Care and Repair of Shop Machines--A Complete Guide to Setup, Troubleshooting, and Maintenance

Wood-working tips:

Checking Diagonals during Assembly

Comparing the diagonals of a cabinet or a box is a good way to check for squareness.

But when you're working alone in the woodshop, accurately measuring long diagonals

can be difficult. To make the job easier, here is an easy project. Make a pair

of simple tape holders.

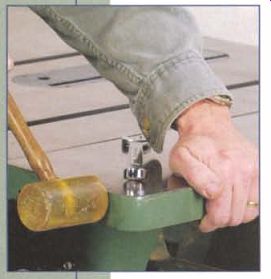

Each holder is simply a scrap of ¾″ thick plywood cut to 4½″ square. Two pieces

of ¼″ Masonite 2″ × 4½″ are screwed to two edges of the plywood that make up

a corner. Then, to hold the tape and allow for an accurate reading, the corner

is mitered to form a slot that fits the blade.

A handy layout tool

Scenario: you’re preparing to install a plywood back in a cabinet. The plans

called for a large number of woodscrews to be placed evenly around the edge

of the plywood. This means a lot of screws to lay out. How do you make your

job easier?

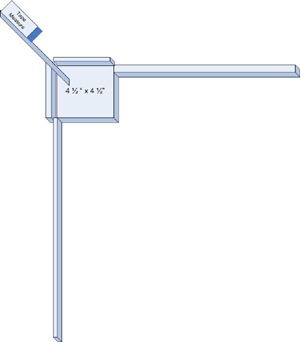

To mark all the screw holes the same distance in from the edge of the plywood

back, mount a ruler on a piece of scrap wood (see diagram). This eliminates

the need for a tape measure.

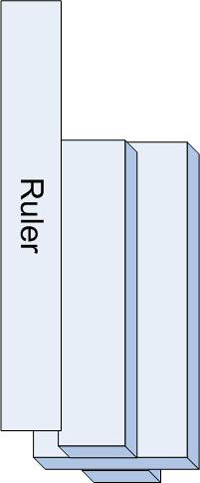

Next, cut the piece of scrap 3½″ wide and to match the length of his ruler

(12″). Then cut a shallow rabbet along one edge to hold the rule in position.

Cut the width of the rabbet narrower than his rule. That way, it overhangs

the edge of the scrap. The amount of overhang equaled the inset you need for

the position of the screw holes.

This tool can be made even more useful by cutting a rabbet on the other three

edges of the tool, too (see diagram). This way, the tool can be used to lay

out screw holes that require different inset.

Using the right tool for refinishing a deck floor

Scenario: Say you have an old 12 x 24 cedar deck (2x6's) which has

been neglected for a while. It will take you virtually forever to sand down

with a belt sander (not to mention the cost of belts). Unfortunately you used

rifled nails so when you try to remove the decking the boards only rip through

the nails and this is very, very laborious.

Ideally you could remove the decking and purchase a planing table to trim the

top of the distressed planking. Now it seems you only have two choices. You

could rent a deck sanding machine (the cross grain mess) but would still have

to sand. You would prefer to purchase a hand held planer but are unsure if

this is up to such a large job? You are unable to determine how much of the

surface you will have to remove; some brads are very bad but most are more

manageable (for a planner).

Would you go through a ton of blades? Will it be difficult to keep the two

cuts on each (half) board even? You figured you could make a fence to keep

me in line with the seem of each board.

What tips and suggestions will are there, and in particular which hand planer

would be the best for this continuous duty job?

As Lou says, a planer is not the right tool. The nails would destroy the planer in short order. The right tool for this job is a floor sander. You can rent these from equipment rental companies and the belts they use. The sanders have belts that range from 24 to about 120 and they will make very short work on the task. They will not have a problem with the nails and the hand planer will.

The sanders take a bit of skill to use but for a deck they will work very well.

Just in case you've never used one before... be wary of lifting the sander during passes... Make full length long passes and don't rock the sander. It creates a rippling effect on the wood due to the tiny differences in thickness caused by "lifting out" during a pass that sometimes can't be seen until it comes time to refinish.

