Types of ships

The type of merchant vessel employed on a trade route is determined basically by the traffic carried. Broadly speaking there are three main divisions: liners, tramps and specialized vessels such as tankers.

On occasion, and in particular when merchant vessels in one division are underemployed, a number may be transferred to another division. For example, a tramp may be put on a liner berth to compete for liner cargoes. Conversely, liners may at times carry tramp cargoes, either as full or part cargoes.

During the past decade there has been a trend towards the development of the

multi-purpose vessel and the combined transport system. The need for the multi-purpose

vessel has arisen to combat trade fluctuations and enable the vessel to become

more flexible in her operation. Not only can the vessel vary the cargo mixture

capacity on a particular voyage, but also she can switch from one trade to

another. Such tonnage, although more expensive to build, should enable the

volume of laid-up tonnage to fall. Examples of multi-purpose tonnage are found

particularly in the vehicular ferry and container vessel plus an increasing

number of combination bulk cargo vessels including the tramp vessels.

A further significant factor is the growing emphasis on quick port turn round time, the development of logistics and rising standards in ship management and a range of IMO regulatory measures. This has been manifest in tankers, LNG, container tonnage and a whole range of types of ships. An example of a new range of vessels is the fast ferry. A description of each division follows.

Today, developing countries are taking an increasing share of the world's manufacturing output consequent on the accelerating trend for relocation from high cost to low cost countries. This in turn has lengthened average transport distances for many manufactured articles; and since most of this international transport of raw materials and manufactured goods is by ship, some of it 'added value', demand for shipping services has naturally increased as well. Hence the growing shift from European tonnage ownership to Asian countries.

Liners

These are vessels that ply on a regular scheduled service between groups of ports. The student should note that it’s this function, and not the size or speed, which defines the liner. Liner services offer cargo space to all shippers who require them. They sail on scheduled dates, irrespective of whether they are full or not. Hence in liner operation the regular scheduled service is the basis of this particular division, and it’s vitally important to the ship-owner that everything is done to have punctual sailing and arrival dates, otherwise his prestige will quickly decline. Liner operation involves an adequately sized fleet, and a fairly large shore establishment. Today the modern liner cargo service is multi-modal and very sophisticated in terms of its logistics and computerized operations. Such companies are continuously striving to improve efficiency and overall transit times thereby stimulating trade development and improvement in market share. The liner company therefore tends to be a large concern and in more recent years operating container tonnage on a consortia basis. However, there still remains a very small volume of 'tween-deck break-bulk cargo vessels in service, particularly in the subcontinent, Orient area, the developing countries and Eastern bloc markets.

These are being phased out and displaced by container tonnage, a growing proportion of which is multi-purpose.

The cargo liner operation today falls into several distinct divisions but is characterized by a regular service all year round on a fixed route to a group of ports situated in different countries and conveying general cargo in a container or trailer/truck or as break bulk (loose cargo). The vessel sails whether she is full or not. The development of combined transport also involves inland distribution by road/rail through the use of a combined transport bill of lading involving a through-rate door-to-door from warehouse to warehouse. Each type is designed to achieve fast turn-round times and a high level of ship management efficiency. Vessels are completely integrated into the seaport operation which involves purpose-built berths and extensive port and inland infrastructure (see Section 17), and include container tonnage, ro/ro passenger (road haulage unit/motorist/passenger), ro/ro container, ro/ro other cargo, general cargo/passenger, general cargo single-deck, general cargo multi-deck, and general cargo/container. The container and ro/ro tonnage make up the prime growth sectors as countries worldwide develop their seaports and infrastructure to accept this very efficient and reliable unitized method of global distribution. With the container tonnage much of it’s integrated with the seaport overland rail distribution network. More and more liner cargo in all categories of tonnage are being customs cleared inland and away from the former traditional seaport area, and an increasing amount of the port infrastructure operation is computerized. The era of the global logistics supply chain, is fast developing and it involves the hub and spoke system. Moreover, the decline of the liner conference network has resulted in a new breed of liner management which focuses on the door-to-door transit, the supplier to consumer, embracing combined transport and not as hitherto seaport to seaport transit. Overall it’s high-tech, with continuous monitoring/tracking of the container throughout its transit.

===

Bulk carrier, a ship designed with a single deck hull, which includes an arrangement of topside ballast tanks and holds specifically designed for the bulk carriage of various types of loose dry cargo of a homogeneous nature. The cargo handling mode may be lift on/lift off to and from the holds by way of weather deck hatches or, alternatively, by way of specialized shore-based equipment. Various features may include: hopper side tanks (which may be combined with the topside tanks);

strengthening for the carriage of heavy cargo (including ore); holds equipped for the carriage of containers (container securing arrangements) or for the carriage of vehicles (hoistable vehicle decks, accessed by way of shell side doors); weather deck equipped with stanchions for the carriage of logs; self-discharging apparatus, including hopper-shaped holds, in-hold conveyor belts and a self-unloading boom; design restraints and service restrictions pertaining to operation on the Great Lakes of North America. Related types include: wood chip carrier; cement carrier, with no weather deck hatches, but pumping; piping arrangements for the loading and unloading of cement; ore carrier, two longitudinal bulkheads, side tanks, ore carried in centre holds only;

Ore/Bulk/Oil carrier (OBO), a bulk carrier with the additional facilities for the alternative (but not simultaneous) bulk carriage of oil; ore/oil carrier, an ore carrier with additional facilities for alternative (but not simultaneous) bulk carriage of oil

===

Table 1 Bulk carrier world fleet and new building orders comparison at 1 January 2005

Existing fleet New building orders including: including:

Age group (yrs) Delivery schedule Tonnage total 20+ 15-19 total 2005 2006 existing orders

Number of vessels

10,000-19,999 597 399 45 17 9 7 20,000-39,999 2,136 1,152 308 144 69 52 40,000-59,999 1,297 234 200 266 106 83 60,000-79,999 1,148 284 114 188 74 56 80,000-99,999 58 14 2 87 14 35 100,000-159,999 239 65 27 1 0 0 160,000 plus 372 20 64 131 40 42 Total 5,847 2,168 760 834 312 275 Deadweight equivalent (million tonnes)

10,000-19,999 9.4 6.4 0.7 0.3 0.1 0.1 20,000-39,999 63.6 34.8 9.5 4.4 2.1 1.5 40,000-59,999 60.8 10.5 8.9 14.3 5.7 4.4 60,000-79,999 81.3 18.7 7.6 14.2 5.5 4.2 80,000-99,999 5.1 1.2 0.2 7.4 1.2 3.0 100,000-159,999 34.3 8.8 3.9 0.1 0.0 0.0 160,000 plus 67.8 3.9 12.9 26.1 7.3 7.7 Total 322.4 84.3 43.7 66.8 22.1 21.0

===

Tramps

The tramp, or general trader as she is often called, does not operate on a fixed sailing schedule, but merely trades in all parts of the world in search of cargo, primarily bulk cargo. Such cargoes include coal, grain, timber, sugar, ores, fertilizers, copra etc., which are carried in complete shiploads.

