An orchid, half a hemisphere removed from its birthplace in the Amazon jungle, flourishes in wintry Canada. Roses, larger than any rose has a right to be, blossom in time for Christmas. Fruits and vegetables are ready for the table on a schedule that is set by you, not the planet. Such feats of horticulture become routine once you establish a home greenhouse. You become the absolute ruler of a small and beautiful kingdom. With powers denied monarchs of the past, you can determine the conditions that govern the existence of the inhabitants of that domain. You have the last word on the supply of food, light, heat, air and water—all the requisites of plant life. With light and warmth under your control, soils precisely tailored, nutrients carefully calculated to foster plant health and pruning skillfully executed, you can create almost any plant world you could dream of.

Only recently has such grand command over growing plants been attainable. One of the earliest recorded controlled gardens was made for the Roman emperor Tiberius, who reigned from 14 to 37 A.D. Tiberius had a passion for cucumbers, in or out of sea son. To satisfy it in that pre-glass era, his gardeners set the plants in beds of dung enclosed in sheets of mica, a mineral that can be split into thin translucent plates, permitting sunlight to penetrate.

Other Roman horticulturists improved this technique. They built specularia, sheds with roofs of mica and ducts to carry heated water or air for temperature control. In these buildings grapes, peaches, roses, cucumbers and decorative plants were grown.

But as Rome declined, so did horticulture. Not until the Italian Renaissance were the ancient skills revived, as indicated by accounts of entertainments held in 1295 in the heated garden of Albert Magnus, a celebrated Paduan. By the 17th Century, the growing of orange trees had become the fashion, and structures called orangeries were set up to protect them from frost. In 1619 Solomon de Caus invented a covering of shutters that was placed over and around 340 orange trees in the municipal garden of Heidelberg each September, then removed at Easter. De Caus’s method was improved on by English gardeners at Beddington, where England’s first orange trees were grown. John Evelyn, the diarist and amateur horticulturist who is credited with coining the term greenhouse, reported in 1658 that in winter Beddington’s orange trees were protected by “a wooden tabernacle and stoves.”

But it was at the magnificent palace of Versailles that the orangerie reached its peak. The Versailles building had a solid roof and was heated by the sun’s rays streaming through tall windows with southern exposure. The central section of the orangerie was 508 feet long, 42 feet wide and 45 feet high. Eight years after the orangerie was completed, the superintendent of the royal garden designed a hothouse kept warm with stoves.

In a simple pit greenhouse with an A-frame roof a Massachusetts gardener produces an early-spring crop of azaleas, hyacinths and primroses, left; came/has, background and foreground; and primroses in the rear.

----

The fumes from stoves killed plants, so ingenious horticulturists reinvented the Roman method of heating with flues through which hot air flowed. By the time George I became king of England in 1714, the orangerie had become a greenhouse and he, like Tiberius, could indulge a taste for fresh cucumbers at Christmas time. And at St. Petersburg, between 1801 and 1805, Czar Alexander I erected three parallel greenhouses, each 700 feet long, connecting their ends with two more buildings the same length. This enormous structure was heated through Russian winters with wood-burning furnaces.

THE GREENHOUSE BOOM

But it was in 19th Century England that greenhouses became a craze. By now glass was being manufactured in quantity, and a prohibitive tax on it was repealed in 1845. Soon every wealthy family felt it should construct a greenhouse and add a gardener to the household staff. The aristocracy undertook breathtaking ventures, the most notable being the huge glass house built at the Duke of Devonshire’s Chatsworth estate. This Great Conservatory, with its soaring, gracefully arched glass walls and roof, was so large that a carriage and pair of horses could be driven through it.

By the middle of the 19th Century all of the techniques needed for successful Ultimate Greenhouse Gardening had been developed. But greenhouses, expensive to build and needing full-time gardeners to adjust heat, ventilation and moisture, remained luxuries for the elite. The drawbacks of costly construction and maintenance were not eliminated until after World War II. Then the introduction of mass-produced extruded-aluminum building components reduced the initial investment. And the invention of electrical devices to provide automatic 24-hour climate supervision eliminated the need for full-time gardeners. Today a variety of greenhouses are available, many of them built in modular form to permit easy expansion and designed for do-it-yourself assembly. By the late 1970s, it was possible to build a small one with automatic controls for less than one third the cost of a small car.

