Main features of hull and machinery

There are two main parts to a ship: the hull and the machinery. The hull is the actual shell of the ship including the superstructure, while the machinery includes not only the engines required to drive it, but also the ancillary equipment serving the electrical installations, winches and refrigerated accommodation.

The hull is virtually the shell of the ship and usually designed for a particular trade in accordance with a ship owner’s specification. A vessel is constructed of a series of transverse frames, which extend from the fore to aft of the vessel, rising at right angles to the keel. In reality they form the ribs of the ship. Statutory regulations exist regarding the distance between each frame.

Each vessel, depending on its classification - passenger, container, tanker, bulk carrier - must have a number of bulkheads which are virtually steel walls isolating various parts of the vessel. This is necessary in the interests of containing a fire or flooding following a collision. Ocean-going vessels must have at the fore end a collision bulkhead installed at a distance of not less than 5% of the ship's length from its bow. The obligatory after-peak bulkhead function is to seal off the stern tubes through which run the tailshaft driving the propeller.

The rear portion of the ship is termed the after end or stern. When moving stern first, the vessel is said to be moving astern. The front portion of the ship is termed the fore end, whilst the extreme forward end is called the bows. When moving bow first, the vessel is said to be moving ahead. Fore and aft are generally used for directional purposes. The area between the forward and aft portions of the vessel is called amidships. The maximum breadth of the vessel, which is found in the amidships body, is known as the beam.

The engine room houses both the machinery required to drive the vessel and the generators required for lighting, refrigeration and other auxiliary loads. Engines are usually situated aft, thus releasing the amidships space - at the broadest part of the vessel - for cargo and passenger accommodation.

Today a new era of the electric ship is being developed. The ship's funnel, painted in the shipping line colors, is situated above the engine room. In modern passenger liners, it’s specially designed to keep fumes and smuts clear of the passenger accommodation. The propeller shaft, linking the propeller with the engines, passes through a shaft tunnel and is usually a single controllable pitch specification. The ship's anchors and the windlasses used to lower and raise them are found in the bow section. Additional anchors might also be provided on a large ship. All tankers and bulk carriers are constructed of a double hull formation.

Modern tonnage, particularly tankers, container ships and passenger liners, have transverse propulsion units in the bows termed bow thrusters. A number of vessels have side thrusters situated at the stern of the ship. Both bow and side thrusters are situated on the port and starboard sides. Their purpose is to give greater maneuverability in confined waters, e.g. ports, and so reduce or eliminate the need for tugs. The rudder which enables the vessel to maintain its course is situated aft. Some ships have an additional rudder in the bows for easier maneuverability in port. A recent development is the Azipull propeller. Stabilizers are in appearance similar to the fins of a fish, and are fitted to modern passenger liners and container ships to reduce rolling in heavy seas. They are fitted in pairs, and when in use protrude at right angles from the hull, deep below the water line. Their number depends on the size of the vessel. The provision of a bulbous bow can also improve passenger comfort, as it can reduce pitching in heavy seas and has also been provided in tankers, bulk carriers and modern cargo liners to increase speed when in ballast.

The modern tendency is to have large unobstructed holds with electrically operated hatch covers, for the speedy handling of cargo, and to reduce turn round time to a minimum.

Their actual design and the number of decks will depend on the trade in which the ship plies. A vessel comprises various decks with the upper most decks being called the navigational, boat and promenade decks. A continuous deck in a ship would run throughout the length of the vessel from fore to aft.

The transverse bulkheads run from the tank tops or floors of the hold to the deck. The longitudinal framing consists of steel sections running the length of the ship into which are fixed the skin plates forming the hull.

Nowadays, with the development of the welded construction, vessels are constructed on the combined system which uses the longitudinal system in the double bottom, and at deck level uses transverse framing for the sides.

Basically the combined system is better for welded construction.

