.

...

New Faces for Old Cabinets

One economical alternative to installing new kitchen cabinets is to

reface the old ones. The job consists of replacing old doors and drawer

fronts with new ones and veneering the cabinet frames to match.

Acquiring Materials: Supplies for the job are available through millworks,

cabinetmakers, or firms that specialize in cabinet re-facing. After choosing

a style and finish for the new doors and drawer fronts, order veneer

in a matching finish to cover the ends and faces of the cabinets.

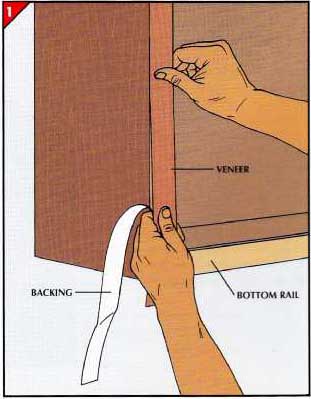

Two kinds of veneer are required. Thin peel-and-stick veneer for the

cabinet faces comes in sections that are 2 by 8 feet and are pre-coated

with a pressure-sensitive adhesive. Veneer for cabinet ends is mounted

on 1/8-inch plywood and is available only in 4- by 8-foot sheets. Ask

your supplier to cut the veneer for you slightly larger than the ends

of your cabinets.

Things Not to Overlook: Besides the veneer, you’ll want prefinished

molding to trim the tops of eye-level cabinets and the ends where they

meet the kitchen ceiling and walls. To fill joints and nail holes, ask

for a touch-up kit containing a wood crayon—a stick of filler that matches

the finish on the veneer.

The face of many a cabinet extends 0.25 inch beyond the ends, creating

a void that must be filled before the ends can be veneered. For this

purpose, purchase 0.25-inch luan plywood, which is named for the tree

whose wood gives the material a smooth surface ideally suited to adhering

veneer.

TOOLS

- Utility knife

- Hand roller

- Fine-toothed hand saw

- Combination square

- Nail set

- Level

- Circular saw with plywood blade

- Backsaw

- Miter box

- 0.25-inch drill

MATERIALS:

- Doors

- Plywood-backed veneer

- Peel-and-stick veneer

- Trim molding

- Hinges

- Door handles

- Drawer pulls

- Drawer fronts

- Contact cement

- 0.25-inch luan plywood

- Medium sandpaper

- Clear lacquer spray

- 1.25-inch finishing nails

- Wood filler

- Wood crayon

- Felt or plastic bumpers

- - - - - - -

VENEERING CABINET ENDS

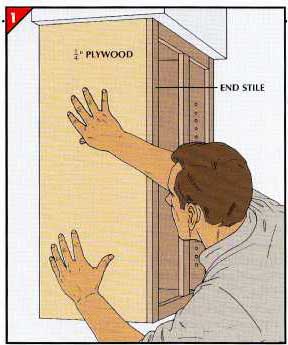

1. Preparing the cabinet frames.

• Remove drawers, doors, and hinges from the cabinet frames. Pry off

any trim and save the pieces as guides for cutting new molding.

• Strip painted surfaces and fill nail and screw holes with wood filler.

Sand the cabinets smooth, then wipe them clean with a damp cloth.

• If necessary, measure and cut pieces of 0.25-inch luan plywood to

fit between the stiles and the wall. With a small paint roller, coat

the plywood and cabinet ends with contact cement. Press the plywood to

the cabinet and secure it with 0.5-inch nails.

• Spray the cabinet exterior and plywood with three coats of clear lacquer.

2. Securing the veneer.

• Hold a piece of veneer against the end of the cabinet. Run a pencil

along front and bottom edges of the cabinet to mark guidelines on the

back of the veneer.

• With a circular saw, trim the piece about inch shorter and 1/16-inch

wider than marked.

• Coat the cabinet and the back of the veneer with contact cement. Press

the plywood in place, with one edge against the wall and another even

with the bottom of the cabinet.

• Sand the protruding edge of the veneer piece flush with the end stile,

then spray clear lacquer on the sanded edge. Recoat any sanded areas

of the stile.

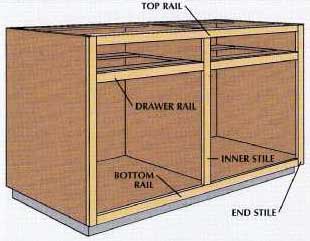

PEEL-AND-STICK VENEER AROUND OPENINGS

The best sequence.

