AMAZON multi-meters discounts AMAZON oscilloscope discounts

<< cont. from part 1

Combination Smoke and Carbon Monoxide Detectors/Alarms

Combination smoke and carbon monoxide detectors/alarms are readily available. Some com munities are requiring that this type be installed in new construction. Check with your local electrical inspector.

Some inspectors require a "lock-off" device over the handle of the circuit breaker that serves the alarms so that it will not unintentionally be turned off. This lock-off device is really not necessary.

Should the breaker supplying the alarms get turned off intentionally or unintentionally, or if it trips due to trouble in the circuit, the battery backup would power the alarms. When the batteries get low, the alarms start "chirping." The usual way to connect alarms is to run the 2-wire branch circuit to the first alarm, then run 3-wire nonmetallic-sheathed cable from the first alarm to all other alarms. The third conductor pro vides the interconnect feature that will sound all alarms should any one of the alarms activate. See FIG. 4.

Disconnecting means: When installing detectors and alarms, ask your self, "Where will the smoke and greatly heated air travel?" Because smoke and heated air rise, detectors and alarms must be in the path of the smoke and greatly heated air.

FIGs. 5, 6, 7, 8, and 9 illustrate some of the more important issues regarding smoke and heat alarms.

Here is a list of the Do’s and Do not’s in no particular order of importance.

The Do’s:

1. Do install listed smoke alarms, and install them according to the manufacturer's instructions.

2. Do install smoke alarms on the ceiling, as close as possible to the center of the room or hallway. Note: Because ceiling paddle fans are often installed in bedrooms, install the alarms on the wall space above the bedroom door, not closer than 4 in (102 mm) nor more than 12 in. (305 mm) from the ceiling.

3. Do make sure that the path of rising smoke will reach the alarm when the alarm is installed in a stairwell. This is usually at the top of the stairway. The alarm must not be located in a dead airspace created by a closed door at the head of the stairway.

4. Do space according to the instructions furnished with the devices.

5. Do install the type that has a "hush" button if located within 20 ft (6.1 m) of a cooking appliance, or install a photoelectric type.

6. Do install smoke alarms at the high end of a room that has a sloped, gabled, or peaked ceiling where the rise is greater than 1 ft (305 mm) per 8 ft (2.6 m). Do not install in the dead airspace.

7. Do mount on the bottom of open joists or beams.

8. Do install a smoke alarm on the basement ceiling close to the stairway to the first floor.

9. Do install smoke alarms in split-level homes.

A smoke alarm installed on the ceiling of an upper level can suffice for the protection of an adjacent lower level if the two levels are not separated by a door. Better protection is to install alarms for each level.

10. Do install in new construction dual-powered smoke alarms that are hard-wired directly to a 120-volt ac source and also have a battery.

In existing homes, battery-powered alarms are the most common, but 120-volt ac alarms or dual-powered alarms can be installed.

Remember, battery-powered alarms will not operate with dead batteries. Ac-powered alarms will not operate when the power sup ply is off.

11. Do install interconnected smoke alarms in new construction so that the operation of any alarm will cause all other alarms that are interconnected to sound.

12. Do install smoke alarms so they are not the only load on the branch circuit. Connect smoke alarms to a branch circuit that supplies other lighting outlets in habitable spaces. Because smoke alarms draw such a miniscule amount of current, they can easily be connected to a general lighting branch circuit, such as a bedroom branch circuit.

13. Do always consider the fact that doors, beams, joists, walls, partitions, and similar obstructions will interfere with the flow of smoke and heat, and, in most cases, create new areas needing additional smoke alarms and heat alarms.

14. Do make sure that the gap around the ceiling outlet box is sealed to prevent dust from entering the smoke chamber. This is a big problem for ceiling-mounted alarms.

15. Do clean smoke alarms according to the manufacturers' instructions.

16. Do consider that the maximum distance between heat alarms mounted on flat ceilings is 50 ft (15 m) and 25 ft (7.5 m) from the detector to the wall. This information is explained in detail by NFPA 72. Where obstructions such as beams and joists will interfere with the flow of heat, the 50-ft distance is reduced to 25 ft (7.5 m), and the 25-ft distance is reduced to 12½ ft (3.75 m).

