AMAZON multi-meters discounts AMAZON oscilloscope discounts

Thermography is a predictive maintenance technique that can be used to monitor the condition of plant machinery, structures, and systems. It uses instrumentation designed to monitor the emission of infrared energy (i.e., temperature) to determine operating condition. By detecting thermal anomalies (i.e., areas that are hotter or colder than they should be), an experienced surveyor can locate and define incipient problems within the plant.

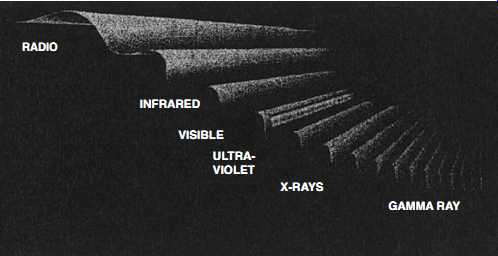

FIG. 1 Energy emissions. All bodies emit energy within the infrared

band. This provides the basis for infrared imaging or thermography. A

= Absorbed energy. R = Reflected energy. T = Transmitted energy. E =

Emitted energy. A + R + T = 1 E = A E + R + T = 1

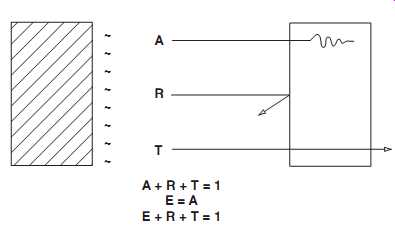

FIG. 2 Blackbody emissions. A perfect or blackbody absorbs all infrared

energy. A = Absorbed energy. R = Reflected energy. T = Transmitted energy.

E = Emitted energy. E = A = 1 R = 0 T = 0

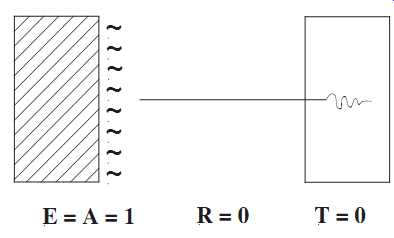

FIG. 3 Gray-body emissions. All bodies that are not blackbodies will

emit some amount of infrared energy. The emissivity of each machine must

be known before implementing a thermographic program. A = Absorbed energy.

R = Reflected energy. T = Transmitted energy. E = Emitted energy. E =

A = .7 R = .3 T = 0

INFRARED BASICS

Infrared technology is predicated on the fact that all objects with a temperature above absolute zero emit energy or radiation. Infrared radiation is one form of this emitted energy. Infrared emissions, or below red, are the shortest wavelengths of all radiated energy and are invisible without special instrumentation. The intensity of infrared radiation from an object is a function of its surface temperature; however, tempera ture measurement using infrared methods is complicated because three sources of thermal energy can be detected from any object: energy emitted from the object itself, energy reflected from the object, and energy transmitted by the object ( FIG. 1).

Only the emitted energy is important in a predictive maintenance program. Reflected and transmitted energies will distort raw infrared data. Therefore, the reflected and transmitted energies must be filtered out of acquired data before a meaningful analysis can be completed.

The surface of an object influences the amount of emitted or reflected energy. A perfect emitting surface, FIG. 2, is called a "blackbody" and has an emissivity equal to 1.0. These surfaces don’t reflect. Instead, they absorb all external energy and re-emit it as infrared energy.

Surfaces that reflect infrared energy are called "graybodies" and have an emissivity less than 1.0 ( FIG. 3). Most plant equipment falls into this classification. Careful considerations of the actual emissivity of an object improve the accuracy of tempera ture measurements used for predictive maintenance. To help users determine emissivity, tables have been developed to serve as guidelines for most common materials; however, these guidelines are not absolute emissivity values for all machines or plant equipment.

Variations in surface condition, paint, or other protective coatings and many other variables can affect the actual emissivity factor for plant equipment. In addition to reflected and transmitted energy, the user of thermographic techniques must also consider the atmosphere between the object and the measurement instrument. Water vapor and other gases absorb infrared radiation. Airborne dust, some lighting, and other variables in the surrounding atmosphere can distort measured infrared radiation. Because the atmospheric environment is constantly changing, using thermographic techniques requires extreme care each time infrared data are acquired.

TYPES OF INFRARED INSTRUMENTS

Most infrared-monitoring systems or instruments provide special filters that can be used to avoid the negative effects of atmospheric attenuation of infrared data; however, the plant user must recognize the specific factors that will affect the accuracy of the infrared data and apply the correct filters or other signal conditioning required to negate that specific attenuating factor or factors.

Collecting optics, radiation detectors, and some form of indicator are the basic elements of an industrial infrared instrument. The optical system collects radiant energy and focuses it on a detector, which converts it into an electrical signal. The instrument's electronics amplifies the output signal and processes it into a form that can be displayed. Three general types of instruments can be used for predictive maintenance: infrared thermometers or spot radiometers, line scanners, and imaging systems.

Infrared Thermometers

Infrared thermometers or spot radiometers are designed to provide the actual surface temperature at a single, relatively small point on a machine or surface. Within a predictive maintenance program, the point-of-use infrared thermometer can be used in conjunction with many of the microprocessor-based vibration instruments to monitor the temperature at critical points on plant machinery or equipment. This technique is typically used to monitor bearing cap temperatures, motor winding temperatures, spot checks of process piping temperatures, and similar applications. It’s limited in that the temperature represents a single point on the machine or structure. When used in con junction with vibration data, however, point-of-use infrared data can be valuable.

Line Scanners

This type of infrared instrument provides a single-dimensional scan or line of comparative radiation. Although this type of instrument provides a somewhat larger field of view (i.e., area of machine surface), it’s limited in predictive maintenance applications.

Infrared Imaging

Unlike other infrared techniques, thermal or infrared imaging provides the means to scan the infrared emissions of complete machines, process, or equipment in a very short time. Most of the imaging systems function much like a video camera. The user can view the thermal emission profile of a wide area by simply looking through the instrument's optics. A variety of thermal imaging instruments are on the market, ranging from relatively inexpensive, black-and-white scanners to full-color, microprocessor-based systems. Many of the less expensive units are designed strictly as scanners and cannot store and recall thermal images. The inability to store and recall previous thermal data limits a long-term predictive maintenance program.

Point-of-use infrared thermometers are commercially available and relatively inexpensive. The typical cost for this type of infrared instrument is less than $1,000.