Scantlings basically are the dimensions of the structural parts of the ship embracing size of frames, beams, steel plating, bulkheads and decks. A vessel built to the full scantlings would be based on the maximum draught when the freeboard measured from the loadline to the deckline (the upper side of the continuous main-deck or freeboard deck which is equipped with permanent means of closing all openings to the elements) is at its minimum.

Single deck vessels fall within this category such as an ore carrier which needs the strongest type of ship construction to convey such heavy deadweight cargoes with low stowage factors. Such vessels are built to the highest specification of the classification societies such as Lloyd's Register of Shipping, American Bureau of Shipping, Bureau Veritas, etc., as regards strength of the component parts of the structure.

To give access to cargo holds, openings are cut into the deck of the vessel which are termed hatchways and are surrounded by coamings which are like steel walls rising from the deck. The height of these coamings is regulated by statute or classification society regulations.

Each mercantile type vessel has a certain number of various types of tanks for a variety of purposes and the following are the more salient ones:

(a) The forepeak tank is situated in the bows of the vessel between the bows and the collision bulkhead.

(b) Conversely the aft peak tank is situated in the stern of the vessel. It forms the aftermost watertight bulkhead.

(c) The wing tank is located at the side of the holds designed for carrying water ballast. These are found particularly in specialized bulk carriers.

(d) The deep tanks are situated one in each of the holds at the two ends of the ship. Such tanks are used for carrying water ballast and can be used to carry dry cargo. In modern vessels they are constructed to convey oil, either as bunkers, or wood or palm oil.

A tramp, carrying shipments of coal or ore, will be a single-deck vessel with large unobstructed hatches to facilitate loading and discharge.

The handling of cargo will be mechanized as far as possible with the use of conveyor belts, pallets and containers. The holds of a modern cargo liner are designed to facilitate dealing with such modern methods of cargo handling.

The derricks are the ship's cranes, and are electrically operated. Their lifting capacity can vary from 3 to 50 tonnes. If heavy items such as loco motives or boilers are commonly carried, jumbo derricks capable of lifting up to 120 tonnes are provided (see Fgr. 4). The decks are strengthened to accommodate such heavy lift cargoes.

A modern vessel called a Combi carrier (see Fgr. 4) has superseded the 'tween-deck tonnage in trades unable to invest in container tonnage and its infrastructure of port facilities and distribution overland network.

The bridge of a vessel is the navigating centre of the ship where its course is determined. Most modern tonnage today has the navigating bridge and machinery situated aft thereby facilitating the naval architect's designing the vessel of the maximum cargo capacity. The engines are bridge controlled and the navigating officer on watch makes use of a bridge computer to steer the vessel, to work out its course, and give position reports etc. In an era of high-tech it’s mandatory for all vessels to have Global Navigation Satellite system (GNSS) receivers, Automatic Identification System (AIS) transponders, voyage data recorders (VDRs) and optionally Electronic Chart Display Information Systems (ECDIS) in lieu of paper charts. The bridge is in direct communication with all parts of the vessel.

It’s also mandatory for a continuous synopsis record to be provided on board of the history of the ship under the ISPS code together with a ship security alert system. In regard to radio communication, as from February 1999 the SOLAS Section IV 1974 was revised in 1988 to embrace amendments to introduce the GMDSS which became operative from February 1999. A key area was all passenger and cargo ships of 300 gross tonnage and upwards on international voyages are required to carry equipment designed to improve the chances of rescue following an accident, including satellite emergency position indicating radio beacons (EPIRBs) and search and rescue transponders (SARTs) for the location of the ship or survival craft. Section IV has been renamed Radio Communications, deleting the previous title Radiotelegraphy and Radiotelephony.

Many vessels today have an Integrated Bridge System (IBS)/Integrated Navigational System (INS) and a global electronic chart service to plan their voyages. The system is distinct from a manual updating, is electronic and suppliers are able to offer a real time updating service also embracing the official ENC via internet or e-mail.

