AMAZON multi-meters discounts AMAZON oscilloscope discounts

GOALS:

1. Identify common shop hazards.

2. Identify and use common shop safety equipment

= = = = !!CAUTION!! = = = =

Safety is not often thought about as you proceed through your daily tasks. Often you expose yourself to needless risk because you have experienced no harmful effects in the past. Unsafe habits become almost automatic. You may drive your automobile without wearing a seat belt. You know this to be unsafe, but you have done it before and so far no harm has resulted. None of us really likes to think about the possible consequences of an unsafe act. However, safety can and does have an important effect on anyone who makes his or her living in a potentially dangerous environment such as a machine shop. An accident can reduce or end your career as a machinist. You may spend several years learning the trade and more years gaining experience. Experience is a particularly valuable asset. It can only be gained through time spent on the job.

= = = =

This becomes economically valuable to you and to your employer. Years spent in training and gaining experience can be wasted in an instant if you should have an accident, not to mention a possible permanent physical handicap for you arid hardship on your family. Safety is an attitude that should extend far beyond the ma chine shop and into every facet of your life. You must constantly think about safety in every thing you do.

Personal Safety

EYE PROTECTION

Eye protection is a primary safety consideration around the machine shop. Machine tools pro duce metal chips, and there is always a possibility that these may be ejected from a machine at high velocity. Sometimes they can fly many feet. Furthermore, most cutting tools are made from hard materials. They can occasionally break or shatter from the stress applied to them during a cut. The result can be more flying metal particles.

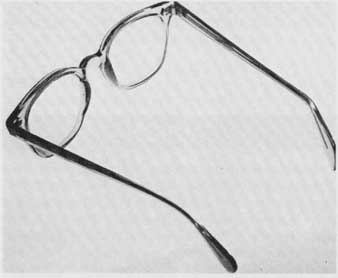

FIG. A-5 Common fixed-bow safety glasses.

Eye protection must be worn at all times in the machine shop. There are several types of eye protection available. Plain safety glasses are all that are required in most shops. These have shatterproof lenses that may be replaced if they become scratched. The lenses have a high resistance to impact. Common types include fixed- bow safety glasses ( FIG. A-5) and flexible bow safety glasses. The flexible bows may be adjusted to the most comfortable position for the wearer.

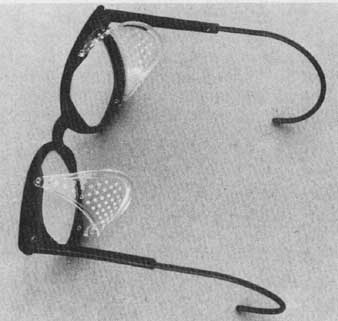

Side shield safety glasses must be worn around any grinding operation. The side shield protects the side of the eye from flying particles. Side shield safety glasses may be of the solid or perforated type ( FIG. A-6). The perforated side shield fits closer to the eye. Bows may wrap around the ear. This prevents the safety glasses from falling off.

FIG. A-6 Perforated side shield safety glasses.

If you wear prescription glasses, you may want to cover them with a safety goggle. The full face shield may also be used ( FIG. A-7). Prescription glasses can be made as safety glasses. In industry, prescription safety glasses are sometimes provided free to employees.

FOOT PROTECTION

Generally, the machine shop does not present too great a hazard to the feet. However, there is always a possibility that you could drop something on your foot. A safety shoe is available, with a steel toe shield designed to resist impacts. Some safety shoes also have an instep guard. Shoes must be worn at all times in the machine shop. A solid leather shoe is recommended. Ten is shoes and sandals should not be worn. You must never even enter a machine shop with bare feet. Remember that the floor is often covered with razor-sharp metal chips.

EAR PROTECTION

The instructional machine shop usually does not present a noise problem. However, an industrial machine shop may be adjacent to a fabrication or punch press facility. New safety regulations are quite strict regarding exposure to noise. Several types of sound suppressors and noise-reducing ear plugs may be worn. Excess noise can cause a permanent hearing loss. Usually this occurs over a period of time, depending on the intensity of the exposure. Noise is considered an industrial hazard if it is continuously above 85 decibels, the units used in measuring sound waves. If it is over 115 decibels for short periods of time ear protection must be worn (FIG. A-8). Earmuffs or earplugs should be used wherever high intensity noise occurs. A considerate worker will not create excessive noise when it is not necessary. Table A-1 shows the decibel level of various sounds: sudden sharp or high-intensity noises are the most harmful to your eardrums.