Infrared imaging systems have a price range from $8,000 for a black-and-white scanner without storage capability to more than $60,000 for a microprocessor-based, color imaging system.

TRAINING

Training is critical with any of the imaging systems. The variables that can destroy the accuracy and repeatability of thermal data must be compensated for each time infrared data are acquired. In addition, interpretation of infrared data requires extensive training and experience.

Inclusion of thermography into a predictive maintenance program will enable you to monitor the thermal efficiency of critical process systems that rely on heat transfer or retention; electrical equipment; and other parameters that will improve both the reliability and efficiency of plant systems. Infrared techniques can be used to detect problems in a variety of plant systems and equipment, including electrical switchgear, gearboxes, electrical substations, transmissions, circuit breaker panels, motors, building envelopes, bearings, steam lines, and process systems that rely on heat retention or transfer.

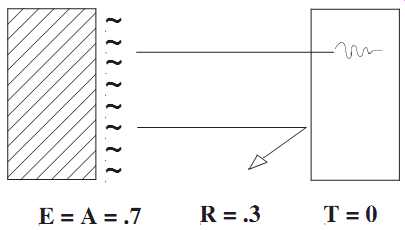

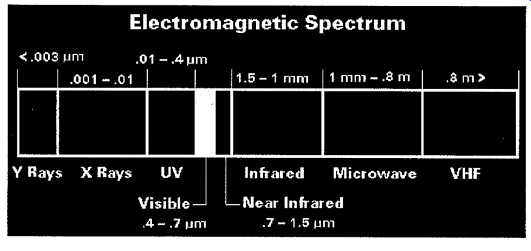

FIG. 4 Electromagnetic spectrum.

BASIC INFRARED THEORY

Infrared energy is light that functions outside the dynamic range of the human eye.

Infrared imagers were developed to see and measure this heat. These data are transformed into digital data and processed into video images called thermograms. Each pixel of a thermogram has a temperature value, and the image's contrast is derived from the differences in surface temperature. An infrared inspection is a nondestructive technique for detecting thermal differences that indicate problems with equipment. Infrared surveys are conducted with the plant equipment in operation, so production need not be interrupted. The comprehensive information can then be used to prepare repair time/cost estimates, evaluate the scope of the problem, plan to have repair materials available, and perform repairs effectively.

Electromagnetic Spectrum

All objects emit electromagnetic energy when heated. The amount of energy is related to the temperature. The higher the temperature, the more electromagnetic energy it emits. The electromagnetic spectrum contains various forms of radiated energy, including X-ray, ultraviolet, infrared, and radio. Infrared energy covers the spectrum of 0.7 micron to 100 microns.

The electromagnetic spectrum is a continuum of all electromagnetic waves arranged according to frequency and wavelength. A wave has several characteristics ( FIG. 5). The highest point in the wave is called the crest. The lowest point in the wave is referred to as the trough. The distance from wavecrest to wavecrest is called a wave length. Frequency is the number of wavecrests passing a given point per second. As the wave frequency increases, the wavelength decreases. The shorter the wavelength, the more energy contained; the longer the wavelength, the less energy.

For example, a steel slab exiting the furnace at the hot strip will have short wave lengths. You can feel the heat and see the red glow of the slab. The wavelengths have become shorter crest to crest and the energy being emitted has increased, entering the visible band on the spectrum. By contrast, (infrared energy) when the coil comes off of the coilers it has been cooled. Energy is lost. The wavelength have increased crest to crest and decreased in frequency.

Heat Transfer Concepts

Heat is a form of thermal energy. The first law of thermodynamics is that heat given up by one object must equal that taken up by another. The second law is that the transfer of heat takes place from the hotter system to the colder system. If the object is cold, it absorbs rather than emits energy. All objects emit thermal energy or infrared energy through three different types or modes: conduction, convection, and radiation.

It’s important to understand the differences among these three forms.

Conduction:

Conduction is the transfer of energy through or between solid objects. A metal bar heated at one end will, in time, become hot at the other end. When a motor bearing is defective, the heat generated by the bearing is transferred to the motor casing. This is a form of conduction.

Convection:

Convection is the transfer of energy through or between fluids or gases. If you took the same motor mentioned previously and placed a fan blowing directly on the hot bearing, the surface temperature would be different. This is convection cooling. It occurs on the surface of an object. An operator must be careful to identify the true cause and effect. In this case, the difference between good and bad source heating and the surface cooling is caused by convection.

Radiation:

Radiation is the transfer of heat by wavelengths of electromagnetic energy. The most common cause of radiation is solar energy. Only radiated energy is detected by an infrared imager. If the aforementioned motor were sitting outside in the slab storage yard with slabs stacked around it, the electromagnetic energy from the sun and from the slabs would increase the temperature.

The purpose of the previous example was to make the thermographer aware that other causes of the thermal energy could be found or not found. In this case, was the motor hot because of a bad bearing or because of solar radiation? Was the motor missed and failed later because of the fan blowing on it and causing convection cooling? Conduction is the only mode that transfers thermal energy from location to location within a solid; however, at the surface of a solid or liquid, and in a gas, it’s normal for all three modes to operate simultaneously.

Emissivity:

Emissivity is the percentage of energy emitted by an object. Infrared energy hits an object; the energy is then transmitted, reflected, or absorbed. A common term used in infrared thermography is blackbody. A blackbody is a perfect thermal emitter. Its emissivity is 100 percent. It has no reflection or transmittance. The objects you will be scanning will each have a different emissivity value. A percentage of the total energy will be caused by reflection and transmittance; however, because most of your infrared inspection will be quantitative thermography, the emissivity value won’t be as important now.

INFRARED EQUIPMENT

Listed as follows are the criteria used to evaluate infrared equipment. It’s important to determine which model best fits your needs before a purchase is made. Some of these points will be important to you and others will not. You will know more about your needs after you have finished reading this guide.

• Portability. How much portability does your application require? Does weight and size of the instrument affect your data collection? What kind of equipment will you be scanning?

• Ease of Use. How much training is required to use the imager? Can it be used easily in your environment?

• Qualitative or Quantitative. Does it measure temperatures? If yes, what temperature range will be measured? Will you need more than one range?

• Ambient or Quantitative Measurements. What are the maximum upper and minimum lower ambient temperatures in which you will be scanning?

• Short or Long Wavelengths. Long-wavelength systems offer less solar reflection and operate in the 8- to 14-micron bandwidth. Short-wavelength systems offer smaller temperature errors when an incorrect emissivity value is entered. The operating bandwidth for a short-wave unit is 2 to 5.6 microns.