17. Do install alarms after construction clean-up of all trades is complete and final.

18. Do install interconnected units of the same manufacturer. Different manufacturers' units may or may not be compatible.

19. Do connect all interconnected units to the same branch circuit. Different circuits cannot be shared.

The Do Not’s:

1. Do not install smoke alarms in the dead airspace at the top of a stairway that can be closed off by a door.

2. Do not install within 36 in. (914 mm) of a door to a kitchen or to a bathroom containing a shower or tub.

3. Do not locate where the smoke alarm will be subject to temperature and/or humidity that exceeds the limitations stated by the manufacturer.

4. Do not install within a 36-in. (914-mm) horizontal path from a supply hot air register.

Install outside the direct flow of air from these registers.

5. Do not install within a horizontal path 36 in. (914 mm) from the tip of the blade of a ceiling-suspended paddle fan.

6. Do not install where smoke rising in a stair way could be blocked by a closed door or an obstruction.

7. Do not place the edge of a ceiling-mounted smoke alarm or heat alarm closer than 4 in. (102 mm) from the wall.

8. Do not place the top edge of a wall-mounted smoke alarm or heat alarm closer than 4 in. (102 mm) from the ceiling and farther than 12 in. (305 mm) down from the ceiling. Some manufacturers recommend placement not farther down than 6 in. (153 mm).

9. Do not install smoke alarms or heat detectors on an outside wall that is not insulated, or one that is poorly insulated. Instead mount the alarms on an inside wall.

10. Do not install smoke alarms or heat alarms on a ceiling where the ceiling will be excessively cold or hot. Smoke and heat will have difficulty reaching the alarms. This could be the case in older homes that are not insulated or are poorly insulated. Instead mount the alarms on an inside wall.

11. Do not install smoke alarms or heat alarms where the ceiling meets the wall because this is considered dead airspace where smoke and heat may not reach the detector.

12. Do not connect smoke alarms or heat alarms to wiring that is controlled by a wall switch.

13. Do not install smoke alarms or heat alarms where the relative humidity exceeds 85%, such as in bathrooms with showers, laundry areas, or other areas where large amounts of visible water vapor collect. Check the manufacturer's instructions.

14. Do not install smoke alarms or heat alarms in front of air ducts, air conditioners, or any high draft areas where the moving air will keep the smoke or heat from entering the detector.

15. Do not install smoke alarms or heat alarms in kitchens where the accumulation of household smoke can result in setting off an alarm, even though there is no real hazard. The person in the kitchen will know why the alarm sounded, but other people in the house may panic. This problem exists in multifamily dwelling units, where unwanted triggering of the alarm in one dwelling unit might cause people in the other units to panic. The photoelectric type may be installed in kitchens but must not be installed directly over the range or cooking appliance. A better choice in a kitchen is to install a heat alarm.

16. Do not install smoke alarms where the temperature can fall below 32°F (0°C) or rise above 120°F (49°C) unless the detector is specifically identified for this application.

17. Do not install smoke alarms in garages where vehicle exhaust might set off the detector.

Instead of a smoke alarm, install a heat detector.

18. Do not install smoke alarms in airstreams that will pass air originating at the kitchen cooking appliances across the alarm. False alarms will result.

19. Do not install smoke alarms or heat detectors on ceilings that employ radiant heating.

20. Do not install smoke alarms or heat alarms in a recessed location.

21. Do not connect smoke alarms or heat alarms to a switched circuit or a circuit controlled by a dimmer.

22. Do not install smoke detectors in attics because of possible nuisance triggering. Check the manufacturers' instructions.

MAINTENANCE AND TESTING

Once installed, smoke, heat, and carbon monoxide alarms must be tested periodically and maintained (blow out accumulated dust) to make sure they are operating properly. This is a requirement of NFPA 72, which states, Homeowners shall inspect and test smoke alarms and all connected appliances in accordance with the manufacturer's instructions at least monthly.

Failure rate: Field studies indicate a probable failure rate of:

3% in the first year 30% in the first 10 years 50% in the first 15 years Nearly 100% in 30 years

The need for periodic testing and replacement is obvious.

