AMAZON multi-meters discounts AMAZON oscilloscope discounts

General Features:

- Create/Generate Preventive Maintenance Schedules and Work Orders

- Create/Generate General Work Orders

- Plan/Create/Generate Reports of: Asset Management

- Create/Generate Multiple Reports

- Logical/Intuitive Search and Query

- Easy Learning Curve -- No Extensive Training Required

AMAZON multi-meters discounts AMAZON oscilloscope discounts

Must be able to manage equipment maintenance on multiple pieces of equipment, each one with multiple schedules, pictures and procedure notes.

Content and Special Features:

- PM Remainder: Equipment not due for maintenance, but need counter updates such as Miles, Km, Hour meters or operator service.

- PM Task To do: Equipment ready for maintenance, or due for maintenance according to the schedule.

- Open Work Orders: Service or repair orders still open and require immediate attention.

- Inventory Items that need to be ordered: List of items to reorder, or out of stock.

- Graphic calendar with user options, select a particular group of days of any month. Check maintenance tasks, work planning.

Preventive Maintenance Tasks are scheduled by Days, Miles, or Meter readings. You should be the judge of how your equipment tasks need to be scheduled. Any tasks that are not completed within the cycle are rescheduled by your chosen CMMS the next time you generate your equipment PM tasks. The CMMS should never make you feel as if you've misplaced a critical work order; the WOs should be automatically regenerated until completed. Any repeat preventive-maintenance tasks should be clearly defined on your newly generated work orders. Duplicate preventive-maintenance work orders should also be eliminated, which is not always a feature of preventive programs so be sure to check the features list carefully. Software maintenance should be nominal when you introduce your new CMMS for your equipment maintenance program. A preventative maintenance system should establish an immensely stable maintenance program for your plant for years to come.

Applications:

- Factory maintenance

- Construction equipment

- Apartment buildings

- Hotel and resorts

-Truck fleet operations

- Health care providers

- Retail establishments

- Equipment maintenance - General contractors

- Maintenance services

- HVAC maintenance

- Facility maintenance

- On site services

- Farm machinery

- Marine services

- Repair shops

A decent CMMS preventive-maintenance program, which also provides scheduling, offers convenient automation for your maintenance-management operation. Good CMMS's can be used in virtually any computerized maintenance environment that requires preventive-maintenance programs. Good CMMS software can be effectively utilized as essentially any type of maintenance software you need, including: building maintenance software, facility maintenance software, fleet maintenance software, plant maintenance software, vehicle maintenance software, affordable educational facility maintenance software, heavy equipment maintenance software, electrical preventive maintenance software, hospital CMMS software, hotel maintenance software, and many others.

Requirements:

PC, min 256MB Ram, 60 MB hard drive space.

Windows 2000, 2003, NT or XP

Free CMMS programs -- are they worth trying?

Free CMMS is a web based Computerized Maintenance Management System released under the GPL license. It is free to use and free to modify (see the GPL License). It aims to be a feature rich CMMS that meets most plant maintenance departments needs for managing work orders, PMs, parts inventory, and labor tracking.

For downloads, documentation, bug reports, news and developer information visit http://sourceforge.net/projects/free-cmms/.

Free CMMS was started out of neccessity by a Plant Engineer when the money for a commercial CMMS was chopped from his budget. The Plant Engineer picked up a PHP/MYSQL book and intended to write a bare bones work order system. He got a bit carried away and soon realized that the quality and functionality of commercial CMMS's were not beyond his reach. He decided to release the code as open source hoping that others would find the program usefull and contribute to its development. Commercial CMMSs typically cost upwards of $10k. The developer thinks within a year, Free CMMS can impliment 80% of the functionallity of most commercial packages at (if his major in math serves correctly) 0% of the cost. Personal note: I tried to implement Free CMMS but could not get it to work. This was quite frustrating becuase setting up Free CMMS is a bit time consuming. Sigh.

