AMAZON multi-meters discounts AMAZON oscilloscope discounts

Part II--Technical Information for Preventive Maintenance Success

The benefit of PM is that by doing a few cheap, fast, and simple things now, we can prevent expensive, time consuming, and difficult repairs later. Most PM tasks are very simple. Being a good PM mechanic does not require a degree in engineering or even years of experience working as a repair technician. Anyone with a bit of mechanical ability can quickly be taught to perform preventive maintenance. That does not mean that experience and knowledge of maintenance technology is not valuable. In fact, there are a few specific areas of maintenance knowledge that can make a significant difference in how effective your PM program can be. There are areas of PM where a little understanding can make a big difference in doing PM correctly. There are also areas of maintenance knowledge where even seasoned maintenance technicians often lack knowledge or have learned inaccurate on-the-job folklore. Hopefully, this Section will dispel some of the maintenance myths and provide some useful technical wisdom that will make your PM team better at what they do.

Section 5: Lubrication Theory

One of the areas where even experienced maintenance mechanics of ten lack knowledge is lubrication theory. I have worked with very skilled and experienced maintenance mechanics that did not have a fundamental understanding of lubricant selection, did not know how much or how often equipment needed to be lubricated, or even how lubricants really work. Maintenance folks usually know some rules of thumb about proper lubrication. Unfortunately many of the rules of thumb amount to work site folklore and are simply wrong. Having a basic understanding of the science behind lubrication will help the building manager to make wise lubrication decisions and will make your staff better PM mechanics.

Section 6: Commercial Roofing

Commercial roofing is another area where there is a lack of knowledge among maintenance mechanics. While it is common for maintenance mechanics to have some working background as electricians, plumbers, or HVAC techs, few maintenance mechanics have ever worked as commercial roofers. Lack of experience with the trade combined with the wide variety of roofing materials in use makes commercial roofing an area where in-house maintenance staff are often not very skilled. Fortunately, Most organizations use outside roofers for most roof repairs so a lack of in-house roofing skills is not usually a big problem. However, if we are expecting our in-house maintenance staff to perform scheduled PM inspections, knowledge of roofing technology will make that part of our PM program more effective. When you consider that a facility's roof is often the most expensive building component in the entire facility and a roof failure can lead to so many other types of problems, it's easy to see why roofs are one of the most important areas of PM.

Section 7: HVAC

The third technical area in this section is Heating, Ventilation, and Air Conditioning systems. Like roofs, these systems are usually one of the most expensive systems in a commercial building. Like lubrication and roofing, HVAC is an area often misunderstood by in-house maintenance staff. Well meaning maintenance staff often understand the operation of one part of an HVAC system, but do not always understand how all the pieces fit together. In many facilities, adjustments and alterations to one part often cause performance problems in other areas.

Section 8: Belt Drives

Belt Drives are such a simple design and so easy for anyone with mechanical ability to understand that it may seem silly to include a whole section on the technical theory on something as simple as a belt drive.

However, since drive belts account for a high percentage of equipment failures, they have earned a place here. A belt drive that is adjusted properly during PM can be expected to run dependably for a long time with few problems. An improperly adjusted drive will run hot, wear quickly, slip under load, throw belts, and fail prematurely. Since the primary application for drive belts in buildings is heating and cooling, drive belt failures are near the top of the list of failures directly effecting building occupants.

Section 9: Indoor Air Quality

One of the most recent and significant changes in the operation of facilities is the concept of indoor air quality (IAQ). In today's facilities, it seems that every sniffle or allergy triggers fears about a facilities indoor air quality. IAQ concerns are often brought to the building manager for investigation. Not many managers have the knowledge or tools to separate real problems from unfounded worries. Preventive maintenance practices can have more impact on a buildings indoor air quality than any other business activity and PM techs should understand how the work they do contributes or harms a building's IAQ.

Section 10: Paint and Protective Coatings

Few things offer greater protection to our buildings for such minimal effort and cost than a quality coat of paint. Our buildings are left out in the elements exposed to rain, salt, wind driven dirt, UV radiation, and corrosive smog and pollution. A layer of polymer only a few thousandths of an inch thick is all that stands between these damaging elements and our vulnerable facilities. Failure of this protective layer of paint cannot only allow damage but accelerate it. Recent advances in paint formulations and changes in the availability of traditional paints has been driven largely by environmental and indoor air quality (IAQ) concerns and increasing regulations on Volatile Organic Compounds (VOCs). With these changes and increase paint selection, the proper preparation, selection, and application of paint has become more complex than in the past.