When to replace: In conformance to 10.4.7 and 29.8.1.4.(5) in NFPA 72, smoke alarms shall be replaced when they fail to respond to tests and shall not remain in service longer than 10 years from the date of manufacture. Note: The 10-year mandatory replacement requirement is often overlooked. This requirement is based on studies of tens of thousands of smoke alarms in operation, to determine the acceptable number of failures over many years. Code commit tees and manufacturers analyzed the data and agreed that 10 years in service provided a reasonable life time. The 10-year replacement program, along with regular testing per the manufacturer's instruction, results in very few homes going unprotected for any extended period of time. Hard-wired and battery operated alarms are equally affected by age.

The expected life of lithium batteries used in some alarms is said to be 10 years.

At least one major manufacturer of smoke alarms has incorporated a feature that

• sets off a chirping sound after the alarm has been in service for 10 years. The chirping sound repeats every 30 seconds.

• sets off a chirping sound when the battery is low. The chirping sound repeats every minute.

Suggestion: It is difficult to know when a smoke, heat, or carbon monoxide alarm was installed. The instructions are usually filed away or were discarded or otherwise separated from these devices. It might not be a bad idea when installing the alarm to mark the installation date on the device.

After You Install Smoke and Heat Alarms, Then What?

After installing smoke and heat alarms, there is still more to do. NFPA 72 requires that the installer of the fire warning system provide the homeowner with the following information:

1. An instruction booklet illustrating typical installation layouts

2. Instruction charts describing the operation, method, and frequency of testing and maintenance of fire warning equipment

3. Printed information for establishing an emergency evacuation plan

4. Printed information to inform owners where they can obtain repair or replacement service, and where and how parts requiring regular replacement, such as batteries or bulbs, can be obtained within 2 weeks

5. Information that, unless otherwise recommended by the manufacturer, smoke alarms shall be replaced when they fail to respond to tests

6. Instruction that smoke alarms shall not remain in service longer than 10 years from the date of installation This information is usually part of the instructions furnished by the manufacturer of the alarms.

Exceeding Minimum Levels of Protection

The following are recommendations for attaining levels of fire warning protection that exceed the minimum level stated previously and include guidelines for installing smoke and heat detectors in a home.

• Install smoke alarms in all rooms, basements, hallways, heated attached garages, and storage areas. Installing alarms in these locations will increase escape time, particularly if the room or area is separated by a door(s). In some instances, smoke alarms are installed in attics and crawl spaces.

• Install heat alarms in kitchens because conventional smoke alarms can nuisance sound an alarm.

• Install heat alarms in garages because gasoline fires give off little smoke.

• Consider special alarms that light up or vibrate for occupants who are hard of hearing.

• Consider smoke alarms that have an "escape" light.

• Consider low temperature alarms (e.g., 45°F [7°C]) that can detect low temperatures should the heating system fail. The damage caused by frozen water pipes bursting can be extremely costly.

Building Codes

In most instances the various building codes published by the International Code Council (ICC) (formerly BOCA, ICBO, and SBCCI) adopt NFPA 72 and NFPA 720 by reference, but it would be wise to check with your local AHJ to find out if there are any differences between these codes that might affect your installation. See Section 1 for information about these building code organizations. Also refer to the Web site list following the Appendix of this text.

Many companies specialize in installing complete fire and security systems. They also offer sys tem monitoring at a central office and can notify the police or fire department when the system gives the alarm. How elaborate the system should be is up to the homeowner.

The ICC Code requires that smoke alarms be connected to a circuit that also supplies lighting outlets in habitable spaces. The logic is that should the alarms be connected to a separate circuit, that circuit could unknowingly be off.

Manufacturers' Requirements

Here are a few of the responsibilities of the manufacturers of smoke alarms and heat alarms.

Complete data are found in NFPA 72.

• The power supply must be capable of operating the signal for at least 4 minutes continuously.

• Battery-powered units must be capable of a low-battery warning "chirp" of at least one chirp per minute for 7 consecutive days.

• Direct-connected 120-volt ac alarms must have a visible indicator that shows "power-on."

• Alarms must not signal when a power loss occurs or when power is restored.

Note: In 4.3.1 and 2.3.1 in NFPA 72, we find that we must

• always install fire alarm equipment that is "Listed for the purpose."

• always install fire alarm equipment in accordance with the manufacturers' installation and maintenance instructions.