Many of the cargoes are seasonal. The tramp companies are much smaller than their liner cargo counterparts, and their business demands an intimate knowledge of market conditions. In recent years the family tramp business has merged with like-minded family tramp businesses to raise capital for new/second-hand tonnage and become more efficient in both operation and ship management. Many tramp businesses are adopting a third party ship management strategy, especially in manning, ship survey, bunkering and insurance.

Tramps are an unspecialized type of vessel with two to six holds, each with large unobstructed hatches, and are primarily designed for the conveyance of bulk cargoes. Some ships are built with special facilities particularly suitable to the five main tramp trades: grain, coal, bauxite, phosphates and iron ore.

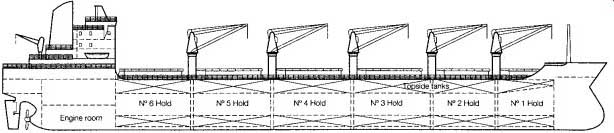

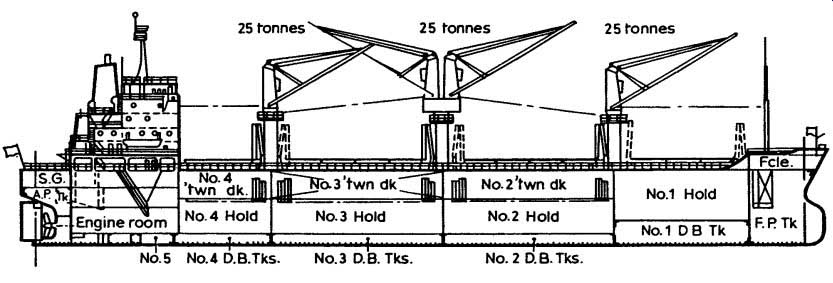

The modern tramp vessel has a speed of 14/15 knots. The bulk carrier (Fgr. 1) is designed with a single deck hull which includes an arrangement of topside ballast tanks and holds specially designed for the bulk carriage of various types of loose dry cargo of a homogeneous nature. This includes grain, coal and iron ore. The cargo handling mode may be lift on/lift off to and from the holds by way of weather deck hatches or, alternatively, by way of specialized shore-based equipment. Various features may include (a) hopper tanks - which may be combined with topside tanks, (b) strengthening for the carriage of heavy cargo (including ore), (c) holds equipped for the carriage of containers - container securing arrangements - or for the carriage of vehicles - hoistable vehicle decks accessed by way of sheet side doors, (d) weather deck equipped with stanchions for the carriage of logs, (e) self discharging apparatus including hopper-shaped holds and in-hold conveyer belts, (f) and design restraints and service restrictions pertaining to operations on the Great Lakes of North America.

===

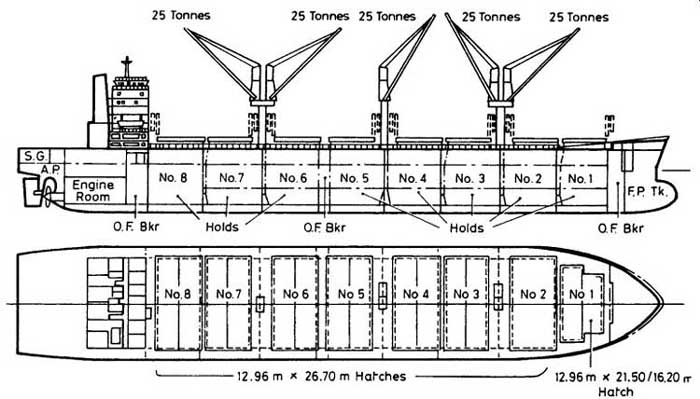

Combi King 45 flexible container/bulk carrier. This vessel, of 45,000 dwt, has a grain capacity of 58,700 m3 or a container capacity of 2,127 TEU. It’s suitable for worldwide trading in the bulk carriage of grain, coal, ore, bauxite, phosphates, packaged timber, standard pipe lengths, and containers. (Shipbuilders Ltd)

===

An analysis of the bulk carrier world fleet and new building orders comparison is given in Table 4.1. The family tramp operator tends to manage the smaller capacity vessel and with a limited range of multipurpose shipboard facilities concentrating on the five bulk homogeneous tramp trades.

To raise safety standards in the bulk carrier tonnage and take advantage of new technology, the IMO revised the SOLAS Section XII which was adopted by the MSC79 in December 2004 and became mandatory in July 2006 (--32). It features damage stability requirements applicable to bulk carriers, structural strength of bulk carriers and structural and other requirements for bulk carriers. It also included an enhanced program of inspections of bulk carriers, operative from January 2007.

Further types of bulk carrier include the cement carrier with no weather deck hatches but pumping and piping arrangements for the loading and unloading of cement. This type of vessel is in decline as the containerized shipment is displacing it. The ore carrier has two longitudinal bulkheads, side tanks, with one being carried in the centre holds only.

An example of a modern flexible container/bulk carrier ship is found in Fgr. 2. It has eight holds and a deadweight tonnage of 45 500 with a draught of 12.2 m. The service speed is 14 knots and the ship's overall length is 194.30 m. The cargo hold grain capacity is 58 700 m^3 . Container capacity totals 2,127 TEUs of which 1,069 TEUs are above deck. It has one single 25 tonnes and two twin 25 tonnes electro-hydraulic deck cranes all of which are fitted with grabs. The crew accommodation complement is 25 of which nine are officers. The vessel is suitable for worldwide trading in the bulk carriage of grain, coal, ore, bauxite, phosphates, packaged timber, standard pipe lengths and containers. The vessel is called the Combi King 45 flexible container/bulk carrier.

Tramp vessels are engaged under a document called a charter party, on a time or voyage basis. The role of the tramp vessel market continues to change.

The tramp operator tends to buy second-hand tonnage and the Greeks remain strong in the market. The trend to have long-term time charters of five to 10 years' duration is becoming more popular.