• Batteries. What is the weight and size of the batteries? How long will they last? Will you need additional batteries? How long do they take to charge?

• Interchangeable Lenses. Do the ones available fit your application? What are their costs?

• Monitor, Eyepiece, or Both. Will you need to show a live image to others while performing an inspection?

• Analog or Digital. How will you process the images? Does the imager have analog, digital, or both capabilities?

• Software. Can the software package produce quality reports and store and retrieve images? Do you require colonization and temperature editing?

INFRARED THERMOGRAPHY SAFETY

Equipment included in an infrared thermography inspection is almost always energized. Therefore, a lot of attention must be given to safety. The following are basic rules for safety while performing an infrared inspection:

• Plant safety rules must be followed at all times.

• Notify area personnel before entering the area for scanning.

• A qualified electrician from the area should be assigned to open and close all panels.

• Where safe and possible, all equipment to be scanned will be online and under normal load with a clear line of sight to the item.

• Equipment whose covers are interlocked without an interlock defect mechanism should be shut down when allowable. If safe, their control covers should be opened and equipment restarted.

INFRARED SCANNING PROCEDURES

The purpose of an infrared inspection is to identify and document problems in an electrical or mechanical system. The information provided by an inspection is presented in an easily and understandable form. A high percentage of problems occur in termination and connections, especially in copper-to-aluminum connections. A splice or a lug connector should not look warmer than its conductors if it has been sized properly. All problem connections should be dismantled, cleaned, reassembled, or replaced as necessary.

TYPES OF INFRARED PROBLEMS

There are three basic types of thermal problems:

- Mechanical looseness

- Load problems

- Component failure

Mechanical Looseness:

Mechanical looseness occurs most often. A loose connection will result in thermal stress fatigue from overuse. Fuse clips are a good example because the constant heat up and cooldown creates a poor connection. An accurate temperature measurement, or use of an isotherm, will identify a loose condition. When the isotherm is brought down to a single pixel, or temperature, it will identify the source of the loose condition.

Component Failure:

Understanding the nomenclature of the problem can identify component failure.

Specifically, the actual component will be the heat source. For example, a heat-stressed fuse in a three-phase assembly will appear hotter than the other two fusses.

Common Problems Found and What to Scan:

Following are examples of what to scan while performing an infrared survey to easily detect common problems.

Motor Control and Distribution Centers:

Have the switchgear panel covers opened or removed by qualified personnel before inspection. Scan cable, cable connections, fuse holders, fuse circuit breakers, and bus.

Main Secondary Switchgear:

Have the switchgear panel covers opened or removed by qualified personnel before inspection. Scan cables, cables connections, circuit breakers (front and back), and bus.

Circuit Breaker Distribution Panels:

Covers on small circuit breaker panels don’t have to be removed for scanning. Circuit breakers and conductors are very close to the metal covers. Defective components are usually detectable by the heating of the cover in the area of the problem. If a problem exists, remove the panel cover to locate the problem. Only remove panel covers that can safely be removed.

Bus Duct:

Electrical conductors are very close to the metal "skin" of the duct. Defective joints are usually detectable by the heating of the cover in the vicinity of the problem.

Motors:

Don’t scan motors less than 25 horsepower unless they are critical to production. On motors greater than 25 horsepower, scan the "T" boxes, visible conductors, connections, and rotors. Bearing problems can be found by comparing the surface tempera ture of like motors. Overheating conditions are documented as hot spots on the CRT and are usually found in comparing equipment, end bell and end bell (same type bearings), and stator to end bell.

Transformer--Oil-Filled:

Scan transformer, transformer fins, cable connections, bushings, and tap changer. On all transformers, the oil level should be inspected during the survey. During the infrared survey, if a transformer appears exceptionally warm, the cooling radiators are near ambient temperature, and the transformer is above 50 percent of full load, the oil level is too low to circulate the oil and cooling is not taking place. Oil in the transformers is cooled by convection; as the load increases, the oil expands and the level increases until it then circulates in the cooling radiators. As a result of repeated oil samples and oil leaks, the reduced volume of oil causes the winding to overheat, thus reducing the life of the transformer. Plugged cooling heaters, isolated radiators, and plugged individual cooling fins can also be detected.

Transformers--Dry-Type:

Scan transfers, cable connections, bushings, and tap changer. Enclosure covers on dry-type transformers should be removed only if there is safe clearance between the transformer connections and the enclosure panels. Some models, especially the newer ones, have screened openings for ventilation. Use these openings for your scanning survey.

The iron in these transformers is hot. It will heat the bus work and cause substantial infrared reflection. By increasing the temperature scale and adjusting the level control on the imager, you will be able to get uniform images, which will show hot spots in the secondary bus or the iron. A hot spot in the iron usually indicates a short. Make certain that reflection is not a factor.

Compare all windings. If temperatures are over a winding, but there is a difference in temperature of two windings, there may be an unbalanced load. A hot spot on a winding may point to a shorted turn.

Transformer Bushings:

As a scanner moves upward on the transformer main tank and tap changer compartment, the bushings, lighting arresters, and their bus connections should be observed.

This area is also critical because the integrity of the transformer, substation, or the complete system depends on proper installation and maintenance of each component.

A survey of the transformer bushings, comparing one to the other, will reveal any loose connections or bushing problems. With the scanner, you can determine if the connection is loose internally or externally.

Capacitors:

A capacitor has two conductive surfaces, which are separated by a dielectric barrier.

Capacitors usually function as power factor correctors. When energized, all units should have the same temperature if the size is the same. A high uniform temperature is normal. A cold capacitor usually indicates a blown fuse or bad cell. Isolated spots showing a high temperature on a surface of the capacitor may indicate a bad capacitor.

High-Voltage Switchgear:

Scan lighting arresters, insulators, cables, cables connections, bussing, circuit breakers, and disconnect switches.

Load Break Switches:

In the switch, two metal surfaces act as conductors when they are brought into contact.

Usually, problems are restricted to the contact surface. Poor contacts usually show up as hot spots.

Fuses:

A fuse is a metal conductor, which is deliberately melted when an overload of current is forced on it. Major problems affected are loose mechanical stab clips that cause hot spots, corroded or oxidized external contact surfaces, and/or poor internal connections, which are bolted or soldered.