The cabinet face is composed of vertical pieces, called stiles, and

horizontal ones, called rails. Using the technique shown below, veneer

each piece individually, beginning with the end stiles. Cover top and

bottom rails next, followed by inner stiles. Veneer drawer rails last.

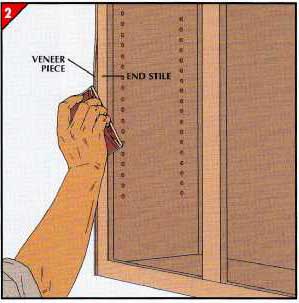

1. Veneering end stiles.

• With a straightedge and utility knife, cut two strips of veneer that

are 0.5 inch wider and 1 inch longer than the end stiles.

• Peel a few inches of backing from one strip and, with the grain running

vertically, lightly press it against the stile, flush with the top. Working

down the stile, continue peeling off the backing and pressing the veneer

against the cabinet. Cover the other end stile in the same way.

TOP RAIL

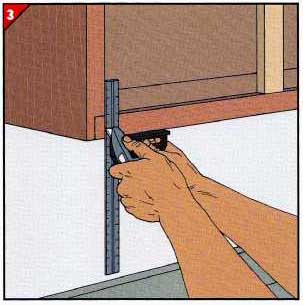

2. Trimming the veneer.

• Run a utility knife down the inner edge of each stile, then cut along

the top of the bottom rail, leaving a small tab of veneer on the bottom

rail.

• Next trim along the outer edge of the stile (above) and the bottom

edge of the rail.

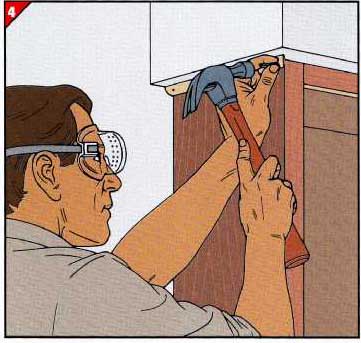

3. Covering the rails.

• Cut two strips of veneer 0.5 inch wider than the top and bottom rails

and long enough to overlap both end stiles.

• Press the veneer against the rails as described in Step 1, then trim

the veneer along the top and bottom edges of both rails.

• Using a combination square as shown above, cut through the rail veneer

and the tab of stile veneer at each end of the two rails. Remove the

scraps thus formed, and press the rail veneer into place.

• Follow the same procedure to veneer first the inner stiles and then

the drawer rails.

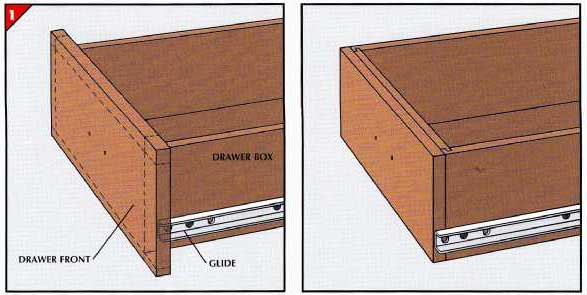

4. Finishing up.

• When all the peel-and-stick veneer is in place, run a hand roller

along the stiles and rails to permanently bond the veneer to the cabinet

face.

• Cut trim molding with a backsaw and a miter box to cover the joints

that the cabinets form with the walls and the ceiling. Nail the molding

to the cabinets with 1.25” finishing nails.

• Sink the nail heads into the trim molding with a nail set.

• Conceal the nail holes—as well as joints between pieces of molding

and veneer—with a wood crayon.

DRAWER FRONTS AND DOORS

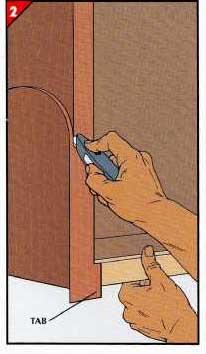

1. Putting on new drawer fronts.

• Remove the old drawer fronts if you can do so without damaging the

drawer box. Other wise, unscrew the drawer glides and trim each front

flush with the drawer box (dotted lines) using a fine-toothed saw. Reposition

the drawer glides so that they are flush with the drawer front as shown

above right, and drill two screw holes through the drawer front and the

drawer box.