===

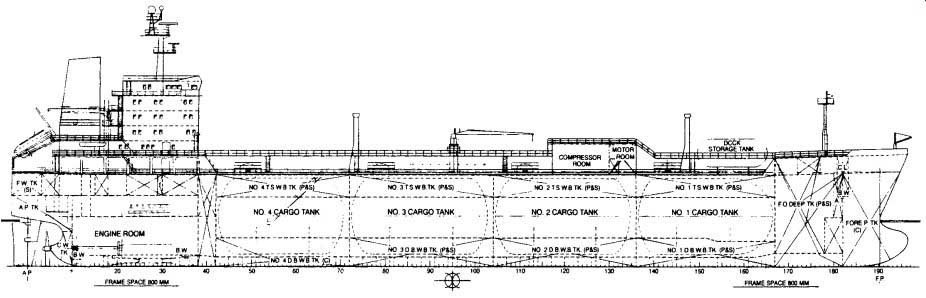

Tanker, a category of ship designed with a single deck hull which includes an arrangement of integral or independent tanks specifically for the bulk carriage of cargo in liquid form. Cargo handling to and from the tanks is by way of shore- and/or ship-based pumping and piping equipment. Tanker types include: oil tanker; chemical tanker; liquefled gas tanker (for LPG and/or LNG), with mainly independent tanks; liquefied gas/chemical tanker; other tankers, e.g. asphalt tanker, fruit juice tanker, with refrigerated holds), wine tanker; water tanker. Various features may include: a double bottom structure, double skin sides and double deck; a particular tank structure/tank coating, or other structural features, which reflect the nature and hazard of the cargo carried; the additional carriage of liquid cargo in independent tanks situated on the weather deck; an additional forward hold for the carriage of dry cargo

===

Specialized vessels and their trades

A number of cargo ships are designed for carrying a particular commodity, or group of commodities. Such specialization is the result of demand, but its provision may also create a new demand depending on the extent of the market. Examples of such specialized vessels are ore carriers and sugar carriers. A description follows of the more usual types of ship, and in view of the preponderance of tankers in this group, these will be examined first.

(a) Oil tanker tonnage

The growth of oil tanker tonnage continues to increase annually and the percentage change 2003/04 was a rise of 4.1%. Overall, it represented 37%, 316,759,000 dwt, of the world's fleet. Moreover, the average age was 10.9 years in 2003. This is due to the mandatory requirement of all 'Category 1' tankers to be double hull structured, thereby displacing the single hull tonnage.

The phasing out of single hull oil tankers banning the carriage of heavy grade oil in such tonnage was adopted in December 2003 as amendments to Annex I of the MARPOL Convention following the November 2002 sinking of the oil tanker Prestige off the Spanish coast. Category 2 oil tankers must be phased out by 2010 and likewise Category 3. The double hull requirements for oil tankers are principally designed to reduce the risk of oil spills from tankers involved in low energy collisions or groundings.

Category 1 oil tankers - commonly known as PREMARPOL tankers - include oil tankers of 20,000 dwt and above carrying crude oil, fuel oil, heavy diesel oil or lubricating oil as cargo and tankers of 30,000 dwt and above carrying other oils, which don’t comply with the requirements of protectively located segregated ballast tanks.

Category 2 oil tankers - commonly known as MARPOL tankers - feature oil tankers of 20,000 dwt and above carrying crude oil, fuel oil, heavy diesel oil or lubricating oil as cargo and oil tankers of 30,000 dwt and above carrying other oils which comply with the protectively located segregated ballast tank requirement.

Finally, Category 3 tankers are oil tankers of 5,000 dwt and above, but less than category 1 and 2 tankers. Exemptions are permitted under categories 2 and 3 under special circumstances, subject to a condition assessment scheme, but the phase-out date must not go beyond 2015 or the date on which the ship reaches 25 years of age. Hence by 2010 the average age of the world tanker tonnage will be the lowest on record and overall very modern and increasingly productive. Throughout this period many shipyards have been experiencing a full order book.

In more recent years the oil-producing countries have tended both to own and operate their own tanker fleet thereby having complete control over the distribution arrangements and costs. Moreover, they are shipping it as refined oil and not, as they previously did, allowing major importing industrial nations to refine it and re-export it. Their income is thus improved. A significant proportion of the world tanker fleet is under charter often on a long-term charter to the oil companies. Hitherto the oil companies owned and managed the tanker, but that era has ceased.

Crude oil is transported from the oil fields to refineries and petroleum and fuel oil from refineries to distribution centers and bunkering ports, so that there is a worldwide network of tanker routes. Investment in pipeline distribution continues globally and this is resulting in a reduction in the short haul business. This strategy together with other considerations has resulted in increased productivity measured in ton-miles per deadweight ton from an increase in the long haul business, notably crude oil. Productivity in terms of tons carried per deadweight ton for oil tanker was 6.7 in 2003 compared with 4.8 in 1980. This improvement will continue as the double hull tonnage investment program nears completion in 2010. We will now examine the range of oil tankers.

(b) Ultra Large Crude Carriers (ULCC)

Vessels in this category range from 300,000 dwt to 500,000 dwt and this category is being phased out and replacement tonnage is almost nil. The reason is the inflexibility of the tonnage as few ports could accommodate them and some have adopted a multi-port operation calling/discharging at two ports.

(c) Very Large Crude Carriers (VLCC)

Tankers in this category range from 150,000 dwt to 299,999 dwt capacity.

The tanker size exploits the economies of scale and the new build program is very buoyant. The vessel is very popular in the Arabian Gulf export trade, which represents 80% of demand and West African crude trade to Asia.

The future of Arabian Gulf exports and hence VLCC prospects lies in Asia. The bulk of Asian incremental oil needs will be satisfied by imports from the Arabian Gulf or from West Africa. Long-term demand risks include the deepening and widening of the Suez Canal to accommodate fully loaded VLCCs and the construction of an Iraq-Syria pipeline to the Mediterranean.

Most Middle East crude arrives in the Mediterranean via the Sumed pipeline that runs parallel to the canal. Hence fully loaded VLCC transiting the Suez Canal are likely to put pressure on Sumed rates rather than adversely affect VLCC owners. Of greater concern would be the construction of pipelines to permit the export of Iraqi crude through Syrian ports. This would eliminate crude shipments on the far longer sea route around the Cape of Good Hope, creating a serious reduction in VLCC demand.

(d) Suezmax tanker

This embraces a capacity range from 120,000 dwt to 149,999 dwt. Historically, the name applied to the largest vessels that could transit the Suez Canal.

Today the Suezmax vessels are primarily associated with crude exports from West Africa. Other markets that favor this tonnage are the North Sea and Mediterranean trades for local distribution. Growing Black Sea exports from pipelines being built to the Caspian Sea oilfields together with the growing trade from the Caribbean basin to the United States as the berths are improved will benefit from this tonnage.

(e) Aframax tanker

Aframax tankers are between 80,000 dwt and 119,999 dwt. The fleet has expanded dramatically in recent years in response to growing demand, including clean product trading. Clean products are refined products such as aviation spirit and motor spirit, as compared with dirty products which are crude oils such as heavy fuel oils. With the exception of the North Sea Aframax crude carriers have exhibited growth on all their trade routes, especially the Caribbean basin and east coast of North America (f) Panamax tanker

Tankers in this category range from 50,000 dwt to 80,000 dwt. These tankers are presumed to be able to pass through the Panama Canal, but a number of vessels in this size category are too beamy to pass through the locks.

