AMAZON multi-meters discounts AMAZON oscilloscope discounts

11. Use of External Services

The retention of staff and facilities for analysis and test and the maintenance of procedures and training can only be cost-effective when the products involve fairly intensive and continuous development. In advanced product areas such as defense and aerospace, electronic instrumentation, control and communications, vehicles, and for large manufacturers of less advanced products such as domestic equipment and less complex industrial equipment, a dedicated reliability engineering organization is necessary, even if it’s not a contractual requirement. Smaller companies with less involvement in risk-type development may have as great a need for reliability engineering expertise, but not on a continuous basis. External reliability engineering services can fulfill the requirements of smaller companies by providing the specialist support and facilities when needed.

Reliability engineering consultants and specialist test establishments can often be useful to larger companies also, in support of internal staff and facilities. Since they are engaged full time across a number of different types of project they should be considered whenever new problems arise. However, they should be selected carefully and integrated in the project team.

Small companies should also be prepared to seek the help of their major customers when appropriate. This cooperative approach benefit s both supplier and customer.

12 Customer Management of Reliability

When a product is being developed under a development contract, as is often the case with military and other public purchasing, the purchasing organization plays an important role in the reliability and quality program. As has been shown, such organizations often produce standards for application to development con tracts, covering topics such as reliability program management, design analysis methods and test methods.

Are liability manager should be assigned to each project, reporting to the project manager. Project reliability management by a centralized reliability department, not responsible to the project manager, is likely to result in lower effectiveness. A central reliability department is necessary to provide general standards, training and advice, but should not be relied upon to manage reliability programs across a range of projects. If there is a tendency for this to happen it’s usually an indication that inadequate standards or training have been provided for project staff, and these problems should then be corrected.

The prime responsibilities of the purchaser in a development reliability program are to:

- 1 Specify the reliability requirements.

- 2 Specify the standards and methods to be used.

- 3 Set up the financial and contractual framework.

- 4 Specify the reporting requirements.

- 5 Monitor contract performance.

Proper attention to the first three items above should ensure that the supplier is effectively directed and motivated, so that the purchaser has visibility of activities and progress without having to become too deeply involved.

It’s usually necessary to negotiate aspects of the specification and contract. During the specification and negotiation phases it’s usual for a central reliability organization to be involved, since it’s important that uniform approaches are applied. Specification tailoring (Section 10.1) is now a common feature of development contracting and this is an important aspect in the negotiation phase, requiring experience and knowledge of the situation of other contracts being operated or negotiated.

The supplier's reliability plan, prepared in response to the purchaser's requirement, should also be reviewed by the central organization, particularly for major contracts.

The contractor's reporting tasks are often specified in the statement of work (SOW). These usually include:

- 1 The reliability plan.

- 2 Design analysis reports and updates (prediction, FMECA, FTA, etc.).

- 3 Test reports.

Reporting should be limited to what would be useful for monitoring performance. For example, a 50-page FMECA report, tabulating every failure mode in a system, is unlikely to be useful to the purchaser. Therefore the statement of work should specify the content, format and size of reports. The detailed analyses leading to the reports should be available for specific queries or for audit.

The purchaser should observe the supplier's design reviews. Some large organizations assign staff to supplier's premises, to monitor development and to advise on problems such as interpretation of specifications.

This can be very useful on major projects such as aircraft, ships and plant, particularly if the assigned staff are subsequently involved in operation and maintenance of the system.

There are many purchasers of equipment who don’t specify complete systems or let total development contracts. Also, many such purchasers don’t have their own reliability standards. Nevertheless, they can usually influence the reliability and availability of equipment they buy. We will use an example to illustrate how a typical purchaser might do this.

Ex. 2:

A medium-sized food-processing plant is being planned by a small group of entrepreneurs. Amongst other things, the plant will consist of:

- 1 Two large continuous-feed ovens, which are catalogue items but have some modifications added by the supplier, to the purchaser's specification. These are the most expensive items in the plant. There is only one potential supplier.

- 2 A conveyor feed system.

- 3 Several standard machines (flakers, packaging machines, etc.).

- 4 A process control system, operated by a central computer, for which both the hardware and software will be provided by a specialist supplier to the purchaser's specification.

The major installations except item 4 will be designed and fit ted by a specialist contractor; the process control system integration will be handled by the purchasers. The plant must comply with the statutory safety standards, and the group is keen that both safety and plant availability are maximized. What should they do to ensure this?