Crew accommodation on modern cargo ships and tankers is situated aft in close proximity to the machinery. Standards of accommodation are high, and are controlled by various statutory regulations.

In the late 1960s the development of the container ship became evident in many cargo liner trades. Such vessels are usually free of derricks and the seventh generation have a capacity in excess of 10,000 high capacity ISO container TEUs (Twenty-foot Equivalent Units). Their speed is between 16 and 22 knots and the more sophisticated type of container vessel is called a cellular ship. Such a vessel is built in the form of a series of cells into which the containers are placed, usually by sophisticated shore-based cranes.

The most recent container vessel tends to be multi-purpose in design with ramp facilities for trans-shipping vehicle cargo. This improves the general cargo mix flexibility of the vessel (see Fgr. 4).

Passenger accommodation will be either one-class with different grades of cabin comfort, as on a hotel basis, or two-class, incorporating first class and tourist. This ensures that the most economical use is made of the cubic capacity of the ship. In a cruise passenger liner, it’s common to find a swimming pool, cinema, shops, hospital, nursery and numerous other amenities and recreational facilities (see Fgr. 7).

There are various statutory provisions concerning the quantity and type of life-saving apparatus carried on a vessel. Broadly, it’s determined by the type of vessel, crew establishment and passenger certificate (authorized number of passengers permitted to be carried). Life-saving apparatus includes lifeboats, inflatable rubber life rafts, lifebuoys and individual lifejackets. Freeboard is the distance measured amidships from the waterline to the main deck of vessel. This is normally the uppermost continuous deck in a ship with one or more decks. However, in a shelter dock vessel it would be the deck below.

The draught of a vessel is the vertical distance from the keel to the waterline.

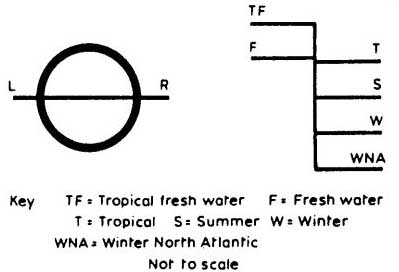

The maximum permitted draught varies according to the seasons and waters in which she plies. The markings are given in Fgr. 1 and all ships must be loaded so that the loadline corresponding to the zone in which they are steaming must not be submerged. The seasons to which the markings apply are Tropical (T), Summer (S), Winter (W) and Winter North Atlantic (WNA).

The world has been mapped off into sections showing where those sections apply.

Fgr. 1 International load line of cargo vessel. Passenger and timber vessels

have additional lines

International navigation limits

On 1 November 2003 the Institute Warranty Limits - the former trading limits - were amended and renamed the International Navigation Limits (INL). Details are given below of the INL.

Navigation Limits

Unless and to the extent otherwise agreed by the underwriters in accordance with, the vessel shall not enter, navigate or remain in the areas specified below at any time or, where applicable, between the dates specified below (both days inclusive).

Area 1 - Arctic

(a) North of 70° N. Lat.

(b) Barents Sea except for calls at Kola Bay, Murmansk or any port or place in Norway, provided that the vessel does not enter, navigate or remain north of 72° 30° N. lat. or east of 35° E. long.

Area 2 - Northern Seas (a) White Sea.

(b) Chukchi Sea.

Area 3 - Baltic

(a) Gulf of Bothnia north of a line between Umea (63° 50° N. lat.) and Vasa (63° 06° N. lat.) between 10 December and 25 May.

(b) Where the vessel is equal to or less than 90,000 dwt, Gulf of Finland east of 28° 45° E. long. between 15 December and 15 May.

(c) Vessels greater than 90,000 dwt may not enter, navigate or remain in the Gulf of Finland east of 28° 45° E. long. at any time.

(d) Gulf of Bothnia, Gulf of Finland and adjacent waters north of 59° 24° N. lat. between 8 January and 5 May, except for calls at Stockholm, Tallinn or Helsinki.