In this residence, the smoke alarms and heat detectors are connected to Circuit A17 located in Panel A in the Workshop. Run two conductors (the circuit) to the first alarm, then interconnect the other alarms by running three conductors between all other detectors.

According to the plans for this residence, smoke, heat, and carbon monoxide alarms (detectors) are located as follows:

Smoke: Bedrooms 3 Hall between bedrooms 1 Entry 1 Recreation Room 1 Rear Hall 1 Total 7 Heat: Kitchen 1 Laundry Room 1 Workshop 1 Garage 1 Total 4 Carbon monoxide:

Recreation Room 1 Hall between bedrooms 1 Total 2

CARBON MONOXIDE ALARMS

Carbon monoxide alarms are installed in addition to smoke and heat alarms! Carbon monoxide (CO) is referred to as the "silent killer"! It is responsible for more deaths than any other single poison.

When a heat or smoke alarm is triggered, it is generally not difficult to determine the source of the problem. But when a carbon monoxide alarm goes off, it is hard to determine the source.

Carbon monoxide is odorless, colorless, and tasteless-undetectable by any of a person's five senses, taste, smell, sight, touch, hearing-but is highly poisonous. Carbon monoxide replaces oxygen in the bloodstream, resulting in brain damage or total suffocation.

Carbon monoxide is produced by the incomplete burning of fuels. Common sources of carbon monoxide in a home are a malfunctioning furnace, gas appliances, kerosene heaters, automobile or other gas engines, charcoal grills, fireplaces, or a clogged chimney.

Symptoms of carbon monoxide poisoning are similar to those of flulike illnesses, such as dizziness, fatigue, headaches, nausea, diarrhea, stomach pains, irregular breathing, and erratic behavior.

Carbon monoxide has about the same characteristics as air. It moves about just like air.

Carbon monoxide alarms detect carbon monoxide from any source of combustion. They are not designed to detect smoke, heat, or gas. The Consumer Product Safety Commission (CPSC) recommends that at least one carbon monoxide alarm be installed in each home, and preferably one on each floor of a multilevel house. Some cities require this. If only one carbon monoxide alarm is installed, it should be in the area just outside individual bedrooms.

Carbon monoxide alarms monitor the air in the house and sound a loud alarm when carbon monoxide above a predetermined level is detected. They provide early warning before deadly gases build up to dangerous levels.

For residential applications, carbon monoxide alarms are available for hard-wiring (direct connection to the branch-circuit wiring), plug-in (the male attachment plug is built into the back of the detector for plugging directly into a 120-volt wall receptacle outlet), and combination 120-volt and battery operated units. They are available with the interconnect feature for interconnecting with smoke and heat alarms. Some carbon monoxide alarms also have an explosive gas sensor.

NFPA 720 contains the installation recommendations for carbon monoxide alarms. Here is a summary of these recommendations.

Installation "Dos" for Carbon Monoxide Alarms

1. Do install carbon monoxide alarms that are tested and listed in conformance to UL Standard 2034.

2. Do install carbon monoxide alarms according to the manufacturer's instructions.

3. Do use household electricity as the primary source of power. In existing homes, monitored battery units are permitted.

4. Do install carbon monoxide alarms in or near bedrooms and living areas.

5. Do install carbon monoxide alarms in locations where smoke alarms are installed.

6. Do test carbon monoxide alarms once each month or as recommended by the manufacturer.

7. Do remove carbon monoxide alarms before painting, stripping, wallpapering, or using aerosol sprays. Store in a plastic bag until the project is completed.

8. Do carefully vacuum carbon monoxide alarms once each month or as recommended by the manufacturer.

9. Do interconnect alarms where multiple alarms are installed.

Installation "Do Not’s" for Carbon Monoxide Alarms

1. Do not connect carbon monoxide alarms to a switched circuit or a circuit controlled by a dimmer.

2. Do not install carbon monoxide alarms closer than 6 in. (150 mm) from a ceiling. This is considered dead airspace.

3. Do not install carbon monoxide alarms in garages, kitchens, or furnace rooms. This could lead to nuisance alarms, may subject the detector to substances that can damage or contaminate the alarm, or the alarm might not be heard.

4. Do not install carbon monoxide alarms within 15 ft (4.5 m) of a cooking or heating gas appliance.

5. Do not install carbon monoxide alarms in dusty, dirty, or greasy areas. The sensor inside of the alarm can become coated or contaminated.