Panamax tanker trades are mainly identified with fuel oil cargoes. Long term fuel oil trading will be under pressure as refinery upgrades cut the yield on fuel oil in favor of higher-valued products such as gasoline, gas oil and natural gas. The Panamax fleet remains small and likely to remain so as tanker profitability depends on the volatility in the expanding natural gas prices.

(g) Product carrier

Product carriers can be segregated into four major divisions: Aframax, Panamax, 'Handy' and small. Aframaxes primarily carry naphtha cargoes between Arabian Gulf and Japan. Both Aframax and Panamax product carriers often require improvements in port and terminals in order to utilize these larger-size vessels. The traditional classes of product carriers are medium sized or handy product carriers between 30,000 dwt and 50,000 dwt and small sized product carriers between 10,000 dwt and 30,000 dwt. Prospects for small sized product carriers are limited to intra-regional markets. While intra-regional trading is a sizeable business, small sized product carriers are vulnerable to improvements in port and terminal facilities. The prospects for medium-size products are rather better in that these vessels are properly sized to take advantage of future increases in intra-regional movements of clean products, but these vessels are also vulnerable to improvements in ports and terminals that allow for the use of Panamax and Aframax product carriers.

(h) Parcel tanker

Parcel tankers are designed to carry chemicals, petroleum products, edible oils and molasses. Vessels of this range vary in size, but have a capacity range between 30,000 dwt and 80,000 dwt. The tanker would have a double hull structure embracing double bottom, double skin sides and other structural features which reflect the nature and hazard of the cargo carried.

(i) FPSO and FSU

A growth development in recent years is the provision of offshore floating production, storage and off loading facilities (FPSOs) and floating storage units (FSUs). Such facilities are for bulk liquids and gases. The FSU is a vessel of hull form structure similar to the FPSO, but without any oil processing capacity; the processing being accomplished at nearby platforms.

MARPOL Annex 1 regulations were introduced in January 2007 relative to the prevention of pollution by oil. Both FPSO and FSU have been developed to reduce oil production costs.

(j) Bulk carrier types

The bulk carrier and oil tanker world fleets represent over 70% of the dwt tonnage - each having about 37% of the tonnage. It’s a growth market and represents single commodity shipments usually under charter. It represents a leading industry in the world and subject to continuous change and possible innovation is the shuttle oil tanker. The four main commodities are steel, iron ore, coal and grain.

(i) The Panamax tonnage range is between 50,000 dwt and 79,999 dwt.

They are deployed on several routes, from east North America, Canada, South Africa, China, India, Sweden and Indonesia. The vessels convey primarily coal and iron ore.

(ii) The Capesize dry bulk carrier has a carrying capacity between 80,000 dwt to 170,000 dwt. Such vessels are too large for the Panama Canal and fertilizer/grain berths. The Capesize vessels convey coal and iron ore, and are not economical for fertilizer and grain shipments. Many of the ships were built in Japan and China and their average age is 15 years and world average size 169,000 dwt. The tonnage is becoming uneconomic, due to their draught and length size, but still remain cheaper and more economical than two Handymax tonnage.

(iii) The Handymax ship has a capacity range from 35,000 dwt to 49,999 dwt. The world fleet average age is nine years. The vessels are popular with smaller shipments and ideal for smaller ports such as those in Brazil with restrictions on draught, length and storage. Cargoes include coal, iron ore, fertilizer grain, steel slabs, bauxite, alumina, rock-phosphate and grain. The major routes are Black Sea to the Far East, the US Gulf to Ncsa/Skaw Passero, the Far East to the Atlantic and Australia to India.

(iv) The Handysize bulk carrier has a capacity range from 20,000 dwt to 34,999 dwt. It’s ideal for smaller shipments of a range of bulk cargo types and serving ports of limited draught and berth length. An example is grain shipments through the Black Sea from the Ukraine and Russia to the Middle East countries.

To focus on seaborne trade volume/analysis in dry bulk in 2003, world seaborne trade in ton miles totaled 25,000 billion. Crude oil represented 10,500 billion ton miles, with the five main bulk cargoes totaling 7,500 billion ton miles. Grain shipments totaled 1,400 billion ton miles, coal 2,700 billion ton miles and iron ore 3,100 billion ton miles.

Brazil and Australia account for 65% of world iron ore exports. China and Japan are the biggest iron ore consumers. Other importers include Middle East countries, America, Africa and EU countries - the latter which represents 25% of world iron ore products.

Steel production and consumption continues to increase globally both industrially and consumer products. This is likely to continue as global industrial/infrastructure develops and consumer demand rises. China and the United States have a high steel consumption. The volume of steel scrap currently at 400 million tonnes, annually continues to rise, with China a leading importer.

Coal remains a significant energy source in some markets, especially China.

In 1970 the world seaborne trade in billions of ton miles was 481 and by 2003 it had risen to 2,700. Thermal coal makes up 70% of world coal trade.

Australia is the largest exporter of coal and accounts for 30% of world shipment. The United States and Canada are coking coal exporters. Coking coal is used in steel production. China, Indonesia and South Africa are exporters of thermal coal. Main importers are the EU and Japan - 28% each.

The Republic of Korea, Taiwan and Province of China are also importers.

The trade depends on thermal coal: prices are affected by deregulation of the energy market. Coal fuels about 75% of China's electricity generation.

Grain shipments, wheat, maize, barley, oats, rye, sorghum and soya beans, are subject to seasonal developments. In 1970 world seaborne trade in ton miles of grain was 475 and by 2003 it had risen to 1,335. The largest grain exporter is North America, at 50%, followed by Australia, the EU and east coast of South America, which accounted for 18%.

(k) Coaster:

These are all-purpose cargo carriers, operating around our coasts. They are normally provided with two holds, each supplied with derricks to handle a variety of cargoes, Machinery and crew accommodation are aft. Coasters are subject to severe competition from inland transport.

