CAREER OPPORTUNITIES IN THE POWER EQUIPMENT ENGINE INDUSTRY

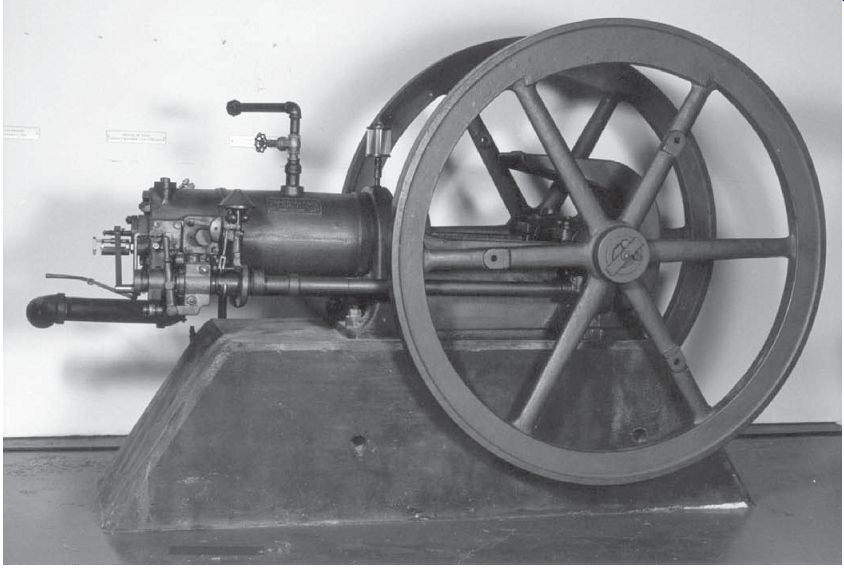

FIG. 7 An early model of a Briggs & Stratton engine.

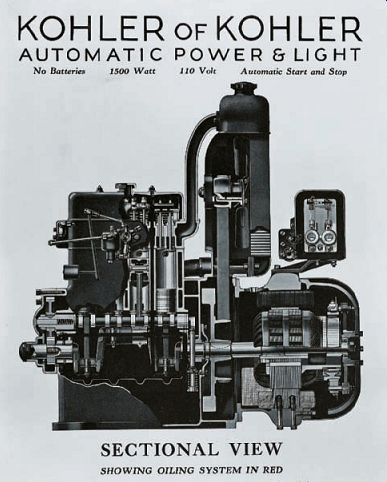

FIG. 8 The engine manufacturer Kohler was first known for a 1500-W generator

powered by a four-cylinder, water-cooled engine built in 1920. Kohler Co.

This section outlines career opportunities available in the power equipment industry.

Millions of power equipment engines are sold every year, which ensures the need for qualified technicians to keep these machines maintained and repaired. Upon completion of their training, many students obtain their first job as entry level engine technicians at franchised dealerships.

An entry-level technician has very little hands on experience with engines. A franchised dealership is authorized to sell a particular engine or component company's products and services in a particular area. Many positions are available at power equipment dealerships for individuals with engine repair backgrounds.

Even if you're not interested in a career in the power equipment industry now, this section will give you an idea of what the industry is all about.

There are many career opportunities in the field of power equipment engine repair such as working in rental yards, city park departments, school districts, landscape companies, and golf courses. To obtain a better understanding of the positions available at a power equipment dealership, let's take a look at the various positions at the dealership.

Opportunities in Dealerships

A power equipment dealership is an excellent place to begin a career in power equipment engine repair. Often, prospective employees must be willing to start at an entry-level position and work their way up the ladder to higher positions.

Most franchised and independent dealer ships have three main departments:

- Sales

- Parts

- Service

Before we discuss the service department, let's take a look at the other two departments. It's possible that your entry-level job may be in the sales or parts department. You can gain valuable experience in these departments as well. The ability to get along with people is a key requirement for working in any area of a power equipment engine dealership. This is particularly true in the sales department, where products are displayed and sold. As a skilled salesperson, you must also be able to discuss the technical features of different engines and component attachments with customers. An education in engine repair pro vides you with a definite advantage as a member of the sales staff. If you possess the ability to deal directly with people, the sales department is an excellent place to learn how a power equipment dealership operates. The sales area provides valuable exposure to business-related activities.

The experience can be especially beneficial if you plan to run your own business someday.

The parts department is also a great place to use your people skills. Parts departments sell re pair parts and accessories. As a member of the parts department, you'll have constant contact with retail customers, the sales department, and the service department. You'll be dealing directly with customers, both in person and on the telephone. The parts department is more closely related to the service department than to the sales department, especially if you work as a parts technician. A parts technician is responsible for supplying the service department technicians with the parts they need to complete their service and repair work.

The third department within a power equipment dealership is the service department, where power equipment engines are brought in for maintenance and repairs. A small shop may have a service department that employs only one or two technicians. A medium-sized shop might employ three or four technicians plus a service manager. It's not unusual to find a significant number of employees in the service department of a large dealership.

