Goals of the Care and Repair of Shop Machines guide:

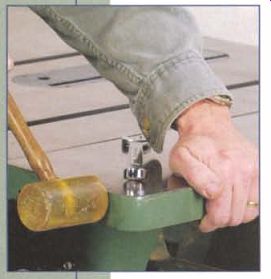

• Setting up a table saw for accuracy

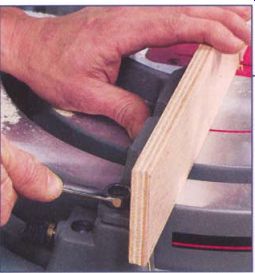

• Tuning a bandsaw for smooth cuts

• Building your own setup jigs

• Solving persistent tool problems

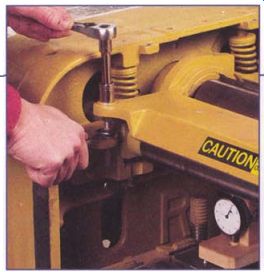

• Changing jointer and planer knives

• Creating maintenance schedules

• Choosing essential setup tools

• Troubleshooting shop machines

• Making a router table more accurate

Care and Repair of Shop Machines is a comprehensive guide to the setup, maintenance, and repair of all the major shop machines, including table saws, jointers, planers, bandsaws, drill presses, routers, and miter saws. Going beyond owner's manuals, this guide will show you how to get your machines in top condition so they'll perform accurately and consistently for better and safer woodworking.

CONTENTS

- Tune-Up and Maintenance Tools

- The Jointer

- The Table Saw

- The Thickness Planer

- The Drill Press

- The Bandsaw

- The Router Table

- The Miter Saw

ABOUT YOUR SAFETY

Working wood is inherently dangerous. Using hand or power tools improperly or ignoring safety practices can lead to permanent injury or even death. Don't try to perform operations you learn about here (or elsewhere) unless you're certain they are safe for you. If something about an operation doesn't feel right, don't do it. Look for another way. We want you to enjoy the craft, so please keep safety foremost in your mind whenever you're in the shop.

Introduction

There is great advantage in the consistent accuracy a woodworking machine can achieve. But this precision is not guaranteed, since no machine will cut square and straight forever. Even brand-new tools, straight out of the box, can't be assumed to be accurate. Some are not correctly tuned when they leave the factory. The parts are bolted together and brought approximately into line, but the final adjustments are always left up to the person using the machine. Some machines go out of alignment from having suffered bumps and shoves in their journey from the assembly line to your shop. In older machines, time and use take their toll. Parts wear, bolts may loosen, and even massive castings can warp.

The engineers and machinists who build power tools know that their machines will need adjusting, and all power tools are designed with this reality in mind. Some owner's manuals will supply the information you need to tune up a machine, but most manuals lack the detailed information you need to bring your tools into precise adjustment.

The purpose of this guide is to supply the information you need to make your tools perform at their best, to pick up where the manuals, if they haven't been lost, left off. Although there have been dozens if not hundreds of models of each power tool built over the past century, most tools are very similar in their basic elements. The tune-up techniques in each Section aren't specific to any one machine but will in most cases be adaptable to the power tools you own. Even if you don't see exactly your make and model machine in this guide, you will be able to apply the basic principle.

There is no one right way to set up machinery. In fact, I've tried to offer alternatives where I could, especially low-tech or shop-made solutions in place of expensive, dedicated tools. If you own a professional shop and need to keep your machines in top form every day, then dedicated measuring tools and jigs may be right for you. If you're a home-shop woodworker, low-tech solutions are often adequate for the occasions when you check and maintain your machines.

Most important is to take the time to set up your machinery correctly and to maintain the settings. The result will be more accurate cuts, square, flat stock, and better, safer woodworking.

Acknowledgments

I was never a good student, so I never had a master as a teacher, except for my father, who was a quiet master in many fields. Much of what I know, especially about machinery, came from the authors of Popular Science and Popular Mechanics who wrote in the 1940s and '50s.

Only now, as I try to become a writer myself, can I appreciate their abilities both as craftsmen and writers.

Closer to home, I want to thank the editors and authors of Fine Woodworking magazine and the editors at Taunton books for their patience, encouragement, and editorial guidance.

Next | Article Index | Home