It’s the automatic controls more than economical structures that have made Ultimate Greenhouse Gardening feasible for the part-time gardener. The most important of these automatic assistants are thermostat devices that control heating and ventilation. With their help, a gardener can tend a small greenhouse in as little as 15 minutes a day, plus perhaps one weekend morning a month. To day’s challenge, in fact, is of a different dimension. The increasing costs of fuel for heat and light require maximum use of natural illumination and solar warmth. Such considerations as site selection, plant selection, insulation and windbreaks are acquiring an importance unknown until recently.

A number of experimental greenhouses that rely entirely on the sun for warmth have been built at research stations ( -- 34- 41), and several amateurs have devised their own systems. One gardener in Hyattsville, Maryland, set up a greenhouse with an insulated north wall two feet thick. From the top of the wall a glass roof sloped to the south almost to the ground. It included panels, painted flat black on one side and lined with aluminum foil on the other, that could be tilted to absorb or reflect the sun’s rays. Rimming each panel was tubing filled with water that was heated by the sun and piped into barrels under the greenhouse benches. This homemade system maintained a night temperature 30 degrees above the outside temperature without supplemental heat.

The need for energy conservation has also forced a reversal of the conventional advice for beginners. Until recently, the rule was:

Start with the largest greenhouse you can afford, larger than you think you will ever need. Today the wise course is to start with a small modular greenhouse that can be expanded later, but make the most efficient use possible of every available inch.

A greenhouse can be built to either of two basic designs— attached to a house, generally as a lean-to, or freestanding. The freestanding greenhouse has several advantages. If its long axis is placed in an east-west direction, plants in every corner receive maximum light. Its isolation simplifies pest control, permitting fumigation without danger of toxic fumes leaking into the dwelling. And it may offer a tax economy—in some communities freestanding greenhouses, considered outbuildings, are taxed at a lower rate than attached greenhouses, considered home improvements.

====

The freestanding prefabricated Victorian greenhouse pictured above was a popular model through the 1880s, ordered by scores of American gardeners. It measured 20 feet wide, 32 feet long and about 15 feet high at the peak and was constructed of steel with wooden supports for the glazing. The kit included a hooded doorway and cast iron finials and fleurs-de-lys to top off the gambrel roof. In 1880 the price was $2,000 unassembled; today it would cost at least $60,000.

====

Calculating the costs of heating

The expense of fuel is a major consideration in planning a greenhouse. The map and chart below provide data for calculating the cost of heating the aver age greenhouse over an average winter. For each of the geographic regions, figures are given for temperatures typical of home greenhouses and the three most commonly used fuels: gas, oil and electricity.

Three steps are involved in the computation. First, locate your home region on the map, which is divided into 12 zones of winter cold. Second, choose the column in the chart that shows the temperature you intend to maintain and the fuel you will use, and from it select the fuel-consumption factor for your zone. This gives fuel consumption per square foot of glass; the third step is to multiply this factor by the area, in square feet, of the total amount of glass in the greenhouse.

The result of your computation will be the season’s fuel consumption (in cubic feet of gas, gallons of oil or kilowatt-hours of electricity). Your local fuel supplier or utility company can then tell you how much that quantity of additional fuel will cost.

The figures in the chart are projected for an uninsulated greenhouse on a calm site. A windy site will increase fuel consumption as much as 20 percent; insulation can lower consumption up to 50 percent.

FUEL CONSUMPTION PER SQUARE FOOT OF GREENHOUSE GLASS

Greenhouse temperature; HEATING REQUIREMENT ZONES; Zone A - J; Based on data supplied by the U.S. National Climatic Center and the Atmospheric Environment Service of Canada

A detached greenhouse, however, is more expensive to erect, to heat and to connect to utility lines than the more popular attached type. The latter saves the cost of one wall, it can be served by heat, water and electricity lines extended from the house, and the house wall not only eliminates heat loss on that side but adds heat from radiation from the house interior.