The first step is to ensure that every supplier has, as far as can be ascertained, a good reputation for reliability and service. The purchasers should survey the range of equipment available, and if possible obtain information on reliability and service from other users. Equipment and supplier selection should be based to a large extent on these factors.

For the standard machines, the warranties provided should be studied. Since plant availability is important, the purchasers should attempt to negotiate service agreements which will guarantee up-time, For example for guaranteed repair or replacement within 24 hours. If this is not practicable, they should consider, in conjunction with the supplier, what spares they should hold.

Since the ovens are critical items and are being modified, the purchasers should ensure that the supplier's normal warranty applies, and service support should be guaranteed as for the standard items. They should consider negotiating an extended warranty for these items.

The process control system, being a totally new development (except for the computer), should be very carefully specified, with particular attention given to reliability, safety and maintainability, as described below.

Key features of the specification and contract should be:

- 1 Definition of safety-critical failure effects.

- 2 Definition of operational failure effects.

- 3 Validation of correct operation when installed.

- 4 Guaranteed support for hardware and software, covering all repairs and corrections found to be necessary.

- 5 Clear, comprehensive documentation (test, operating and maintenance instructions, program listings, program notes).

For this development work, the purchasers should consider invoking appropriate standards in the contract, such as BS 5760. For example, FMECA and FTA could be very valuable for this system, and the software development should be properly controlled and documented. The supplier should be required to show how those aspects of the specification and contract will be addressed, to ensure that the requirements are fully understood. A suitable consultant engineer might be employed to specify and manage this effort.

The installation contract should also cover reliability, safety and maintainability, and service.

During commissioning, all operating modes should be tested. Safety aspects should be particularly covered, by simulating as far as possible all safety-critical failure modes.

The purchasers should formulate a maintenance plan, based upon the guidelines given in Section 16. A consultant engineer might be employed for this work also.

Finally, the purchasers should insure themselves against the risks. They should use the record of careful risk control during development to negotiate favorable terms with their insurers.

13 Selecting and Training for Reliability

Within the reliability organization, staff are required who are familiar with the product (its design, manufacture and test) and with reliability engineering techniques. Therefore the same qualifications and experience as apply to the other engineering departments should be represented within the reliability organization. The objective should be to create a balanced organization, in which some of the staff are drawn from product engineering departments and given the necessary reliability training, and the others are specialists in the reliability engineering techniques who should receive training to familiarize them with the product. Reliability engineering should be included as part of the normal engineering staff rotation for career development purposes. By having a balanced department, and engineers in other departments with experience of reliability engineering, the reliability effort will have credibility and will make the most effective contribution.

Reliability engineers need not necessarily be specialists in particular disciplines, such as electronic circuit design or metallurgy. Rather, a more widely based experience and sufficient knowledge to understand the specialists' problems is appropriate. The reliability engineer's task is not to solve design or production problems but to help to prevent them, and to ascertain causes of failure. He or she must, therefore, be a communicator, competent to participate with the engineering specialists in the team and able to demonstrate the value and relevance of the reliability methods applied. Experience and knowledge of the product, including manufacturing, operation and maintenance, enables the reliability engineer to contribute effectively and with credibility. Therefore engineers with backgrounds in areas such as test, product support, and user maintenance should be short-listed for reliability engineering positions.

Since reliability engineering and quality control have much in common, quality control work often provides suitable experience from which to draw, provided that the quality control (QC) experience has been deeper than the traditional test and inspection approach, with no design or development involvement. For those in the reliability organization providing data analysis and statistical engineering support, specialist training is relatively more important than product familiarity.

The qualities required of the reliability engineering staff obviously are equally relevant for the head of the reliability function. Since reliability engineering should involve interfaces with several other functions, including such non-engineering areas as marketing and finance, this position should not be viewed as the end of the line for moderately competent engineers, but rather as one in which potential top management staff can develop general talents and further insight into the overall business, as well as providing further reliability awareness at higher levels in due course.

Specialists in statistics and lately six-sigma black belt masters can make a significant contribution to the integrated reliability effort. Such skills are needed for design of experiments and analysis of data, and not many engineers are suitably trained and experienced. It’s important that statistics experts working in engineering are made aware of the 'noisy' nature of the statistics generated, as described in earlier sections. They should be taught the main engineering and scientific principles of the problems being addressed, and integrated into the engineering teams. They also have an important role to play in training engineers to understand and use the appropriate statistical methods.