FIG. A-8 Sound suppressors ore designed to protect the ears from damage caused

by loud noises.

GRINDING DUST AND HAZARDOUS FUMES

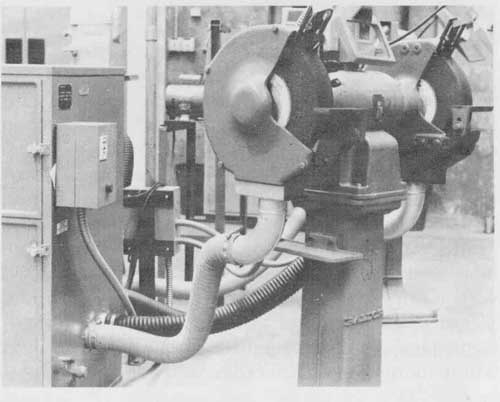

FIG. A-9 Vacuum dust collector on grinders.

Grinding dust is produced by abrasive wheels arid consists of extremely fine metal particles and abrasive wheel particles. These should not be inhaled. In the machine shop, most grinding machines have a vacuum dust collector ( FIG. A-9). Grinding may be done with coolants that aid in dust control. A machinist may be involved in portable grinding operations. This is common in such industries as shipbuilding. You should wear an approved respirator if you are exposed to grinding dust. Change the respirator filter at regular intervals. Grinding dust can present a great danger to health. Examples include the dust of such metals as beryllium, or the presence of radioactivity in nuclear systems. In these situations, the spread of grinding dust must be carefully controlled.

Some metals such as zinc give off toxic fumes when heated above their boiling point. Some of these fumes when inhaled cause only temporary sickness, but other fumes can be severe or even fatal. The fumes of mercury and lead are especially dangerous, as their effect is cumulative in your body and can cause irreversible damage. Cadmium and beryllium com pounds are also very poisonous. Therefore, when welding, burning, or heat treating metals, adequate ventilation is an absolute necessity. This is also true when parts are being carburized with compounds containing potassium cyanide. These cyanogen compounds are deadly poisonous and every precaution should be taken when using them. Kasenite, a trade name for a carburizing compound that is not toxic, is often found in school shops and in machine shops. Uranium salts are toxic, and all radioactive materials are extremely dangerous.

=== ===

TABLE 1 Decibel Level of Various Sounds

130—Painful sounds: jet engine on ground

1 20—Airplane on ground: reciprocating engine

110—Boiler factory

—Pneumatic riveter

100—

—Maximum street noise

—Roaring lion

90—

—Loud shout 80—Diesel truck

—Piano practice

—Average city street

70—

—Dog barking

—Average conversation

60—

—Average city office

50—

—Average city residence

40—One typewriter

—Average country residence

30—Turning page of newspaper

—Purring cat

20—

—Rustle of leaves in breeze

—Human heartbeat

10-0—Faintest audible sound

= == = =

CLOTHING, HAIR, AND JEWELRY

Wear a short-sleeved shirt or roll up long sleeves above the elbow. Keep your shirt tucked in and remove your necktie. It is recommended that you wear a shop apron. If you do, keep it tied behind you. If apron strings become entangled in the machine, you may be reeled in as well. A shop coat may be worn as long as you roll up long sleeves. Do not wear fuzzy sweaters around ma chine tools.

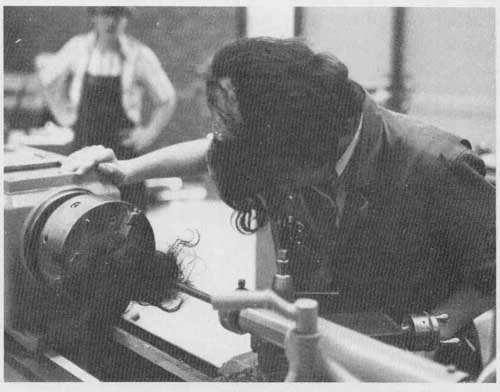

If you have long hair, keep it secured properly. In industry, you may be required to wear a hair net so that your hair cannot become entangled in a moving machine. The result of this can be disastrous ( FIG. A-10).

Remove your wristwatch arid rings before operating any machine tool. These can cause serious injury if they should be caught in a moving machine part.

FIG. A-10 Long hair may be caught and reeled into the machine.

