AMAZON multi-meters discounts AMAZON oscilloscope discounts

We know why PM is important to both the maintenance department and to the bottom line. We know some of the science and engineering principles behind preventive maintenance tasks. We have also learned several methods of keeping track of all of the scheduled PM, and how to get your staff prepared for your new PM program. You now know more about preventive maintenance programs than most maintenance supervisors or facilities managers. So what do we do with this newfound knowledge? We finally get to stop talking about it and actually do it.

This final Section is about the actual work that PM requires. This Section is about the PM tasks that belong on your PM calendar and the individual preventive maintenance jobs that you and your maintenance staff will be performing. Every piece of equipment, building component, or mechanical system listed on the following pages will benefit from a scheduled program of maintenance.

On the following pages, you will find preventive maintenance in formation for many types of equipment found in facilities. Each piece of equipment is listed in several ways. To help set up your PM calendar, each piece of equipment is listed according to how often it needs PM. In order to familiarize you with PM tasks that are required by regulations, codes, and standards there is a listing of exactly which codes and standards govern specific PM tasks. And finally, there is an alphabetical listing of the equipment ordinarily included in most facilities PM programs with general maintenance requirements for each item.

It is important to note that the PM tasks listed here are general guidelines. Specific manufacturers will likely have specific PM requirements that may vary from the ones in this guide. In all cases, the manufacture knows their equipment better than anyone else and their maintenance recommendations should be followed whenever available.

Most common types of equipment are listed in this Section. You can use this list as a checklist of what to include in your PM program.

However, every facility is unique and you may have a few unusual kinds of equipment in your equipment inventory that do not appear here. This list is comprehensive but not complete.

Now that you know all you need to start your PM program, it is time to get going. Your PM calendar is probably not perfect yet. You probably have not had the opportunity to complete all of the training you would like your staff to have, and you have not been able to get all of the new tools and equipment you believe will make your PM program perfect. Do not let any of that stop you. If you wait until the perfect time, you will never start. Do not let the fact that you only have a good PM program, and not a great one, stop you from jumping in with both feet. This brings us to truism #9, and one of the reasons so many PM programs (and other good ideas) never get off the ground.

PREVENTIVE MAINTENANE TRUISM #9 Good is the Evil Enemy of Great

If you wait until your PM program is great, you will probably never start. It is time to put your wrenches and grease guns to work and start maintaining the equipment you have been fixing for so long.

Over the next few months, you will continue to make adjustments and changes until you find exactly what works for your facility. You will figure out what types of equipment will make PM easier for you and what will not. You may even start with a simple paperwork system and decide that your PM program is extensive and successful enough to warrant upgrading to a computerized maintenance management system.

Regardless of the current state of your fledgling PM program, the time to start is now.

The information that follows is in three separate lists. Each list includes the same types of building components and equipment organized in three different ways. The first list organizes equipment according to the frequency with which PM is required. The second lists equipment that is required to maintained according to codes or regulations and gives the code or regulation that applies. The third section is an alphabetical listing of roughly 100 pieces of the most common equipment to include in a PM program. This third list suggests PM procedures and technical information about each type of equipment.

LIST 1: PM TASKS LISTED BY FREQUENCY

Please see the alphabetical listing of equipment later in this Section for preventive maintenance procedures and technical details about each type of equipment.

Daily

Carpets-vacuum high traffic areas

Chillers-cursory inspection visually checking status screen Cooling towers-cursory inspection

Flag poles Resilient floors-mop Safety inspection of swimming pools

Weekly

Carpets-vacuum

Chillers-in-house operating observation

Cooling towers-operate fans, pump, observe operation

Emergency generator-running test Fire sprinkler-check pressure gauges, inspect control valves (without tamper switches)

Lawn Irrigation-walk lawns during operating season

Monthly

Air compressors Boiler/water heater inspection (in house)

Carbon monoxide detectors

Circulator pumps

Door inspections and adjustments (entrance doors and smoke and fire doors)

Elevator-in house inspection

Emergency generator-full load test

Emergency lighting and exit signs

Floor drains

Fire alarm in-house test

Fire drill (varies with location and type of facility

Fire extinguisher inspections (visual, in-house)

Fire sprinkler-check pressure gauges, inspect control valves (with tamper switches)

Housekeeping equipment

Ice machines

Kitchen fire suppression system in-house inspection

Laundry (commercial washers and dryers)

Lighting (exterior)

Lighting (interior)

Parking lots

Resilient floors-spray buff or clean with pad and apply additional coats of finish

Roof (in house visual inspection)

Smoke detectors

Sump pumps

Water softeners

Quarterly

Air conditioners

Chiller-inspection by service company

Condensate drains

Cooling tower-complete inspection, grease motors

Dishwashers

Exhaust fans

Fire sprinklers-quarterly sprinkler inspection

Furnaces (in house inspection)

Grease traps

Refrigerators and freezers (commercial reach-ins or walk-in boxes)

Retention ponds

Smoke detector battery change

Semi-annually

Automatic air eliminators on heating/cooling systems

Backflow prevention device testing (RP type only) by qualified tester

Carbon monoxide detectors (change batteries)

Fire alarm (by certified professional)

Kitchen fire suppression system testing by certified or licensed contractor

Rain gutters

Resilient floors-strip, seal, and refinish

Smoke detector batteries (usually October and August)

Sweep parking lot

Water valves

Annually

Backflow prevention devices-testing by certified tester, drain to prevent freezing in winter

Boiler/water heater inspection (certified inspector)

Chiller-complete system inspection by service company

Electrical systems-visual building wide inspection

Elevator-3rd party inspection

Emergency generator-annual service by service company

Emergency lighting and exit signs

Fire extinguisher inspection by licensed contractor (annual maintenance)

Fire hydrant-flow test

Fire sprinklers-annual sprinkler inspection

Furnaces (complete service by qualified professional) Ice machine-change water filter

Lawn irrigation systems-shut down system in the fall, start up in the spring

Lockers-change combinations and repair

Municipal fire inspections

Parking lot (seal coat)

Retention ponds

Roof (inspection by installing contractor)

Swimming pool seasonal startup and shutdown

Bi-annually or Less Often

Automatic air eliminators-replace every 5 years

Carbon monoxide detectors-replace every 2 years

Electrical bonding inspection of swimming pools every 5 years.