Whilst selection and training of reliability people is important, it’s also necessary to train and motivate all other members of the engineering team (design, test, production, etc.). Since product failures are nearly always due to human shortcomings, in terms of lack of knowledge, skill or effort, all involved with the product must be trained so that the chances of such failures are minimized. For example, if electronics designers understand electromagnetic interference as it affects their system they are less likely to provide inadequate protection, and test engineers who understand variation will conduct more searching tests. Therefore the reliability training effort must be related to the whole team, and not just to the reliability specialists.

Despite its importance, quality and reliability education is paradoxically lacking in today's engineering curricula. Few engineering schools offer degree programs or even a sufficient variety of courses in quality or reliability methods. Therefore, the majority of the quality and reliability practitioners receive their professional training from their colleagues as 'on the job' training.

14 Organization for Reliability

Because several different activities contribute to the reliability of a product it’s difficult to be categorical about the optimum organization to ensure effective management of reliability. Reliability is affected by design, development, production quality control, control of suppliers and subcontractors, and maintenance.

These activities need to be coordinated, and the resources applied to them must be related to the requirements of the product. The requirements may be determined by a market assessment, by warranty cost considerations or by the customer. The amount of customer involvement in the reliability effort varies. The military and other public organizations often stipulate the activities required in detail, and demand access to design data, test records and other information, particularly when the procurement agency funds the development. At the other extreme, domestic customers are not involved in any way directly with the development and production program. Different activities will have greater or lesser importance depending on whether the product involves innovative or complex design, or is simple and based upon considerable experience. The reliability effort also varies as the project moves through the development, production and in-use phases, so that the design department will be very much involved to begin with, but later the emphasis will shift to the production, quality control and maintenance functions. However, the design must take account of production, test and maintenance, so these downstream activities must be considered by the specification writers and designers.

Since the knowledge, skills and techniques required for the reliability engineering tasks are essentially the same as those required for safety analysis and for maintainability engineering, it’s logical and effective to combine these responsibilities in the same department or project team.

Reliability management must be integrated with other project management functions, to ensure that re liability is given the appropriate attention and resources in relation to all the other project requirements and constraints.

Two main forms of reliability organization have evolved. These are described below.

===

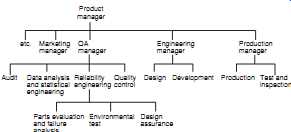

FIG. 5 QA based reliability organization.

Product manager etc. Marketing manager QA manager Engineering manager Production manager Data analysis and statistical engineering Audit Reliability engineering Quality control Design Development Production Test and inspection Parts evaluation and failure analysis Environmental test Design assurance

===

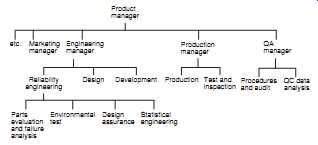

FIG. 6 Engineering based reliability organization.

Product manager etc. Marketing manager QA manager Engineering manager Production manager Parts evaluation and failure analysis Environmental test Design assurance Statistical engineering Reliability engineering Design Development Production Test and inspection Procedures and audit QC data analysis.

===

14.1 Quality Assurance Based Organization

The quality assurance (QA) based organization places responsibility for reliability with QA management, which then controls the 'quality' of design, maintenance, and so on, as well as of production. This organizational form is based upon the definition of quality as the totality of features which bear on a product's ability to satisfy the requirement. This is the formal European definition of quality. Consequently, in Europe the QA department or project QA manager is often responsible for all aspects of product reliability. FIG. 5 shows a typical organization. The reliability engineering team interfaces mainly with the engineering departments, while quality control is mainly concerned with production. However, there is close coordination of reliability engineering and quality control, and shared functions: For example a common failure data collection and analysis system can be operated, covering development, production and in-use. The QA department then provides the feedback loop from in-use experience to future design and production. This form of organization is used by most manufacturers of commercial and domestic products.

14.2 Engineering Based Organization

In the engineering based organization, reliability is made the responsibility of the engineering manager. The QA (or quality control) manager is responsible only for controlling production quality and may report direct to the product manager or to the production manager. FIG. 6 shows a typical organization. This type of organization is more common in the United States.