• Lay a new drawer front on the floor with the finish side down, and

center the drawer box on it. Through the screw holes in the box, mark

the front for pilot holes and drill them as shown earlier. Then screw

on the new front from inside the drawer.

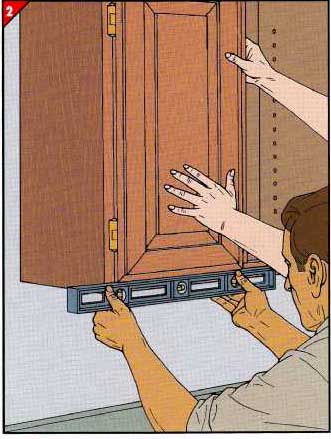

2. Hanging new doors.

• Attach hinges to each door 2 to 3 inches from the top and bottom edges.

• With a helper holding the door in place, center it on the door opening

and level it. Then reach inside the cabinet and mark the frame for pilot

holes where the hinges will attach to the cabinet frame. Drill pilot

holes, and mount the door.

• Install the adjacent door by aligning it with the level on the one

that is al ready in place.

• Mount the door and drawer handles and put felt or plastic bumpers

on the inside of the doors and the drawers to protect the veneer.

++++++++++++++++++++++++++++++++++++

Installing a Sheet-Vinyl Floor

If your kitchen floor is worn or damaged beyond repair, or if you just

want a new look, you may want to consider using vinyl. Available in square

tiles or in large sheets, vinyl flooring comes in a wide variety of colors

and patterns with a durable, no-wax finish. Vinyl is also easy to install;

doing the project yourself will result in a significant cost savings.

One of the biggest advantages of vinyl is that it can usually be laid

right over the existing floor. A variety of products are available to

smooth and level the old surface in preparation for installation of a

new floor. Talk to a salesperson when purchasing your new flooring, and

read the manufacturer’s instructions to determine what you need.

Measurements and Preparations: To calculate how much flooring you will

have to buy, measure the dimensions of your kitchen floor at the widest

and longest points in the room and add 6 inches at each wall for overlap.

If you find you will need more than one sheet, note the width of the

pattern repetition on the flooring you have chosen; it’s usually printed

on the back of the sheet. For ex ample, if your pattern repeats every

3 feet, allow 3 feet of extra width when you buy the material.

Before beginning the installation, remove the shoe molding or vinyl

wall base as shown earlier and move appliances out of the kitchen so

the new flooring can be laid underneath. Scoot these heavy items on a

piece of hardboard to protect the floor.

The Finishing Touch: When the floor is in place, attach metal edging

at the kitchen doorways to conceal the edge of the vinyl sheet.

TOOLS:

- Utility knife

- Notched spreader

- Rolling pin

- Metal yardstick

- MATERIALS:

- Vinyl-flooring adhesive

- Seam sealer

CUTTING THE MATERIAL TO FIT

1. Rolling out the material.

• Let the material adjust to room temperature for an hour or so; then,

if you are using more than one sheet, start in one corner and unroll

the larger sheet from the longest wall of the room. Leave 6 inches of

overlap at each wall.

• When you reach a large immovable object, such as a center island,

you will need to leave 6 inches of overlap as you cut around it. Reach

under the roll and unroll the sheet back toward the starting wall. Push

the unrolled section against the object and, about 6 inches above the

floor, cut from the outside edge toward the center with a utility knife.

When you are about 6 inches short of the vertical side of the object,

cut back toward the starting wall; make this cut at least 6 inches shorter

than the object’s depth.

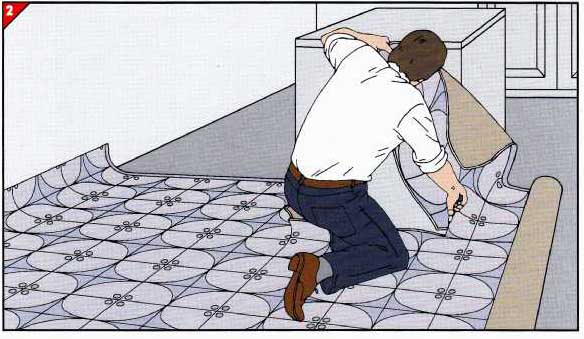

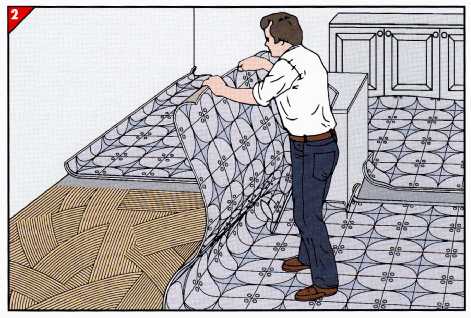

2. Fitting around a large object.

Lift the roll over the object and lower it to the floor on the other

side. Holding the corner of the flap you have made in the sheet, cut

at a right angle toward the outside edge of the sheet. This should give

you a 6-inch overlap along all three sides of the object.