(e) Gulf of Riga and adjacent waters east of 22° E. long, and south of 59° N. lat. between 28 December and 5 May.

Area 4 - Greenland

Greenland territorial waters.

Area 5 - North America (east)

(a) North of 52° 10° N. lat. and between 50° W. long, and 100° W. long.

(b) Gulf of St Lawrence, St Lawrence River and its tributaries (east of Les Escoumins), Strait of Belle Isle (west of Belle Isle), Cabot Strait (west of a line between Cape Ray and Cape North) and Strait of Canso (north of the Canso Causeway) between 21 December and 30 April.

(c) St Lawrence River and its tributaries (west of Les Escoumins) between 1 December and 30 April.

(d) St Lawrence Seaway.

(e) Great Lakes.

Area 6 - North America (west) (a) North of 54° 30° N. lat. and between 100° W. long. and 170° W. long.

(b) Any port or place in the Queen Charlotte Islands or the Aleutian Islands.

Area 7 - Southern Ocean

South of 50° S. lat. except within the triangular area formed by rhumb lines drawn between the following points:

(a) 50° S. lat; 50° W. long.

(b) 57° S. lat.; 67° 30° W. long.

(c) 50° S. lat.; 160° W. long.

Area 8 - Kerguelen/Crozet Territorial waters of Kerguelen Islands and Crozet Islands.

Area 9 - East Asia (a) Sea of Okhotsk north of 55° N. lat. and east of 140° E. long. between 1 November and 1 June.

(b) Sea of Okhotsk north of 53° N. lat. and west of 140° E. long, between 1 November and 1 June.

(c) East Asian waters north of 46° N. lat. and west of the Kurile Islands and west of the Kamchatka Peninsula between 1 December and 1 May.

Area 10 - Bering Sea

Bering Sea except on through voyages and provided that:

(a) Vessel does not enter, navigate or remain north of 54° 30° N. lat.; and (b) The vessel enters and exits west of Buldir Island, Alaska, or through the Amchitka, Amukta or Unimak passes; and (c) The vessel is equipped and properly fitted with two independent marine radar sets, a global positioning system receiver (or Loran-C radio positioning receiver), a radio transceiver and GMDSS, a weather facsimile recorder (or alternative equipment for the receipt of weather and routing information) and a gyro-compass, in each case to be fully operational and manned by qualified personnel; and (d) The vessel is in possession of appropriate navigational charts, corrected up-to-date sailing directions and pilot books.

International Convention on Load Lines 1966

The first International Convention on Load Lines, adopted in 1930, was based on the principle of reserve buoyancy, although it was recognized then that the freeboard should also ensure adequate stability and avoid excessive stress on the ship's hull as a result of overloading.

In the 1966 Load Lines convention, adopted by IMO, provisions are made determining the freeboard of tankers by subdivision and damage stability calculations. The Convention includes Annex I, divided into four sections:

Section I, General; Section II, Conditions of assignment of freeboard; Section III, Freeboards; Section IV, Special requirements for ships assigned timber freeboards. Annex II covers zones, areas and seasonal periods, and Annex III contains certificates, including the International Load Line Certificate.

The 1966 Convention provided for amendments to be made by positive acceptance. Amendments could be considered by the Maritime Safety Committee, the IMO Assembly or by a conference of governments.

The 1988 Protocol was primarily adopted in order to harmonize the Convention's survey and certification requirement with those contained in SOLAS and MARPOL 73/78. All three instruments require the issuing of certificates to show that requirements have been met and this has to be done by means of a survey which can involve the ship being out of service for several days. The harmonized system alleviates the problems caused by survey dates and intervals between surveys which don’t coincide, so that a ship should no longer have to go into port or repair yard for a survey required by one Convention shortly after doing the same thing in connection with another instrument.