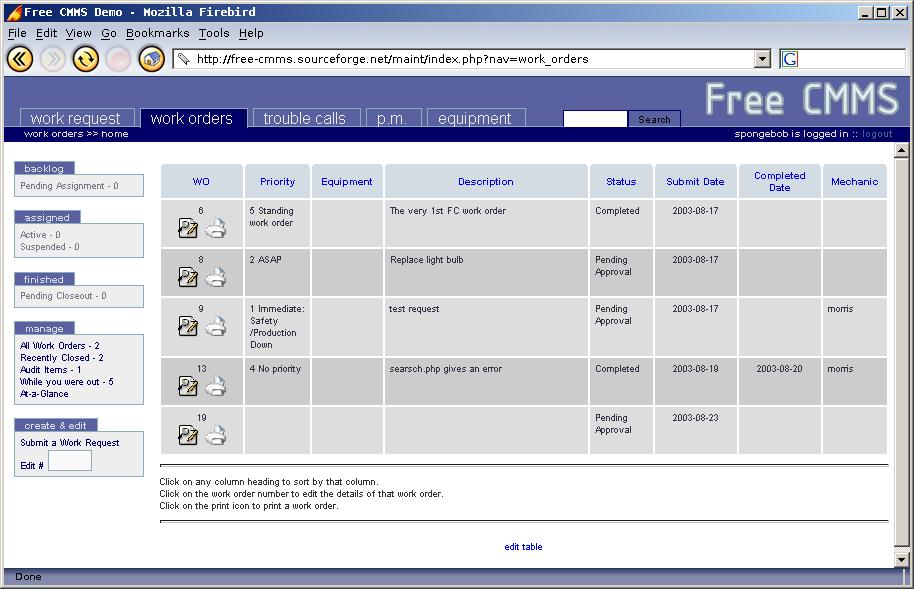

Here's a screen shot of Free CMMS:

Another "free" CMMS comes from Malaysia. It's called CWorks. The manufacturer claims that Cworks comes with "no catches, no spyware, no hidden costs anywhere!" But, of course, they all say that. Here is a rundown of some of its features (quotes from cworks.com.my):

Maintenance Software for Plant and Facility Management

Ranging from the simple CWorks Free for new users to the dependable CWorks Pro Series and comprehensive CWorks EAM series, the CWorks range of CMMS/EAM meets your needs for effectiveness and affordability to assist you to:

- easily record the who, what, where, when and why of each task, asset and resources

- easily report for more effective plan, do, check and act (PDCA) on

plant and facility management improvement activities

- easily report for proper justification of budgets and resources

- easily automate maintenance tasks such as PM time and meter based scheduling, spares holding and reorder tracking, purchasing tracking, request recording on local area network, password protection and many more

CWorks Free is a computerized maintenance management system (CMMS). It is ideal for sites who wants to start on a CMMS. Using CWorks, users may start their CMMS initiatives at a cost effective pace as they can start simple tracking of asset, locations and employee registers. Track outstanding and completed work type, description, times and costs. Also the ideal, simple preventive maintenance freeware. All this on a free unrestricted software.

This free CMMS software is developed for MS Access and is shipped with full source code. Full customization control from access to source code brings better look and feel, easier report creation, and more adaptable to internal processes. With the source codes, users may avail themselves to MS Access report builders and query builders without the need of buying expensive add-ons.

Source codes are for user's internal use only and re-distribution in any form is prohibited. This free CMMS software requires about 5MB of hard disk space and that MS Access 200x is pre-installed and operating in the installed PC before CWorks can be used. The CWorks application package consists of 3 main components namely:

- Asset/Equipment Register

- Work Order

- Preventive Maintenance

Asset / Equipment Register

The Asset Register provides you with the facility to record and manage your organizations assets. This module stores data on every asset which you want a record of maintenance activities.

- Asset List Summary

- Current Asset Register

- New Asset Registration

- Additional Info - Information about the registered asset can be listed in this section

- Relationship - Enables an asset tree to be built using the parent-child relationship

Work Order

The work order module provides you with an ability to view and manage all maintenance activities. It provides an accurate basis for work order costing, analysis and management of site activities. The work order module is integrated with the Planned Maintenance module in order to integrate scheduled preventive maintenance work with ad-hoc breakdown work. Work orders can also be raised for non-asset activities, such as changing a light bulb, repairing a leaking roof or plumbing problems. The module enables the capture of all material and labor costs and labour utilization.

AMAZON multi-meters discounts AMAZON oscilloscope discounts

Preventive Maintenance

The Preventive Maintenance (PM) Module enables PM tasks to be scheduled for a particular asset or physical location based on a fixed time interval. Preventive maintenance work orders for assets meeting the defined PM time interval are automatically generated by the system upon user instructions.

So what's the difference between the Free and Pro/Plus/SQL versions? Check out this page. A potentially important feature that you don't get for free is "Multiple sites functionality".

NEXT: Features of Good Computerized Maintenance-Management Software (CMMS) -- Part 2