HAND PROTECTION

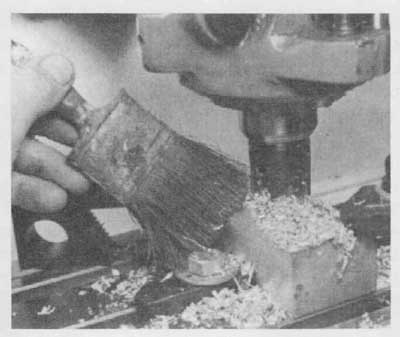

FIG. A-11 Use a brush to clear chips.

There is really no device that will totally protect your hands from injury. Next to your eyes, your hands are the most important tools you have. It is up to you to keep them out of danger. Use a brush to remove chips from a machine ( FIG. A-11). Do not use your hands. Chips are not only razor sharp, they are often extremely hot. Resist the temptation to grab chips as they come from a cut. Long chips are extremely dangerous. These can often be eliminated by properly sharpening your cutting tools. Chips should riot be re moved with a rag. The metal particles become embedded in the cloth and they may cut you. Furthermore, the rag may be caught in a moving machine. Gloves must not be worn around most machine tools, although they are acceptable when working with a band saw blade. If a glove should be caught in a moving part, it will be pulled in. along with the hand inside it.

Various cutting oils, coolants, and solvents may affect your skin. The result may be a rash or an infection. Avoid direct contact with these products as much as possible and wash your hands as soon as possible after contact.

LIFTING

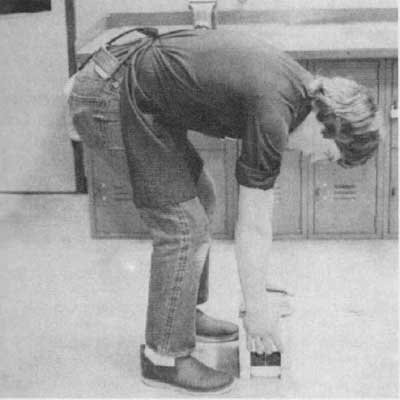

Improper lifting ( FIG. A-12) can result in a permanent back injury that can limit or even end your career. Back injury can be avoided if you lift properly at all times. If you must lift a large or heavy object, get some help or use a hoist or forklift. Don’t try to be a “superman” and lift something that you know is too heavy. It is not worth the risk.

FIG. A-12 The wrong way to lift, placing excessive strain on the back.

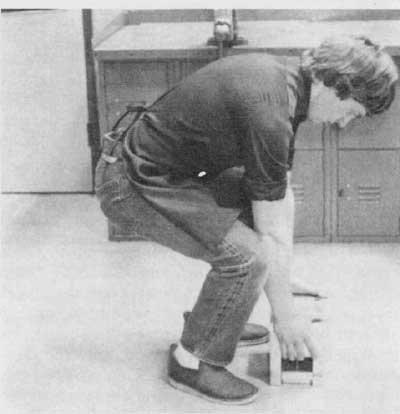

FIG. A-13 The right way to lift with knees bent, using leg muscles to do

the work.

Objects within your lifting capability can be lifted safely by using the following procedure (FIG. A-13):

1. Keep your back straight.

2. Squat down, bending your knees.

3. Lift smoothly, using the muscles in your legs to do the work. Keep your back straight. Bending over the load puts an excessive stress on your spine.

4. Position the load so that it is comfortable to carry. Watch where you are walking when carrying a load.

5. If you are placing the load back at floor level, lower it in the same manner you picked it up.

SCUFFLING AND HORSEPLAY

The machine shop is no place for scuffling and horseplay. This activity can result in a serious injury to you, a fellow student, or worker. Practical joking is also very hazardous. What might appear to be a comical situation to you could result in a disastrous accident to someone else. In industry, horseplay and practical joking are often grounds for dismissal of an employee.

INJURIES

If you should be injured, report it immediately to your instructor.

Identifying Shop Hazards

A machine shop is not so much a dangerous place as a potentially dangerous place. One of the best ways to be safe is to be able to identify shop hazards before they can involve you in an accident. By being aware of potential danger, you can better make safety part of your work in the machine shop.

COMPRESSED AIR

Most machine shops have compressed air. This is needed to operate certain machine tools. Often flexible air hoses are hanging about the shop. Few people realize the large amount of energy that can be stored in a compressed gas such as air. When this energy is released, extreme danger may be present. You may be tempted to blow chips from a machine tool using compressed air. This is not good practice. The air will propel metal particles at high velocity. They can injure you or someone on the other side of the shop. Use a brush to clean chips from the machine. Do not blow compressed air on your clothing or skin. The air can be dirty and the force can implant dirt and germs into your skin. Air can be a hazard to ears as well. An eardrum can be ruptured.