Section 5: Lubrication Theory

TRIBOLOGY

Lubrication is one of the most frequent preventive maintenance tasks and also one of the most misunderstood. Since so much preventive maintenance work involves some sort of lubrication, it is important for PM staff to have some understanding of the science of lubrication. Most of the time, we will be able to follow a manufacturer's recommendation on frequency of oil changes, type of lubricant, and proper application methods and tools to use. However, when we do not have these recommendations, we still need to make educated choices. This requires a basic understanding of lubrication theory.

The field of engineering that deals with lubrication, friction, and wear is known as "tribology" [trahy-bol-uh-jee or tri-bol-uh-jee].

Tribologists will tell you that a lubricant has three primary functions.

As expected, the first function of a lubricant is to reduce friction between interacting parts. This reduction in friction is the result of the lubricant forming a very thin film between parts which prevents the solid surfaces from actually touching.

The second function of a lubricant is to remove heat. This is obvious on systems such as a car engine or hydraulic pump where the lubricant is pumped through the system and can absorb heat and transfer the heat elsewhere. On small systems such as rotating bearings, lubricant will help to prevent the development of damaging "hot spots."

The third function of a lubricant is to suspend contaminants. By keeping dust, dirt, or metal particles in suspension, the particles are not available to scratch bearing surfaces and wear them away.

REYNOLD'S THEORY

Today's modern theory of lubrication was first proposed near the end of the nineteenth century by a mathematician named Osborn Reynolds. Reynolds was hired by the railroad industry to help in the design of axle bearings. One of his experiments showed that when a train's axel was rotating, oil would seep out of a hole drilled in the loaded side of the bearing journal. The loaded side is the side where metal to metal contact would occur. In fact, if a wooden plug was driven into the hole, the oil's pressure was great enough to push the plug out of the hole. Reynolds wanted to know how a rotating axle could produce such a high oil pressure.

What Reynolds determined was a small amount of oil was picked up by the rotating axle. This fluid was being drug into the narrow space between the axle and the journal.

The journal is the machinery part that surrounds and supports the axel. As this fluid was compressed into this small space at a high rate of speed, the pressure of the fluid increased.

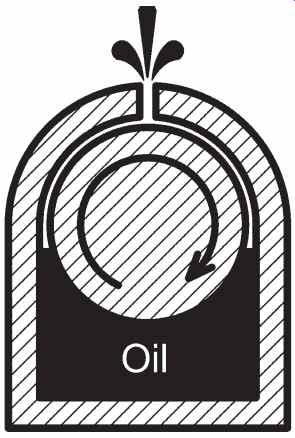

FIG. 1. Reynolds wondered why a rotating shaft would cause oil to seep

from a hole drilled in a bearing journal with enough pressure to force out

a wooden plug.

When fluids are com pressed rapidly, they develop high hydrodynamic pressures. One example is a pair of water skis skipping across a lake. If the water skis move fast enough, the fluid (water) under them is compressed so quickly that the water develops a pressure high enough to keep the skier on top of the water. Another example of hydrodynamic pressure is seen when someone does a belly flop in a pool. When the diver's body strikes the water fast enough, the water pushes back with a hydrodynamic pressure high enough to cause pain. Even a soft fluid like water can feel hard if it's compressed fast enough.

The same hydrodynamic pressure that keeps a water skier above water and that causes the belly flopping diver's belly to sting was causing oil to drive the wooden plug from the hole drilled in the bearing journal.

FIG. 2 shows a drawing of a shaft in a bearing. You will notice the shaft is not centered in the bearing but is offset to one side. This could be due to the sideways pull of a drive belt, gravity, or the shaft itself could be out of balance. All bearings experience some amount of sideways pres sure and will have more clearance on one side of the bearing than on the other. The amount of bearing clearance is exaggerated in this picture. A real bearing would never have such a large gap between shaft and bearing journal.

FIG. 2. Exaggerated image of a rotating shaft in a bearing journal. Notice

that the shaft is displaced to one side.

FIG. 3. Drawing 1: Oil is pooled on one side of the shaft. 2: The rotating

shaft drags oil into the narrow space between parts. 3: Compressing the oil

into this space causes high hydrodynamic pressure in the oil which lifts the

shaft.

From the picture you can see if no lubricant is used, there will be surface to surface contact at the lower left side of the shaft. There is one point where the shaft will touch the bearing journal. By adding a lubricating oil to the space between shaft and journal, this contact can be prevented. This is because the pressure of the oil being dragged into this narrow space will be enough to lift the shaft away from the journal. A film of oil that had no pressure could not push against the surfaces to keep them apart. It is the pressure caused by the oil being compressed into the small space that gives the oil film the "strength" to lift the shaft away from the journal. As long as the shaft continues to rotate, the thin film of oil will maintain its high hydrodynamic pressure and will be able to keep the two surfaces apart. Typical oil pressures between bearing surfaces can be as high as 8,000psi.