The 1988 Load Lines Protocol provides for amendments to the Convention to be considered either by the Maritime Safety Committee or by a conference of Parties and to be adopted by a two-thirds majority of Parties to the Convention present and voting. Amendments enter into force six months after the deemed date of acceptance - which must be at least a year after the date of communication of adoption of amendments unless they are rejected by one-third of Parties. Usually, the date from adoption to deemed acceptance is two years.

The 1995 amendments concern the southern tropical zone off the coast of Australia and have been incorporated in the 2003 amendments. The amendments adopted in June 2003 and entered into force on 1 January 2005 (under tacit acceptance) to Annex B to the 1988 Load Lines Protocol (i.e. the International Convention on Load Lines, 1966, as modified by the Protocol of 1988 relating thereto) include a number of important revisions, in particular to regulations concerning: strength and intact stability of ships; definitions; superstructure and bulkheads; doors; position of hatchways, doorways and ventilators; hatchway coamings; hatch covers; machinery space opening; miscellaneous openings in freeboard and superstructure decks; cargo ports and other similar openings; spurling pipes and cable lockers; side scuttles; windows and skylights; calculation of freeing ports; protection of the crew and means of safe passage for crew; calculation of freeboard; sheer; minimum bow height and reserve buoyancy; and others.

The amendments, which amount to comprehensive revision of the technical regulations of the original Load Lines Convention, won’t affect the 1966 Load Line Convention and will only apply to approximately two-thirds of the world's fleet, i.e. to those ships flying the flags of States Party to the 1988 Load Line Protocol.

Types of propulsion and future trends

Today the world's mercantile fleet is powered primarily by diesel engines.

They have a low fuel consumption which gives added deadweight and cubic capacity for cargo. Factors influencing choice of propulsion unit embrace initial cost, required speed, cost and availability of fuel on the route used, cargo carrying capacity required, length of duration of voyage, and operational expenses. With the tendency for higher capacity ships, longer hauls, rising bunker costs, need for improved ship productivity, a surge in new builds and the need to make better and more productive use of available shipboard cargo and passenger space, it has presented a new opportunity for innovative ship space and operational cost productivity.

The twenty-first century has therefore brought a new resurgence of interest in marine propulsion. This has been driven by demand for the environmental friendliness and cost-effectiveness of marine transport. Hence the focus on the development of ships that can offer larger carrying capacities and higher speeds, lower capital and operating costs, increased maneuverability, reliability and safety and reduced environmental impact. Developments in technology in ships' power, propulsion and motion control systems are essential to meet many of the requirements outlined. Details are given below of recent developments to achieve this objective, which was initially driven by the growth in cruise tonnage.

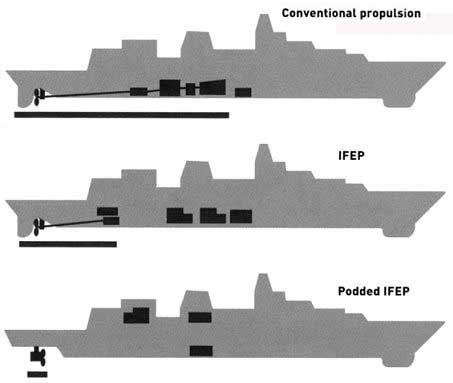

Fgr. 2 Layout of mechanical and electric propulsion systems

The need to make better utilization of ship capacity is the concept of the electric ship. Integrated Full Electric Propulsion (IFEP) lies at the heart of the electric ship. It offers lower running costs and sometimes reduced capital investment. The IFEP system involves the ship's propulsors being driven by electric motors alone, and the power for the electric motors is drawn from a unified electrical power system that also provides all the ship's electrical services. The power and propulsion systems are therefore integrated, because there is only one electrical power system where more conventionally there might have been two.

A major benefit of the IFEP is the layout flexibility offered by the elimination of the shaft tunnel housing the conventional propulsion unit ( Fgr. 2) as the prime mover is no longer coupled to the propulsors. It also provides more freedom for the prime mover location and thereby more effective use of available space. Further benefits of electrical propulsion - both in terms of internal layout and vessel maneuverability - can be realized through the use of podded propulsion, in which an electric motor driving a propeller is mounted in a 'pod' beneath the ship. An example of such an arrangement is the Mermaid pod.