6. Do not install carbon monoxide alarms where the air will be blocked from reaching the alarm.

7. Do not install carbon monoxide alarms in dead airspaces such as in the peak of a vaulted ceiling or where a ceiling and wall meet.

8. Do not install carbon monoxide alarms where the detector will be in the direct airstream of a fan.

9. Do not install carbon monoxide alarms where temperatures are expected to drop below 40°F (4°C) or get hotter than l00°F (38°C). Their sensitivity will be affected.

10. Do not install carbon monoxide alarms in damp or wet locations such as showers and steamy bathrooms. Their sensitivity will be affected.

11. Do not mount carbon monoxide alarms directly above or near a diaper pail. The high methane gas will cause the detector to register, and this is not carbon monoxide.

12. Do not clean carbon monoxide alarms with detergents or solvents.

13. Do not spray carbon monoxide alarms with hair spray, paint, air fresheners, or other aerosol sprays.

FIRE ALARM SYSTEMS

These are the more comprehensive installations involving a central control panel, alarms, sensors, detectors as covered in the National Fire Alarm Code, NFPA 72, Sections 1 through 10.

Fire alarm systems are also covered in Article 760 of the NEC.

NEC 760.2 defines a fire alarm circuit as The portion of the wiring system between the load side of the overcurrent device or the power-limited supply and the connected equipment of all circuits powered and controlled by the fire alarm system. Fire alarm circuits are classified as either non power-limited or power-limited.* Fire-protective signaling systems installed in homes have power-limited fire alarm (PLFA) circuits where the power output is limited by the listed power supply for the system. Here are the key requirements in Article 760, Part III:

• The power supply must have power output capabilities limited to the values specified in Section 9, Table 12(A) and Table 12(B). Refer to 760.121. Residential fire-protective signaling systems are generally "power-limited."

• Do not connect the equipment to a GFCI- or AFCI-protected branch circuit, 760.41(B) and 760.121(B).

• Wiring on the supply side of the equipment is installed according to the conventional wiring methods found in Section 1 through Section 4 of the NEC. See 760.127.

• The branch-circuit overcurrent protection supplying the fire alarm system shall not exceed 20 amperes, 760.127.

• Cables may be run on the surface or be concealed and shall be adequately supported and protected against physical damage, 760.130(B)(1).

• When run exposed within 7 ft (2.1 m) of the floor, the cable shall be securely fastened at intervals not over 18 in. (450 mm), 760.130(B)(1).

• Cables shall not be run in the same raceway, cable, outlet box, device box, or be in the same enclosure as light and power conductors unless separated by a barrier, or introduced solely to connect that particular piece of equipment.

Refer to 760.136(A) and (B). This is also a ruling in 725.136(A) and (B).

• Cables shall not be supported by taping, strap ping, or attaching by any means to any electrical conduits, or other raceways, 760.143.

• Cables shall be supported by structural components, 760.24.

• Wiring on the load side shall be insulated solid or stranded copper conductors of the types listed in Table 760.179(A).

• Table 760.179(I) shows different types of cable that can be substituted for one another when necessary.

• If installed in a duct or plenum, the cable must be plenum rated, 760.179(D). The cable will be marked FPLP.

• Type FPL cable is permitted in one- and two family dwellings, 760.179(F).

- Conductors in cable shall not be smaller than 26 AWG. Single conductors shall not be smaller than 18 AWG. Refer to 760.179(B).

- Cable minimum voltage rating is 300 volts, 760.179(C).

• Remove abandoned conductors and cables.

They add fuel to a fire. Here is a list of where the removal requirements are found in the NEC: 372.13, 374.7, 390.7, 640.2, 640.6(C), 645.2, 645.5(F), 725.2, 725.3(B), 760.2, 760.3(A), 770.2, 770.25, 770.154(A), 800.2, 800.25, 800.154, 820.2, 820.25, 820.154, 830.2, 830.25.

It makes a lot of sense to contact your local inspection authority before installing a fire alarm sys tem to be sure the system you intend to install meets the requirements of the local codes! Contractors who specialize in this kind of work are well aware of the Code requirements and will install the proper types of cables.

