| PREV.: Pressure Relief Valves | NEXT: Importance of Valve’s Pressure Override Characteristics | Article Index | Home |

AMAZON multi-meters discounts AMAZON oscilloscope discounts In discussions involving relief valves, the following terms are used to describe their operating characteristics. A basic understanding of these terms is essential in understanding the features of various relief valve designs. Cracking Pressure is the pressure at which the valve just begins to let oil escape from the system. Full Flow Pressure is the pressure needed to pass all of the output flow of the pump through the relief. |

Pressure Override is the difference between full flow pressure and cracking pressure for any particular valve. Pressure override is higher than cracking pressure for several reasons. First, the valve itself is a restriction (orifice), and the higher the flow across an orifice, the higher the pressure drop. Since the outlet of the relief is exposed to atmospheric pressure, the increase in pressure drop, with increased flow, is solely an increase in pressure at the valve’s inlet.

Second, in any pressure control the ball, poppet, or spool is directly supported by a spring. If the spring tension is adjusted so that the valve just “cracks” at, say 3000 PSI, then the poppet moves just far enough from the seat to let the first drops of oil out of the system at this pressure.

When a bigger opening is required to pass more of the output of the pump, the poppet must be moved further from its seat. In moving the poppet, the spring must be compressed more, which in turn increases spring force and hydraulic system pressure.

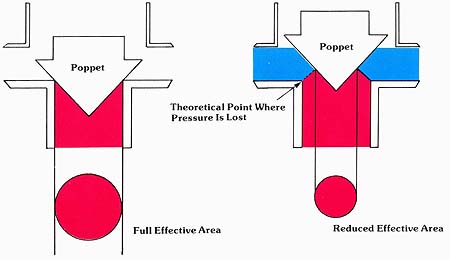

A less obvious reason for pressure override is that a loss of effective area occurs as the poppet moves away from the seat. When the relief is closed, the effective area can be calculated by using the full inside diameter of the seat. However, when the poppet moves away from the seat, the theoretical point of pressure loss occurs along the perpendicular line between the poppet and the seat. As shown in the diagram, this can cause a substantial reduction in the effective area.

(See Color code legend for above image)

Hysteresis is pressure variation between pressure increase and pressure decrease as related to flow.

Reseat Pressure is the pressure at which the valve closes again.

Stability is the fluctuation in pressure at any given setting.

Overshoot is the pressure rise above set pressure during the short time period when the valve is responding.

| Top of Page | PREV.: Pressure Relief Valves | NEXT: Importance of Valve’s Pressure Override Characteristics | Article Index | Home |