14.3 Comparison of Types of Organization

The QA based organization for reliability allows easier integration of some tasks that are common to design, development and production. The ability to operate a common failure data system has been mentioned. In addition, the statistical methods used to design experiments and to analyze development test and production failure data are the same, as is much of the test equipment and test methods. For example, the environmental test equipment used to perform reliability tests in development might be the same as that used for production reliability acceptance tests and screening. Engineers with experience or qualifications in QA are often familiar with reliability engineering methods, as their professional associations on both sides of the Atlantic include reliability in their areas of interest. However, for products or systems where a considerable amount of innovative design is required, the engineering based organization has advantages, since more of the reliability effort will have to be directed towards design assurance, such as stress analysis, design review and development testing.

The main question to be addressed in deciding upon which type of organization should be adopted is whether the split of responsibility for reliability activities inherent in the engineering based organization can be justified in relation to the amount of reliability effort considered necessary during design and development.

In fact the type of organization adopted is much less important than the need to ensure integrated management of the reliability program. So long as the engineers performing reliability activities are properly absorbed into the project team, and report to the same manager as the engineers responsible for other performance aspects, functional departmental loyalties are of secondary importance. To ensure an integrated team approach reliability engineers should be attached to and work alongside the design and other staff directly involved with the project. These engineers should have access to the departmental supporting services, such as data analysis and component evaluation, but their prime responsibility should be to the project.

15 Reliability Capability and Maturity of an Organization

The ability to evaluate how well an organization can handle reliability aspects of the design, development and manufacturing processes (i.e. have the required tool sets, expertise, resources, and the reliability-focused priorities) requires objective criteria. However industry was lacking methods to quantify the capability of an organization to develop and build reliable products. This problem was addressed by developing standardized measurement criteria for assessing and quantifying the reliability capability of an organization. The evaluation methods for organizational reliability processes are reliability capability and reliability maturity assessments.

Sometimes those terms are used interchangeably in regards to an organization and its reliability processes, however there are some subtle differences in the ways they are evaluated.

15.1 Reliability Capability

Reliability capability is a measure of the practices within an organization that contribute to the reliability of the final product and the effectiveness of these practices in meeting the reliability requirements of customers. In order to produce industry-accepted criteria for assessing and quantifying the reliability capability IEEE has developed a standard IEEE Std 1624. Standardized and objective measurement criteria define the eight key reliability practices and their inputs, activities, and outputs.

These key reliability practices are the following:

- - Reliability requirements and planning.

- - Training and development.

- - Reliability analysis.

- - Reliability testing.

- - Supply chain management.

- - Failure data tracking and analysis.

- - Verification and validation.

- - Reliability improvements.

For each of these eight categories the standard defines the inputs, the required activities and the expected outputs. Each of the reliability practices are individually assessed (levels 1-5) with reference to the specified set of activities required to obtain a specific capability level. These ?ve levels represent the metrics or measures of the organizational reliability capability and reflect stages in the evolutionary transition of that practice.

Five reliability capability levels of IEEE Std 1624 can be associated with ?ve reliability maturity stages discussed in Silverman (2010). Those levels are: 1-Uncertainty; 2-Awakening, 3-Enlightenment, 4-Wisdom, 5-Certainty, which verbally characterize the levels of reliability maturity of an organization.

Although IEEE Std 1624 was developed for the electronics industry, it can be used for self-assessment by organizations or for supplier/customer relationship development in virtually any industry with no or minor adjustments.

15.2 Reliability Maturity

In 2004 the Automotive Industry Action Group (AIAG) published Reliability Methods Guideline (AIAG, 2004) containing 45 key reliability tools, some of which are covered in this section and the rest are in the other sections. This activity was later expanded to develop an organizational capabilities maturity concept.

The AIAG workgroup produced a reliability maturity assessment (RMA) manual that contains nine reliability categories:

A Reliability planning.

B Design for reliability.

C Reliability prediction and modeling.

D Reliability of mechanical components and systems.

E Statistical concepts.

F Failure reporting and analysis.

G Analyzing reliability data.

H Reliability testing.

I Reliability in manufacturing.

Although the RMA category B is called 'Design for reliability', it contains only a subset of reliability tools discussed in Section 7. Each of the nine categories above included the appropriate set of reliability tools from 'Reliability Methods Guideline'. For each reliability tool within the category the RMA suggested scoring criteria.