Circuit Breakers:

Circuit breakers serve the same function as a fuse. It’s a switching device that breaks an electrical circuit automatically. Problem areas are caused by corroded or oxidized contact surfaces, poor internal connections, poor control circuitry, and/or defective bushings.

Conductors:

The melting points and current-carrying capacity of conductors are determined by the size and base material of the conductors. During a survey, compare between phases and between conductors and connections. An unbalanced load will account for some differences between conductors. Use metering devices already installed to check the differences.

The type of load will affect whether the load is balanced. Three-phase motor loads should be balanced; lighting and single-phase loads may be unbalanced.

Other Problems:

• Broken strands. These hot spots are found at the support and at the cable termination.

• Spiral heating. This is found on stranded wire, which is heavily oxidized. The problem will show up as a hot spiral from one connection to another. There is a load imbalance between the strands, which results in a poor connection.

• Ground conductor. Usually there are no hot spots on a ground conductor. They do show up, however, as hot spots when there is abnormal leakage current to the ground. Be suspicious about such spots. Always point them out in the inspection report.

• Parallel feeders. A cold cable indicates a problem when parallel conductors are feeding the same load.

Abbreviations

DT Delta temperature. The delta notation represents the difference in two temperatures.

m Electrical units for ohms. Also used to describe microns in the infrared electromagnetic scale.

°C Degrees Celsius

°F Degrees Fahrenheit

Glossary

A/D conversion---The conversion of continuous-type electrical signals varying in amplitude, frequency, or phase into proportional, discrete digital signals by means of an analog-digital converter.

Absorptivity---Ratio of the absorbed to incident electro magnetic radiation on a surface.

Ambient temperature Ambient temperature is the temperature of the air in the immediate neighborhood of the equipment.

Analog data ---Data represented in continuous form, as contrasted with digital data having discrete values.

Atmospheric absorption The process whereby some or all of the energy of sound-waves or electromagnetic waves is transferred to the constituents of the atmosphere.

Atmospheric attenuation The process whereby some or all of the energy of the soundwaves or electromagnetic radiation is absorbed and/or scattered when traversing the atmosphere.

Atmospheric emission Electromagnetic radiation emitted by the atmosphere.

Atmospheric radiance The radiant flux per unit solid angle per unit of projected area of the source in the atmosphere.

Atmospheric reflectance Ratio of reflected radiation from the atmosphere to incident radiation.

Band A specification of a spectral range (say, from 0.4 to 0.5 microns) that is used for radiate measurements. The term channel is also in common use, with the same meaning as band. In the electromagnetic spectrum, the term band refers to a specific frequency range, designated as L-Band, S-Band, X Band, and so on.

Bandwidth A certain range of frequencies within a band.

Conduction The transfer of heat through or between solids.

Convection The transfer of heat through or between fluids.

Corona The glow or brush discharge around conductors when air is stressed beyond its ionization point without developing flashover.

Electromagnetic spectrum Electromagnetic radiation is energy propagated through space between electrical and magnetic fields. The electromagnetic spectrum is the extent of that energy ranging from cosmic rays, gamma rays, and X-rays to ultraviolet, visible, and infrared radiation, including microwave energy.

Emissivity Consideration of the characteristics of materials, particularly with respect to the ability to absorb, transmit, or reflect infrared energy.

Emittance Power radiated per unit area of a radiating surface.

Far-infrared Infrared radiation extending approximately from 15 to 100 micrometers.

Gamma ray---A high-energy photon, especially as emitted by a nucleus in a transition between two energy levels.

Hot spot---An area of a negative or print revealing excessive light on that part of the subject.

Infrared band -- The band of electromagnetic wavelengths lying between the extreme of the visible (approximately 0.70 micrometer) and the shortest microwaves (approximately 100 micrometers).

Infrared radiation -- Electromagnetic radiation lying in the wavelength interval from 0.7 to 1,000 microns (or roughly between 1 micron and 1 millimeter wavelength). Its lower limit is bounded by visible radiation, and its upper limit by microwave radiation.

Isothermal mapping---Mapping of all regions with the same temperature.

Microwave band---The portion of the electromagnetic spectrum lying between the far-infrared and the conventional radio frequency portion. Although not bounded by definition, it’s commonly regarded as extending from 0.1 cm (100 microns) to 30 cm in wavelength (1 to 100 giga-Hertz frequency).

Mid-infrared -- Infrared radiation extending approximately from 1.3 to 3.0 micrometers and being part of the reflective infrared. Often referred to as short-wavelength infrared radiation (SWIR).

Near-infrared -- Infrared radiation extending approximately from 0.7 to 1.3 micrometers and being part of the radiative infrared.

Qualitative infrared thermography -- The practice of gathering information about a system or process by observing images of infrared radiation and recording and presenting that information.

Quantitative infrared thermography -- The practice of measuring temperatures of the observed patterns of infrared radiation.

Radar band-- Frequency and designation with wave lengths within the range of approximately 100 microns to 2 meters.

Radiation The emission and propagation of waves transmitting energy through space or through some medium.

Radio band The range of wavelengths or frequencies of electromagnetic radiation designated as radio waves; approximately 4 to 9Hz in frequency.

Reflectivity The fraction of the incident radiant energy reflected by a surface that is exposed to uniform radiation from a source that fills its field of view.

Spectral band An interval in the electromagnetic spectrum defined by two wavelengths, two frequencies, or two wave numbers.

Temperature gradient Rate of change of temperature with distance.

Thermal emittance---Emittance of radiation by a body not at absolute zero because of the thermal agitation of its molecules.

Thermography The recording of the thermal qualities of objects and surfaces by means of scanning equipment in which the infrared radiation or microwave radiation recorded can be converted into a thermal image.

Transmittance The ratio of energy transmitted by a body to that incident on it.

Ultraviolet band That portion of the electromagnetic spectrum ranging from just above the visible (about 4,000 ang.) to below 400 ang., on the border of the X-ray region.

Visible band The band of the electromagnetic spectrum, which can be perceived by the naked eye. This band ranges from 7,500 ang. to 4,000 ang., being bordered by the infrared and ultraviolet bands.

X-ray Electromagnetic waves of short wavelength from .00001 ang. to 3,000 ang.

Electrical Terminology

Alternating current (AC) Electrical current that reverses direction periodically, expressed in hertz (Hz) or cycles per second (cps).

Alternator An AC generator that produces alternating current, which is internally rectified to direct current before being released.

Ampacity A term used to describe the current handling capacity of an electrical device.

Amperage A term synonymous with current; used in describing electrical current. The total amount of current (amperes) flowing in a circuit.