Selecting first tools for woodworking

Say you're starting from absolute scratch. You would actually prefer working with hand tools over power tools, and so you've decided to get a set of 6 firmer chisels (1/4", 3/8", 1/2", 3/4" and 1"), a 14" number 5 Stanley Jack plane, a dovetail saw, coping saw, and then lastly, some sort of power saw -- either band, table, or compound miter, for ripping long lengths accurately. The questions are:

-Whats a good brand for firmer chisels? You were going to go with plastic

handles, but the only brand you've seen is marples, and you read where one

person complained about them not holding an edge well.

-You're fairly certain I'll stick with getting the Stanley 5 Jack plane (anything

better?)

-With regards to dovetail saw, you are going to get a typical dovetail backsaw,

although you've heard very good things about Dokuzi.. Should you start with

the cheaper option or just get the Dokuzi?

-Your main question is with regard to the power saw. You're between the table

and miter. Can you rip long lengths very easily on a compound miter saw? It

seems fairly versatile, and much cheaper than a table saw, and if you're going

to buy a table saw you'd rather not get a crappy aluminum frame saw. Your friend

has an older saw that has a cast iron base and top, which weighs a ton (not

literally, but you get the point). He claims you want a lot of weight in a

table saw and that the sort you get at home depot aren't worth your time. Is

this correct? Where in the world would I even find a cast iron table saw? You'd

rather buy a high quality miter saw that you can keep for a while than settle

for a junky table saw.

Obviously you're not including things such as clamps and squares and rulers, etc. but you are already asking what seems like too many questions.

Answers:

One of the first things that would be helpful for us is to have some idea from you what you are planning to build. Tooling up is pretty much a matter of personal preferences in accordance to method of work, especially where hand tools are concerned.

With that said, table saws can be grouped into 3 categories, bench top, contractor, and stationary. Cast iron tables and wings are desirable because they dampen vibration -- we're not aware of any bench tops that have cast iron. Just about every manufacturer makes a contractor saw with cast iron table and wings.

Radial arm saws are certainly versatile, some would say that ripping is their downfall. We disagree but then, we have an older DeWalt. The current "state of the art" is owned by The Original Saw Company, they acquired DeWalt's original patents...

When you speak of chisels, are you wanting a set of all-purpose bench chisels? Firmers are generally used for mortise work.

As to dovetail saws, we prefer the Western style.

The #5 jack is an excellent 1st bench plane, would only suggest that you get a low angle block with an adjustable mouth for end grain work. Since planes are like rabbits, you'll need two to get started.

Chisel Question:

As for the chisels, perhaps a set of all purpose bench chisels would be desirable. The project you are hoping to complete, say, is a West Greenland skin-on-frame kayak. There would be quite a bit of mortise work with the ribs (20 or so). Would bench chisels be able to handle this adequately? One other question I have is this; how difficult is it to hand saw very long lengths, say 12 feet or so? There are probably problems with precision and the amount of time it takes, but really time is not an issue. Obviously, it has been done without power tools for thousands of years, but are there any specific techniques or hand tools employed?

Answer:

In view of the fact that you will indeed be mortising, go with the firmer in the sizes you need.

Certainly the frames and ribbands can be cut by hand, though it will be very tedious at best, very frustrating at worst; particularly getting your ribbands to final dimensions. FWIW, the boats that we've built the table saw and bandsaw were the "power" tools that were indispensable.

Best-Rated Woodworking Tools: we searched the Internet for editorial and customer and came up with a fairly comprehensive list for both novice and pro woodworkers.

Best Sellers — Books and Videos:

Top choices for Woodworking and related-arts Books

Essential videos for Woodworking, Furniture-Making, Finishing and other areas of Carpentry

Links:

- Bink's Woodworking: Woodworking Plans, Project Ideas, & Shop Tips

- Carpentry and Construction Career Guide

- Some useful Woodworking and Carpentry articles

- Woodworking Industry Information

- Woodworker's Website Association