SECURITY SYSTEMS

It is beyond the scope of this text to cover all types of residential security systems. What follows is a typical system.

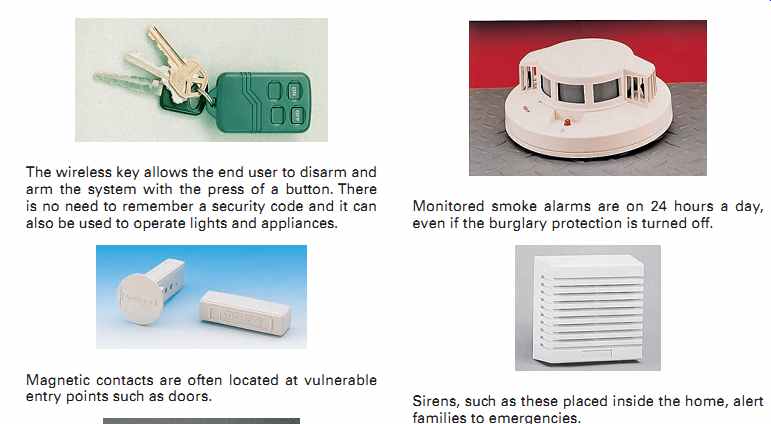

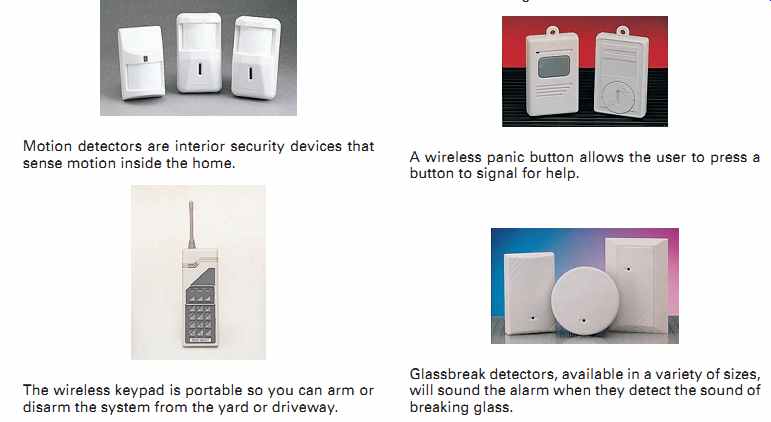

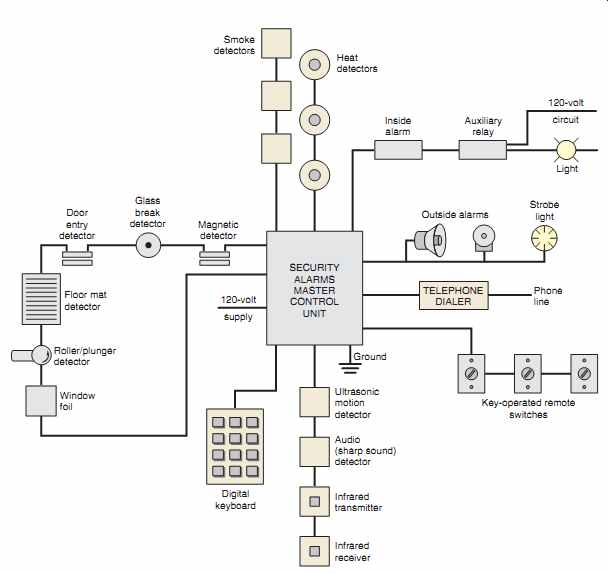

Professionally installed and homeowner installed security systems can range from a simple system to a very complex one. Features and options include master control panels, remote controls, perimeter sensors for doors and windows, motion sensors, passive infrared sensors, wireless devices, interior and exterior sirens, bells, electronic buzzers, strobe lights to provide audio (sound) as well as visual detection, heat sensors, carbon monoxide alarms, smoke alarms, glass break sensors, flood sensors, low temperature sensors, and lighting modules. FIG. 10 shows some of these devices. FIG. 11 shows a schematic one-line diagram for a typical security system.

Monitored security systems are connected by telephone lines to a central station, a 24-hour monitoring facility. If the alarm sounds, security professionals will contact the end user to verify the alarm before sending the appropriate authorities (fire, police, or ambulance) to the home.