(l) Combi carrier:

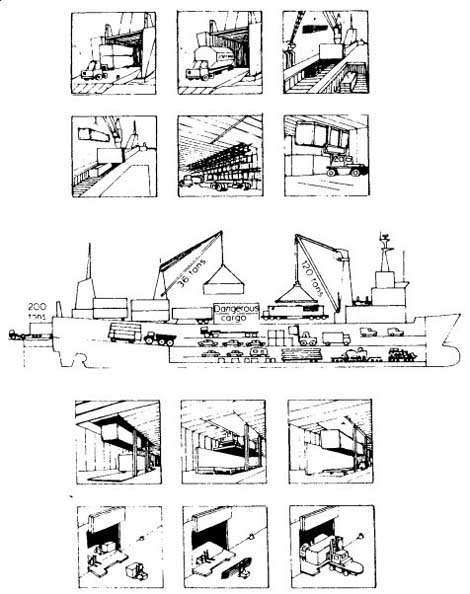

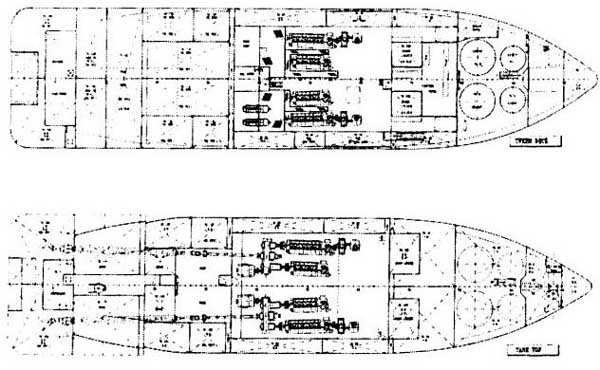

To cater for the need to improve ship turn-round time, to increase the versatility of vessel employment and to contain operating cost, an increasing number of vessels are now being introduced called Combi carriers as illustrated in Fgr. 4. Such vessels are a unitized type of cargo carrier combining container and vehicular shipments including ro/ro.

The Combi vessel in Fgr. 4 has an overall length of 135 m and beam of 25 m with an NRT of 1,714 and GRT of 4,496. Her draught is 6.68 m and dwt (metric) 8,000. The vessel has a container capacity of 516 TEUs with 264 TEUs on the upper deck, 216 TEUs on the main deck and 36 TEUs on the lower deck. The ship has a lane capacity of 563 m on the upper deck, 603 m on the main deck, and 250 m on the lower hold. The car deck area totals 212 m^2 on the main deck and 293 m^2 in the lower hold. The cargo conveyed will vary by individual sailing and be a mixture of containers and vehicle traffic as illustrated in the figure. This aids flexibility of ship operation and ensures the best use is made of the available vessel capacity having regard to market demand.

The vessel is equipped with two derricks of 36 tons and 120 tons thereby aiding the transhipment of heavy indivisible loads which are much on the increase. By using a medium/heavy duty mobile crane on the quay it’s possible to load and discharge at the same time with the vessel using its own gear for loading/discharging through the lift hatch. Loading of containers or other cargo is through the aft hatch. A high capacity fork lift is available for stowing on the main deck. The vessel has a crew of 30.

The stern ramp is 14 m long and has a flap of 4.2 m. The width of the ramp is 8.5 m at the shore-based end. It can be used for fast loading/discharging of containers on trailers or by heavy fork lifts operating with 20 ft containers athwart ships.

===

Fgr. 4 Omni carrier, roll on/roll off, lift on/lift off, and side-loading

Combi carrier

===

The spacious main deck may be used for awkward shaped goods, e.g. building cranes, offshore and refinery equipment, prefab building components etc. The clear height of 6.3 m on the main deck allows double stacking of containers each up to 9 ft 6 in high.

Special suspension hooks underneath the lift provide an additional lifting facility of 60 tons for the transfer of units onto trailers. Containers are placed on trailers for transfer by lift to the lower hold. The lift hatch when required serves as a third point of access for loading/discharging cargo by use of the shore crane.

A side door of 7.5 × 4.0 m width is provided which allows simultaneous operation by two fork lifts handling palletized cargo. The wide side door also allows truck loading or the discharge of large items. Containers of 20 ft length can also be handled through the side door.

Advantages of the Combi carrier can be summarized as follows:

(a) It has a versatile cargo mixture permitting a variation of unitized cargo to be conveyed plus awkward shaped cargo. This is a major advantage in the cargo liner field where more consignments are indivisible loads.

(b) The range of cargo transhipment facilities on the vessel, i.e. derricks, stern ramp, side doors etc., aid quick transhipment and is virtually independent of quay transhipment facilities. This improves the ship's versatility particularly in ports where cargo transhipment facilities are virtually non-existent. It also reduces the cost of using port equipment.

(c) Good shipboard cargo transhipment facilities quicken the ship turn-round time and improve ship utilization/efficiency.

(d) The vessel specification, i.e. draught, beam, length, is an optimum ideal for a wide range of ports and thereby generates versatility of ship employment and operation worldwide.

(e) The vessel is able to convey a wide variety of cargo at economical cost including particularly ease of handling.

(f) The ship's specification facilities reduce port congestion as the vessel is independent with its own handling equipment. Furthermore, For example, the 200 ton capacity stern ramp requires only 30 m of quay space.

The foregoing explanation of the Combi carrier specification as illustrated in Fgr. 4 demonstrates the versatility of the vessel. This tonnage is expensive to maintain and is operational in the liner cargo deep sea trades involving less developed nations' seaboards and being displaced by container and ro/ro tonnage.

(m) Container vessel

These are becoming increasingly predominant in many cargo liner trades and such tonnage has been described in Section 4 together with Fgr. 3.3.

The merits of containerization are described in Section 16.

(n) Fruit carrier

These are similar in design to refrigerated vessels. Cool air systems are installed in the holds to keep the fruit from over-ripening. Such vessels convey apples, oranges and bananas, and may be owned by the cargo owners. Fast voyage times are essential, otherwise the fruit over-ripens and deteriorates.

This type of vessel is in decline as many shipments are containerized.

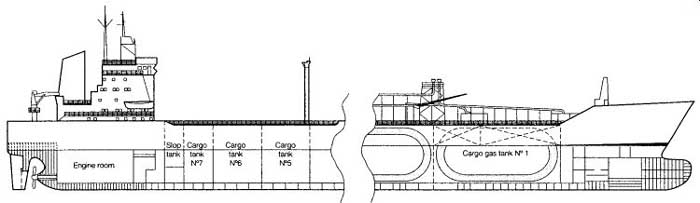

(o) Gas tanker

===

Fgr. 5 LPG/C gas tanker Hans Maersk, built 1993, 23,257 dwt, length 159.98

m, beam 25.6 m, draught 8.78/10.90 m depending on cargo type; four bi-lobe

tanks under deck connected by a pipeline system so that two different grades

can be cooled simultaneously

===

In 2004 the world fleet of liquefied natural gas carriers (LNG) was 21,000 million deadweight tonnes representing an 8% growth in three years and 2.4% of the world fleet. This is likely to accelerate to cater for the North American growth. The first liquefied gas carrier was built in 1959 and today it’s a growth area. World demand for this energy source will grow by 2.75% for the next 20 years. Moreover, production and transport costs have been reduced by half during the past decade, and the cost of sea transport and re-gasification plant dropped by a third and a quarter respectively. Major producers are the United States, Russia Federation, Canada, UK, Algeria and Indonesia. Smaller producers are in the Middle East, Latin America and Asia, often obtaining natural gas as a result of oil production. Over 20% of natural gas production is exported mainly by pipelines, which carries 75% of all exports.