Ready-to-assemble prefabricated greenhouses of either type are offered with wood or aluminum frames and with glazing of glass, flexible plastic (principally polyethylene) or rigid, corrugated fiberglass. Wood framing is less expensive than aluminum and loses less heat. It needs an annual washing to prevent algae from flourishing in the humid atmosphere, and it must be repainted about every three years with aluminum or white fungus-inhibiting paint. Even with that care, there is still danger of rot. As a result, most people choose aluminum. It never needs painting, and its strength permits framing members to be very thin, admitting maximum light and casting minimum shadows.

GLASS OR PLASTIC?

Glass is still the most widely used wall and roofing material. It’s the least expensive rigid transparent covering, and the most attractive. It’s very durable; after 50 years’ exposure to the elements, glass transmits almost as much light as it did when it was new. But of course it’s breakable.

Flexible plastics are transparent or translucent—if floppy and noisy in the wind—and inexpensive, and need only light framing for support, but they have a limited life span. Some must be replaced as often as twice a year because they deteriorate so quickly; other plastics, heavier (and much more expensive), may last up to 10 years.

Rigid fiberglass costs about as much as glass. It’s very strong and can be used in large pieces with fewer supporting frames than glass requires. Its resistance to breaking makes it useful in areas where hail is common, or under trees where falling limbs are a hazard. Some gardeners treasure fiberglass for the way it diffuses light, making it possible to grow plants that require sun alongside those needing shade. But fiberglass is translucent rather than transparent, and thus less attractive to many. Its surface eventually crackles, catching dust and reducing light transmission. And it’s a fire hazard unless treated with a flame retardant. Many gardeners use a roof of fiberglass, for strength and light diffusion, with walls of glass to let the beauty show through.

= = = = =

A greenhouse constructed from a kit

When Russell Morash, an enthusiastic outdoor gardener for more than 20 years, decided to add a greenhouse to his farmhouse in constructed Lexington, Massachusetts, he asked an expert neighbor for advice. Morash was the producer of the television program Crockett’s Victory Garden, hosted by the author of this book; the neighbor was Jim Crockett. At Crockett’s suggestion, he elected to build the largest greenhouse that his house and budget could accommodate. Also, he decided to build it himself, from a prefabricated kit.

The model he chose was 9¾ feet wide and 21 feet long, a glass and aluminum lean-to with a curving eave. He ordered only one extra: motorized vents in the roof for summer cooling. The manufacturer shipped the 50-page instruction manual ahead of the cartons of building materials. “That was fortunate,” said Morash; the mason hired to prepare the foundation never appeared. So Morash did the masonry for the project, too.

Although not too sure of himself as a mason, Morash had done a good deal of carpentry, as well as the plumbing, wiring and heating alterations for his renovated farmhouse. When he started the greenhouse project, he considered himself “somewhat skilled.” As the weeks passed, however, he began to doubt some of his abilities: Didn’t it make more sense to do step 11 after step 29? After he assembled the eight sections of eave glass, only to find they were off by 1 inch—too much—Morash swallowed his pride and called in a professional greenhouse builder who in six hours “got me back on the right track.” An electrician friend helped with the wiring, a plumber installed the 40 feet of radiant-heating con- vectors purchased at a scrap yard, and a young neighbor pitched in for three days to help with the actual assembly.

Morash worked 12 weekends in all. His investment in the pre fabricated greenhouse, additional materials and outside labor came to less than the price of a small car. He later estimated that heating his greenhouse—the biggest operating expense—would cost him “only about a third of what it would cost to belong to a golf club.”

In his greenhouse, Russell Morash waters a calamondin orange. Begonias, geraniums, cyclamen, narcissus and a Boston fern 4 feet wide defy 2½ feet of snow outside.

= = = =

Assembling a prefab lean-to

Morash lays the first of four courses of concrete blocks to form

a foundation 2 feet 8 inches high. The blocks rest on a 3½-foot concrete

footing, and enclose a gravel floor 3 inches deep. Excess water drains

through gravel into the ground rather than forming puddles on the greenhouse

floor. The gravel’s surface is 7 inches below the sill of the sliding

glass patio doors, to keep soil and water from washing into the adjacent

living room.

With seven of the nine rafters in place (two more lie near the

doorway), Morash inspects the greenhouse-to-be.

Morash uses a level to check the vertical alignment of each successive

course of concrete blocks. He lines up the level with strings stretched

between the posts marking the foundation’s outer edge.