Electrical distribution systems-thermal imaging

Fire extinguishers, 5-year hydrostatic testing for dry chemical extinguishers. 6-year inspection and 12-year hydrostatic testing for CO2 and wet chemical extinguishers

Fire hydrants-pipe flow test

Lockers-have lockers repainted

Re-stripe parking lots every 5 to 10 years.

Roof inspection by independent 3rd party every 5 years

Roof-asphalt or tar seal coat every 3 to 5 years (if required by roofing warranty)

Undetermined

Automated external defibrillators

Carpets-extract or shampoo carpets determined by the amount of foot traffic.

Septic tanks-depend on usage.

Termite inspections-depends on region of country.

Vehicles-varies depending on model.

Water filter elements. Based on volume of water used, concentration of contaminants in water, and size of filters.

LIST 2: PM TASKS REQUIRED BY BUILDING CODES OR REGULATORY AGENCIES

Many PM tasks are required by regulation or building code. Codes often vary by location. The following list includes the specific codes and regulations that apply in most jurisdictions in the US. Most often, these specific standards are not a written part of a local building code but are referenced by the locally adopted code. You will need to check with your local, county, or state agencies to find out if other codes or standards apply in your location.

In addition to differences in local jurisdictions, many industries will have industry specific regulations or even industry specific regulatory agencies that can alter this list. Health care facilities will often have additional requirements enforced by a state department of health while Schools will often have additional specific regulations created by a state departments of education.

The following list may need to be adjusted for your specific location and industry. For PM tasks, or frequency see the specific equipment description listed in this Section alphabetically.

Backflow Prevention Device Testing-EPA and National Standard Plumbing Code

Boilers/Water heaters-ASME Boiler and Pressure Vessel Code

Carbon Monoxide Detectors-NFPA 720 Standard for the Installation of Carbon Monoxide (CO) Warning Equipment in Dwelling Units

Doors (smoke and fire doors) inspect and adjust--NFPA 101 Life Safety Code

Elevators-ASME A17.1--Safety Code for Elevators and Escalators, ASME A17.2.1 (or ASME A17.2.2)--Inspectors Manual for Electric (or Hydraulic) Elevators, ASME A17.3-Safety Code for Existing Elevators

Emergency Generators-NFPA 101 Life Safety Code, NFPA 110 Standard for Emergency and Standby Power Systems

Emergency Lighting and Exit Signs-NFPA 101 Life Safety Code

Exhaust Fans-ASHRAE 62 Ventilation for Acceptable Indoor Air Quality

Fire Alarm System-NFPA 72 The National Fire Alarm Code

Fire Extinguisher Inspections-NFPA 10 Standards for Portable fire Extinguishers

Fire Hydrants-NFPA 25 Standard for Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems

Fire Sprinkler Systems-NFPA 25 Standard for Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems

Kitchen Exhaust Hoods and Fans-NFPA 96 Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations

Kitchen Fire Suppression Systems-NFPA 96 Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations, NFPA 13 Standard for the Installation of Sprinkler Systems, NFPA 17 Standard for Dry Chemical Extinguishing Systems, NFPA 17A Standard for Wet Chemical Extinguishing Systems

Playground Equipment-CPSC Handbook for Public Playground Safety Smoke Detectors (battery operated)-NFPA 72 The National Fire Alarm Code

Code Writing and Regulatory Agency Contact Information NFPA-National Fire Prevention Association

1 Batterymarch Park,

Quincy, Massachusetts

USA02169-7471 Tel: (617) 770-3000

www.nfpa.org

ASHRAE-American Society of Heating, Refrigeration, and Air conditioning Engineers

1791 Tullie Circle, N.E.

Atlanta, GA 30329

Tel: (800) 527-4723

www.ashrae.org

ASME-American Society of Mechanical Engineers

Three Park Avenue,

New York, NY 10016-5990

Tel: (800) 843-2763

www.asme.org

EPA-U.S. Environmental Protection Agency

Ariel Rios Building,

1200 Pennsylvania Avenue, N.W.

Washington, DC 20460

Tel: (202) 272-0167

www.epa.gov

CPSC-Consumer Product Safety Commission

4330 East West Highway,

Bethesda, MD 20814 Tel:

Tel: (301) 504-7923

www.cpsc.gov

LIST 3: EQUIPMENT SPECIFIC PROCEDURES, REQUIREMENTS, AND TECHNICAL DETAILS FOR PM

The following is an alphabetical listing of roughly 100 different types of equipment that should be considered for inclusion in your preventive maintenance program. Under the heading for each type of equipment are suggested PM procedures and PM frequency, information on applicable building codes or regulations, and technical information useful to the PM technicians that will be performing the actual preventive maintenance.

In this section, four symbols are used to provide additional information about each type of equipment listed. The four symbols and their meanings are:

INFORMATIONAL SYMBOLS

h-The ambulance symbol indicates that maintenance of this type of equipment may effect the health and safety of building occupants.

