Once you know what machines will be in your workshop, you need to determine their location. Allow for infeed and outfeed space and place them near machines they're used with most frequently.

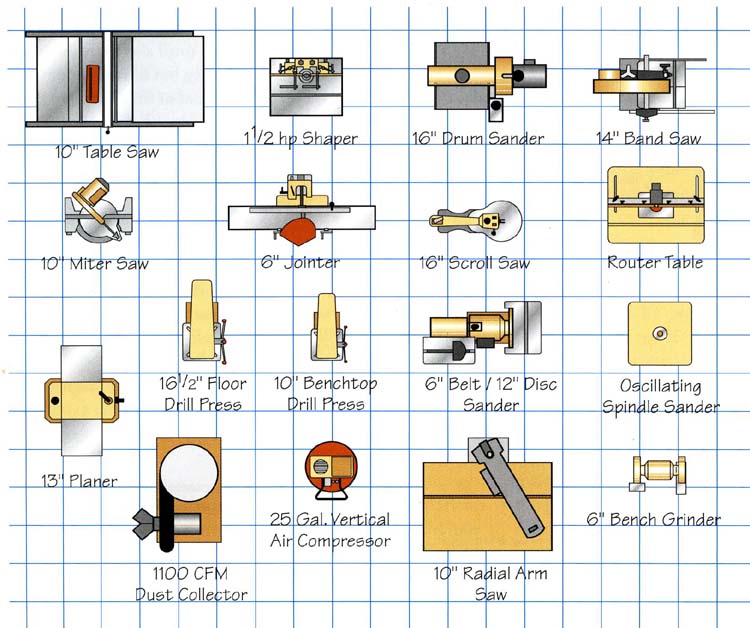

Each machine requires space for itself and space to use the tool. With a table saw, you need to be able to maneuver a 4' x 8' sheet of plywood to the back, front and left side of the saw. This means a pretty big footprint for the machine when in use (you can overlap the "in-use" footprints of multiple machines). We've added a diagram below that shows the necessary working footprint for each major machine. We suggest you draw your shop on graph paper, cut out the tools and try different arrangements to see what works.

The trick to positioning your machines in your shop is to create an orderly flow of work from raw lumber to the finished product. The work flow always starts where the wood is stored, or where it enters the workshop. Next, the lumber is prepared for use by jointing, planing and sawing to the proper dimensions. Conveniently, the machines required for these steps are also the ones that need the most power and create the most dust, allowing you to locate your power and dust collection in a "machining" area, with these machines close to one another.

From the machining phase, the next step is joinery and assembly, usually requiring hand tools, a band saw, drill press and handheld power tools, such as a router, biscuit joiner and brad nailer. A stable workbench or assembly table is ideal for this step.

The assembly area should be located out of the way of the machining area, but not so far away that you end up carrying lots of milled lumber across the shop. Your hand and small power tools should be easily accessible (stored in handy drawers or on the wall), and quick access to clamps will make things easier, as well.

Once assembly is complete, the third phase is finishing. No matter what finish you use, a clean, well-ventilated area is required.

When applying a varnish or shellac finish, the vapors given off as the finish dries are flammable and should be kept away from any ignition points, such as water heaters or space heaters. In concentrated exposure, the vapors can also be harmful to you, so ventilation is important. Also, when storing solvent-based finishes (such as varnishes) a fireproof storage cabinet is a must.

If you're going to use a spray-on finishing system, ventilation is even more critical to move the overspray away from your lungs.

From here, the rest of your shop will fall into place in the space left. Keep in mind that to save space, many tools can be stored under cabinets until needed.

Putting Things Away While we've talked about where your lumber storage should be in the work triangle, we haven't talked about how to store the lumber.

Three types of wood are stored in a workshop: sheet goods (such as plywood), rough or full-size lumber, and shorts and scraps. Shorts and scraps are the pieces you can't bring yourself to throw away. Not only are there usually more of these pieces, but they're harder to store than plywood or rough lumber because of their odd shapes and sizes. Let's start with the easy stuff first.