After assessment of the individual scores they are combined by categories resulting in a rating based on the percentage of the maximum available score for each category. The scores for each category can be combined based on the weighted averages to obtain the total score for an organization. Score above 60% is classified as B-level and above 80% is A-level. Scores below 60% are considered as reliability deficiencies.

Both reliability maturity and capability assessments provide important tools to evaluate the organizational capability from a product reliability perspective. The assessments can also be used for supplier selection process and can be conducted as self-assessment and/or 2nd or 3rd party assessment. These activities also help to identify gaps and weaknesses in the reliability process and can be instrumental in developing an efficient product and process improvement plan.

16 Managing Production Quality

The production department should have ultimate responsibility for the manufacturing quality of the product. It’s often said that quality cannot be 'inspected in' or 'tested in' to a product. The QA department is responsible for assessing the quality of production but not for the operations which determine quality. QA thus has the same relationship to production as reliability engineering has to design and development.

In much modern production, inspection and test operations have become integrated with production operations. For example, in operator control of computerized machine tools the machine operator might carry out workpiece gauging and machine calibration. Also, the costs of inspection and test can be considered to be production costs, particularly when it’s not practicable to separate the functions or when, as in electronics production, the test policy can have a great impact on production costs. For these reasons, there is a trend towards routine inspection and test work being made the responsibility of production, with QA providing support services such as patrol inspection, and possibly final inspection, as well as training, calibration, and so on. Determination of inspection and test policy methods and staffing should then be primarily a production responsibility, with QA in a supporting role, providing advice and ensuring that quality standards will be met.

This approach to modern quality results in much smaller QA departments than under the older system whereby production produced and passed the products to QA for inspection and test at each stage. It also obviously reduces the total cost of production (production cost plus inspection and test costs). Motivation for quality is enhanced and QA staff are better placed to contribute positively, rather than acting primarily in a policing role. The quality circles movement has also heavily influenced this trend; quality circles could not operate effectively under the old approach.

The QA department should be responsible for:

- 1 Setting production quality criteria.

- 2 Monitoring production quality performance and costs.

- 3 QA training (SPC, motivational, etc.).

- 4 Specialist facilities and services.

- 5 Quality audit and registration.

These will be discussed in turn.

16.1 Setting Production Quality Criteria

The quality manager must decide the production quality criteria (such as tolerances, yields, etc.) to be met.

These might have been set by the customer, as is often the case in commercial as well as in defense equipment manufacture, in which case the quality manager is the interface with the customer on production quality matters. Quality criteria apply to the finished product, to production processes and to bought-in materials and components. Therefore the quality manager should determine, or approve, the final inspection and test methods and criteria to ensure conformance. He or she should also determine such details as quality levels of components, quality control of suppliers and calibration requirements for test and measuring equipment.

16.2 Monitoring Production Quality Performance and Costs

The quality manager must be satisfied that the quality objectives are being attained or that action is being taken to ensure this. These include quality cost objectives, as described earlier. QA staff should therefore oversee and monitor functions such as failure reporting and final conformance inspection and test. The QA department should prepare or approve quality performance and cost reports, and should monitor and assist with problem-solving. The methods described in Sections 11 and 15 are particularly appropriate for this task.

16.3 Quality Training

The quality manager is responsible for all quality control training. This is particularly important in training for operator control and quality circles, since all production people must understand and apply basic quality concepts such as simple SPC and data analysis.

16.4 Specialist Facilities and Services

The quality department provides facilities such as calibration services and records, vendor appraisal, component and material assessment, and data collection and analysis.

The assessment facilities used for testing components and materials so that their use can be approved are also the best services to use for failure investigation, since this makes the optimum use of expensive resources such as spectroscopic analysis equipment and scanning electron microscopes, and the associated specialist staff.

The joint use of these services in support of development, manufacturing and in-service is best achieved by operating an integrated approach to quality and reliability engineering.

16.5 Quality Audit and Registration

Quality audit is an independent appraisal of all of the operations, processes and management activities that can affect the quality of a product or service. The objective is to ensure that procedures are effective, that they are understood and that they are being followed.