?-The earth symbol indicates that maintenance of this type of equipment may have an impact on the environment or may be governed by environmental regulations.

G-The government building symbol indicates that maintenance of this type of equipment may be regulated by codes or government regulations.

?-The telephone symbol indicates that maintenance of this type of equipment often requires calling an outside contractor instead of per forming the work in-house.

AEDs

See Automated External Defibrillators

AIR COMPRESSORS

The most common uses for air compressors in facilities are as a shop tool in the maintenance department, to provide air for older pneumatic HVAC controls, or to provide air for dry pipe fire sprinkler systems. All of these types of Compressors require similar maintenance.

PM Tasks

There are three maintenance tasks that can significantly extend the useful life of an air compressor. These are maintaining proper lubrication, keeping standing water from accumulating in the pressure tank, and keeping air intake filters clean.

Compressor crank case oil will rarely, if ever, need to be changed.

Unlike the oil in the crank cases of internal combustion engines, compressor oil is not exposed to soot, carbon, and other products of combustion and is not subject to the high operating temperatures found in engines.

Compressor oil will therefore last for a very long time, most likely the life of the compressor. The oil level should be checked monthly.

Humidity in the air tends to condense as liquid water inside the pressure tank of air compressors. This water can contribute to rust which can lead to tank failure or rust particles clogging devices in the air stream. Water should be purged from compressors at least monthly.

Intake filters protect compressor bearing surfaces from wear caused by dirt particles. As with air conditioners, dirty air tends to bypass clogged filters and enter the compressor where it can cause abrasive damage and contaminate lubricating oil. Air filters should be inspected, and cleaned if necessary monthly.

Recommended PM Frequency

Monthly: Check oil level, purge water from tank, inspect and clean air filters.

Technical Notes

Automatic bleed devices are available from most industrial sup pliers that are installed at the tank drain petcock to bleed off any water automatically. These simple devices open a drain valve for a few seconds every day.

Air compressors that are part of your dry fire sprinkler system should be serviced with your fire sprinkler system. See Fire Sprinkler Systems for more details.

AIR CONDITIONERS

Few kinds of equipment benefit from PM as much as air conditioners. Preventive maintenance will maintain their efficiency, extend the equipment's life, and have a dramatic effect on the bottom line. AC PM is important enough that you can find an entire section in this guide on the technical aspects of maintaining air conditioners in Section 7.

Be sure to read that section when setting up your PM system or when performing air conditioner PM.

PM Tasks

Quarterly: (during operating season) Change filters. Check for oil spots (indicating leaks). Check condensate pan for corrosion or leaks.

Check condensate drain line and operate condensate pump. Grease blower and motor bearings. Verify operation of compressor. Check condition of drive belts.

Annually: (at start of cooling season) Clean condenser and evaporator coils. Verify operation by running unit. Check superheat to verify proper charge (requires EPA license). Check condition of drive belts and pulleys.

Recommended PM Frequency

Quarterly: minor maintenance (see section above)

Annually: major maintenance (see section above).

Technical Notes

See Section 7-HVAC Systems.

See Condensate Drains, Chillers, Cooling Towers

AIR ELIMINATOR

See Automatic Air Eliminator AIR VENT

See Automatic Air Eliminator

ANSUL SYSTEMS

See Kitchen Fire Suppression Systems. Fire suppression systems from all manufacturers are sometimes incorrectly referred to as "Ansul" systems. Ansul is a subsidiary of Tyco Fire and Safety.

AUTOMATED EXTERNAL DEFIBRILLATORS

Automated defibrillators were almost unheard of a decade ago but are becoming commonplace in many facilities today. Since AEDs first started being accepted as crucial life saving equipment in facilities a few years ago, many lives have been saved with these devices.

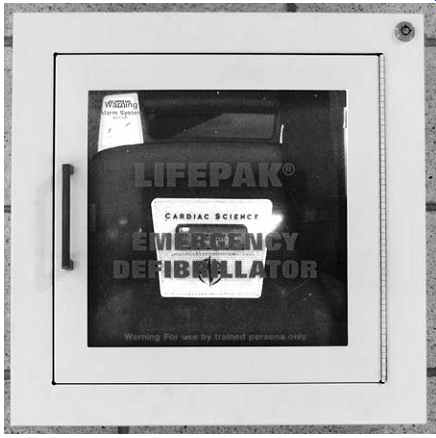

FIG. 1. Automated External Defibrillator

PM Tasks

Each manufacturer will have very specific maintenance requirements that must be fol lowed.

AEDs are largely self diagnostic and will

alarm if the batteries are low or if there are other problems with the units. Inspections usually include making sure that the paddles, gloves, CPR mask, and other items are present, checking the units display or status indicator lights, and making sure that the unit is accessible and that there is appropriate signage in place throughout the building indicating the location of the AED.

Recommended PM Frequency

Follow the manufacturer's requirements Technical Notes

These medical devices can deliver a controlled electric shock to help someone experiencing a heart attack. AEDs are designed to be used by first responders with little training and are able to diagnose cardiac arrhythmia (electrical problems with the heart) and provide a life saving jolt of electricity.

Many facilities now have AEDs located in areas where many people are likely to congregate or in areas such as on-site gyms where people experience physical exertion. AEDs are usually brightly colored and wall mounted in distinctively recognizable cabinets similar to fire extinguisher cabinets.

AUTOMATIC AIR ELIMINATOR

Many facilities have boilers or chillers to heat or cool water which is circulated throughout the building to unit ventilators, duct coils, or other heating or cooling appliances to condition building air. In buildings that use heated or chilled water for temperature control, there can be no air in the closed circulating loop. Air in the system will prevent circulating pumps from working efficiently and can block water flow. When air pockets prevent the flow of water in a heating or cooling, the system is said to be air bound. Air in heating systems also leads to corrosion of pipes, pumps, and other equipment.