Sections of aluminum sill to support the framework are joined

and laid on top of the foundation. Wooden blocks and wedges level the

sill, and remain until the superstructure is 15c---assembled. Then the

sill is set into mortar.

Using a power saw, Morash cuts a slot 4 inches wide and the height

of the greenhouse in the house wall. He will insert a 2-by-4 into the

slot and fasten the end rafter to it.

A 2-by-8 is inserted in a slot cut horizontally in the clapboards,

just above the greenhouse. It will support a 3-foot-wide plywood deck

that will run the length of the greenhouse and will protect the glass

from ice that may fall off the roof above.

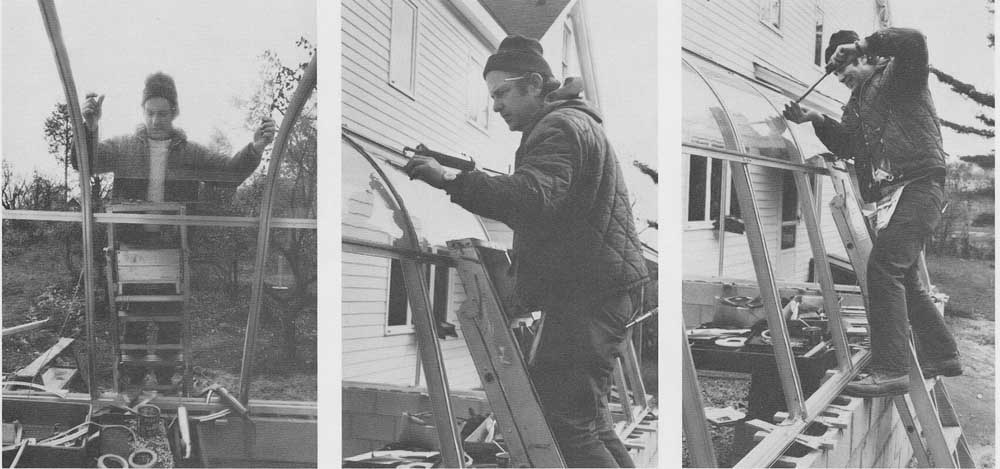

(l) Morash eases a curved section of the glass roof onto the aluminum rafters. Strips of foam tape placed along the metal ribs cushion the glass. (m) Using a caulking gun, Morash applies a glazing compound to the edges where glass meets metal, sealing them and anchoring the glass in place. (r) Metal caps are screwed into place along the exterior of all the rafters to complete securing the glass and waterproofing the structure.

(top) With all the sections in place, Morash again checks the level

of the sill before fastening it into its permanent position. The interior

of the greenhouse is large enough to hold two plant benches, each 30

inches wide, with more than 30 running feet of growing space. There is

also room for a potting bench and two chairs. (above) Morash screws rust-resistant

angles onto a section of the redwood bench that will be set along the outer

foundation wall; another bench will be put at the right of the living-room

door. By building the benches, he cut the cost in half and got equipment that

suited his own needs.

= = = = =

Whatever the type of construction, most greenhouses are set on foundations. In a mild climate, it’s feasible to set a portable greenhouse on a sill anchored to the ground with tie rods. But in areas where the ground freezes, the foundation footings need to be made of poured concrete extending as far below frost line as the local building code specifies. The foundation wall, generally of concrete block, is best extended aboveground to the height of a greenhouse bench, as a heat-conservation measure. It can be insulated on the inside with sheets of rigid plastic foam set between wood furring strips and covered with gypsum wallboard for fire safety. The top of this wall must be level and the corners square; otherwise the intractable materials of the greenhouse framing won’t fit snugly. Even with a close fit, the joint between greenhouse and foundation must be sealed with a mortar grouting.

CHOOSING A LOCATION

The choice of a greenhouse depends partly on where you plan to put it. It ought to have sunlight, of course, a requirement easier to satisfy for the freestanding type than for the attached one, which ideally should nestle against the south side of the house. If such a location is impossible, you can still plant species that manage on little light—many attractive foliage plants need no direct sunlight— and install fluorescent lamps for supplemental illumination. Before settling on the site of either type of greenhouse, however, take a full season to study the changes in the sun’s position. You want all the winter light inside your greenhouse that you can get. You will find that some sites are very bright in summer, but at the same time of day in winter are shaded by buildings or trees. For a freestanding greenhouse, the best possible site generally will be in an open area with the long east-west axis tilted perhaps 10 degreeson the compass, northeast to southwest.