Should an air hose break, or the nozzle on the end come unscrewed, the hose will whip about wildly. This can result in an injury if you happen to be standing nearby. When an air hose is not in use, it is good practice to shut off the supply valve. The air trapped in the hose should be vented. When removing an air hose from its supply valve, be sure that the supply is turned off and the hose has been vented. Removing a charged air hose will result in a sudden venting of air. This can surprise you and an accident might result.

HOUSEKEEPING

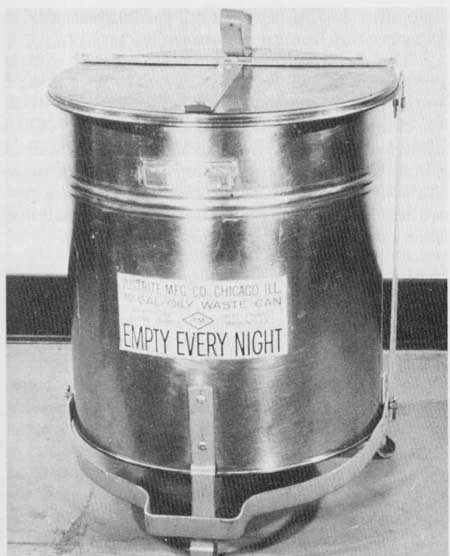

Keep floor and aisles clear of stock and tools. This will insure that all exits are clear if the building should have to be evacuated. Material on the floor, especially round bars, can cause falls. Clean oils or coolants that spill on the floor. Several preparations designed to absorb oil are available. These may be used from time to time in the shop. Keep oily rags in an approved safety can ( FIG. A- 14). This will prevent possible fire from spontaneous combustion.

FIRE EXTINGUISHERS

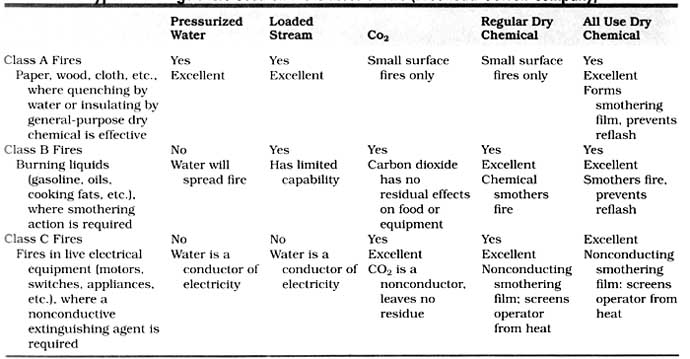

It is an important safety consideration to know the correct fire extinguisher to use for a particular fire. For example, if you should use a water- based extinguisher on an electrical fire, you could receive a severe or fatal electrical shock. Fires are classed according to types as given in Table 2.

There are four basic types of fire extinguishers used other than the use of tap water.

1. The dry chemical type is effective on classes B and C fires.

2. The pressurized water and loaded stream types are safe only on class A fires. These types may actually spread an oil or gasoline fire.

3. The dry chemical multi-purpose extinguisher may be safely used on classes A, B, and C fires.

4. Pressurized carbon dioxide (CO can be used on classes B and C fires.

You should always make yourself aware of the locations of fire extinguishers in your working area. Take time to look at them closely and note their types and capabilities. This way, if there should ever be an oil-based or electrical fire in your area, you will know how to put it out safely.

FIG. A-14 Store oil soaked rags in an approved safety can.

ELECTRICAL

Electricity is another potential danger in a ma chine shop. Your exposure to electrical hazard will be minimal unless you become involved with machine maintenance, A machinist is mainly concerned with the on and off switch on a ma chine tool. However, if you are adjusting the ma chine or accomplishing maintenance, you should unplug it from the electrical service. If it is permanently wired, the circuit breaker may be switched off and tagged with an appropriate warning. In industry, this procedure often means that the operator must sign a clearance stating that electrical service has been secured. Service cannot be restored until the operator signs a restoration order. Normally you will not disconnect the electrical service for routine adjustments such as changing speeds. However, when a speed change involves a belt change, you must insure that no other person is likely to turn on the machine while you hands are in contact with belts and pulleys.