Air can enter a heating or cooling system when boilers or chillers are opened for inspection or service, when circulating pumps are re paired, or when water with dissolved gasses enter the system as make up water.

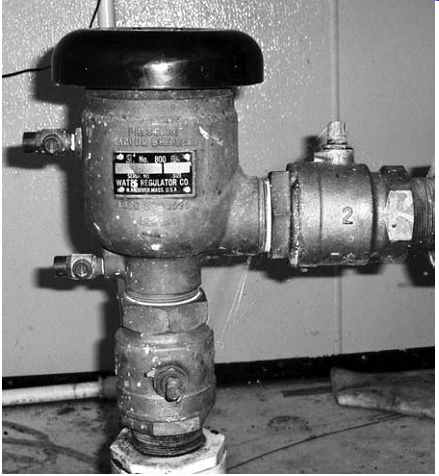

FIG. 2. Automatic Air Eliminator

Automatic air eliminators, also called automatic air vents are simple devices located at the points of highest elevation in the system (where air will collect) that allow air to exit the system but prevent water from leaking.

PM Tasks

Automatic Air Eliminators often fail due to corrosion or age. A failed air eliminator may fail in the closed position and not allow air to escape or they can fail in the open position resulting in a fairly significant water leak.

Air vents should be tested at the start of the heating season for heating systems and should be tested at the start of the cooling system for chilled water systems. When both systems are used, air vents should be tested twice a year.

Air vents are very inexpensive, costing a few dollars each. Many heating and cooling specialists recommend replacing automatic air eliminators every 5 years.

Recommended PM Frequency

Annually: test by depressing valve stem to make sure air vent will open at start of heating season for hot water heating systems.

Annually: test by depressing valve stem to make sure air vent will open at start of cooling season for chilled water heating systems.

Every 5 years: replace all air vents in the facility.

Technical Notes

Most automatic air eliminators have an internal float that closes a small needle valve when the float is lifted by water in the heating system and opens the valve when the float drops whenever air is present.

Whenever replacing air eliminators, it is good practice to install a ball valve between the air eliminator and the heating or cooling loop.

Adding this very inexpensive part can make a very big difference in preventing a flood if an air vent should fail in the open position. Having such a valve will make replacing a faulty air vent much faster and easier in the future.

Larger heating/cooling systems may include air separators in addition to or as part of an air vent assembly. Water flows through a large chamber in an air separator where the water velocity is slowed. Various structures are used inside the air separator chambers to cause micro bubbles of air to combine into bubbles that are large enough to float to the top of the chamber where they are released through an automatic air eliminator.

AUTOMATIC AIR VENT

See Automatic Air Eliminator AUTOMATIC TRANSFER SWITCHES (ATS)

See Emergency Generators AUTOMOBILES

See Vehicles BACKFLOW PREVENTION DEVICES

Backflow prevention devices are designed to protect drinking water from sources of contamination. Backflow devices are often required between municipal water service and individual buildings or between buildings and sources of possible contamination such as lawn irrigation systems, boilers, fire sprinkler systems, chemical treatment systems, and others. Contamination of water can occur if potable (drinking) water pressure were to drop allowing contaminated water to flow back into the potable water supply.

PM Tasks

The National Standard Plumbing Code and the EPA require testing of backflow protection devices annually. Some jurisdictions require RP type devices to be tested semi-annually. Depending on your local jurisdiction, testing must be done by either a licensed plumbing contractor or by a certified backflow device tester.

Recommended PM Frequency

Annually: Test proper operation of AVP and PVB devices.

Annually: Drain outdoor backflow preventers to prevent freezing damage.

Semi-annually: Test proper operation of RP devices.

Technical Notes

There are four basic types of backflow prevention devices in use.

1. Double Check Valve

The simplest type of back flow prevention device is the double check valve. As the name implies, this device is made of two check valves in series. Using two check valves instead of one provides redundancy and an added level of protection. Many jurisdictions do not allow double check valve back flow preventers to be used to protect the public water supply. Where they are allowed, they are not suitable for high hazard applications.

2. Atmospheric Vacuum Breaker

The simplest type of backflow device approved for most applications is the atmospheric vacuum breaker (AVB). An AVB includes a vent at the top to allow air to enter the system if a siphon should develop and a floating poppet which seals off this vent when water pressure is present. If water pressure should drop, the poppet will fall opening the air vent preventing contaminated water from siphoning into the potable water side of the a device. For AVPs to work properly, they must be installed at least 6" above the highest water level downstream from the device. AVPs are only suited to applications where the hazard of contamination is low. The Hose bibb vacuum breaker (HBVB) is a simple type of AVP that is in-stalled onto a hose bib or faucet to prevent backflow from garden hoses into a building's water system.

3. Pressure Vacuum Breaker

The pressure vacuum breaker (PVB) type of backflow device is similar to the AVP except that the poppet is spring loaded. The poppet spring ensures that the poppet will open before water pressure drops to atmospheric pressure. Approved PVBs will also include a test cock (a small valve with a port for attaching a set of testing gauges) on both the inlet and outlet side of the device and two isolation valves. PVBs can be installed in locations where there is a high hazard of contamination and they may have valves installed downstream of the device.

FIG. 3. Faucet with Atmospheric Vacuum Breaker

FIG. 4. Pressure Vacuum Breaker (PVB)

4. Reduced Pressure Backflow Prevention Assembly

A reduced pressure (RP) backflow prevention assemblies are also known as reduced pressure zone (RPZ) or reduced pressure principal (RPP) backflow devices. These devices include two check valves with a pressure relief valve between the two check valves.