3. Reversing the roll.

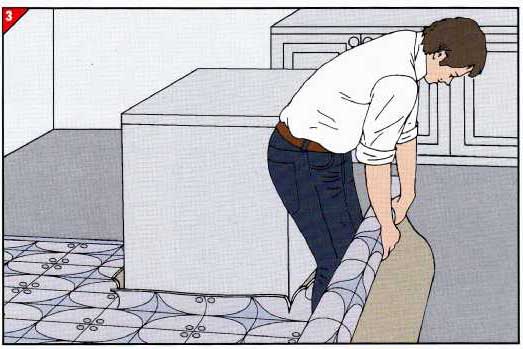

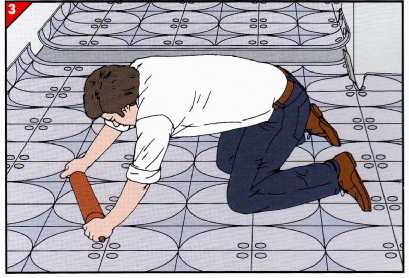

• Unroll the sheet completely, then pull it back and reroll the sheet

from the far edge as shown at left. The tightness of the inner part of

the original roll compresses the pattern; unless the roll is reversed

briefly, the pattern will be smaller in one part of the room than the

other.

• Unroll the sheet again and press it into all corners, to the extent

that its natural resiliency will allow.

4. Laying the second sheet.

• Before bringing the second sheet into the kitchen, measure the width

of uncovered floor from the first sheet’s edge to the opposite wall.

Add 6 inches, plus the amount of overlap required to match the pattern.

• Unroll the second sheet completely in an area free of obstructions.

Mark the above measurement on the sheet and cut. Reroll the sheet and

bring it into the kitchen.

• Starting again from the longest wall, roll the second sheet out as

far as the obstruction, then pull it over the first sheet until the patterns

match (above). Cut and fit the second sheet around objects as you did

the first, leaving 6-inch overlaps at the walls.

5. Trimming the edges.

Pull the second sheet off the first and out of the way. At each wall

and object, cut the first sheet back to about 3 inches above the floor.

Take care in making this cut— you are now close to the final trim.

BONDING THE VINYL TO THE FLOOR

1. Applying the adhesive.

Pull the first sheet halfway back upon itself. With a notched trowel,

spread adhesive over the exposed floor as closely as possible to the

walls and corners, but leaving bare a 6-inch strip along the line where

the first sheet will meet the second.

2. Affixing the first sheet.

Lift the edge of the sheet high above the floor and slowly walk it back

into place over the adhesive. Press it against the wall and into the

corners as closely as its resiliency will allow.

3. Rolling out the bumps.

With a rolling pin, start from the center and roll the material toward

each of its edges. Work slowly, and be sure to flatten any bulges or

air bubbles in the vinyl’s surface.

4. Making the final cuts.

• To crease the material, press a metal yardstick into the angle where

walls or objects meet the floor. Then slice along the edge of the yardstick

with a utility knife. Make the cuts as straight and accurate as possible;

shoe molding or wall base will cover errors up to about inch.

• Repeat Steps 1 through 4 for the other half of the sheet.

MATCHING THE PATTERN AT SEAMS

1. Cutting off the trim.

Place a metal yardstick along the over lap edge of the second vinyl

sheet. With a utility knife, cut off the - to 1-inch trim along this

edge. On inlaid vinyl this trim is likely to be an extra- wide grout

line; cut along the line so that its width matches the widths of the

other grout lines in the pattern.

2. Matching the pattern.

Pull the second sheet over the first until the patterns of the two sheets

match perfectly. Note the pattern care fully to be sure the overlap continues

the pattern in the same manner—a mismatched pattern will spoil the appearance

of the finished job.