Quality audit, like financial audit, requires both internal and external audit. Internal audit is a continuing function whereby QA staff review the operations and controls, and report on discrepancies. External audit is performed by the third party assessors on a regular schedule, typically annually, in order to obtain and retain registration to quality standards, in particular ISO9000.

An effective quality audit should include review of all design, development and production, test and inspection operations, as well as associated procedures and documentation. An important aspect is the assurance that personnel know and understand their role in the quality system, including relevant procedures and responsibilities.

The quality manager's responsibility for audit includes all internal audit, for ensuring that the company is successful in customer or third party audits and for quality auditing of suppliers. Preparation for external audit and being subjected to it can be a very important task, and much effort is involved. The quality department should be skilled in undertaking this responsibility with minimum disruption to normal design and production matters. Quality criteria apply to the finished product, to production processes and to bought-in materials and components. Therefore the quality manager should determine, or approve, the final inspection and test methods and criteria to ensure conformance. He or she should also determine such details as quality levels of components, quality control of suppliers and calibration requirements for test and measuring equipment.

16.2 Monitoring Production Quality Performance and Costs

The quality manager must be satisfied that the quality objectives are being attained or that action is being taken to ensure this. These include quality cost objectives, as described earlier. QA staff should therefore oversee and monitor functions such as failure reporting and final conformance inspection and test. The QA department should prepare or approve quality performance and cost reports, and should monitor and assist with problem-solving. The methods described in Sections 11 and 15 are particularly appropriate for this task.

16.3 Quality Training

The quality manager is responsible for all quality control training. This is particularly important in training for operator control and quality circles, since all production people must understand and apply basic quality concepts such as simple SPC and data analysis.

16.4 Specialist Facilities and Services

The quality department provides facilities such as calibration services and records, vendor appraisal, component and material assessment, and data collection and analysis.

The assessment facilities used for testing components and materials so that their use can be approved are also the best services to use for failure investigation, since this makes the optimum use of expensive resources such as spectroscopic analysis equipment and scanning electron microscopes, and the associated specialist staff.

The joint use of these services in support of development, manufacturing and in-service is best achieved by operating an integrated approach to quality and reliability engineering.

16.5 Quality Audit and Registration

Quality audit is an independent appraisal of all of the operations, processes and management activities that can affect the quality of a product or service. The objective is to ensure that procedures are effective, that they are understood and that they are being followed.

Quality audit, like financial audit, requires both internal and external audit. Internal audit is a continuing function whereby QA staff review the operations and controls, and report on discrepancies. External audit is performed by the third party assessors on a regular schedule, typically annually, in order to obtain and retain registration to quality standards, in particular ISO9000.

An effective quality audit should include review of all design, development and production, test and inspection operations, as well as associated procedures and documentation. An important aspect is the assurance that personnel know and understand their role in the quality system, including relevant procedures and responsibilities.

The quality manager's responsibility for audit includes all internal audit, for ensuring that the company is successful in customer or third party audits and for quality auditing of suppliers. Preparation for external audit and being subjected to it can be a very important task, and much effort is involved. The quality department should be skilled in undertaking this responsibility with minimum disruption to normal design and production work. This demands thorough knowledge of the appropriate standards and methods and the ways in which they are applied. Training is an important feature to ensure that personnel will respond correctly during audit.

Reliability aspects are included in quality audit, since there is so much common ground, particularly in relation to failure reporting and corrective action. Ideally, internal audits should be carried out by the managers responsible for the procedures and tasks concerned, or by other knowledgeable staff on their behalf. The audits should have the objective of improving processes, not merely of determining compliance.

Rothery (1996) and Rabbitt and Bergh (1994) are among the many books on quality auditing to ISO9000.

17 Quality Management Approaches

17.1 Quality Systems

The quality systems approach is epitomized by ISO9000, described earlier. It’s based on the premise that if the 'system' is described and followed, then the output (products, services) will be of high quality. A good quality system (effective procedures, training, etc.) is necessary, but it can provide only a baseline for achieving high quality and reliability. The quality systems approach based on ISO9000 or similar standards is the most widely-applied approach in most engineering business.