The check valves provide redundant protection against flow in the wrong direction while the pressure relief valve provides protection if the check valves were to fail. RVPs also include a test cock before the first check valve, between the two check valves, and after the second check valve to allow the device to be tested. RPVs are used where a high hazard of contamination exists.

BACKUP GENERATORS

See Emergency Generators

BOILERS AND WATER HEATERS

Regulations vary depending on the size of the boiler (in Btu or Hp), whether the boiler produces hot water or steam, and the boiler's operating pressure. In most jurisdictions there are several classes of boiler licenses (called seals) required to operate certain types of boilers.

PM Tasks

FIG. 5. Reduced Pressure Backflow Preventer

Operating temperatures and pressures need to be monitored regularly, often every two hours for larger boilers. The operation of safety devices such as low water cut outs and safety valves should be tested for proper operation daily or on every shift.

Combustion burners (oil or gas) should be cleaned and adjusted every year, at the start of the heating season by someone qualified to do this work. Oil nozzles and oil filters should be replaced, oil pump pressure should be tested, and the combustion chamber should be cleaned and inspected. Gas appliances need to be cleaned and burners adjusted for the most efficient operation. Barometric dampers should be adjusted. Water tube and fire tube boilers should be opened for inspection annually.

Inspections by certified service companies are often required as well as regular inspections by regulatory agencies for safety issues and environmental impact. Environmental permitting may be required to operate boilers.

Recommended PM Frequency

Note: Frequency of PM tasks is different for different size boilers.

If you are performing PM on a boiler with specific requirements, you should have the appropriate operating license for that boiler and will be familiar with the requirements. The following requirements are generic for smaller boilers and hot water heaters.

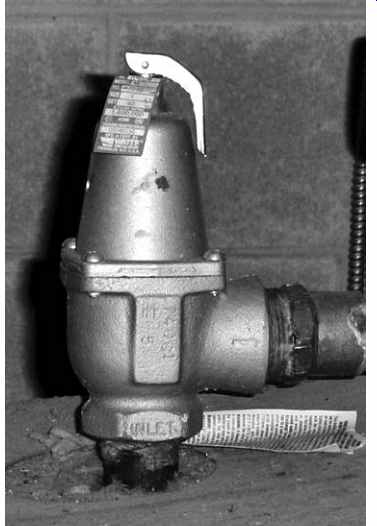

FIG. 6. Safety relief valve. Test by lifting handle until water runs

clear.

Monthly: If a boiler was to malfunction and overheat, there are two devices that will prevent a boiler explosion, the safety relief valve and low water cut off. Test the safety relief valve by manually lifting the handle until water runs clear. Test low water cut off by opening LWCO drain or following manufacturer's instructions. Test these devices at least monthly. Many jurisdictions require daily testing for larger boilers.

Annually : Boilers should have a safety inspection by a certified inspector or by your regulatory agency if required. Combustion boilers should be inspected by a qualified company for operation prior to start of heating season.

Technical Notes

One often overlooked item on small tank type hot water heaters is the anode rod. To prevent the hot water heater tank from corroding, this sacrificial rod is installed at the factory. The anode rod is designed to corrode to protect the tank. This rod should be inspected with your annual inspection and replaced if significantly corroded.

See also Furnaces.

CARBON MONOXIDE (CO) DETECTORS -- CO is a colorless, odorless gas produced by the incomplete combustion of fossil fuels such as oil, natural gas or propane. CO is poisonous and at low exposure levels can produce symptoms similar to the flu. At high concentrations, death can result. Approximately 250 people die in the US from CO poisoning each year.

Many jurisdictions require CO detectors to be installed in sleeping units (hotel rooms, patient rooms, apartments) whenever combustion appliances are present.

PM Tasks

CO detectors should be tested monthly, usually by pressing the "test" button on the detector. Detector batteries should be changed twice a year, traditionally in October and April. Most manufacturers agree that CO detectors sensors have a design life of only 2 years. Consequently, CO detectors will need to be replaced every 2 years.

Because CO detectors are similar to Smoke Detectors in their maintenance requirements and location, Smoke detectors and CO detectors are normally included on the PM calendar together.

Recommended PM Frequency

Monthly: test detectors

Semi-annually: change detector batteries

Every 2 years: replace detectors unless manufacturer recommends a different replacement interval.

Technical Notes

Installation and maintenance of CO detectors is regulated by NFPA 720: "Standard for the Installation of Carbon Monoxide (CO) Detection and Warning Equipment.

CO detectors have a replaceable "sensor kits" that can be replaced instead of having to purchase new CO detectors every two years. When pressing the "test" button on a CO detector, you are probably only testing the detectors electrical circuits, not the condition of the sensor. If a detector is older than 2 years old, it may test fine and still have a bad sensor.

CARPET CARE

Carpet care often falls under the scope of the janitorial or house keeping department. However, there are many buildings where the lines between maintenance and custodial work are blurred. In some instances, the maintenance and housekeeping department are one and the same. In other instances, housekeeping may handle daily vacuuming of carpets with maintenance handling "heavy housekeeping" tasks such as carpet extraction when it is needed.

PM Tasks

The first and often overlooked step in carpet care is to keep the dirt from reaching the carpet in the first place. Keeping dirt out of your building will help to extend both the life of your carpets and the time between cleanings. Walk-off mats at entrance ways can have an enormous impact on the amount of dirt entering your building. A good system of walk off mats will knock off dirt, absorb water, and finally wipe shoes clean of any oils that that will yellow and attract more dirt to your carpet. A walk-off mat will need to be long enough for several steps to be made on the mat to be effective.