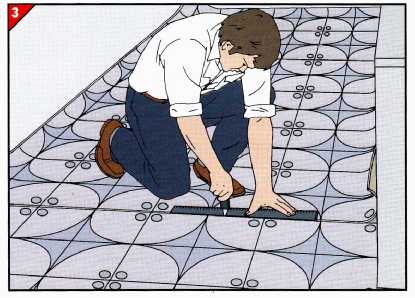

3. Cutting off the overlap.

• Place a metal yardstick along a grout line or other inconspicuous

part of the pattern where the seam is less likely to show. Then, cut

straight down through both sheets. Don’t worry if it takes more than

one pass with the knife to cut completely through the material; the important

thing is that the cut be straight and clean. Remove the strips you have

cut; the sheets should now abut tightly and have a perfect pattern match.

• Lay the second sheet as you did the first, trimming overlaps to 3

inches around objects and against walls.

• Spread adhesive to within 6 inches of the edge of the first sheet,

and make a final trim along each wall and object.

4. Applying adhesive under the seam.

Follow the manufacturer’s directions for sealing the seam between two

sheets. Some vinyl flooring requires a special sealing adhesive below

the sheets; with others you use regular adhesive underneath and seal

the seam from the top.

• Pull back the butted edges on both sheets and spread adhesive over

the bare floor along the en tire length of the seam. Then press the sheets

back in place, pushing the edges together until you get a tight fit.

• If seam sealer is called for by the manufacturer, proceed immediately

to Step 5.

5. Sealing the seam.

Press the seam together with the thumb and fingers of one hand while

applying seam sealer with the other. Wipe away any excess sealer immediately

and keep off the seam for at least 24 hours.

+++++++++++++++++++++++++++

The Versatility of Vinyl Tiles

Vinyl tiles offer virtually endless design possibilities for a kitchen

floor. More often than not, tiles are laid in rows parallel to the walls

of the room, but there are other options as well. You can, For example,

create a diagonal checkerboard of contrasting colors, a pattern that

can make a small kitchen look larger.

Learning from a Dry Run: Begin by snapping chalk lines to divide the

room into roughly equal quadrants, then lay tiles along the lines. For

a simple parallel layout, begin the dry run at the intersection, and

set tiles along each line to the walls. The dry run for a diagonal checkerboard,

explained on these pages, is somewhat more complex. In either case, if

the dry run would result in cutting very small pieces of tile in order

to fill in along walls and elsewhere, start over with chalk lines in

slightly different locations.

Laying the Tiles: When the dry run is satisfactory, prepare the old

surface as described, then begin laying the tiles. Fill in a parallel

pattern one quadrant at a time, working from the center to the walls.

A checkerboard pattern proceeds as shown beginning below. Cut tiles to

fit in spaces against walls and cabinets, taking care that the edges

you cut form the outer edge of the floor, where they can be covered by

baseboard.

When all the tiles are down, wipe up any excess adhesive, then press

the tiles against the floor with a rolling pin or with a tile roller,

which lets you do the work standing up. Keep traffic to a minimum for

48 hours to let the adhesive cure.

TOOLS

- Tape measure

- Contour gauge

- Framing square

- Scissors

- Masking tape

- Chalk line

- Rolling pin

MATERIALS

- Vinyl tiles

- Notched trowel

- Premixed adhesive

- Utility knife

- Paper

- - - - - - - -

ESTABLISHING THE LAYOUT

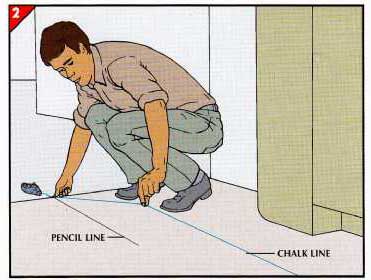

1. Determining the starting point.

• Mark the center of the main kitchen doorway on the threshold. If there

is no threshold to serve as a baseline, establish the center point on

a line drawn between the corners of the doorframe.

• Position a framing square at the midpoint of the doorway, and draw

a pencil line about 2 feet into the kitchen.

2. Marking the primary axis.

• With a helper, stretch a chalk line from the doorway to the opposite

wall. Hold your end on the center point of the doorway, and have your

helper move the other end to position the string directly over the pencil

line on the floor.