A further benefit of the IFEP system is reduced fuel consumption, because the base load of the ship's service power demand can be used to ensure that the load on the prime movers never falls to inefficient levels. Cruise liners (--41) with relatively high service loads and operational profiles that frequently leave the propulsion system operating at fractional loads, offer an ideal platform for the IFEP system to generate fuel savings.

The next generation of marine prime movers is found in the advanced marine gas turbine. It incorporates both intercooler and recuperator heat exchangers, the combined effect of which is to allow 'waste' heat to be recovered from the gas turbine exhaust, providing significant fuel savings across the entire power range. These complex cycles have been adopted by Celebrity Cruises' Millennium class ships by the selection of a combined gas turbine and steam turbine electric drive system (COGES). In this situation a steam bottoming cycle rather than intercooling and recuperation has been chosen as an alternative solution to reduce fuel consumption through recovery of exhaust heat.

The LNG tonnage prime mover technology is changing, embracing duel fuel diesel engines (natural gas and MDO), heavy fuel diesel engines with a re-liquefaction plant, gas turbines - either single or combined cycle - and a combination of these ideas.

Maneuverability is a basic safety requirement for all vessels as well as being an intrinsic element of the operational capability in some applications.

The thruster system enables a more dynamic positioning of the vessel and widely used in ro-ro ships, cruise ships and types of offshore support ships.

Three types of thrusters exist. The azimuth thruster provides the main or auxiliary inboard or outboard propulsion and maneuvering with 360° turn, using controllable or fixed pitch propeller. The bow and stern thrusters are conventional turned thrusters with controllable or fixed pitch propellers.

A recent development in ship maneuverability realized through a combination of compact, powerful and efficient thrusters and control systems that manage them, is the podded propulsor. These provide a high level of maneuverability as found, for example, on the Millennium Ship (--18), which has a tactical diameter of less than two ships' lengths from an initial speed of 24 knots. Moreover, there are equally innovative designs for mechanical drive applications.

An example of a steerable mechanical thruster is the Azipull, which has a pulling propeller. This design has a very compact body, since it contains only gears and driveshaft rather than an electric motor. It’s ideal for the smaller ferries where electric propulsion is not an economic alternative. In tunnel thrusters, designs with two contra-rotating propellers, one on each side of the gear housing, improve the thrust output per tunnel diameter, which is of great importance for high-speed ships where they have been applied in order to decrease drag.

Noise and vibration are key areas of ongoing research. The major technical areas being addressed include: reduction of propulsor noise at source, isolation of propulsion machinery noise and control of intake and exhaust noise. This is focused on developing new comfort class requirements for cruise ships and fast ferries.

Types and methods of tonnage measurement

There are five main kinds of tonnage in use in shipping business. These are deadweight, cargo, displacement, gross and net tonnages, now superseded by the International Convention on Tonnage Measurement of Ships 1969 (2.4).

Deadweight tonnage (dwt) expresses the number of tons (of 2,240 lb) a vessel can transport of cargo, stores and bunker fuel. It’s the difference between the number of tons of water a vessel displaces 'light' and the number of tons of water a vessel displaces when submerged to her loadline.

Deadweight tonnage is used interchangeably with deadweight carrying capacity. A vessel's capacity for weight cargo is less than its total deadweight tonnage.

Cargo tonnage is expressed in terms of a weight or measurement. The weight ton in the United States and sometimes in the UK is the American short ton of 2,000 lb, or the English long ton of 2,240 lb. A measurement ton is usually 40 ft^3, but in some instances a larger number of cubic feet is taken for a ton. Most ocean package freight is taken at weight or measurement (W/M) ship's option. With the growth in use of the metric system the metric tonne of 1,000 kg or cubic meter is becoming more widely used. The freight ton is a mixture of weight and measurement tons and can lead to confusion in the collection and analysis of statistics.