If existing trees cast too much shade, prune them, or if necessary, remove them. But keep in mind that some shade may be desirable in midsummer, depending on what you want to grow, and deciduous trees cast little shade in winter.

On an unobstructed site, winds may make your greenhouse costly to heat; heat loss from a glass greenhouse in a 15-mile-an- hour wind is double that in still air. This problem can be overcome by planting a windbreak to create an obstruction that slows the wind’s forward velocity, deflecting as much as half of the air stream up and over the greenhouse. For the best windbreak, use evergreens as tall as the greenhouse, with branches to the ground, planted in a staggered row 15 to 25 feet from the green house and located so that it will block the prevailing winter wind. If the property is not large enough to permit such a living windbreak, build a fence instead; commercial snow fence works well.

When you have decided what kind of greenhouse you will build and where you will put it, you can turn your thoughts to the fixtures that will control its climate. The four factors that make up the greenhouse climate—heat, air, water and light—will determine what you can grow there. Horticulturists divide greenhouse plants into three groups according to the night temperatures they require —cool (45 to 50 degrees), intermediate (50° to 60°) and warm (60° to 70°). For economical operation, most home greenhouses are set up for cool-temperature plants. But because the temperature is seldom entirely uniform you can generally find some zones near the ceiling or house wall of a cool greenhouse to support a few warm- and intermediate-greenhouse plants.

SYSTEMS FOR HEATING

The simplest and least expensive way to heat an attached greenhouse is to extend pipes, ducts or wiring from your home heating system; most homes have unused capacity. However, adding a special thermostat to control the greenhouse zone separately from the house may prove complicated. For this reason you may need an independent thermostatically controlled heater, which will be required in any case if your home system does not have sufficient capacity or if you are building a freestanding greenhouse some distance away. Which system—gas, oil or electricity—to in stall will depend mainly on the availability of fuel and its relative cost, but simple electric heaters are generally suited to small attached greenhouses.

Ventilators are as important as the heating system to cool the greenhouse and supply the plants with fresh air. Movable panels have been used to provide ventilation just about as long as there have been greenhouses. In the past, however, these panels, in stalled at the highest point in the greenhouse walls, were opened and closed by hand. This required the nearly constant presence of someone to adjust the ventilators. In a modern system, a thermo static control operates motors to open and close the ventilators as the inside temperature rises and falls. Both the ventilator thermo stat and the heater thermostat should be installed at bench level, where most of the plants will grow, rather than at more convenient eye level. In another automatic ventilator system, a fan moves air in at a low level and out near the roof as needed to keep the inside temperature the same as it’s outdoors.

THE EMERGENCY ALARM

Because automatic devices sometimes fail (and power black outs occur), you need a temperature alarm to warn you against fatal temperature plunges in winter or soaring heat, equally disastrous, in summer. This warning device is called a maximum-minimum alarm. Independently powered by batteries, it rings a bell in the house when the greenhouse temperature is too low or too high, summoning you to save your plants.

Automatic equipment controls watering in commercial green houses, but most home gardeners, growing a few examples of many kinds of plants, each with its own moisture requirement, perform this chore manually. You do need water outlets, both hot and cold, with a mixing faucet threaded for a garden hose. Mixing provides the tepid water valuable in winter, when cold water can harm plants. Also useful is a water breaker, a device that lets you control the force of the stream from a hose.

= == = =

SIX WAYS TO SAVE HEAT

1. The best way to prevent heat loss through the glass of greenhouse walls is with an insulating layer of air. This can be provided by applying a sheet of bubble plastic (detail) to the inside of the glass. Wet the smooth side and press it to the glass; it will stick by itself. Alternatively, tape a sheet of plastic film to the interior frame.

2. To prevent heat loss through an aboveground foundation, build a wall of masonry block outside the foundation and fill the space between the two with dirt—or better yet, with foamed plastic insulating boards.

