You have only one chance to do it right! Here’s how.

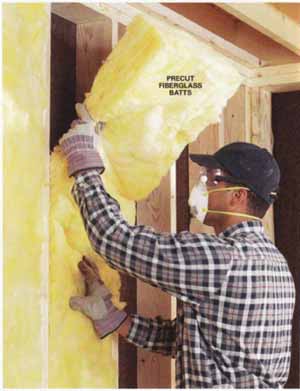

Filling stud spaces with fiberglass batts is the cheapest easiest way for you to insulate new walls. It’s also the best way to upgrade wall insulation during remodeling. Installing the batts doesn’t require any special skills, but it’s slow, tedious, itchy work. It’s often done poorly, and even small gaps can reduce efficiency as much as 25 percent. Here you’ll discover how to cut and fit fiberglass batts and how to work around electrical outlets and cables to get the best job with the least hassle.

Push batts all the way to the back of each stud space and then pull out the front edges until they’re flush with the face

of the studs.

Fill all voids

The key to a quality insulating job is tight-fitting batts that completely fill the stud cavity with no voids or gaps. You can do top-quality work with only a few basic tools. You’ll need a utility knife with a good supply of sharp blades, a tape measure and a straightedge, and a 3- or 4-in. putty knife for stuffing insulation around doors and windows. Fiberglass can irritate your throat and skin, so wear protective gear. Buy a two-strap mask rated for fiberglass insulation (3M No. 8210 is one example) and wear a hat, gloves, a long-sleeve shirt and goggles to keep fibers out of your eyes.

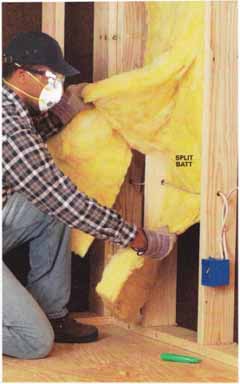

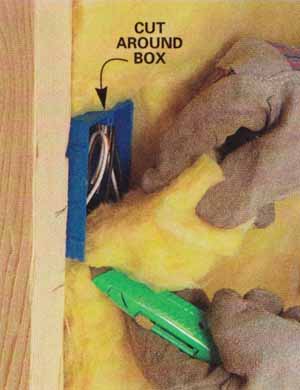

Fit batts tightly around electrical cables and boxes

Running a full batt in front of electrical cables leaves an uninsulated space behind. Avoid this by splitting the batt as shown. Then when you come to an electrical box, trim the insulation to fit snugly around it. Run your knife blade against the outside of the box to guide the cut. But don’t cut too deep or you risk nicking the wires. If you have plumbing pipes on an outside wall, insulate behind them, but leave the side facing the interior uncovered to allow heat from the house to keep the pipes warm.

Split balls to fit around electrical cables. Tear the

ball in half, starting from the bottom. Slide one half behind the cable and lay the other half over the top.

Split and cut batts to fit behind and around

electrical boxes. Slide half the ball behind the box. Then cut the

front half to fit tightly around the box.

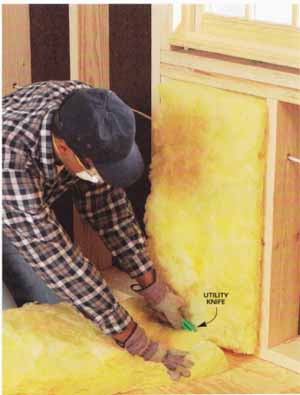

Fit first, then cut to length

We’re using unfaced batts that are sized to friction-fit into standard stud spaces (either 16-in, or 24-in, on-center studs). They’re also available precut to lengths that fit standard 8- ft. and 9-ft. walls. Buying precut batts eliminates some work, but you’ll still have to cut some batts to length. You could measure the space and cut the batt to fit, but a quicker method that’s just as accurate is shown below. Leave an extra 1/2 in. of length for a snug fit.

We’re using unfaced batts because they’re easier to cut and install. In most climates, you’ll have to staple 4-mil plastic sheeting over the batts to form a vapor barrier. Check with your local building inspector for the recommended practice in your area.

Cut balls to length by setting the top of the ball

into the space and cutting against the bottom plate with a sharp utility

knife. Leave an extra 1/2 in. of length for a tighter fit.

Next: Batt insulation basics

Prev: What is R-value?