Displacement of a vessel is the weight in tons of 2,240 lb of the ship and its contents. It’s the weight of water the ship displaces. Displacement light is the weight of the vessel without stores, bunker fuel or cargo. Displacement loaded is the weight of the vessel plus cargo, passengers, fuel and stores.

Gross tonnage applies to vessels, not to cargo. It’s determined by dividing by 100 the volume in cubic feet of the vessel's closed-in spaces, and is usually referred to as the gross registered tonnage (GRT). The spaces exempt from the measurement include light and air spaces; wheelhouse; galley; lavatories; stairways; houses enclosing deck machinery; hatchways to a maximum of 0.5% of the gross tonnage and open shelter deck. A vessel ton is 100 ft^3. It’s used as a basis for pilotage and dry-dock dues, and sometimes tonnage dues. Additionally, it’s employed for official statistical purposes, when comparing ships' sizes, and as a basis for Protection and Indemnity Club entries.

Net tonnage is a vessel's gross tonnage after deducting space occupied by crew accommodation, including facilities for the Master and officers; spaces used for navigation; boatswain's store room; water ballast and fresh water spaces, including forward and aft peak tanks, deep tanks provided only fitted with manholds and not employable for carriage of liquid cargo; propelling and machinery space which does not represent earning capacity of the ship. A vessel's net tonnage expresses the space available for the accommodation of passengers and stowage of cargo, and is usually referred to as net registered tonnage (NRT). A ton of cargo in most instances occupies less than 100 ft^3: hence the vessel's cargo tonnage may exceed its net tonnage, and indeed the tonnage of cargo carried is almost always greater than the gross tonnage. It’s the cubic capacity of all earning space, and it’s on this tonnage figure that most harbor dues and other charges are calculated. The aim of the average ship-owner is to achieve a low net tonnage consistent with a maximum cubic capacity for cargo and/or passengers.

The Suez and Panama tonnage regulations make it obligatory for vessels to be measured for tonnage if they require to use the canals.

International Convention on Tonnage Measurement of Ships 1969

The Convention, adopted by IMO in 1969, was the first successful attempt to introduce a universal tonnage measurement system. Previously, various systems were used to calculate the tonnage of merchant ships. Although all went back to the method devised by George Moorsom of the British Board of Trade in 1854, there were considerable differences between them and it was recognized that there was a great need for one single international system.

The Convention provides for gross and net tonnages, both of which are calculated independently. The rules apply to all ships built on or after 18 July 1982 - the date of entry into force - while ships built before that date were allowed to retain their existing tonnage for 12 years after entry into force or until 18 July 1994.

This phase-in period was intended to ensure that ships were given reasonable economic safeguards, since port and other dues are charged according to ship tonnage. At the same time, and as far as possible, the Convention was drafted to ensure that gross and net tonnages calculated under the new system did not differ too greatly from those calculated under previous methods.

The Convention meant a transition from the traditionally used terms gross register tons (grt) and net register tons (nrt) to gross tons (GT) and net tons (NT). Gross tonnage forms the basis for manning regulations, safety rules and registration fees. Both gross and net tonnages are used to calculate port dues. The gross tonnage is a function of the molded volume of all enclosed spaces of the ship. The net tonnage is produced by a formula which is a function of the molded volume of all cargo spaces of the ship. The net tonnage shall not be taken as less than 30% of the gross tonnage.

Today the tonnage measurement criterion is under continuous review as vessel design changes in numerous trades. In 2006 the IMO sub-committee agreed to amend the provisional formulas for reduced gross tonnage (GT) for open-top container ships prescribed in TM5/circ. 4, which was issued in 1993, to give preliminary IMO formula to be used for the calculation of gross tonnage for open-top container ships of up to 30,000 gross tonnage under the International Convention on Tonnage Measurement of Ships 1969.