• Holding the chalk line taut, with both ends pressed against the floor,

lift the line directly up ward a few inches and let go. It will snap

to the floor, leaving a straight line of powdered chalk.

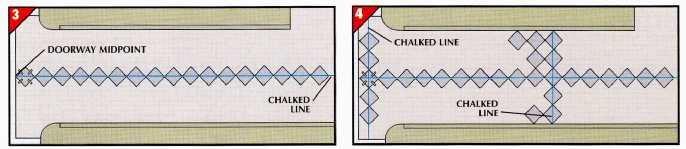

3. Starting the dry run.

• Place a tile diagonally along the chalked line with one corner at

the point marking the center of the doorway. Tape it to the floor with

masking tape.

• Set tiles of a single color along the chalked line until you come

within 1 tile width of the wall.

4. Establishing secondary axes.

• At about the midpoint of the dry run—and wherever the room widens

into an alcove or into a T or L shape— snap a chalk line the width of

the room and perpendicular to the primary axis.

• Lay tiles of a single color along each of these secondary axes.

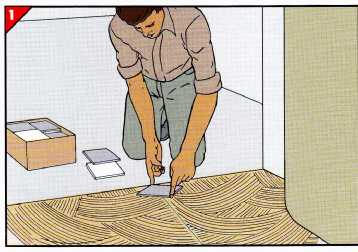

STICKING DOWN THE TILES

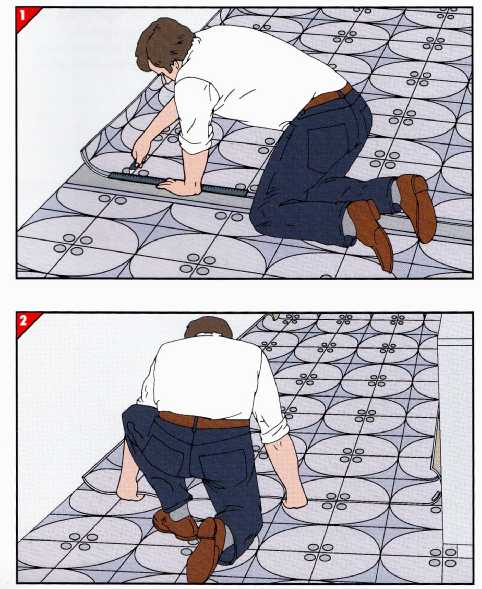

1. Laying the first tile.

• Note the working time of the adhesive, and make a conservative estimate

of the area you can cover with tile in that time. Pick up all the tiles

from the dry run, then pour equal amounts of adhesive on both sides of

the chalk line near the doorway. Spread the adhesive evenly with a notched

trowel to the chalk line but not across it.

• Holding a tile as shown at left, set one corner on the adhesive on

the baseline at the midpoint of the doorway. Align the other corner with

the chalk line and let it fall onto the adhesive. This tile must be absolutely

straight, since it will determine the alignment of all the rest. Adjust

the tile if necessary by nudging it gently.

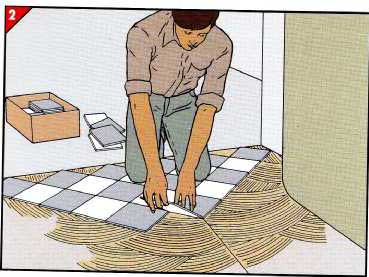

2. Working across the floor.

• Begin by laying tiles of one color, corner to corner, along the baseline.

Next lay a row of tiles of contrasting colors, creating the pointed array

at left. Fill in the half-tile spaces at the baseline.

• Continue laying rows of tiles along the sides of the point to extend

it to the far end of the room, alternating colors and aligning tile edges

carefully.

• Where the room widens, use the zigzag edge of the tiled area as a

baseline from which to extend the tiles to the left or right.

CUTTING TILES TO FILL GAPS

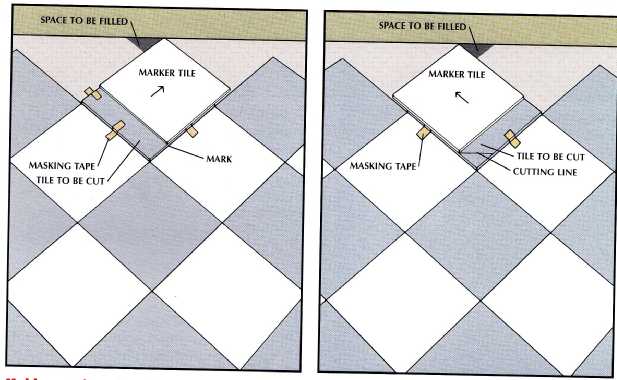

Making a triangular piece.