The decision about how detailed an individual residential security system should be generally begins with a meeting between the homeowner and the security consultant or licensed electrical con tractor before the actual installation. Most security system installers, consultants, and licensed electrical contractors are familiar with a particular manufacturer's system.

The systems are usually explained and even demonstrated during an in-home security presentation. They are then professionally installed by the security system company or licensed electrical contractor.

===

FIG. 10 Types of security systems.

The wireless key allows the end user to disarm and arm the system with the press of a button. There is no need to remember a security code and it can also be used to operate lights and appliances.

Monitored smoke alarms are on 24 hours a day, even if the burglary protection is turned off.

Magnetic contacts are often located at vulnerable entry points such as doors.

Sirens, such as these placed inside the home, alert families to emergencies.

Motion detectors are interior security devices that sense motion inside the home.

A wireless panic button allows the user to press a button to signal for help.

The wireless keypad is portable so you can arm or disarm the system from the yard or driveway.

Glassbreak detectors, available in a variety of sizes, will sound the alarm when they detect the sound of breaking glass.

===

FIG. 11: Diagram of typical residential security system showing some of the devices

available. Complete wiring and installation instructions are included with

these systems.

Check local code requirements in addition to following the detailed instructions furnished with the system. Most of the interconnecting conductors are 18 AWG.

SECURITY ALARMS MASTER CONTROL UNIT

Inside alarm; Auxiliary relay

TELEPHONE DIALER

Key-operated remote switches Digital keyboard Ground Ultrasonic motion detector Audio (sharp sound) detector Roller/plunger detector Window foil Floor mat detector Glass break detector Magnetic detector Smoke detectors Heat detectors Door entry detector Infrared transmitter Infrared receiver Phone line 120-volt circuit Light Strobe light Outside alarms 120-volt supply

===

Do-it-yourself kits that contain many of the features provided by the professionally installed systems can be found at home centers, hardware stores, electrical distributors, and electronics stores.

Depending on the system, it may or may not be possible to connect to a central monitoring facility.

The wiring of a security system consists of small, easy-to-install low-voltage, multiconductor cables made up of 18 AWG conductors. These conductors should be installed after the regular house wiring is completed to prevent damage to these smaller cables. Usually the wiring can be done at the same time as the chime wiring is being installed.

Security system wiring comes under the scope of Article 725.

When wiring detectors such as door entry, glass break, floor mat, and window foil detectors, circuits are electrically connected in series so that if any part of the circuit is opened, the security system will detect the open circuit. These circuits are generally referred to as "closed" or "closed loop." Alarms, horns, and other signaling devices are connected in parallel, because they will all signal at the same time when the security system is set off. Heat detectors and smoke detectors are generally connected in parallel because any of these devices will "close" the circuit to the security master control unit, setting off the alarms.

The instructions furnished with all security systems cover the installation requirements in detail, alerting the installer to Code regulations, clearances, suggested locations, and mounting heights of the systems' components.

Always check with the local electrical inspector to determine if there are any special requirements in your locality relative to the installation of security systems.

Sprinkler Systems Code -- Home fire protection sprinkler systems are covered by NFPA 13D, which is the Standard for the Installation of Sprinkler Systems in One- and Two Family Dwellings and Manufactured Homes.

The 2009 International Residential Code (IRC) in section R313.2 will require, effective January 1, 2011, that new one and two-family dwellings have an automatic residential fire sprinkler system.

An exception provides that the automatic residential fire sprinkler system is not required for additions or alterations to existing buildings that are not already provided with an automatic residential sprinkler system.

Automatic residential fire sprinkler systems are required to be designed and installed in accordance with IRC Section P2904 or NFPA 13D.

This rule will apply where the International Residential Code is adopted and enforced. A parallel requirement is in the 2009 International Building Code.