An example of a gas tanker is illustrated in Fgr. 5, the LPG/C Hans Maersk which was built in 1993 of 23,257 dwt. The tanker's overall length is 159.98 m with a beam of 25.6 m and draught of 8.78/10.90 m depending on cargo type. The vessel has four bilobe tanks under deck with a pipeline system connected so that two different grades can be cooled simultaneously with two different uncooled grades. The tanks are constructed for loading and carrying cargoes with a temperature down to -48°C. A cargo heater/ vaporizer is provided. Cargo can be heated by means of a heat exchanger using sea water. The vessel is equipped with a fixed methanol washing system and methanol storage tank with a capacity of 40 m^3. The tanker can carry anhydrous acids, ammonia, butane, propane, butadiene, propylene, isoprene, monomer propylene oxide, vinyl chloride monomer, methyl chloride and others.

Today, the industry is poised to see a new generation of LNG ship designs.

These include larger LNG ships, evolution of tank and hull design; new approaches to LNG ship boil-off and propulsion, and new concepts for offshore floating LNG production and storage terminals that will necessitate innovative shiploading and discharge facilities. Today's deep-water large LNG carriers are 125,000 m^3 to 138,000 m^3 capacity. Smaller tonnage of 19,000 m^3 to 100,000 m^3 account for 24% of the fleet and 12% total cargo capacity and serve trans-Mediterranean and buyers in Japan markets. New builds are usually up to 145,000 m^3 capacity.

There are three categories of cargo tank design. Two are based on independent tank design and the other of membrane design which utilizes the ship's hull to support the shape of the cargo tank. A feature of the LNG is that the cargo is very cold, -163°C.

The cargo is kept cold in the ship tanks by auto-refrigeration. This involves boiling the cargo. This boil-off gas must be handled safely. The technique is to burn it in the ship's boilers and produce steam for propulsion and electricity generation. As a result all LNG ships today are powered by steam turbine engines using dual-fuel boilers that fire heavy fuel oil and the boil off gas from the cargo tanks.

The new generation of LNG feature improvements in tank design, hull design and propulsion type which will lead to increased cargo-carrying capability, improved efficient and lower cost for LNG shipments. Ship capacity could rise to 200,000 m^3 which will result in changes in berth design, shore storage tank capacity, harbor design featuring channel depth and turning basin and harbor traffic control. These developments will favor the long haul trades. Other major areas are found in the engine room: (a) dual-fuel diesel engines (natural gas and MDO), (b) heavy fuel diesel engines with a re-liquefaction plant, (c) gas turbines - either single or combined cycle, (d) or combination of these ideas.

Gas field discoveries located many miles offshore have created an impetus to examine floating production and storage units to serve these remote fields.

The design embraces a floating production storage and offloading vessel that embraces an LNG manufacturing module. Additional modules include a processing facility for dehydration of the gas and extracting liquid petroleum gas, plus a pre-treatment package for removing carbon dioxide, mercury and other contaminants. The whole processing package is designed to fit into the deck of a 312 m long vessel and capable of delivering 1.5 tonnes per year of LNG from three small trains. The vessel is designed to store the LNG until a gas carrier is available for loading, so the vessel has a storage capacity of 200,000 m^3 with six tanks - four for LNG and two for LPG (liquid petroleum gas).

(p) General cargo ship

The general cargo ship represents 11% of the world fleet size and is designed with a single deck hull which includes a single holder arrangement of holds and 'tween decks, specially for the carriage of diverse forms of dry cargo.

The cargo handling mode is lift on/lift off to and from the holds (and 'tween decks) by way of weather deck (and 'tween deck) hatches.

Various features may include (a) a single deck, double skin sides and wide deck openings (box shape holds). Vessels of this type may be intended specifically for the carriage of forest products cargo handling of which may be by use of a gantry crane, (b) strengthening for the carriage of heavy cargoes (including ore), (c) certain holds equipped with container securing arrangements, hoistable or movable vehicle decks, or other facilities pertaining to the carriage of a particular type of cargo, (d) the weather deck equipped with container securing arrangements, or arrangements for the shipment of timber, (e) carriage of liquid cargo specially designed tanks, (f) a refrigerated cargo space for the carriage of perishable cargoes, (g) additional cargo handling to and from the cargo spaces by way of a slide-loading/unloading system (for the carriage of cargo in pallet form and other unitized cargo) and finally additional cargo handling to and from a 'tween deck by way of a stern, side, or bow door/ramp situated below the weather deck, or where additional cargo segregation is provided by hinged 'tween-deck openings or a hinged movable bulk head. The average age of the world general cargo fleet in 2004 was 17.5 years. This type of tonnage is being displaced by container vessels as port modernization develop more container berths and its related infrastructure.

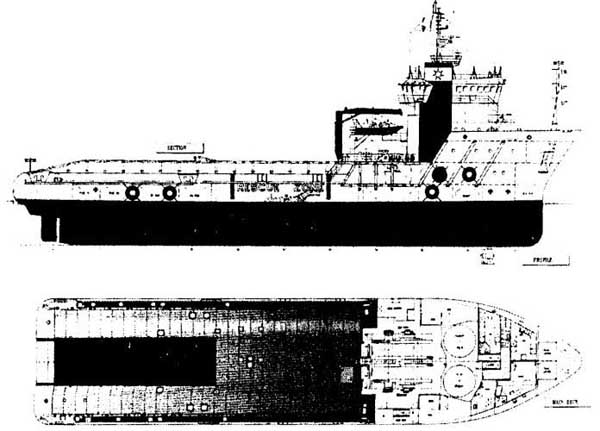

An example of a multi-purpose general cargo ship is shown in Fgr. 6.

It has four holds and a deadweight tonnage of 21,500 with a draught of 10.75 m. The vessel's overall length is 155.5 m and the service speed is 15.3 knots. The cargo hold grain capacity is 30,340 m^3 and bale capacity 27,950 m^3 . The container capacity is 746 TEU, of which some 408 TEU are above deck. The crew complement is 25, nine of whom are officers. The vessel has two single 25 tonnes and one twin 25 tonnes electro-hydraulic deck cranes. The vessel is suitable for worldwide trading in general cargoes, dry bulk, long steel products, grain cargoes and containers. The vessel is called the Multi King 22 multi-purpose general cargo ship.

(q) OBO

Ore/bulk/oil ships are multi-purpose bulk carriers designed for switching between bulk shipments of oil, bulk grain, fertilizer and ore trades. A typical vessel would have an overall length of 280 m, draught of 17 m and 270,000 dwt. Its dry cargo capacity would be 170,000 m3 whilst its oil capacity totals 224,000 m^3. Cargo space is provided in 11 holds to carry oil of which seven can ship dry cargo or ore as an alternative shipment. Crew accommodation and machinery - much automated - is situated aft. Such vessels although of high initial cost are very flexible in their use, keeping ballast voyages to a minimum and are of course ideal for modern-day requirements in international trade, which demand high capacity (optimum-sized) vessels to move world bulk shipments at a very low cost per ton.