17.2 'Six Sigma'

The 'six sigma' approach was developed by the Motorola company in 1986. A six sigma process should operate within 6s limits, which implies that 99.999 66% of the products manufactured are statistically expected to be free of defects (3.4 defects per million). This in turn implies that every process follows the normal distribution. As explained in Section 2, this is not always the case. The six sigma process involves application of statistical and other methods to identify opportunities for process improvements. To this end specialists are trained in the methods, gaining credentials that culminate in 'black belt' and 'master black belt' status. They are given the task of finding opportunities, driving the improvements and training the organization in six sigma methods. Top management involvement and leadership is essential. The six sigma approach is credited with generating very large savings in several big companies, although its use is not without controversy.

The six sigma methods, including 'lean' six sigma and design for six sigma (DFSS) continue to be used to improve engineering practices, facilitate product improvement and generate cost saving. There is a multitude of references on the six sigma methods including books, periodic publications, various websites, forums, blogs, and so on.

17.3 Quality Circles

The quality circles approach to improving production quality was described in Section 15. It’s an inherent part of the total quality management (TQM) approach described in Section 17.5.

17.4 Quality Awards

The first national quality awards to be introduced were the Deming Awards in Japan. These are presented every year to individuals, groups and companies which achieve notable quality levels or improvements. Later the idea was followed in the USA with the Baldrige Awards, named after the then Secretary for Trade. US companies submit themselves to the assessment process, which is conducted by independent assessors, to determine whether they achieve the highest scores in a range of company categories. The award winners gain good publicity in the years that they win, and they can also generate improvements as a result of their efforts to impress the assessors.

In Europe the European Foundation of Quality Management (EFQM) has produced a self-assessment guide, which companies can use to conduct their own evaluations. The EFQM Excellence Award is given to companies or other organizations that show outstanding results across a wide spectrum, not only quality and reliability.

17.5 Total Quality Management

The terms total quality management (TQM) (or total quality control (TQC)) are often used to describe a system whereby all the activities that contribute to product quality, not just production quality control, are appraised and controlled by one manager. In this context quality is defined as the totality of features which determine a product's acceptability, and as such includes appearance, performance, reliability, support, and so on.

Under this concept the quality manager has very wide authority for setting and monitoring quality standards, in this wide sense, throughout all functions of the organization. The quality manager then reports directly to the chief executive. It remains essential for line functions such as design, test and production to retain responsibility for their contributions to quality and reliability. However, the quality manager is responsible for ensuring that the total approach is coordinated, through the setting of standards, training and performance monitoring.

The TQM approach to reliability and quality can be very effective, particularly when applied to correct a situation in which quality is perceived as being lower than is required, but the reasons cannot be pinned down.

It’s not easy to find people who can effectively fulfill the total quality management role. The task demands rather exceptional talents of persuasiveness and ability. It’s easy for the quality manager and the organization to become dissociated from corporate realities, and the authority of the quality manager might be questioned by line departments and project managers.

The obvious solution to this is for the chief executive to personally 'drive' the TQM effort, by ensuring that all functions support it and by monitoring the results. This has the supreme advantage of showing that quality and reliability are of top level concern. Functions such as design reliability and production quality control can then be integrated with design and production, and coordination of standards, training, and so on, can be achieved through a chief executive's quality committee.

Only the chief executive can ensure total integration of the quality and reliability functions with the management of specifying, designing, producing and supporting the product. The increasing integration of design and production, and the pace and competitiveness of modern markets for technology-based products, demand that a fully integrated approach be used. This is to be found in many of the modern high technology companies that have grown up in the last 30 years, and in those older companies that have perceived quality and reliability as being matters too important to be left to chance or to lower levels of management. Their success has been largely due to this recognition, and to the commitment and involvement of the most senior executives.

Bergman and Clefs (1994) and O'Connor (2004) describe the management principles and methods of TQM.

18 Choosing the Methods: Strategy and Tactics

We must apply the methods that are known to be effective in creating reliable products. We should also try to avoid methods that are misleading or counter-productive. We can consider management methods to be either strategic or tactical. Strategic principles and methods prepare the organization for the work that must be done in the future. Tactical methods are applied when necessary.

The important strategic principles and methods are:

- Top management commitment, through all functions and product phases.

- Effective organization and people.

- Effective methods, capabilities and procedures.

- Supplier selection and development.

- Training, covering management, technology, the tactical methods and consistent with the organization and procedures.

- Research.

The important tactical methods are:

- Design for reliability (DfR) (QFD, FMECA, stress, variation, etc., and effective use of CAE tools).

- Test, with the emphasis on HALT and design of experiments.

- FRACAS.