==== ====

TABLE 2 Types of Extinguishers Used on the Classes of Fire

=== ===

CARRYING OBJECTS

If material is over 6 feet long it should be carried in the horizontal position. If it must be carried in the vertical position, be careful of light fixtures and ceilings. If the material is both long and over 40 pounds in weight, it should be carried by two people, one at each end. Heavy stock, even if it is short, should be carried by two people.

Machine Hazards

There are many machine hazards. Each section of this book will discuss the specific dangers applicable to that type of machine tool. Remember that a machine cannot distinguish between cut ting metal and cutting fingers. Do not think that you are strong enough to stop a machine should you become tangled in moving parts. You are not. When operating a machine, think about what you are going to do before you do it. Go over a safety checklist.

1. Do I know how to operate this machine?

2. What are the potential hazards involved?

3. Are all guards in place?

4. Are my procedures safe?

5. Am I doing something that I probably should not do?

6. Have I made all the proper adjustments and tightened all locking bolts and clamps?

7. Is the workpiece secured properly?

8. Do I have proper safety equipment?

9. Do I know where the stop switch is?

10. Do I think about safety in everything that I do?

Industrial Safety and Federal Law

In 1970, Congress passed the Williams-Steiger Occupational Safety and Health Act. This act took effect on April 28, 1971. The purpose and policy of the act is “to assure so far as possible every working man and woman in the Nation safe and healthful working conditions and to preserve our human resources.”

The Occupational Safety and Health Act is commonly known as OSHA. Prior to its passage, industrial safety was the individual responsibility of each state. The establishment of OSHA added a degree of standardization to industrial safety throughout the nation. OSHA encourages states to assume full responsibility in administration and enforcement of federal occupational safety and health regulations.

DUTIES OF EMPLOYERS AND EMPLOYEES

Each employer under OSHA has the general duty to furnish employment and places of employment free from recognized hazards causing or likely to cause death or serious physical harm. The employer has the specific duty of complying with safety and health standards as defined under OSHA. Each employee has the duty to comply with safety and health standards and all rules and regulations established by OSHA.

OCCUPATIONAL SAFETY AND HEALTH STANDARDS

Job safety and health standards consist of rules for avoiding hazards that have been proven by research and experience to be harmful to personal safety and health. These rules may apply to all employees, as in the case of fire protection standards. Many standards apply only to workers engaged in specific types of work. A typical standard might state that aisles and passage- ways shall be kept clear and in good repair, with no obstruction across or in aisles that could create a hazard.

COMPLAINTS OF VIOLATIONS

Any employee who believes that a violation of job safety or health standards exists may re quest an inspection by sending a signed written notice to OSHA. This includes anything that threatens physical harm or represents an imminent danger. A copy must also be provided to the employer. However, the name of the person complaining need not be revealed to the employer.

ENFORCEMENT OF OSHA STANDARDS

OSHA inspectors may enter a plant or school at any reasonable time and conduct an inspection. They are not permitted to give prior notice for this. They may question any employer, owner, operator, agent, or employee in regard to any safety violation. The employer and a representative of the employees have the right to accompany the inspector during the inspection.

If a violation is discovered, a written citation is issued to the employer. A reasonable time is permitted to correct the condition. The citation must be posted at or near the place of the violation. If, after a reasonable time, the condition has not been corrected, a fine may be imposed on the employer. If the employer is making an attempt to correct the unsafe condition but has exceeded the time limit, a hearing may be held to determine progress.

PENALTIES

Willful or repeated violations may incur penalties up to $10,000. Citations issued for serious violations incur mandatory penalties of $1000. A se nous violation where extreme danger exists may be penalized up to $1000 for each day the violation exists.

OSHA EDUCATION AND TRAINING PROGRAMS

The Occupational Safety and Health Act pro sides for programs to be conducted by the Department of Labor. These programs provide for education and training of employers and employees in recognizing, avoiding, and preventing unsafe and unhealthful working conditions. The act also provides for training an adequate supply of qualified personnel to carry out OSHA’s purpose.

Quiz:

1. What is the primary piece of safety equipment in the machine shop?

2. What can you do if you wear prescription glasses?

3. Describe proper dress for the machine shop.

4. What can be done to control grinding dust?

5. What hazards exist from coolants, oils, and solvents?

6. Describe proper lifting procedure.

7. Describe at least two compressed air hazards.

8. Describe good housekeeping procedures.

9. How should long pieces of material be carried?

10. List at least five points from the safety check list for a machine tool.