Ampere The quantitative unit measurement of electrical current.

Armature The main power winding in a motor in which electromotive force is produced, usually the rotor of a DC motor or the stator of an AC motor.

Arrester A device placed from phase to ground whose nonlinear impedance characteristics provide a path for high-amplitude transients.

Attenuator A passive device used to reduce signal strength.

Brush A piece of conducting material, which, when bearing against a commutator, slip ring, or the like will provide a passage for electrical current.

Capacitor A discrete electrical device that has two electrodes and an intervening insulator, which is called the dielectric. A device used to store an electrical charge.

Circuit (closed) An electrical circuit in which current flow is not interrupted.

Circuit (open) Any break or lack of contact in an electrical circuit either intentional (switch) or unintentional (bad connection).

Circuit (parallel) An electrical system in which all positive terminals are joined through one wire, and all negative terminals through another wire.

Circuit (series) An electrical system in which separate parts are connected end to end, to form a single path for current to flow through.

Circuit breaker A resettable device that responds to a preset level of excess current flow by opening the circuit, thereby preventing damage to circuit elements.

Circuit protector A circuit protector is a device that will open the circuit if it becomes overheated because of too much electricity flowing through it. Thus, it protects other components from damage if the circuit is accidentally grounded or overloaded. Fuses, fusible links, and circuit breakers are circuit protectors.

Coil A continuous winding arrangement of a conductor, which combines the separate magnetic fields of all the winding loops to produce a single, stronger field.

Current The flow of electricity in a circuit as expressed in amperes. Current refers to the quantity or intensity of electrical flow.

Voltage, on the other hand, refers to the pressure or force causing the electrical flow.

Diode A device that permits current to flow in one direction only. Used to change alternating current to direct current. A rectifier.

Direct current (DC) Electrical current that flows consistently in one direction.

Distribution The way in which power is routed to various current-using sites or devices.

Outside the building, distribution refers to the process of routing power from the power plant to the users. Inside the building, distribution is the process of using feeders and circuits to provide power to devices.

Electromagnetic interference (EMI)---A term that describes electrically induced noise or transients.

Filter---An electronic device that opposes the passage of a certain frequency band while allowing other frequencies to pass. Filters are designed to produce four different results: (1) a high-pass filter allows all signals above a given frequency to pass; (2) a low-pass filter allows only frequencies below a given frequency to pass; (3) a bandpass filter allows a given band of frequencies to pass while attenuating all others; and (4) a trap filter allows all frequencies to pass but acts as a high-impedance device to the tuned frequency of the filter.

Flashover Arcing that is caused by the breakdown of insulation between two conductors where a high current flow exists, with a high potential difference between the conductors.

Fuse -- A device that automatically self-destructs when the current passing through it exceeds the rated value of the fuse. A plug in protector with a filament that melts or burns out when overloaded.

Ground -- A general term that refers to the point at which other portions of a circuit are referenced when making measurements. A power system's grounding is that point to which the neutral conductor, safety ground, and building ground are connected. This grounding electrode may be a water pipe, driven ground rod, or the steel frame of the building.

Harmonic A frequency that is a multiple of the fundamental frequency. For example, 120Hz is the second harmonic of 60Hz, 180Hz is the third harmonic, and so forth.

Harmonic distortion Excessive harmonic content that distorts the normal sinusoidal waveform is harmonic distortion. This can cause overheating of circuit elements and might appear to a device as data-corrupting noise.

Hertz (Hz) -- A term describing the frequency of alternating current. The term hertz is synonymous with cycles per second.

Impedance (Z) -- Measured in ohms, impedance is the total opposition to current flow in a circuit in which alternating current is flowing. This includes inductive reactance, capacitive reactance, and resistance.

Inductance This term describes the electrical properties of a coil of wire and its resultant magnetic field when an alternating current is passed through it. This interaction offers impedance to current flow, thereby causing the current waveform to lag behind the voltage waveform. This results in what's known as a lagging power factor.

Inductor -- A discrete circuit element, which has the property of inductance. It should be noted that at very high radio frequencies, a straight wire or a path on a printed-circuit board can act as an inductor.

Insulator -- A nonconducting substance or body, such as porcelain, glass, or Bakelite, that is used for insulating wires in electrical circuits to prevent the undesired flow of electricity.

Inverter An inverter takes DC power and converts it into AC power.

Isolation---The degree to which a device can separate the electrical environment of its input from its output, while allowing the desired trans mission to pass across the separation.

Kilohertz (kHz) -- A term meaning 1,000 cycles per second (cps).

Kilovolt-Ampere (kVA) -- An electrical unit related to the power rating of a piece of equipment. It’s calculated by multiplying the rated voltage of equipment by the current required (or produced). For resistive loads, 1 kilovolt ampere equals 1 kilowatt.

Lightning arrester A device used to pass large impulses to ground.

Mean time between failure (MTBF)---A statistical estimate of the time a component, subassembly, or operating unit will operate before failure will occur.

Megahertz (MHz) A term for 1 million hertz (cycles per second).

Motor alternator A device that consists of an AC generator mechanically linked to an electric motor, which is driven by utility power or by batteries. An alternator is an AC generator.

Motor generator---A motor generator consists of an AC motor coupled to a generator. The utility power energizes the motor to drive the generator, which powers the critical load. Motor generators provide protection against noise and spikes, and, if equipped with a heavy

Flywheel, they may also protect against sags and swells.

Neutral -- One of the conductors of a three-phase wye system is the neutral conductor. Sometimes called the return conductor, it carries the entire current of a single-phase circuit and the resultant current in a three-phase system that is unbalanced. The neutral is bonded to ground on the output of a three phase delta-wye transformer.

Ohm The unit of measurement for electrical resistance.

Ohm's law A law of electricity that states the relation ship between voltage, amperes, and resistance. It takes a pressure of one volt to force one ampere of current through one ohm of resistance. Equation: Volts = amperes x ohms (E = I x R).

Radiation RF energy that is emitted or leaks from a distribution system and travels through space. These signals often cause interference with other communication services.

Rectifier An electrical device containing diodes, used to convert AC to DC.

Relay An electromagnetic switching device using low current to open or close a high-current circuit.

Resistance (R) A term describing the opposition of elements of a circuit to alternating or direct current.

Resistor A device installed in an electrical circuit to permit a predetermined current to flow with a given voltage applied.

Rheostat A device for regulating a current by means of a variable resistance.