Any dirt in a carpet will act as an abrasive and cause carpet fibers to wear under foot traffic. Dirt particles are often microscopically jagged and will damage carpet fibers. This damage is often seen as carpet that appears dull or dingy. Once this damage is done, there is no amount of cleaning that can restore the carpet's appearance. Frequent deep vacuuming not only makes carpet look better, it actually extends carpet life.

A well maintained vacuum with a brush beater will do the best job at removing dirt from within the carpet. Frequent vacuuming can extend carpet life by 50% in high traffic areas.

Spills and stains on carpet should be cleaned up as soon as possible. Stain spotter kits are available from most janitorial suppliers that will have 6 or 8 different spotting chemicals in spray bottles for different types of stains. The longer a stain is allowed to remain, the stronger the stain will be bound with the carpet fibers.

To remove abrasive soil deep within the carpet fibers, some sort of deep cleaning should be performed frequently. This may be steam cleaning, hot water extraction, or some other method that gets down to the bottom of the fibers and lifts the hidden dirt away.

Carpets are usually deep cleaned when they start to look bad. By the time carpets start to look like they need deep cleaning, damage has already been done. Carpets should be cleaned on a regular schedule before carpets appear soiled.

Wet carpets will attract dirt so it is important to dry carpets immediately following deep cleaning and to keep all traffic off of carpets until they are dry. Carpet drying can be accelerated by repeated vacuuming using the extractor, using drying fans, and by using a drying bonnet on a floor scrubbing machine, In areas where traffic cannot be avoided, try extracting only half the carpet each day and direct traffic around wet carpet.

Recommended PM Frequency

The amount of traffic on your carpets dictates how often they will need to be vacuumed and deep cleaned. Remember that both of these tasks should be performed more frequently than the carpet's appearance dictates.

Technical Notes

See also Resilient Flooring Care CARS

See Vehicles

CAULKING -- Caulking is used in many different ways in buildings and will show up in several different ways on your PM calendar. Caulk is used anywhere that a water or air tight seal is needed between two building components. Exterior building expansion joints will need to have the caulk maintained regularly, as does caulking around windows and doors. In hotels, a lot of time can is often spent by maintenance departments to keep the caulk around tubs and showers mildew free. Caulk joints show up around pipe or electric penetrations in exterior walls and at transitions between different roofing components. Caulk is the do-all product wherever there is a crack or gap.

PM Tasks

In most cases, caulk will last a very long time. Excessive movement caused by thermal expansion, wind, or building settling can cause caulk joints to fail. Humid conditions cause caulk to mildew, which is more of a cosmetic problem than a structural one.

PM involves inspection of critical caulk joints such as around penetrations or at building expansion joints. In the real world, inspecting all of the caulk joints around windows and doors would prove to be more time consuming than the benefits would justify unless you have an area with a history of caulk failures.

Having spent several years of my career in the hotel industry, mildewed caulk in bathrooms is one of my pet peeves. Cutting out and replacing mildewed caulk is a common task for the maintenance departments of most hotels. The time spent on mildewed caulk can be practically eliminated if the housekeeping department is given the proper tools, cleaning products, and held accountable for keeping the tub caulking mildew free every day. And reducing the work of the maintenance department is one of the biggest reasons to have a PM program.

Recommended PM Frequency

Annually: inspect building exterior expansion joints, penetrations, and other caulked components.

With Room PM: inspect any caulking in tubs, around AC units, windows, and wallpaper seams.

Technical Notes

There are several types of caulk available, all with different characteristics. When choosing a caulk for your particular job, you will need to consider the following 4 items:

1. Will you be using the caulk indoors or out? Some types will work better in one location than the other.

2. What will be the temperature? Some caulks can handle extreme temperatures while other can't.

3. Moisture Levels. Some caulks perform better in moist environments than others and may even have additives to help prevent mildew and mold from growing.

4. Application method. Some caulks are easier to apply than others and the skill level of the applicator should be considered.

Silicone Caulk

Silicone caulk has become one of the most common types of caulk over the past few years. It is available in many colors and has a rubbery, flexible texture when cured. Silicone caulk tends to stick to surfaces well and is especially useful on non-porous surfaces, such as metal and plastic. Since silicone remains flexible, it rarely cracks due to flexing.

Silicone is one of the most durable caulks lasting 30 years or more and stays flexible in all temperatures. Silicone caulk will not hold paint as paint tends to just slide off of the slippery surface. Silicone requires sol vents for clean up and a mistake or smudge can be impossible to remove.

Silicone caulk on hands often has to wear off after a couple of days.

Latex or Acrylic Caulk

Latex and acrylic caulks are very similar and are often blended as a latex acrylic formulation. Latex caulk is easy to apply, easy to clean up, and can last 20 years. Latex tends to remain flexible, but not quite as flexible as silicone. Latex caulk can be painted and is the most common choice for sealing interior cracks prior to painting.

Latex caulk does not hold up to temperature extremes and becomes very hard and brittle when cold. Latex is a poor choice for exterior caulking in cold climates.

Acrylic Latex Silicone Blend Caulk

This type of caulk is a blend of acrylic, latex, and silicone caulks and has characteristics of all three types. Acrylic latex silicone caulk is easier to apply than silicone but has similar durability and flexibility. Some formulations can be painted while other's can't. This type of caulk is good for use indoors or outdoors in all weather conditions.

Kitchen and Bath Caulk

This type of caulk is usually one of the previous types with chemicals added to prevent mildew growth. Characteristics will be similar to the types mentioned above.