The concept of a high pressure oil film is the essence of lubrication theory. The concept is that a lubricant (usually oil) is drug at a high rate of speed into a narrow restriction between interfering parts. As the fluid is compressed into this restriction, the compression creates a high pres sure in the oil. The high pressure is able to lift the shaft away from the journal. The shaft then rides on a film, or very thin cushion of oil. Typical film thickness is only about .001 inches, but is enough to prevent surface contact.

Reynold's Theory Equation

Like all engineering theories, Reynold's Theory can be expressed as a mathematical equation. Let's look at a simplified version of this equation. Don't worry; we are not actually going to do any math. But just looking at the equation can give us some valuable information to help us understand choosing a lubricant.

A lubricant is supposed to keep surfaces apart. To do this the lubricant's hydrodynamic pressure needs to be high enough to lift one surface away from the other. The higher the hydrodynamic pressure, the better a lubricant can keep surfaces apart.

Even without actually doing any math, we can learn something from Reynold's equation for lubrication. Here is a simplified version of the equation that lets engineers calculate how much load an oil film can sup port. Remember, we want a lubricant to support the highest load possible to keep bearing surfaces from touching each other.

The load that a fluid film can support follows this equation:

b × R3 × w × v ÷ g2

Where:

b is the breadth of bearing journal (the width of the bearing)

R is radius of bearing

w is angular velocity (how fast the shaft is spinning)

v is fluid viscosity (a measurement of the "thickness" of a fluid)

g is gap width (space between shaft and journal)

We know we want a fluid film that can support the largest load possible to prevent metal to metal contact. Therefore, we want the above equation to give an answer that is as large as possible.

There are lots of things we can learn from this equation but we are only going to consider three. Let's look at each part of the above formula.

w-Angular velocity (shaft rotation speed)

Engineers use the letter "w" to represent how fast a shaft rotates.

This is usually given as rotations per minute or RPM. The first thing we're going to consider is how the speed of a shaft effects lubrication. Re member, we want the highest fluid film pressure possible, that means we want to make the above equation as large as possible. Let's see how "w," angular velocity, effects the above equation. Since we are multiplying the rest of the equation by "w," we know that the bigger "w" is, the higher the lubricant pressure will be. That means that the faster a shaft rotates, the higher the lubricant pressure. A slow rotating shaft will have a hard time with lubrication. This is why slow rotating machinery usually relies on heavy greases instead of oil as the lubricant and why some slow rotating machinery have oil pumps to provide the necessary oil pressure to the bearings.

g-gap width (which is the space or clearance between bearing surfaces)

The second part of this equation we are going to consider is what happens as we change the gap width, or bearing clearance. Bearing clearance is how closely a bearing fits a shaft. We can see that the whole equation above is divided by "g," which is the gap width. That means the bigger the gap width, the lower the fluid pressure becomes. In order to have high lubricant pressure, we want to make our gap width, or bearing clearance as small as possible. Close fitting bearings will have a higher lubricant pressure than loose fitting bearings. The tighter a bearing, the better the lubrication of that bearing will be.

v-viscosity (thickness of the fluid)

The third and most important part of this equation for preventive maintenance mechanics is "v" or viscosity. Before we go any further, we need to discuss the term "viscosity." We will go into more detail on this later but viscosity is the measurement of a fluid's resistance to flow. Most people would say viscosity is how "thick," "stiff," or "sticky" a fluid is. Molasses has a very high viscosity; water has a very low viscosity.

Looking at the equation, we can see that the entire equation is multiplied by viscosity (v). That means that if we choose an oil with a high viscosity, we will get a high pressure film of oil and if we choose an oil with a low viscosity we will get a low pressure film of oil. Higher lubricant pressure is good and higher viscosity oils will have higher lubricant pressures.

FIG. 4. Viscous fluid on a spoon

To summarize what we have learned from this equation:

Faster rotation = Better lubrication

Closer bearing fit = Better lubrication

Higher oil viscosity = Better lubrication

Since we are PM technicians and we are not designing the equipment we work on, we do not have any control over rotation speed or bearing clearance. The only thing we can control is the viscosity of oil we are using. It would seem from the equation that we would always want to use the highest viscosity oil we can find because this would produce the highest fluid film pressure. Unfortunately this isn't the case.

