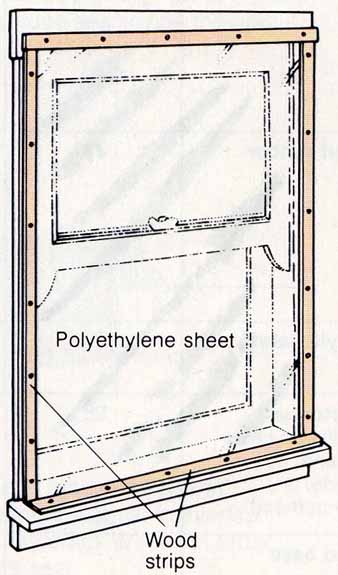

One of the simplest forms of exterior insulation is the plastic sheeting storm window. It is made from 6-mil polyethylene plastic. You can buy it at most hard ware stores or from mail-order catalogues. When sealed tightly around all its edges, this extremely inexpensive form of makeshift storm window (about 70 per linear foot in 10-foot widths, or about $35 to $45 for a roll 10 by 100 feet) is essentially as effective as a far more complicated and expensive one made from glass or rigid plastic, approximately doubling the insulation efficiency of a single-pane window. The reason is that no glazing material in itself provides much in the way of insulation—what it does provide is the extra wall that holds the additional layer of air, the real insulation.

Polyethylene sheeting has its disadvantages, however: it prevents you from opening your window while it is up; it can't be reused because it tears, wears, and yellows, even when transparent (and treated not to go opaque) instead of the more commonly sold opaque white; it distorts your views; and it is not particularly attractive.

The following instructions are for in stalling the sheeting on the outside of your windows.

1. Outside your house, measure your largest window from the outside of the frame on one side to the outside of the frame on the other side. When you buy your roll of plastic, make sure it is at least that wide so you can cover your entire window.

2. Measure the height of all your windows, from the outside of the top of the frame to the outside of the bottom of the frame. Add the total heights together so you’ll know how long a roll, or how many rolls, you will need. Add 2 inches of height for each window as a safety precaution (unless you really like going out to the store).

3. When you buy the plastic sheeting, also buy ¼- by ½-inch wooden strips, or lengths of thin molding, to match the length and width of every measurement you have taken.

4. Cut the plastic sheets to cover each window around the outside of its frame.

5. Starting with the top edge of each window, roll the vinyl around the wood en strip to ensure a tight fit, then nail through the wooden strip to hold the plastic to the window frame so that the nails don’t tear it.

6. Keeping the plastic as taut as possible, nail or staple around the entire window frame.

7. Trim off any excess plastic or strips of wood. You can paint the wood, if you wish.

Polyethylene sheeting

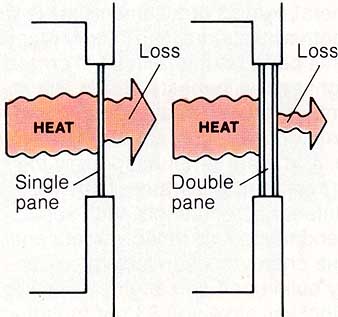

• How heat moves through glass: Not all windows are alike. Generally speaking, a window is a sheet of glass set into some sort of frame that fills an intentionally created hole in the wall. That glass commonly comes in three weights: single pane, double pane or double glazed, and plate glass. The different weights possess different strengths and need to be evaluated in terms of their tensile qualities as well as their ability to conserve heat. Use single-pane glass for a window up to about 5 square feet. After that, single-pane glass is no longer really safe—use double-pane glass instead. If the surface of the window is about 1 0 square feet or more, use plate glass, which is heavier and thicker.

Heat loss: single-pane vs. double-pane

Glass is an excellent heat conduct or; but when that glass is functioning as a window, its ability to conduct heat is not a desirable feature. Motion less or nearly motionless air, on the other hand, conducts heat very poorly. Therefore air is a good insulator when it is in a space small enough to keep its molecules motionless.

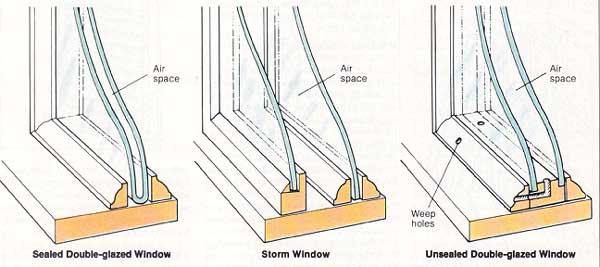

The principle behind both thermal windows and storm windows is to create virtually motionless dead air spaces between layers of glass. (Thermal— double- or triple-glazed—windows have all their layers of glass in a single sash. Storm windows, discussed later, use more than one sash to hold multiple layers of glass.) Since moving air is a good conductor of heat, the air must be fairly still; therefore, the space

Sealed Double-glazed Window; Storm Window; Unsealed Double-glazed

Window: Air space, weep holes.

Next: Glass Storm Windows

Prev: Insulating Windows