Butyl Rubber Caulk

Butyl rubber caulk is probably the most adhesive of any of the caulks. This characteristic along with the fact that Butyl rubber is extremely elastic and flexible makes it an excellent choice for use in large gaps and cracks. Strong and durable, butyl rubber caulk can last up to ten years outdoors.

Because butyl rubber caulk is so sticky, cleanup is nearly impossible. Any drips or application mistakes are best chipped away after the caulk has had several days to cure. Caulk left on caulking guns or other tools will be a permanent addition.

Oil-based Asphalt Caulk

Although probably not an actual caulk, asphalt or tar-based seal ants are available in standard caulking tubes for use in caulking guns and in buckets to be applied with putty knives or trowels. Asphalt sealant is often used to patch or seal around skylights, pitch pockets, chimney flashing, an other roof components. Asphalt sealant tends to take a very long time to dry and remains sticky for months. Asphalt and tar sealants should not be used where anyone might come into contact with the material. Asphalt-based sealants should only be used with asphalt-based materials and tar-based sealants should only be used with tar-based materials. For information on mixing tar and asphalt see Section 6 on commercial roofing.

CHILLERS -- Chillers are large cooling machines that chill water. This chilled water is then pumped throughout the building to cooling coils to pro vide cooling in all areas. An air conditioner with a capacity of 30 tons of cooling would be considered a large air conditioner while chillers are often sized in the hundreds of tons of cooling capacity. A building that would require dozens of large air conditioner units can easily be served with a single chiller machine.

PM Tasks

Probably the largest disadvantage chillers have over conventional air conditioners is that an equipment failure can shut down the cooling for an entire building. Because of this, maintaining chillers should be a very high priority on your to do list. The cost of chiller repairs can also be staggering. Proper maintenance can prevent repairs that can easily cost tens of thousands of dollars. PM performed on reciprocating chillers has an average return on investment (ROI) of 400% and PM on centrifugal type chillers has a return of over 1,000%.

As a rule, I believe in handling as much PM work in-house as possible. Chiller plants are one of the exceptions to that rule. Chillers are expensive, costing upwards of $1,000 per ton of cooling capacity. You want factory trained service people who are familiar with your specific equipment, and who know what problems are likely to occur. The cost of a PM service call will more than be saved in downtime, repair costs, and extended equipment life.

Scale buildup on evaporator tubes reduce the efficiency of heat transfer. Ask your service company about chemical treatment to pre vent scale buildup and how often they recommend having the tubes cleaned.

There are many different brands and types of chiller plants. As with all equipment, the manufacturer's PM instructions should be re-viewed when setting up your PM program. The following PM tasks are generic.

Recommended PM Frequency

Daily: Observe, and listen to system operating. Check computerized operating log and history for any unusual conditions. Most chillers today are largely self-diagnostic and will notify you of any problems.

Weekly: Inspect sight glasses for oil level, operate lag pumps or switch lead/lag pump position to be sure all pumps will work if needed.

Inspect piping for leaks.

Quarterly: Have your service company perform an inspection to include electrical connections, safety controls, superheat/sub-cooling calibration, and to check for refrigerant leaks.

Annually: Have your service company shut down system and take an oil sample for lab analysis, check the entire refrigerant system for leaks, test the condition of motor windings and insulation using a megohm-meter, and calibrate all safety and operating controls. Your ser vice company may recommend vibration analysis to test the condition of compressor bearings.

Technical Notes

See also Section 7-HVAC Systems CIRCUIT BREAKERS

See Electrical Systems CIRCULATOR PUMPS

Circulator pumps move water. They are found in heating and cooling systems, used to move domestic water long distances, used to increase pressure or to move water to the tops of buildings.

PM Tasks

Check motor ventilation openings and clear away any dirt blocking free movement of air. Lubricate bearings with the proper grease or oil. Check condition of rubber resilient motor mounts if used. Check couplers for wear, wobble, or shaft misalignment. Check shaft seal for leakage.

Recommended PM Frequency

Monthly

Technical Notes

Circulator pumps typically include three components: The pump, a driving motor, and a coupler/bearing assembly connecting the two together. Some designs connect the motor shaft directly to the pump impeller. All three components are included when performing PM to circulator pumps.

COOLING TOWERS

Cooling towers are the "other half" of chiller plants. Chillers pro duce chilled water by extracting heat from the chilled water loop running throughout the building. This heat is often transferred to a second water loop, the cooling tower loop where the heat is taken outside and released to the environment. The cooling tower loop is sometimes referred to as the condensate loop.

FIG. 7. Bank of circulator pumps

PM Tasks

Since a failure of the cooling tower can shut down the cooling for an entire building or several buildings, PM of cooling towers should be near the top of your PM priority list.

Cooling towers are fairly simple pieces of equipment and a quick daily inspection should turn up most small problems while they are still small.

Recommended PM Frequency

Daily: Visual inspection of the cooling tower in operation, check the water level in the water reservoir, make sure fans are operating. You should be noting the condensate temperature each day when doing your daily chiller inspection. (see the section on chillers.)

Weekly: Operate each fan independently and listen for any sounds or problems. Operate circulating pump. Check water level and manually operate make up water valve. Check for leaks.

Quarterly: Inspect and change any clogged spray nozzles, check fan motor belts, grease fan motors and circulating pumps.

Technical Notes

There are many different cooling tower designs. In a typical cooling tower, hot water from the chiller machinery is pumped outside to the cooling tower where it is cascaded down through a series of baffles. Fans draw ambient air across the hot water as it cascades down through the tower. As some of the water evaporates, it absorbs heat from the remaining water cooling it down for its return trip to the chiller plant.