Like many engineering formulas, there are limits to how the formula can be applied. In this case, very high viscosity oils do not work on very fast rotating shafts or on bearings with very tight clearances. High viscosity oils simply flow too slowly to be drawn into the narrow spaces in tight fitting bearings and cannot move fast enough to be drawn along by fast rotating shafts. Does that mean everything we have discussed so far was just waste of time? No.

We should understand from the equation is that at slow rotational speeds or when bearings fit loosely, we will need to use high viscosity oils.

On the other hand, for fast rotating shafts and close fitting bearings, lower viscosity oil will be sufficient.

For example, many small (under 2 hp) circulating pumps and blower motors run at 1,700rpm or more, and require a light 20W oil for lubrication. Most automotive differentials have shafts that rotate below 800 RPM and require a heavy 80W or higher gear oil. Reciprocating air compressors have close fitting bearings and can be lubricated with a light 20 or 30W oil. The bearing clearance around tractor axles is usually fairly large and rotation speeds are slow. Grease with a high viscosity base oil (or even with a solid lubricant component) are usually specified in these applications.

Understanding how shaft speed, bearing clearance, and viscosity are related will help you in choosing the proper viscosity lubricant when manufacturer's specifications are not available.

CHOOSING A LUBRICANT

The way to choose a lubricant is to follow a manufacturer's recommendation. There are lots of competent maintenance people that do not understand this. For some reason, they think they know more about lubrication than the engineers who design lubrication systems for a living. They think they can do better by choosing a higher viscosity, using a synthetic where conventional oil is recommended, or by mixing oil with an after-market additive. I believe that the smartest approach is to depend on the manufacturer's recommendations all the time.

Only when a manufacturer's recommendation is not available should we make our own decisions about what lubricant we will use.

Usually we will have similar types of equipment, using similar types of bearings we can use as a guide. With experience performing proper PM, you will begin to recognize which types and viscosities of oil are recommended for which types of bearings and lubricant selection will become almost automatic.

VISCOSITY

As we discussed earlier, viscosity is a lubricant's resistance to flow. Viscosity is measured by several different methods and classified by several different, overlapping systems.

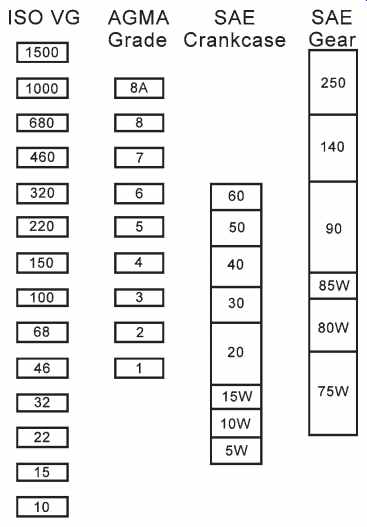

Viscosity can be measured in centipoise (cP), centistokes (cSt), or Saybolt universal seconds (SUS). It can be measured at different temperatures, giving different results. To further complicate matters, oil suppliers can identify the viscosity of their lubricants in several other ways. Most industrial lubricants are sold by ISO number or by SAE weight. A com parison of several different viscosity identification systems can be found in FIG. 5.

FIG. 5. Comparison of four oil viscosity indexes

As we can see from FIG. 5, an SAE 90 weight gear oil will have the same viscosity as an SAE 50 weight crankcase oil or an ISO 220 lubricating oil. Be careful when selecting oils not to confuse the different systems.

The viscosity for oil is different at different temperatures. Oil at cold temperatures will be thicker than at warm temperatures. Some oils will list a "viscosity index." This is a measurement of how dramatically the viscosity of the oil is affected by temperature. Because of the viscosity shift with temperature, many equipment manufacturers will recommend different oil viscosities for winter than they will for summer. Multi viscosity oils solve this problem because they can behave like low viscosity oils in the winter and high viscosity oils in the summer. As one ex ample, SAE 10W-30 motor oil behaves like SAE 10 weight oils in the winter and like SAE 30 weight oil in the summer. Any time you see a "W" in an SAE lubricating oil it indicates the oil was formulated for use in cold (winter) temperatures.

Problems with Choosing the Wrong Viscosity

If we choose an oil with a lower viscosity than recommended by the equipment manufacturer, we run the risk of having damaging surface to surface contact. As we know, oils with low viscosities may not be able to provide a high enough hydrostatic pressure to keep surfaces apart. Another problem with low viscosity oils is they tend to flow past oil seals causing leaks. In combustion engines, low viscosity oil will flow past oil rings into the combustion chamber and you will have problems associated with burning oil.