• Cut corners from tiles to fill small triangular spaces (shaded area)

along walls. To do so, tape the tile to be cut—here a dark one—on a tile

of the same color. Set a third tile on top to act as a marker.

• Slide the marker tile diagonally to the wall (left). At the corner

farthest from the wall, pencil a mark on the tile to be cut. Slide the

marker tile diagonally in the other direction, and make another mark

.

• With a utility knife, cut along a straight line joining the marks,

and set the triangular piece in place.

Filling a five-sided space.

• Tape the tile to be cut—in this case a light one—on top of a tile

of the same color, then set a marker tile alongside it.

• Slide the marker tile diagonally to the wall, and mark where the corner

farthest from the wall touches the tile to be cut. Set the marker tile

on the other side of the tile to be cut and repeat.

• Use a utility knife to cut the tile along a straight line drawn between

the two marks, and fit the five-sided piece in place.

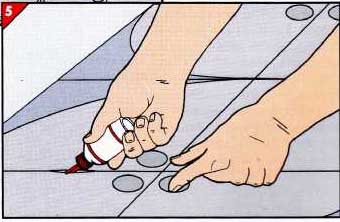

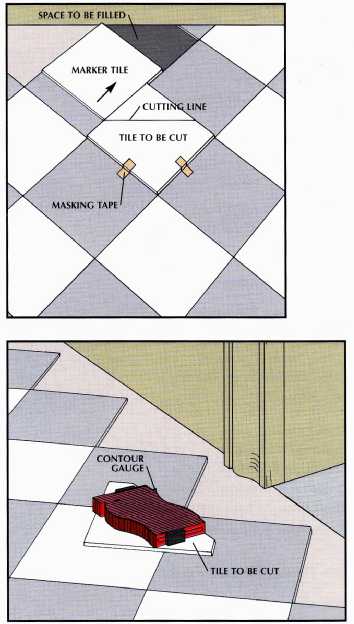

Cutting irregular shapes.

• To fit a tile against an irregularly shaped object, such as door molding,

first cut a tile to fit the space to be filled as if the obstacle were

not there.

• Then press a contour gauge against the irregular shape and part of

the adjoining wall on either side, of it and lock the sliding fingers.

Transfer the contour to the tile .

• Warm the tile in a 200° oven for a few minutes, then cut it to shape

with heavy-duty scissors.

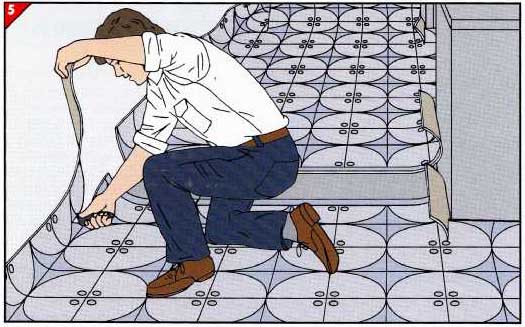

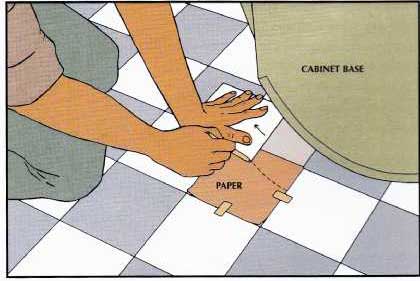

Fitting tiles under a low overhung.

• To fit a tile against the base of an overhanging cabinet or appliance,

tape a tile-size piece of paper to a nearby tile and place a marker tile

atop the paper.

• Slide a corner of the marker tile under the overhang and against the

base. Hold a pencil against the corner as shown at right, and slide the

marker tile along the base, keeping the edges parallel to the tile seams.

• Transfer the pencil line on the paper to a tile of the right color,

and cut the tile to shape. If there is not enough room below the overhang

to trowel the adhesive onto the floor, spread a thin coat on the underside

of the cut tile before fitting it in place.

|