- Production quality control and improvement.

- Maintenance planning and methods (when appropriate).

The strategic methods must be applied over the long term. The timescales for effective payback are typically one to ?ve years, and the benefit s continue to grow. However, without them the application of the tactical methods won’t be as effective. Therefore they must be managed appropriately, and protected from short-term cost-cutting.

The tactical methods must be applied continuously on product design, development, production and in service.

19 Conclusions

In the years since the 1980s there has been a steady improvement in the reliability of engineering products and systems, despite increasingly high levels of complexity. This has been the result of spreading recognition that reliability is a key factor in competitive markets, and the realization that the costs of achieving high reliability are amply repaid by lower costs of failures and enhanced product reputation, even at reliability levels well in excess of previous achievement (as explained in Section 1). Companies across the spectrum of engineering have taken up the challenge and applied the tools described to improve the reliability of their products. As a result we have all benefit ted.

Public safety consciousness has been a powerful spur to quality and reliability in some areas, such as nuclear power and air travel, where government agencies set up and monitor safety standards. Minimizing product liability risks has become a major factor in design and development of a wide range of products.

Reliability is obviously an essential contributor to safety, so the disciplines described in this guide are an important part of the safety assurance process.

There has also been a continuing drive for high reliability in military products, and several of the formal methods for design reliability improvement started in the military in the United States, so that the US military standards on reliability analysis and methods are used in many non-military areas. Whilst the commercial world adopted many of the techniques developed by the military, there has been a swing the other way, with military buyers now applying commercial-type methods and warranties.

The great advances in computer-aided engineering have empowered designers to create and analyze better designs, so that errors are reduced and the transition to manufacturing is made easier and more trouble-free.

Much of the improvement in reliability has also been due to improved quality of manufacturing operations.

Automation has contributed to this, as well as other advances in manufacturing technology such as more precise machining and advances in measurement and test.

However, improvements in human performance as applied to engineering have probably contributed the most, as the principles taught by Drucker (Drucker, 1955), Deming (Deming, 1987) and other leaders have been more widely applied. Ultimately, the drive to high reliability can only come from management. Drucker did not address engineering specifically, but his philosophy is highly appropriate to engineering design, development, production and support. The application of the 'new management' to engineering is described in Clausing (1994) and O'Connor (2004).

Most successful engineering companies and organizations now accept and apply the philosophy, but there is sometimes a tendency to allow 'scientific' ideas to re-surface, inhibiting freedom and initiative. Also, since the main benefit s of high reliability accrue downstream in the product life cycle, there can be a temptation to seek short-term savings by reducing effort on design analysis, test and other DfR methods. The methods we have described, and the ways in which they should be integrated within the whole product life cycle, represent the best practice of the most successful companies in today's engineering industry.

Questions:

1. What are the main elements of an integrated reliability program?

2. a Describe briefly the main cost headings associated with achieving high quality and reliability, and the main consequential costs of failure, in development, production and use.

b Explain and discuss Deming's philosophy of overall quality and reliability cost minimization.

3. a What are the most important aspects to be considered in preparing reliability specifications? b Write an outline reliability specification for (i) a domestic TV set, (ii) a fighter aircraft, and (iii) a gearbox bearing.

4. Discuss the ways in which reliability can be covered in procurement contracts for complex systems.

5. What are the main elements of a project reliability plan? To which other project plans should it refer?

6. What is meant by 'total quality management'? How does the concept differ from the requirements of the international standard for quality systems (ISO9000), and how does it affect reliability?

7. Your firm designs, develops and manufactures a complex consumer product which sells into a highly competitive market. The firm has recently been losing its market share and this is thought to be due to an increasing reputation for unreliable products.

You are currently developing a new product scheduled for volume production in about 18 months' time. This product includes several new technological features and is seen very much as a 'make-or break' product as far as the firm's future survival is concerned. The design concept is 'frozen', but little development work has taken place.

Outline the procedures you would adopt in development and subsequent volume production to ensure the retrieval of your firm's previous reputation for high reliability.

8. Review the nine reliability maturity categories in Section 15.2. In your opinion, are they equally important for an organization? How would you assign weights to those categories? Explain your choice.

9. What subject material you would include in the training of a reliability engineer? What university level courses would you consider for the Reliability Engineering program? Justify your choices?

Prev. | Next

Article Index HOME