Oils with too high a viscosity will tend to leave bearing surfaces "oil starved." Thick oils cannot be pulled as quickly into the narrow spaces between bearing surfaces and will leave the surfaces dry. Rubbing surfaces will quickly be damaged. High viscosity oils can also cause excessive leaking at oil seals since the thicker oil can push against and deform soft rubber seals. Additional problems are a reduction in efficiency due to a thicker oils tendency to resist movement and problems of higher starting torque, particularly in cold weather.

Depending on the application, you may also need to consider whether your lubricant is going to be compatible with:

Rubber components

Modern low HCFC refrigerants

Other lubricants

Plastic components

High or low temperatures

Corrosive environments

Wet environments

Types of Lubricants

All of the lubricants commonly used in institutional maintenance fall into one of four categories. These categories are: 1) mineral oils, 2) synthetic oils, 3) solid lubricants, and 4) greases. All of the lubricants we use for PM will be one or a combination of these four types.

Mineral Oils

Most lubricants used in preventive maintenance will fall into the category of mineral oils. Mineral oils are produced from petroleum oil. Most of the oil familiar to us such as motor oil, penetrating oil, and most spray lubricants are mineral oils.

Mineral oils often include additives to enhance some feature of the grease. Common additives include:

• Detergents • Anti-wear agents

• Dispersants • Extreme pressure additive

• Oxidation inhibitors • Foam depressants

• Corrosion inhibitors • Viscosity index (VI) improvers

• Rust inhibitors • Pour point depressants

• Friction modifiers

Synthetic Oils

As the name suggests, synthetic oils are man made. Synthetic oil formulations can be a combination of synthetic and mineral oil or can be 100% synthetic. Synthetic oils have been developed for high temperature applications, for longer service life, compatibility with plastic or rubber parts, or for use in unusual conditions. Synthetic lubricants used in air conditioning and refrigeration systems have been developed to mix easily with the new generation of non-ozone depleting refrigerants.

The most common synthetic lubricants are polyalpha-olefin (PAO), synthetic esters, polyalkylene glycols (PAG), phosphate esters, alkylated naphthalenes (AN), silicate esters, and ionic fluids.

The cost of synthetics can be several times the cost of mineral based lubricants. The biggest problem with synthetics is that so many skilled maintenance mechanics believe that synthetic oils will out perform the oils recommended by the equipment manufacturers. Whenever the manufacturers recommendations are available, those recommendations should be followed.

Solid Lubricants

Solid lubricants include graphite, molybdenum disulphide, Teflon®, and boron nitride. Most of these are applied as dry powders or are used as a component of greases. The most familiar solid lubricants are probably the grey graphite powder used to lubricate lock keyways and Teflon which is used in pipe thread sealant to lubricate pipe threads.

On the microscopic level, solid lubricants are made up of millions of tiny flat plates that slide easily past each other. They are used in applications where liquid lubricants would attract dirt or where lubricants need to withstand extreme pressures. Extreme pressure greases usually have solid lubricant particles mixed into the grease.

Greases

Most of the grease used today is usually composed of 85-90% lubricating oil mixed with a thickening agent, usually a metallic soap. When used as a lubricant, it is the oil component of the grease that does the lubricating. As the grease warms, it slowly releases the oil over several weeks or months providing a constant supply of lubricating oil.

Another common myth in preventive maintenance is that high temperature grease is in some way better than other types of grease.

The truth is that many high temperature greases will lubricate poorly at temperatures below 250ºF. High temperature greases are formulated to release their oil at high temperatures. Under normal temperatures, most high temperature grease does not get hot enough to release the oil and oil starvation of the bearings can occur.

For applications where there is extreme loading or unusually high forces applied to a bearing, specialty grease will need to be used. The fluid film of most grease cannot stand up to heavy loads and will allow metal to metal contact to occur. An example of the types of bearings subject to this heavy loading would be the pivot joints on the arm of a backhoe or the slowly rotating bearing on the dump body of a dump truck. These bearings rotate far too slowly to develop a hydrodynamic film and they support enormous forces that will cause most grease to fail.

Extreme pressure greases, designated as "EP" grease, contains tiny particles of solid lubricants such as graphite, Teflon®, molybdenum di sulphide, or boron nitride. These solid particles will not ooze out under pressure and are strong enough to maintain bearing clearance even under these heavy loads.

Grease is usually used instead of oil

• For low speed bearings.

• In rolling element bearings which have large voids between rolling elements.

• Whenever a lubricant needs to "stick" to the surface, such as in open gearing.

• In wet applications where the grease tends to seal out water

Different types of thickening soaps can give grease very different characteristics. The most familiar greases are thickened with calcium, sodium, or lithium based soap.

Calcium soap based grease (also called "lime soap") is probably the most common type of grease. It is typically yellow or red in color and is often marked "all purpose."