There are several different designs of cooling towers. Many towers cascade and evaporate the water from the cooling tower loop down through the tower. Others keep the condensate water in a closed exchanger coil and cascade water down around the coil to cool the condensate water but the two water sources are kept separate. Still other cooling towers pump the condensate water through a direct exchange coil with only ambient air drawn through the coil to cool the condensate water.

CONDENSATE DRAINS

Condensate drains can refer to the piping or tubing that carries condensate water away from an air conditioner. Condensate drains can also refer to drains and drain traps in the building that collect this condensate and move it out of the building along with other waste water and sewage.

PM Tasks

For condensate drain lines from AC units, use compressed air to maintain clear lines. Add algae control tablets to condensate pans to prevent the growth of algae which will block condensate drains.

Recommended PM Frequency

Start of cooling season: Blow out condensate lines.

Quarterly: Check air conditioner drain pans and condensate lines during the cooling season. Add algae control tablets to condensate pan.

Monthly: If your building has dedicated plumbing drains to handle condensate water, pour water into these traps during heating season to maintain a water plug against sewer gasses.

Technical Notes

There are tools made specifically for blowing out condensate lines. These take a tiny compressed air cartridge similar to those used in air rifles. Any portable air tank, portable compressor, or even nitrogen tank (with a regulator) will work. Condensate drain lines can be blown from the AC out or can be blown toward the AC from the discharge end.

Condensate lines on many AC units have a plumbing trap close to the air handler as part of the condensate line. When the evaporator coil is located before the fan in an air handler, the fan draws air from the evaporator coil causing the condensate line to be under negative pres sure. This negative pressure will pull air through the condensate line preventing water from flowing away. Eventually the backed up water will cause the condensate pan to overflow. A 4" high drain trap in the condensate line creates a water plug that prevents the fan from pulling air through the condensate drain line. Condensate traps are also places where clogs are common.

There must be an air gap between a condensate line from an AC unit and the building condensate trap it empties into. If a condensate drain were to be connected directly to the building's drain system; sewer gasses could be drawn into the AC system and would be distributed throughout the building through the ductwork.

See Floor Drains in this Section for tips on using baby oil or barrier traps to make condensate drain maintenance easier.

See Air Conditioners.

DEFIBRILLATORS

See Automated External Defibrillators.

DETENTION PONDS

See Retention Ponds

DISHWASHERS--Commercial food service kitchens rely on large, automated dish washers for ware washing.

PM Tasks

Dishwasher temperatures and chemical concentration readings need to be measured and recorded daily. Your local health department will probably want to see these records every time they inspect your kitchen. Daily temperature and chemical readings are probably already being done by the kitchen staff and but should be verified during PM inspections.

During the PM inspection, check for leaks and water under the dishwasher, check door seals and the condition of spray shields on the inlet and outlet side of the tray conveyor. Check spray, drain and chemical pump operation.

Check booster heater and dishwasher heating element current draw. It's not unusual to find that one or two heating elements have failed and that the remaining elements are running for longer intervals to catch up.

The dishwasher drain valve must seat fully or high temperatures will be hard to reach as cooler makeup water will be constantly added to the machine.

Recommended PM Frequency

Quarterly: Inspect and operate all components and systems.

Technical Notes

Most commercial dishwashers are one of two different types. The first is the chemical sanitizing dishwasher and the second is hot water sanitizing dishwasher. Chemical sanitizing dishwashers use sanitizing chemicals to sterilize dishes. Chemical sanitizing machines require a rinse water temperature of at least 120ºF and often a temperature of 140ºF and are known as low temperature dishwashers.

Hot water sanitizing dishwashers rely on the temperature of the water to sterilize dishes. Hot water machines require a temperature of at least 180ºF and are called high temperature dishwashers.

Water is usually supplied to the dishwasher at 140ºF for the wash cycle and built in heating elements in the machine help to maintain this temperature. Booster heaters are used increase the temperature of the water to 180ºF for the rinse cycle.

DOORS--Entrance doors can be subject to an enormous amount of wear and tear. Regular minor adjustments to door closers, strikes, and hinges will keep doors operating for a long time.

Smoke and fire doors are used to contain smoke and fire from spreading through a building. NFPA 101-The Life Safety Code, and local construction codes require that these doors must close and latch on their own and must maintain a tight seal between building compartments.

PM Tasks

Let doors swing closed on their own and verify that doors latch properly. Check hinges, panic hardware, and other hardware for tightness. Adjust closer speed so that doors latch consistently but do not close fast enough to injure a child. If magnetic hold-opens are used, verify that they release automatically during a fire alarm when performing your monthly fire alarm tests. Check operation of door synchronizers on double doors.

Recommended PM Frequency

Monthly: inspect and adjust entrance doors, smoke and fire doors, and any doors subject to frequent use.

Technical Notes

Most manufacturers' door closers are adjusted with two or three screws located on the body of the door closer. The screw marked 'B' adjusts the speed of the backswing or door opening speed. The screw marked "S" adjusts the swing speed of the door as it is closing. If an "L" screw is available, this adjusts the latch speed which is the last few inches of the door's swing just before the door latches.

Electromagnetic door release devices hold smoke and fire doors open until the fire alarm system activates. During a fire alarm, power is dropped to the electromagnets releasing the doors and causing them to close and latch automatically. Doors in corridors or to stairwells are often held open using these devices. Be sure to test the operation of these magnetic releases when performing the monthly test of you building's fire alarm system.

DRAINS

See Floor Drains, Condensate Drains

DRYERS (COMMERCIAL LAUNDRY)

See Laundry