3. A windbreak of trees helps to protect the greenhouse from blasts of cold air. The ideal shield is staggered rows of low-branching evergreens as high as the greenhouse, planted 15 to 25 feet away in the path of the prevailing winter winds. The windbreak should be wide enough to deflect turbulent winds from the greenhouse ends.

4. Place a potting shed at the north end of the greenhouse, which gets the least sun, creating in effect a vestibule to cut down heat loss. Paint the interior shed wall white to reflect light into the greenhouse.

5. Instead of setting the greenhouse glass atop an exposed foundation wall, sink the foundation below ground, making a partially sunken structure with less outside exposure. You can also line the foundation with rigid foam insulation attached with mastic and covered with gypsum wallboard (the foam is otherwise a fire risk).

6. Add free heat to the greenhouse for winter nights with homemade solar energy collectors. Fill black metal 5-gallon paint cans with water and place them under the planting benches along a south wall; the water will store heat during the day and release it at night.

= = = =

HOW TO MAKE A PLANTING BENCH

For a basic bench frame, construct two leg sections from eight 1-by-4s, cut to the length and width desired. Nail them together with rust-proof galvanized nails, and join the leg sections with two horizontal 2-by-2s.

Using the frame, make a bench for potted plants by laying 1-by-4s across the top, spacing them about ½-inch apart to permit drainage. Two 1 -by-6s, added below, make a shelf for plants that need shade.

Convert a slatted bench into a planting bed for cut flowers by fitting it with side boards 6 to 8 inches high. Cover the slats with a layer of chopped straw or a piece of burlap; then fill the bench with potting soil.

= = = = =

BENCHES AND WALKWAYS

A few other simple pieces of equipment complete the green house. Benches (above), to support pots of plants at a comfortable working height, or to be filled with soil like oversized garden flats, are traditionally built of wood that is rot and moisture resistant, such as redwood, cypress or cedar, but they can be built less expensively of pine treated with a wood preservative such as cop per naphthenate that does not harm plants. Their support surfaces are slats, cement-asbestos panels (which are impervious to rot), or the wire mesh called hardware cloth, which is especially suited to orchid growing because it allows easy circulation of air and water vapor. Since greenhouse floors are almost constantly damp, they need walkways made of wooden slats or of brick or flagstone laid in sand over an earthen floor.

One of the most essential elements in a greenhouse—and one of the oddest, considering that a greenhouse is designed mainly to provide maximum light—is some form of shade. In summer overly bright illumination may burn leaves and dry out plants. Flexible shade can be provided by a roller blind installed on top of the glass so it can be rolled up and down with a cord and pulley, or by a kind of venetian blind of aluminum strips held in slotted tracks. For temporary shade in a small area, you can tape muslin to the greenhouse rafters over the plants that need protection. Another method of shading is to apply green plastic sheets to the inside of each pane; these can be peeled off as the days grow short and saved for the following year. Or, for special flair, you can hang old, framed stained-glass windows strategically to filter the sun’s rays. But the easiest way to dim sunlight is to coat the glass panes with any of several commercial compounds made for the purpose. One such compound is cleverly formulated to be opaque on sunny days, translucent when the sky is cloudy.

One greenhouse gardener who had difficulty shading the top panes of his roof made his own shading compound of hydrated lime, applied with a sponge to the inside of the glass. At summer’s end he simply washed it off with a hose. His formula: 5 pounds of hydrated lime, 8 ounces of green poster paint and just enough water to make a thick, no-drip green whitewash.

= = = =

INEXPENSIVE SHADING TECHNIQUES

To reduce the amount of light entering a greenhouse, cut colored plastic film to fit each pane. Wet the glass and smooth the plastic against it with a squeegee. The depth of color in the plastic determines the light reduction.

Hang woven shade cloth, available at greenhouse supply centers, on hooks mounted on the rafters. The closeness of the mesh determines the density of the shade, usually 45 to 65 per cent light reduction.

To shade the greenhouse in summer, paint the outside with a shading compound, sold at garden centers. Rain will slowly wear it away so that by fall most of it will be gone, admitting more light when the plants need it.

Articles in this Guide are based on now-classic Time-Life Encyclopedia of Gardening Series from the 1970s ... a timeless series, some titles of which are still available in libraries and bookstores... see our Amazon Store for purchasing options.