Sodium soap based grease is another all purpose grease, typically used for slow moving equipment such as conveyors, tracks, or wheel bearings. This grease has a high drop point (temperature at which the grease no longer behaves as a solid) of 300-350ºF.

Lithium soap based grease is the most common of the "high temperature" greases but can also be formulated to flow at extremely cold temperatures as low as -60ºF. Lithium grease is brownish red in color and resists water well.

Barium soap based grease is similar in use to sodium based soap.

It is also used for slow moving equipment and has a high drop point of about 275ºF. Barium soap grease is red-yellow or green in color.

Aluminum soap based grease is a specialty grease that is extremely sticky and tends to stay in place well. It is used for surface lubrication of tracks, fifth wheels, and conveyors.

THE USEFUL LIFE OF OIL AND GREASE

Mineral oil, if uncontaminated, does not wear out. Oil that is used in internal combustion engines usually needs to be changed every 100-200 hours of operation because the combustion of fuel adds contaminants to the oil. These contaminants can cause wear to metal surfaces. Most of the oil used for lubrication of bearings is not subject to contamination. Un contaminated oil can easily last 30 years or more under normal conditions without any reduction in effectiveness. Oil needs to be added to bearings to replace oil that has leaked or evaporated away but old oil does not normally need to removed and replaced. Some bearing assemblies have oil reservoirs that slowly supply oil to bearings through some sort of wick.

The oil in these reservoirs will need to be topped off from time to time but the oil will be good for the life of the equipment.

FIG. 6. Oil in a sealed reservoir such as the one on this circulator pump

will continue to do its job for the life of the pump as long as it is not contaminated.

Oil can become damaged by extremely high temperatures or contaminated in several ways. Oil contaminated with dirt and dust will dam age bearings because the particles act as an abrasive. Particles can come from outside sources or from small bits of metal separated from damaged bearing surfaces. Once bearing damage starts, damage from these tiny chips cause wear to progress quickly. Water can also be a damaging oil contaminant. Experiments have shown that as little as .002% water in oil can reduce bearing life by nearly 50%. Six percent water can reduce bearing life by 83%. Water has such a low viscosity that it cannot keep bearing surfaces apart. Minuscule droplets of water in oil will allow surfaces to touch causing abrasive wear.

The only way to be sure of the condition of your oil is to have a sample taken for analysis. Usually, changing the oil is less expensive than having analysis done, which is why we change the oil in our vehicles at regular intervals, whether they really need it or not. For systems such as centrifugal chillers, changing oil is an expensive and time consuming ordeal. In this case, annual oil analysis makes sense. Oil analysis can also look for metal particles or contaminants that can give insight into the condition of chillers, generators, hydraulic systems, and other types of equipment.

HOW OFTEN DO WE NEED TO GREASE BEARINGS?

We know oil, if uncontaminated will last almost forever. This is not the case for grease. Grease is intended to continuously release its oil to the bearing and lasts only until its oil supply is depleted. This could be weeks or months and depends on temperature, size of the bearing, and how many rotations the bearing has gone through. Again the manufacturer's recommendations will tell you how often bearings will need to be greased.

In the absence of manufacturer's recommendations, it is possible to use a simple formula to figure out how often the grease in a bearing will need to be replenished. No formula can take into account all operating conditions. Bearings that operate at high temperatures, dirty environments, under heavy loads, or exposed to water will need to be greased more frequently. This formula will help to point you in the right direction.

When using the formula below, "RPM" is shaft speed in rotations per minute and "diameter" is bearing inner diameter, or shaft diameter in millimeters.

Re-greasing interval (in operating hours) =

14,000,000

-------- -

4 × diameter

RPM × ? diameter

This formula works for bearings with tapered or spherical roller bearings.

For cylindrical or needle bearings, multiply the answer by 5 and for ball bearings, multiply the answer by 10.

As an example:

A circulator pump motor with operating at 1725 RPM with a shaft diameter of 1 inch. We need to know the shaft diameter in mm, not inches.

There are 25.4 mm in an inch so a 1" diameter shaft is 25.4mm in diameter.

Plugging into the formula we get:

14,000,000

------ -

4 × 25.4 = 1508

1725 × ? 25.4

or 1508 hours, which is 62 days. If this motor runs 24 hours per day, it will need to have its bearings greased every 2 months.

Remember that this formula is for motors with spherical or tapered roller elements. If the motor has cylindrical or needle bearings you can extend the lubrication interval by five times. If it has ball bearings you can extend the re-lubrication interval by ten times.

There are other factors that can reduce grease life. Motors that are mounted vertically (shaft up or down) and motors operating in dirty environments should be re-greased twice as often. If bearings operate at temperatures over 160ºF, double the greasing frequency for every 20ºF over 160ºF.