Rotor The part of the alternator that rotates inside the stator and produces an electrical current from induction by the electromagnetic fields of the stator windings.

SCR (semiconductor, or silicon, An electronic DC switch that can be triggered controlled rectifier) into conduction by a pulse to a gate electrode, but can only be cut off by reducing the main current below a predetermined level (usually zero).

Shielding Protective coating that helps eliminate electromagnetic and radio frequency interference.

Shunt A conductor joining two points in a circuit to form a parallel circuit, through which a portion of the current may pass, in order to regulate the amount of current flowing in the main circuit.

Sine wave A fundamental waveform produced by periodic oscillation that expresses the sine or cosine of a linear function of time or space, or both.

Single-phase That portion of a power source that represents only a single phase of the three phases that are available.

Solenoid A tubular coil containing a movable magnetic core, which moves when the coil is energized.

Stator The stationary winding of an alternator (the armature in a DC generator).

Switch A device used to open, close, or redirect current in an electrical circuit.

Three-phase An electrical system with three different voltage lines or legs, which carry sine wave waveforms that are 120 degrees out of phases from one another.

Transformer A device used to change the voltage of an AC circuit and/or isolate a circuit from its power source.

Volt -- Electrical unit of measure (Current x Resistance).

Watt The unit for measuring electrical power or work. A watt is the mathematical product of amperes and volts (W = A x V).

Materials List

Material -- °F -- °C -- Emissivity

Metals:

Alloys 20-Ni, 24-CR, 55-FE, 392 200 0.9

Oxidized

20-Ni, 24-CR, 55-FE, 932 500 0.97

Oxidized

60-Ni, 12-CR, 28-FE, 518 270 0.89

Oxidized

60-Ni, 12-CR, 28-FE, 1040 560 0.82

Oxidized

80-Ni, 20-CR, Oxidized 212 100 0.87

80-Ni, 20-CR, Oxidized 1112 600 0.87

80-Ni, 20-CR, Oxidized 2372 1300 0.89

Aluminum Unoxidized 77 25 0.02

Unoxidized 212 100 0.03

Unoxidized 932 500 0.06

Oxidized 390 199 0.11

Oxidized 1110 599 0.19

Oxidized at 599°C (1110°F) 390 199 0.11

Oxidized at 599°C (1110°F) 1110 599 0.19

Heavily Oxidized 200 93 0.2

Heavily Oxidized 940 504 0.31

Highly Polished 212 100 0.09

Roughly Polished 212 100 0.18

Commercial Sheet 212 100 0.09

Highly Polished Plate 440 227 0.04

Highly Polished Plate 1070 577 0.06

Bright Rolled Plate 338 170 0.04Material °F °C Emissivity

Metals

Alloys 20-Ni, 24-CR, 55-FE, 392 200 0.9

Oxidized

20-Ni, 24-CR, 55-FE, 932 500 0.97

Oxidized

60-Ni, 12-CR, 28-FE, 518 270 0.89

Oxidized

60-Ni, 12-CR, 28-FE, 1040 560 0.82

Oxidized

80-Ni, 20-CR, Oxidized 212 100 0.87

80-Ni, 20-CR, Oxidized 1112 600 0.87

80-Ni, 20-CR, Oxidized 2372 1300 0.89

Aluminum Unoxidized 77 25 0.02

Unoxidized 212 100 0.03

Unoxidized 932 500 0.06

Oxidized 390 199 0.11

Oxidized 1110 599 0.19

Oxidized at 599°C (1110°F) 390 199 0.11

Oxidized at 599°C (1110°F) 1110 599 0.19

Heavily Oxidized 200 93 0.2

Heavily Oxidized 940 504 0.31

Highly Polished 212 100 0.09

Roughly Polished 212 100 0.18

Commercial Sheet 212 100 0.09

Highly Polished Plate 440 227 0.04

Highly Polished Plate 1070 577 0.06

Bright Rolled Plate 338 170 0.04

Bright Rolled Plate 932 500 0.05

Alloy A3003, Oxidized 600 316 0.4

Alloy A3003, Oxidized 900 482 0.4

Alloy 1100-0 200–800 93–427 0.05

Alloy 24ST 75 24 0.09

Alloy 24ST, Polished 75 24 0.09

Alloy 75ST 75 24 0.11

Alloy 75ST, Polished 75 24 0.08

Bismuth Bright 176 80 0.34

Unoxidized 77 25 0.05

Unoxidized 212 100 0.06

Brass 73% Cu, 27% Zn, Polished 476 247 0.03

73% Cu, 27% Zn, Polished 674 357 0.03

62% Cu, 37% Zn, Polished 494 257 0.03

62% Cu, 37% Zn, Polished 710 377 0.04

83% Cu, 17% Zn, Polished 530 277 0.03

Matte 68 20 0.07

Burnished to Brown Color 68 20 0.4

Cu-Zn, Brass Oxidized 392 200 0.61

Cu-Zn, Brass Oxidized 752 400 0.6

Cu-Zn, Brass Oxidized 1112 600 0.61

Unoxidized 77 25 0.04

Unoxidized 212 100 0.04

Cadmium 77 25 0.02

Carbon Lampblack 77 25 0.95

Unoxidized 77 25 0.81

Unoxidized 212 100 0.81

Unoxidized 932 500 0.79

Candle Soot 250 121 0.95

Filament 500 260 0.95

Graphitized 212 100 0.76

Graphitized 572 300 0.75

Graphitized 932 500 0.71

Chromium 100 38 0.08

Chromium 1000 538 0.26

Chromium, Polished 302 150 0.06

Cobalt, Unoxidized 932 500 0.13

Cobalt, Unoxidized 1832 1000 0.23

Columbium, 1500 816 0.19

Unoxidized

Columbium, 2000 1093 0.24

Unoxidized

Copper Cuprous Oxide 100 38 0.87

Cuprous Oxide 500 260 0.83

Cuprous Oxide 1000 538 0.77

Black, Oxidized 100 38 0.78

Etched 100 38 0.09

Matte 100 38 0.22

Roughly Polished 100 38 0.07

Polished 100 38 0.03

Highly Polished 100 38 0.02

Rolled 100 38 0.64

Rough 100 38 0.74

Molten 1000 538 0.15

Molten 1970 1077 0.16

Molten 2230 1221 0.13

Nickel Plated 100–500 38–260 0.37

Dow Metal 0.4–600 D18–316 0.15

Gold Enamel 212 100 0.37

Plate 0.0001

Plate on .0005 Silver 200–750 93–399 .11–.14

Plate on .0005 Nickel 200–750 93–399 .07–.09

Polished 100–500 38–260 0.02

Polished 1000–2000 538–1093 0.03

Haynes Alloy C, Oxidized 600–2000 316–1093 .90–.96

Haynes Alloy 25, Oxidized 600–2000 316–1093 .86–.89

Haynes Alloy X, Oxidized 600–2000 316–1093 .85–.88

Inconel Sheet 1000 (538) 1000 538 0.28

Inconel Sheet 1200 (649) 1200 649 0.42

Inconel Sheet 1400 (760) 1400 760 0.58

Inconel X, Polished 75 (24) 75 24 0.19

Inconel B, Polished 75 (24) 75 24 0.21

Iron Oxidized 212 100 0.74

Oxidized 930 499 0.84

Oxidized 2190 1199 0.89

Unoxidized 212 100 0.05

Red Rust 77 25 0.7

Rusted 77 25 0.65

Liquid 2760–3220 1516–1771 .42–.45

Cast Iron Oxidized 390 199 0.64

Oxidized 1110 599 0.78

Unoxidized 212 100 0.21

Strong Oxidation 40 104 0.95

Strong Oxidation 482 250 0.95

Liquid 2795 1535 0.29

Wrought Iron

Dull 77 25 0.94

Dull 660 349 0.94

Smooth 100 38 0.35

Polished 100 38 0.28

Lead Polished 100–500 38–260 .06–.08

Rough 100 38 0.43

Oxidized 100 38 0.43

Oxidized at 1100¡F 100 38 0.63

Gray Oxidized 100 38 0.28

Magnesium 100–500 38–260 .07–.13

Magnesium Oxide 1880–3140 1027–1727 .16–.20

Mercury 32 0 0.09

77 25 0.1

100 38 0.1

212 100 0.12

Molybdenum 100 38 0.06

500 260 0.08

1000 538 0.11

2000 1093 0.18

Oxidized at 1000°F 600 316 0.8

Oxidized at 1000°F 700 371 0.84

Oxidized at 1000°F 800 427 0.84

Oxidized at 1000°F 900 482 0.83

Oxidized at 1000°F 1000 538 0.82

Monel, Ni-Cu 392 200 0.41

Monel, Ni-Cu 752 400 0.44

Monel, Ni-Cu 1112 600 0.46

Monel, Ni-Cu 68 20 0.43

Oxidized

Monel, Ni-Cu 1110 (599) 1110 599 0.46

Oxidized at

1110°F

Nickel Polished 100 38 0.05

Oxidized 100–500 38–260 .31–.46

Unoxidized 77 25 0.05

Unoxidized 212 100 0.06

Unoxidized 932 500 0.12

Unoxidized 1832 1000 0.19

Electrolytic 100 38 0.04

Electrolytic 500 260 0.06

Electrolytic 1000 538 0.1

Electrolytic 2000 1093 0.16

Nickel Oxide 1000–2000 538–1093 .59–.86

Palladium Plate (.00005 on .0005 silver) 200–750 93–399 .16–.17

Platinum 100 38 0.05

500 260 0.5

1000 538 0.1

Platinum, Black 100 38 0.93

500 260 0.96

2000 1093 0.97

Oxidized at 1100°F 500 260 0.07

1000 538 0.11

Rhodium Flash (0.0002 on 0.0005 Ni) 200–700 93–371 .10–.18

Silver Plate (0.0005 on Ni) 200–700 93–371 .06–.07

Polished 100 38 0.01

500 260 0.02

1000 538 0.03

2000 1093 0.03

Steel Cold Rolled 200 93 .75–.85

Ground Sheet 1720–2010 938–1099 .55–.61

Polished Sheet 100 38 0.07

500 260 0.1

1000 538 0.14

Mild Steel, Polished 75 24 0.1

Mild Steel, Smooth 75 24 0.12

ÊLiquid 2910–3270 1599–1793 0.28

Steel, Unoxidized 212 100 0.08