Standards Relating to Fire, Smoke, Carbon Monoxide, and Security Devices

UL 217-Standard for Single- and Multiple Station Alarms UL 268-Standard for Smoke Detectors for Fire Protective Signaling Systems UL 365-Standard for Police Station Connected Burglar Alarm Units UL 521-Standards for Heat Detectors for Fire Protection Signaling Systems UL 539-Standard for Single- and Multiple Station Heat Detectors UL 609-Standard for Local Burglar Alarm Units and Systems UL 827-Standard for Central Station Alarm Services UL1023-Standard for Household Burglar Alarm System Units UL 1610-Standard for Central Station Burglar Alarm Units UL 1641-Standard for Installation and Classification of Residential Burglar Alarm Systems UL 2034-Standard for Single- and Multiple Station Carbon Monoxide Alarms

REVIEW

1. In your own words, explain the terms alarm and detector.

2. The requirements for household fire alarm systems are found in what NFPA Code and in what section of this code?

3. Do heat alarms and carbon monoxide alarms take the place of smoke alarms? Explain.

4. Name two basic ways that smoke alarms are powered.

5. Name the two types of smoke alarms.

6. List the absolute minimum level of smoke alarm protection in a new one-family dwelling.

7. Circle the correct answer from the following statements:

a. Smoke alarms installed in new one- and two-family homes shall be battery operated only so as not to be affected by a power outage.

b. Smoke alarms installed in new one- and two-family homes shall be dual powered by a 120-volt circuit and a battery.

8. Circle the correct answer from the following statements:

a. Smoke alarms installed in new one- and two-family homes shall be interconnected so that if any one of them is triggered, all other alarms will also sound off.

b. Smoke alarms installed in new one- and two-family homes shall not be interconnected so that each alarm will operate independently of all other alarms in the home.

9. Circle the correct answer from the following statements:

a. Always install smoke and fire alarms in dead airspaces.

b. Never install smoke and fire alarms in dead airspaces.

10. Circle the correct answer from the following statements:

a. Mount wall-mounted smoke alarms so that the top edge is not closer than 4 in. (102 mm) from the ceiling and not more than 12 in. (305 mm) from the ceiling.

b. Mount wall-mounted smoke alarms anywhere on the wall, but not lower than 36 in. (914 mm) from the ceiling.

11. Cooking and baking in the kitchen can produce quite a bit of smoke. The best choice for a smoke alarm in the kitchen is the photoelectric type. The better choice would be to install a (heat alarm) (carbon monoxide alarm). Circle the correct answer.

12. An important but often overlooked requirement in the National Fire Alarm Code, NFPA 72 is that alarms must be replaced after being in service for: (Circle the correct answer.)

a. not more than 5 years.

b. not more than 10 years.

c. not more than 15 years.

13. Carbon monoxide is , and is , , and .

14. Circle the correct answer from the following statements.

a. Carbon monoxide is heavier than air.

b. Carbon monoxide will always rise to the ceiling.

c. Carbon monoxide will drop to the floor.

d. Carbon monoxide is about the same weight as air.

15. The more complex household fire alarm systems are covered in what article of the National Electrical Code? Circle the correct answer.

a. Article 72

b. Article 310

c. Article 760

16. Circle the correct answer from the following statements:

a. Always connect a fire alarm circuit or system to a power supply that has ground fault circuit interrupter (GFCI) protection.

b. Never connect a fire alarm circuit or system to a power supply that has ground-fault circuit interrupter (GFCI) protection.

c. It makes no difference whether or not the branch circuit is GFCI or AFCI protected because the alarms are required to have battery backup power. In the event of a loss of power for whatever reason, the alarms would still be operative.

17. Circle the correct answer from the following statements:

a. Conductors for fire alarm systems shall not be installed in the same raceways, cables, or electrical boxes as the light and power conductors.

b. It is permissible to install fire alarm conductors in the same raceways, cables, or electrical boxes as the light and power conductors because the conductors for fire alarm systems covered in Article 760 are small and would easily fit into other electrical raceways and boxes.

18. Fire alarm cable generally used in more complex residential fire alarm and security systems is marked (FPL) (low-voltage bell wire) (THHN). Circle the correct answer.

19. When installing a fire alarm system or a complete security system package in a home, always follow the installation instructions from: (Circle the correct answer.)

a. the manufacturer of the product and applicable codes.

b. your neighbor, because he knows a lot about codes and standards.

c. the man at the home center who sold you the product.

20. Residential sprinkler fire protection systems are required to be installed in compliance with the following (Circle the best answer):

a. NFPA 13D.

b. IRC P2904.

c. either NFPA 13D or IRC P2904.

d. neither NFPA 13D nor IRC P2904.