Bearings are usually greased using a grease gun which produces high pressure to inject grease into the bearing through a zerk or grease fitting. These fittings are designed with a ball and spring to keep contaminants out of the bearing. It is important to wipe both the grease fitting and the end of the grease gun before greasing a bearing to keep dirt from get ting into the bearing.

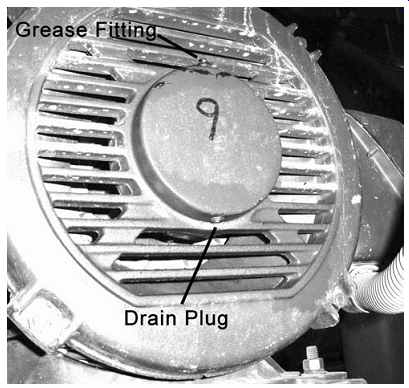

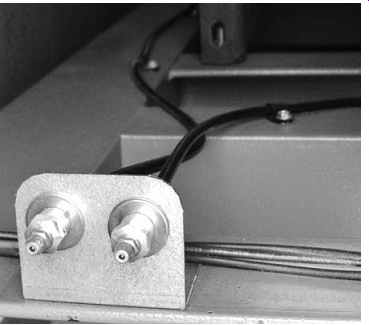

A surprising number of maintenance techs do not know that many larger motors often have grease plugs that should be removed to allow the old depleted grease to be pushed out of the bearing as fresh grease is being pushed in. These plugs are usually opposite the grease fitting on the motor. An example of these drain plugs is shown in FIG. 7.

FIG. 7. Grease drain plug on large electric motor

You should be aware that not all motors that have threaded plugs are meant to be greased. Motor components are sometimes designed to fit several different models of finished motors. The bell end of a motor may have a grease plug that is intended to accept a zerk fitting for one motor design but not another. Inserting a grease fitting and greasing a motor with sealed bearings may just fill the electrical components with grease. Failing to add grease fittings to a bearing that needs to be greased will result in early bearing failure. If you have any questions, consult with the motor's manufacturer or your motor supplier.

One of the most common problems regarding greasing bearings is that bearings that are difficult to reach are often overlooked during PM, either intentionally or otherwise. The obvious result is that the most difficult and time consuming bearings to replace are the ones that are the most likely to fail.

TYPES OF BEARINGS

You now know more about grease and oil than most lubrication salespeople you will meet. Let's learn something about the bearings these products lubricate.

There are two main categories of bearings. The first is known as "plain" or "sleeve" bearings. The second type is "rolling element" bearings. The most familiar type of rolling element bearing is probably the ball bearing.

FIG. 8. Plain or sleeve bearings

Plain or Sleeve Bearings

Plain bearings have no moving parts and depend on a continuous thin film of oil to keep the surfaces from making contact. Most equipment we encounter use plain bearings. Plain bearings are lubricated with oil, never with grease.

Plain bearings often have an oil hole which allows oil to enter the bearing. Oil can only travel about ½ inch to either side of the oil delivery hole. In longer bearings, oil delivery grooves are some times milled into the surface of the bearing to help with distribution of oil.

There are some types of plain bearings that do not require lubrication. One type is known as Oilite bearings (pronounced Oil-light). Oilite bearings are made of porous cast bronze impregnated with oil at the factory. The oil contained in the metal is slowly released to the bearing surface and is designed to last the lifetime of the equipment. Oilite bearings do not need to be re-lubricated.

Many fractional horsepower motors and other types of small equipment use Oilite bearings.

Other bearings are know as "self lubricated" and are made of materials that can slide easily without needing additional lubricants. A few of the more common types are Teflon (PTFE), graphite or molybdenum disulfide (MoS2) bonded with epoxy resins, graphite, powdered metal or ceramics. Lubricating these materials with oil can actually cause damage to the bearing. This is another example of how important it is to read and follow the manufacturer's recommendations when choosing a lubricant.

Oil can be delivered to plain bearings in several different ways. Oil can be delivered through an oil hole or oil tube where it enters the bearing through an oil hole. Oil can also be added to a reservoir where fiber wicks deliver oil to the bearing through capillary action. In some machinery, fiber "wool" kept wet with oil, is packed into a "stuffing box" around a bearing and slowly delivers oil to the bearing as needed.

Rolling Element Bearings

Rolling element bearings have moving parts. Rolling element bearings consist of four parts. These are the inner race, the outer race, the rolling element (ball, roller, or needle), and a cage that holds the rolling elements in their proper place.