Overall, OBO tonnage represents less than 1% of the world fleet and is in decline, with virtually no new build. The reason is to find a balanced or triangle trade, coupled with the cost of cleaning the vessel holds/tank structures which is time consuming. Also maintenance costs are high and new tonnage expensive to build.

===

Fgr. 6 Multi King 22 multi-purpose general cargo vessel, 21,500 dwt, grain

capacity of cargo hold 30,340 m^3 , bale capacity 27,950 m^3 or container capacity

746 TEU. The vessel is suitable for worldwide trading in general cargoes, dry

bulk, long steel products, grain cargoes and containers

===(r) Passenger vessel

These fall into two distinct divisions. There are those which operate in the short sea trade and have limited cabin accommodation. They also convey motorist and ro/ro (roll-on/roll-off) units. The passenger ship is designed with a multi-deck hull and superstructure specifically for the carriage of passengers for when cabin accommodation is provided for 12 or more. The trade may be that of cruising or excursions. Additional features may include forward hold or holds for the carriage of cargo, access to which is by lift on/lift off.

Related types include the ferry, which is a vessel designed to carry passengers, cabin accommodation for 12 or less when provided on a short haul service. The passenger/ro-ro cargo vessel is provided with passenger facilities with additional decks in the hull for the carriage of laden vehicles access to which is by stern or bow door/ramps (fig 7). The passenger/ro-ro cargo/ferry has a passenger certificate to carry more passengers than for whom cabin accommodation is provided.

===

P&O passenger ferry ship Pride of Kent, built Bremerhaven 1991-92 as European Highway, converted 2003: 5,100 dwt, length 179.7 m, beam 28.3 m, displacement 17,894 tonnes, speed 21 knots, capacity 115 15 m units or 520 cars and 2,000 passengers plus 200 crew (--203). (P&O Ferries)

====

Fgr. 8 Advanced multi-purpose offshore support vessel MS Maersk Pacer, built

1991, 2,651 dwt, overall length 73.6 m, beam 16.4 m, draught 6.55 m, speed

16.6 knots

====

(s) Platform supply vessels

The A. P.Møller Group including the Maersk Shipping Company is a market leader in the provision of platform supply vessels for the offshore oil and gas industry. Their fleet exceeds 40 vessels of different types. Platform supply vessels handle the transportation of all necessary equipment such as pipes, cement, tools and provisions to such destinations as the North Sea platforms and drilling rigs. Other tonnage includes multi-purpose anchor handling tug supply vessels, and advanced multi-purpose offshore support ships. The total support vessels tow drilling rigs, handle anchors, work as fire-fighting vessels and are equipped to assist in restraining oil pollution.

In 2004 there were 79 drilling rigs for offshore oil and gas. The largest concentration is in the US 35%; Europe 18%; South East Asia 18% and the remainder in Africa, Caribbean, Latin America, Far East, South Pacific and the Mediterranean

An example of an advanced multi-purpose offshore support vessel is shown in Fgr. 8 featuring the MS Maersk Pacer. It was built in 1991 and has a speed of 16.6 knots. The overall length is 73.6 m, beam 16.4 m and draught 6.85 m. The vessel has extensive versatile equipment including a continuous bollard pull of 180 tonnes, and towage and very extensive anchor-handling equipment including stoppers, shackles, chaser, grapnel, hydraulic guide pins of triangular type, winch, triplex shark jaws and rig chain lockers. The bridge equipment/maneuvering facilities include joystick control, autopilot, gyro compass, repeaters, radars, speed log, Decca and Satnav Shipmates, echo sounder, rapid direction finder facsimile, Navtex and VHF direction finder. Cabin accommodation is provided for six officers and six ratings and there are 12 berths for passengers. A hospital is provided equipped to British and Norwegian stand-by rules. The vessel is also equipped for safety/standby duties for 200 survivors according to Norwegian rules.

The MS Maersk Pacer is low on consumption of heavy fuel and is able to carry deck cargo. For towing/anchor handling, she has a high-speed four drum winch and deep-water anchoring capability, as well as an emergency helicopter landing area, oil recovery capacity, high bow and high freeboard, dry cargo hold, superior station keeping, safe environment for crew, large aft deck, high deck strength, high discharging rates, two powerful bow thrusters and standby/rescue facilities.

The offshore industry remains a growth industry as maritime oil exploration is very focused to meet an energy global market growth. New technology is being continuously introduced and a market lender is Eidesvck Offshore ASA. The company provides ships and integrated services to oil and gas related activities worldwide. The company operates in the following segments:

seismic and survey work; logistics support and platform supply; stand by/rescue, oil recovery and anchor handling and sub-sea operations.

===

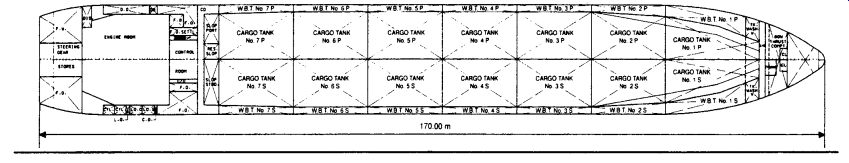

Fgr. 9 Product/chemical carrier MT Rasmine Maersk, built 1986, overall length

170 m, beam 23.10 m, draught 11.41 m, fourteen tanks.

===

(t) Product/chemical carrier

The MT Rasmine Maersk featured in Fgr. 9 was built in 1986 and is 27,350 dwt with a US barrel capacity of 195,000. Its gross tonnage is 16,282 and length overall 170 m with a beam of 23.10 m and draught of 11.41 m. Special features of the vessel include a double hull, bow thruster, stern thruster, a hydraulic hose handling crane of 10 tonne capacity, an aft crane for stores/ provisions of five-tonne capacity, an inert gas generator, nitrogen topping up, a closed loading system with vapor return, stern discharge, crude oil washing and protective location ballast tanks. The carrier has seven twin cargo tanks situated on port and starboard side and one twin slop tank. The vessel is equipped to convey all petroleum products, crude oil, vegetable oils, molasses, etc. as well as selected IMO class 2 and 3 cargoes. Overall up to eight grades are acceptable and each is provided with true line/double valve separation. This type of carrier is very versatile and ideal for many trades.

Cargo and equipment are particularly vulnerable to damage from moisture.

For example, when shipping newsprint from cold to warm climates, cargo temperatures can 'lag behind' and humid air from outside can cause condensation in cargo holds, thus damaging the cargo. Alfsen & Gunderson AS have designed a cargo hold dehumidifier system. It features a sorption dehumidifier, a circulating air fan and a control/monitoring system to ensure that cargo arrives dry and undamaged.