Above: We know that not everyone has the same size work space, so we thought we'd give you some templates to photocopy and cut out to plan your own shop. The grid is a 1/4" pattern in full size (one square equals 1'), which will work with most graph paper you buy in tablets at the store. (Trust us: paper tools are much lighter to move around.) Also, when organizing your tools, remember to include space for the wood on the infeed and outfeed sides.

Plywood takes up the least amount of space when stored standing on edge. Most of us don't store more than a few sheets of plywood, so this can often be stored in a 10"- to 12"deep rack that can slip behind other storage or machinery. This keeps it out of the way but accessible.

Rough lumber is best stored flat and well supported to keep the wood from warping. Keeping it up off the floor also keeps it away from any water that might get into your shop. A wall rack with a number of adjustable-height supports provides the easiest access while keeping the wood flat and dry.

Shorts are the hardest to store, but a rolling box with a number of smaller compartments holding the shorts upright allows easy access to the pieces, and it keeps them from falling against and on top of each other. For plans for a good bin (and 24 other shop projects), get a copy of the book 25 Essential Projects for Your Workshop published by Popular Woodworking Books.

Carrying on with the storage concept, one category that deserves special attention is finishing materials. While waterborne finishes are gaining in popularity, flammable finishes in cans, bottles and jars should be stored in a fireproof storage box and kept clean and organized at all times. A tall cabinet with lots of adjustable shelf space makes room for the many sizes of finishing supplies.

Other workshop storage needs fall into the cabinet and shelving category. Just because a tool sits on the floor against the wall doesn't mean you can't hang a cabinet or shelving above it. In fact, in many cases the tool's accessories and supplies belong on a shelf right above it. And don't hesitate to go all the way to the ceiling with storage. Even though the top shelves are harder to get to, we all have things in our shops that don't get used very often.

Many of us have purchased a tool that had a base tossed in to sweeten the deal. It seems like a good idea, but if you stop and think about it, it's truly wasted space. Throw away that stamped-steel base and build a storage cabinet to go underneath the tool.

When choosing base storage cabinets, you'll have to decide whether you need drawer cabinets, door cabinets or both. If you're storing large, odd-shaped items (belt sanders, arc welders), a drawer can be a real problem. They're designed to hold only so much. A door cabinet is a better place to store bulky items.

On the other hand, if you're storing smaller items (door hinges, glue, seldomly-used jigs), a door cabinet can be a great place to lose these items. Items seem to migrate to the back of the cabinet; and until you're down on your knees peering into the hole, you won't find them. While drawers can get pretty junky if you're not careful, you'll at least be able to stand up and stare down into the drawer to look for your lost metric tape measure.

Beyond doors or drawers, you have two general choices in cabinets: buy 'em or make 'em. If you make your own cabinetry, you will almost certainly get exactly what you need for the best space utilization. You'll also likely save some money, but it'll take a fair amount of time.

Buying shop-grade cabinets from a home center can work out well. Any number of utility cabinets are available in all shapes, sizes and finishes.

Another option is plastic or metal storage units, designed specifically for a workshop. These units offer features that are set up to maximize tool use and convenience.

Beyond cabinets, open shelves are good for storage, but they're a bit of a trade-off.

An example of workflow in a two-car garage. This is the same shop as shown in the other photos, so you know it works on more than paper. Just follow the red arrows to the easiest path for woodworking. The dotted lines show approximate infeed and outfeed room for lumber.

While you can easily see what you're looking for, so can everyone else -- whether it's attractive or not.

Wire-frame shelving is not a good choice for storing small pieces. And knowing the weight limit of the shelves will keep you from picking up all your wood screws from the shop floor when the shelf collapses. Also, while you may view deeper shelves as being capable of storing more (which they are), recognize that smaller items on the shelf can get pushed to the back and get lost.

Previous: Choosing

Your Tools

Next: Now Where did I put that

Saw?