| PREV.: Terms | NEXT: Direct-Acting Reliefs | Article Index | Home |

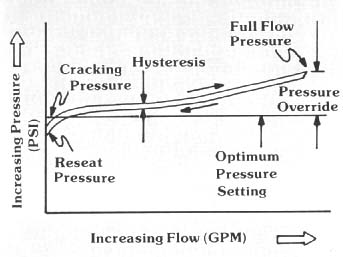

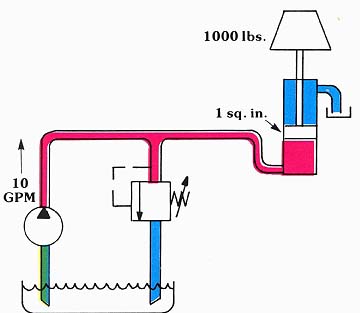

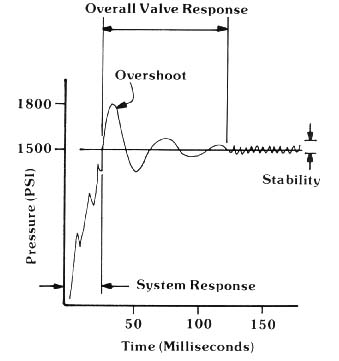

AMAZON multi-meters discounts AMAZON oscilloscope discounts In general, hysteresis, reseat pressure, and overshoot are values which are not detectable on a pressure gauge. Minor instability also has little influence on the satisfactory operation of the system. Therefore, unless you are looking for very precise control, you need not be too concerned with those items which need electronic equipment to detect. But, how does pressure override affect the operation of a system? Let us now consider a 10 GPM pump operating with a relief valve which displays a 500 PSI override between cracking and full flow pressure. Although override characteristics are not perfectly linear, our example is intended only to show the effect of pressure override on the system. For convenience sake, we will eliminate all circuitry except for the pump, relief valve, cylinder and load. |

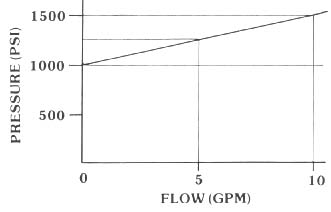

Above: Graph: TYPICAL PRESSURE VS. FLOW CHARACTERISTICS

(See Color code legend for above image)

Above: TYPICAL PRESSURE VS. TIME GRAPH

First, if we are looking for maximum efficiency, we would want to set the relief valve at 1000 PSI since this is all the pressure that is needed to obtain the required force. We find, however, that when the cylinder bottoms out, our pump flow is relieved to tank at 1500 PSI rather than at the initial setting of 1000 PSI. Although all flow across a relief turns energy into heat, a 500 PSI override increases our energy loss by 33%, or a net increase of 3 1/2 hp for this particular example.

Above:

Graph: Pressure (PSI) vs. Flow GPM

Second, if the cylinder encounters a slight increase in load, say 250 pounds, ideally, we would want our system to stall since it was our original intent to limit the output force to 1000 lbs. In actual practice, however, we find that the system will do the work at approximately half speed, while wasting the other 50% of our power input in the form of heat, as oil flows across the relief. When the load is mechanically stalled, our pressure again rises to 1500 PSI creating 500 lbs. more thrust than originally intended.

| Top of Page | PREV.: Terms | NEXT: Direct-Acting Reliefs | Article Index | Home |