Steel, Oxidized 77 25 0.8

Steel Alloys Type 301, Polished 75 24 0.27

Type 301, Polished 450 232 0.57

Type 301, Polished 1740 949 0.55

Type 303, Oxidized 600–2000 316–1093 .74–.87

Type 310, Rolled 1500–2100 816–1149 .56–.81

Type 316, Polished 75 24 0.28

Type 316, Polished 450 232 0.57

Type 316, Polished 1740 949 0.66

Type 321 200–800 93–427 .27–.32

Type 321 Polished 300–1500 149–815 .18–.49

Type 321 w/BK Oxide 200–800 93–427 .66–.76

Type 347, Oxidized 600–2000 316–1093 .87–.91

Type 350 200–800 93–427 .18–.27

Type 350 Polished 300–1800 149–982 .11–.35

Type 446, Polished 300–1500 149–815 .15–.37

Type 17-7 PH 200–600 93–316 .44–.51

ÊPolished 300–1500 149–815 .09–.16

Oxidized 600–2000 316–1093 .87–.91

Type PH-15-7 MO 300–1200 149–649 .07–.19

Stellite Polished 68 20 0.18

Tantalum Unoxidized 1340 727 0.14

2000 1093 0.19

3600 1982 0.26

5306 2930 0.3

Tin, Unoxidized 77 25 0.04

212 100 0.05

Tinned Iron, Bright 76 24 0.05

212 100 0.08

Titanium, Alloy Polished 300–1200 149–649 .08–.19

C110M

Tungsten Unoxidized 77 25 0.02

Unoxidized 212 100 0.03

Unoxidized 932 500 0.07

Unoxidized 1832 1000 0.15

Unoxidized 2732 1500 0.23

Unoxidized 3632 2000 0.28

Filament (Aged) 100 38 0.03

Filament (Aged) 1000 538 0.11

Filament (Aged) 5000 2760 0.35

Uranium Oxide 1880 1027 0.79

Zinc Bright, Galvanized 100 38 0.23

Commercial 99.1% 500 260 0.05

Galvanized 100 38 0.28

Oxidized 500–1000 260–538 0.11

Polished 100 38 0.02

Polished 500 260 0.03

Polished 1000 538 0.04

Polished 2000 1093 0.06

Nonmetals

Adobe 68 (20) 0.9

Asbestos Board 100 38 0.96

Cement 32–392 0–200 0.96

Cement, Red 2500 1371 0.67

Cement, White 2500 1371 0.65

Cloth 199 93 0.9

Paper 100–700 38–371 0.93

Slate 68 20 0.97

Asphalt, pavement 100 38 0.93

Asphalt, tar paper 68 20 0.93

Basalt 68 20 0.72

Brick Red, rough 70 21 0.93

Gault Cream 2500–5000 1371–2760 .26–.30

Fire Clay 2500 1371 0.75

Light Buff 1000 538 0.8

Lime Clay 2500 1371 0.43

Fire Brick 1832 1000 .75–.80

Magnesite, Refractory 1832 1000 0.38

Grey Brick 2012 1100 0.75

Silica, Glazed 2000 1093 0.88

Silica, Unglazed 2000 1093 0.8

Sandlime 2500–5000 1371–2760 .59–.63

Carborundum 1850 1010 0.92

Ceramic Alumina on Inconel 800–2000 427–1093 .69–.45

Earthenware, Glazed 70 21 0.9

Earthenware, Matte 70 21 0.93

Greens No. 5210-2C 200–750 93–399 .89–.82

Coating No. C20A 200–750 93–399 .73–.67

Porcelain 72 22 0.92

White Al2O3 200 93 0.9

Zirconia on Inconel 800–2000 427–1093 .62–.45

Clay 68 (20) 0.39 0.39

Fired at 158 70 0.91

Shale at 68 20 0.69

Tiles, Light Red 2500–5000 1371–2760 .32–.34

Tiles, Red 2500–5000 1371–2760 .40–.51

Dark Purple 2500–5000 1371–2760 0.78

Concrete Rough 32–2000 0–1093 0.94

Tiles, Natural 2500–5000 1371–2760 .63–.62

Tiles, Brown 2500–5000 1371–2760 .87–.83

Tiles, Black 2500–5000 1371–2760 .94–.91

Cotton Cloth 68 (20) 0.77

Dolomite Lime 68 (20) 0.41

Emery Corundum 176 (80) 0.86

Glass Convex D 212 100 0.8

Convex D 600 316 0.8

Convex D 932 500 0.76

Nonex 212 100 0.82

Nonex 600 316 0.82

Nonex 932 500 0.78

Smooth 32–200 0–93 .92–.94

Granite 70 21 0.45

Gravel 100 38 0.28

Gypsum 68 20 .80–.90

Ice, Smooth 32 0 0.97

Ice, Rough 32 0 0.98

Lacquer Black 200 93 0.96

Blue, on Al Foil 100 38 0.78

Clear, on Al Foil (2 coats) 200 93 .08 (.09)

Clear, on Bright Cu 200 93 0.66

Clear, on Tarnished Cu 200 93 0.64

Red, on Al Foil (2 coats) 100 38 .61 (.74)

White 200 93 0.95

White, on Al Foil (2 coats) 100 38 .69 (.88)

Yellow, on Al Foil (2 coats) 100 38 .57 (.79)

Lime Mortar 100–500 38–260 .90–.92

Limestone 100 38 0.95

Marble, White 100 38 0.95

Smooth, White 100 38 0.56

Polished Gray 100 38 0.75

Mica 100 38 0.75

Oil on Nickel 0.001 Film 72 22 0.27

0.002 Film 72 22 0.46

0.005 Film 72 22 0.72

Thick Film 72 22 0.82

Oil, Linseed On Al Foil, uncoated 250 121 0.09

On Al Foil, 1 coat 250 121 0.56

On Al Foil, 2 coats 250 121 0.51

On Polished Iron, .001 Film 100 38 0.22

On Polished Iron, .002 Film 100 38 0.45

On Polished Iron, .004 Film 100 38 0.65

On Polished Iron, Thick 100 38 0.83

Film

Paints Blue, Cu2O3 75 24 0.94

Black, CuO 75 24 0.96

Green, Cu2O3 75 24 0.92

Red, Fe2O3 75 24 0.91

White, Al2O3 75 24 0.94

White, Y2O3 75 24 0.9

White, ZnO 75 24 0.95

White, MgCO3 75 24 0.91

White, ZrO2 75 24 0.95

White, ThO2 75 24 0.9

White, MgO 75 24 0.91

White, PbCO3 75 24 0.93

Yellow, PbO 75 42 0.9

Yellow, PbCrO4 75 24 0.93

Paints, Aluminum 100 (38) 100 38 .27–.67

10% Al 100 38 0.52

26% Al 100 38 0.3

Dow XP-310 200 93 0.22

Paints, Bronze Low .34–.80

Gum Varnish (2 coats) 70 21 0.53

Gum Varnish (3 coats) 70 21 0.5

Cellulose Binder (2 coats) 70 21 0.34

Paints, Oil All colors 200 93 .92–.96

Black 200 93 0.92

Black Gloss 70 21 0.9

Camouflage Green 125 52 0.85

Flat Black 80 27 0.88

Flat White 80 27 0.91

Gray-Green 70 21 0.95

Green 200 93 0.95

Lamp Black 209 98 0.96

Red 200 93 0.95

White 200 93 0.94

Quartz, Rough, Glass, 1.98mm 540 282 0.9

Fused Glass, 1.98mm 1540 838 0.41

Glass, 6.88mm 540 282 0.93

Glass, 6.88mm 1540 838 0.47

Opaque 570 299 0.92

Opaque 1540 838 0.68

Red Lead 212 100 0.93

Rubber, Hard 74 23 0.94

Rubber, Soft, Gray 76 24 0.86

Sand 68 20 0.76

Sandstone 100 38 0.67

Sandstone, Red 100 38 .60–.83

Sawdust 68 20 0.75

Shale 68 20 0.69

Silica, Glazed 1832 1000 0.85

Silica, Unglazed 2012 1100 0.75

Silicon Carbide 300–1200 149–649 .83–.96

Silk Cloth 68 20 0.78

Slate 100 38 .67–.80

Snow, Fine Particles 20 (D7) 0.82

Snow, Granular 18 (D8) 0.89

Soil Surface 100 38 0.38

Black Loam 68 20 0.66

Plowed Field 68 20 0.38

Soot Acetylene 75 24 0.97

Camphor 75 24 0.94

Candle 250 121 0.95

Coal 68 20 0.95

Stonework 100 38 0.93

Water 100 (38) 100 38 0.67

Waterglass 68 (20) 68 20 0.96

Wood Low .80–.90

Beech, Planed 158 70 0.94

Oak, Planed 100 38 0.91

Spruce, Sanded 100 38 0.89