Larger power equipment dealerships typically employ the following personnel in the ser vice department:

- Technicians

- Service writers

- Service managers

The technician is frequently considered the backbone of the service department. As a power equipment engine technician, you'll need a technical background, factory training (which the dealership can arrange for you), tools, and usually some prior mechanical experience. Some dealerships require tests of knowledge to be completed by their technicians to become certified. Some job assignments and responsibilities of a technician include:

- Warranty service

- Dealing with customer questions

- Preventive and scheduled maintenance

- General repair activities

- Staying current with new products, accessories, and service procedures

- Maintaining accurate repair records

- Alerting the service manager to actual or potential problems

Another key employee in the service department is the service writer. The service writer is responsible for writing the repair orders for service work. He or she should be technically trained and have a complete understanding of the service process. When writing a repair order, the service writer must obtain detailed information from the customer, verify the customer's concern, and then provide the customer with an estimate of the services that might be required to correct the problem. In most dealer ships, the service writer creates the repair orders, which are then distributed to the technicians.

The service writer also has a hand in job scheduling, ensuring that the repair process flows smoothly.

The service manager holds the highest position in the service department. Most service managers are responsible for the following:

- Customer transactions

- Warranty claims

- Product update and information publications

- Technician training

- Employee hiring and dismissal

- Equipment needs

- Building/service area maintenance

- Service policy changes

- Servicing files and records

Service managers usually have an extensive service background and prior management experience, including:

- Technical training

- Factory service school training

- Setup/assembly experience

- Engine repair experience

- Customer relations skills

- Management experience

The service manager has the overall responsibility for the service department. He or she must see that everything in the service department is well organized, that all necessary parts are in stock, and that the service work is performed correctly and completed on time. The service manager must handle all customer complaints and any technical questions from both customers and technicians. The service manager needs an extensive amount of engine repair experience and excellent management skills.

Finally, the top position in many power equipment dealerships is the general manager. The general manager has the overall responsibility for the sales, parts, and service departments. He or she oversees the day-to-day operations of the entire business. A general manager is likely to have had experience in all the other departments.

POWER EQUIPMENT INDUSTRY EDUCATION AND CERTIFICATION

Once you decide that you would like to become a power equipment engine technician, you'll need to get the necessary training and experience to do the job. Although it's possible to start out as an on-the-job apprentice, getting for mal education in this subject is preferred by many power equipment dealers. Many dealers will start you as an apprentice or an entry-level technician once you graduate, but your abilities will tend to be more advanced if you have the training that formal education provides. There are training programs in high schools, community colleges, and trade schools. Some manufacturers such as Briggs & Stratton offer Master Tech Certification training. One important advantage that the power equipment industry has over many other service industries is the Equipment & Engine Training Council (EETC) (FIG. 9).

FIG. 9 With a goal of raising the competency level of technicians in the

power equipment industry, the Equipment & Engine Training Council (EETC)

developed and maintains the Outdoor Power Equipment Technician Certification

Program. Equipment & Engine Training Council.

FIG. 10 EETC technician certification is recognized as the standard for

power equipment servicing. Equipment & Engine Training Council.

Equipment & Engine Training Council

With a goal of raising the competency level of technicians in the power equipment industry, the EETC developed and maintains the EETC technician certification program (FIG. 10). EETC technician certification is recognized as the standard for power equipment servicing.

Certified technicians demonstrate a higher level of technical proficiency in their work and this, in turn, increases the level of professionalism at dealerships throughout North America. It's a known fact that consumers seek out dealers employing trained technicians. The technician certification program was initiated in 1995 at the Texas Servicing Dealer Association. The Equipment & Engine Training Council was formed in 1997, and was handed the responsibility of the certification program. The EETC updates certification tests on an annual basis to ensure that the latest technologies are covered.

There are seven tests offered for certification purposes by the EETC. They cover the following subject areas: two-stroke engines, four-stroke engines, electrical, drivelines/hydraulics, compact diesel, generators, and reel technology.

If you desire to document your professional abilities and skills, advance your career, or have a passion for excellence you should consider taking the relevant tests. Certification lasts for 3 years, at which time you must be recertified to maintain your status. The EETC maintains the records and will notify you when you need to be recertified.

The EETC works closely with the Outdoor Power Equipment and Engine Service Association (OPEESA). OPEESA membership includes more than 140 distributors and manufacturers of outdoor power equipment and air-cooled gas and diesel engines. The mission of the OPEESA is to "assist distributors in achieving outstanding channel performance." To fulfill this mission, the OPEESA offers a wide range of services and programs as well as opportunities to share ideas with fellow distributors. In addition, they foster cooperation and proven leadership among manufacturers, distributors, and dealers in the out door power equipment industry.

The most current information on both of these organizations can be found on their Web sites: opeesa.com.

Summary

Engines have a long history that dates back hundreds of years. The power equipment engine is a major factor in that history.

With millions of power equipment engines being sold every year, trained engine technicians will remain in high demand throughout the country.

There are numerous career opportunities within the power equipment engine industry.

The industry-recognized standard of power equipment engine certification is obtained through the Equipment & Engine Training Council.

QUIZ

1. Name the positions mentioned in this section that are available in a power equipment service department: __.

2. Name the three main departments in a power equipment dealership:__ , __, and __.

3. Three things that a service writer must do when working with customers are: __, __, and__ .

4. The four-stroke cycle of intake-compression power-exhaust was developed by: .

5. What are the seven test subject areas offered for certification purposes by the EETC? __ and __.