FIG. 9. Tapered roller rolling element bearing and bearing race.

Rolling element bearings have a few advantages over plain bearings.

Rolling element bearings can run at slower speeds than plain bearings, they can run oil starved with less damage, and they can survive contamination better since particulate matter is pushed to the side and out of the way by the rolling elements.

Rolling elements can be balls, cylindrical rollers, needle shaped rollers, or tapered rollers. Rolling element bearings are lubricated with grease, not oil. Because of the large open spaces within the bearing, grease is needed to hold the oil in place between the rolling elements. Grease is stiff enough to fill the space between the rollers and to not run out of the bearing.

Some rolling element bearings are constructed to be closed to the outside and are not intended to be greased. These bearings, called "sealed" bearings are enclosed with seals on both sides of the bearing designed to keep the factory grease inside and keep contaminants out. Sealed bearings do not have as long a life as bearings that are greased as required. Sealed bearings are often used on lower end equipment or where the equipment designers feel that bearings are unlikely to be greased due to difficult ac cess.

Reynolds lubrication theory also applies to rolling element bearings.

Under ideal conditions, each rolling element rides on a thin film of oil preventing damaging surface to surface contact from occurring. However, under extreme loading or poor lubrication, where surface to surface con tact occurs, rolling element bearings are less likely than plain bearings to be damaged.

When lubricating rolling element bearings, remember that a grease gun can produce up to 10,000psi of grease pressure and bearing seals can be damaged at 500psi. You can sometimes hear a difference in the sound a bearing makes as grease is introduced into the bearing. If you want to hear this, try placing a long screwdriver on the bearing housing and the handle of the screwdriver to your ear as you pump grease into the bearing. The goal is to fill the bearing voids with grease but not to add so much grease that it is pushed out of bearing seals.

Excess friction from damaged seals can reduce bearing life by 50%. As a part of our PM philosophy of continual improvement, you might want to consider installing grease pressure release fittings or pressure release plugs instead of the factory grease plugs on some of your equipment. These devices cost only a few dollars, are available from several industrial suppliers, and will help to prevent over-greasing bearings.

FIG. 10. Grease port extensions make it easy to grease inaccessible bearings.

Lubrication is the area of preventive maintenance that provides the most bang for the buck. The simple, quick, and inexpensive task of lubricating a bearing can save a lot of time and expense in repair costs. Lubrication is also the PM task that will show up on your PM schedule more than any other. Having an understanding of lubrication theory will help make your PM program more successful.

Most industrial suppliers will have grease port extension kits avail able to relocate grease fittings to an easier-to-access location. These extension kits include threaded fittings that replace the existing grease fitting, flexible steel or plastic tubing, tube mounted grease fittings, and mounting hardware. By using these extension kits, grease fittings can be installed where they're easy to reach or even on the outside of equipment cabinets allowing grease to reach the bearings deep inside without even opening a cabinet door. Grease extension kits are an excellent part of a program of continual improvement.

SUMMARY

• The three functions of a lubricant are to reduce friction, remove heat, and suspend contaminants.

• The modern theory of lubrication was developed by the engineer Osborn Reynolds in the late 1800s. According to Reynold's Theory, as lubricating oil is drawn into the narrow space between bearing surfaces the oil is being quickly compressed into the small space. The fast compression of the lubricant causes extremely high hydrodynamic pressure within the oil which creates a thin, high pressure film to keep bearing surfaces from contacting each other.

• Reynold's equation tells us that at slow rotational speeds or when bearings fit loosely, we will need to use high viscosity oils. For fast rotating shafts and close fitting bearings, lower viscosity oil will be sufficient.

• Viscosity is the measurement of a fluid's resistance to flow. High viscosity oils feel sticky and thick while low viscosity oils feel thin and watery.

• There are several different systems for measuring viscosity. When selecting an oil, it is important to make sure you are using the correct system.

• The only right way to choose a lubricant is to follow the manufacturer's recommendations.

• Grease is a combination of lubricating oil and a thickener. Grease slowly releases the oil to the bearing over time. Several different formulations of grease are available for high temperature, extreme pressure, or other specialized applications.

• The most common type of rotating bearing is the plain or sleeve bearing. In this type of bearing, the shaft rotates inside a fixed sleeve which surrounds the shaft. A hydrodynamic film of lubricating oil keeps the shaft and bearing surface separated by a few thousandths of an inch while the shaft is rotating.

• The other type of rotating bearing is the rolling element bearing. The most familiar of this type are ball bearings that use rolling metal balls to separate bearing surfaces. The rolling elements can also be cylinders, tapered cones, small needles or other shapes. Rolling element bearings are lubricated with grease and not oil.