AG-S tank dryers are designed for installation on chemical tankers for efficient drying of tanks after cleaning resulting in reduced lay time. Ags maritime dehumidifiers are based on the Recusorb principle: efficient drying at all relevant temperatures, also below 0°C.

(u) Pure Car and Truck Carrier (PCTC)

This type of tonnage is designed for the conveyance of cars, lorries/trucks and other wheeled units. A modern PCTC has thirteen decks and can convey between 5,500 and 5,800 cars or a permutation of 3,200 cars and 600 trucks.

Such tonnage can also convey containers on 20 ft (6.10 m) or 40 ft (12.2 m) long Ma? trailers. A major operator in this field is Wallenius Lines Ltd, which has a 19 vessel fleet of PCTCs providing a worldwide service embracing the Far East, North America and European markets.

In 2005 three PCTCs, each of 5,000 ceu (car equivalent units), were launched and a further five 4,000 ceu capacity to follow shortly by Wallenius Lines.

Additionally, five vessels built in 1978/9 will undergo a conversion in 2004/05 to enable each vessel to carry an additional 1,300 ceu, giving each ship a capacity of over 7,000 ceu. Another major operator, NYK, has a fleet of 93 car carriers with 10 new builds in 2005 and a further six over 2006/7.

New builds include two 6,000 ceu and one at 5,000 ceu. This tonnage is a growth area and logistically driven. In 2003 8 million cars were transported by sea. Car production is moving out of Europe to the Far East. By 2009 Chinese car production will reach 7 million vehicles, which will triple the country's car production in a decade. The new generation of PCTCs is contributing to reducing the cost of car distribution globally.

(v) Refrigerated vessel

This type of tonnage is in decline as such shipments are containerized in many trades. The ship is designed with a multi-deck hull which includes an arrangement of refrigerated holds and 'tween decks specifically for the carriage of perishable cargoes. The cargo handling mode is lift on/lift off to and from the holds (and 'tween decks) by way of weather deck (and 'tween deck) hatches. Various features include (a) additional side loading by way of side elevators for the specific loading of perishable cargoes on pallets, and (b) the alternative carriage of other forms of cargo including facilities for the carriage of road vehicles (by way of special side elevators or side doors).

(w) Ro/ro vessel

A ro/ro type of vessel was designed for the conveyance of road haulage vehicles and private cars. It’s often called a multi-purpose ship.

Ro/ro combination is now found in the container vessel field as shown.

Another example of a ro/ro (roll on/roll off) - Lo/Lo (lift-on/lift-off) vessel is one of 17,000 dwt, with an overall length of 140 m. The molded breadth is 23 m and she has a speed of 16 knots. The ship has a ro/ro lane capacity of 1,300 m and 600 TEUs container capacity. Hold capacity totals 27,000 m^3 . The vessel has a stern ramp, internal fixed ramps, electro-hydraulic cranes, and hydraulically operated hatch covers. Liquid cargoes (latex or similar) can be conveyed in the foretanks. Such a vessel offers a high cargo mix versatility. Hence such a cargo combination could include general break bulk cargo which could be palletized, bulk cargo, containers, trailers, cars and ro/ro cargo.

The future of ro/ro tonnage lies in the short sea trade markets. It’s unlikely any further deep sea ro/ro tonnage will be built as the new generation of PCTC develops.

(x) Timber carrier

These are provided with large unobstructed holds and large hatches to facilitate cargo handling. They are frequently called three-island vessels and incorporate a raised forecastle, bridge and poop, thereby facilitating stowage of deck cargo which is now packaged.

(y) Ferry fleet

The ferry non cargo fleet had a steady growth until 2000. A slowdown has been forecast with a modest fleet growth over 2004-08 with 175 deliveries compared with 84 in the previous period. Overall, 101 were recycled which was double the previous period.

About a quarter of the ferry fleet is high speed - 30 knots and above - whereas over 50% are multi-hauled. All fast ferry types depend upon the reduction of surface tension and resistance by either reducing hull drag or by creating dynamic lift. There are four main types of fast ferries: mono hull, catamarans, hydrofoils and hovercraft.

Fast ferry investment involves high initial cost, high annual cost and short economic life. To be successful, high income must be generated over a short period involving high fares and high utilization. Advantages over competing conventional ferries (fig 7) are good sea-keeping, quick embarkation/ disembarkation, low noise levels and high quality shipboard facilities. The major advantage is voyage time reduction compared with conventional ferries.

This generates a new market as found on the Italian-Greek passenger trade.

Overall, the fast ferry costs more to operate than conventional ferries. This is due to high fuel consumption to operate at 40 knots and more stringent maintenance costs. Fast ferries are licensed to sail with a crew of 23 while conventional ships have a crew of 34. However, costs increase due to overtime and premium pay rates. Fast ferries seldom operate on routes longer than 150 nautical miles to ensure that frequent each way trips per day can be achieved, thereby enhancing revenue generating potential. This demands fast port turn-round time, and dedicated passenger terminals with good operational planning. It’s forecast improved hull design may generate a new build of high-speed ferries of above 50 knots whilst conventional ships will rise to 33 knots. High speed ferries have a relatively short operational life, with rapid depreciation compared with a conventional ferry of above 30 years. The era of the hovercraft, hydrofoil and jetfoil is in decline.

(z) Heavy lift shipping

The progress of heavy lift shipping has been outstanding in the past decade and this has been driven by offshore opportunities and the transportation of indivisible loads such as fully erected cranes, yachts and project cargo embracing fabrication industries. An example in 2004 was a 60,000 tonne Thunder Horse floating production platform transported from South Korea to the Gulf of Mexico.

It’s a risk market with the spot market providing a reasonable return, but long-term contracts are found in the oil major contractors, fabricators and conversion yards. However, the key to success is through continuous operation.

Lay-up is not an option. A leading heavy lift ship operator, Dockwise, has developed new markets in the transport of fully erected container cranes of 1,000 tonnes. It provides the crane builder with the opportunity to erect a crane fully at its own site, then transport it to its working location where it can become fully operational and within days has proved highly beneficial to both builder and operator. The crane builder can control costs, while the container terminal does not have its operations disrupted.

Emerging from the merger of Wijsmuller/Dock Express in 1997, the company acquired two recently built semi-submersibles, the Blue Marlin and Black Marlin. More recently the Mighty Servant was jumboized and the beam widened by 10 m to 50 m and length to 190 m and increased the deadweight from 27,720 to 45,000 tonnes. In 2004 it transported the largest cargo ever carried on a ship involving an ultra-deep-water semi-submersible Thunder Horse rig from the Daewoo fabrication yard in South Korea to the Gulf of Mexico. The 60,000 tonne rig is designed to operate in 6,000 ft water depth at the Thunder Horse field in the Gulf of Mexico.

In 2003 two Chinese built a semi-submersible vessels ordered by COSCO entered service.

PREV. | NEXT