| PREV.: Operating Principles of Various Main Poppet Designs | NEXT: Symbols for Pilot-Operated Reliefs | Article Index | Home |

AMAZON multi-meters discounts AMAZON oscilloscope discounts Although the mounting conveniences are as numerous as the number of valves themselves, there are six basic mounting options each with its own advantages and disadvantages. The options range from two types of line mounting to sub- plate and sandwich mounting, to two types of cartridges for custom manifolding. In choosing the mounting style for your system, you should consider adjustment accessibility, serviceability, location and its effect on system protection and overall space requirements. |

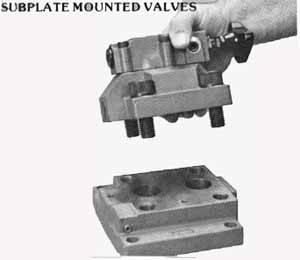

Above: SUBPLATE MOUNTED VALVES (See Color code legend for above image)

Advantages

The subplate mounted valves, by far, offer the best ser viceability. Since the rigid piping is made to the subplate and not to the valve, valve replacement is simply by bolting a new valve to the subplate. Most subplate mounted valves conform to national and international standards, so retrofits are not a problem. In addition, the valve and its sub- plate can be mounted away from the bulk of the system piping for easy operator access.

Disadvantages

The major disadvantages of subplate mounting show up in initial system cost and in space requirements. Not only is the subplate an additional purchase item, which also requires additional piping hardware, it also must be structurally sup ported by some type of valve panel. This additional cost must be weighed against future service costs in your consideration.

SANDWICH MOUNTING

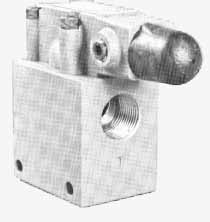

Above: SANDWICH MOUNTING

Advantages

Sandwich mounted valves are through ported and mounted between the directional control valve and its subplate. Their porting configuration is accomplished through passages in the block, and they can relieve either the pump supply or the service lines to the actuator. Either crossport or relief to tank can be compactly accomplished in a single block. Serviceability is equal to that of a subplate mounted valve with a smaller space requirement.

Disadvantages

Because of the compact nature of these valves, their performance characteristics are sometimes compromised. Likewise, because the valve is mounted close to the directional valve rather than to the pump or actuator, the relief’s ability to protect the system is somewhat reduced.

TWO PORT LINE MOUNTED

Advantages

This type of mounting reduces initial installation cost by eliminating the cost of a separate subplate. Also, except for very large valves, the piping itself can serve as the valve’s mounting structure. Since the valve must be teed to the pressure line, it is a relatively simple procedure to locate the valve for the operator’s convenience.

Disadvantages

Care must be taken in “making-up” the fitting for this valve, as in the case with any line mounted valve. Over tightening of a tapered pipe thread can distort the valve housing, causing the valve to malfunction. Serviceability is also complicated because the system has to be partially disassembled to remove the valve. With a cartridge style line mounted valve, these problems are somewhat alleviated, because servicing can be accomplished simply by removing the cart ridges. Likewise, even if a valve housing is distorted by over tightening a pipe connection, the chances are that this distortion will be isolated from the critical clearance in the cart ridge.

THROUGH-PORTED RELIEF VALVES

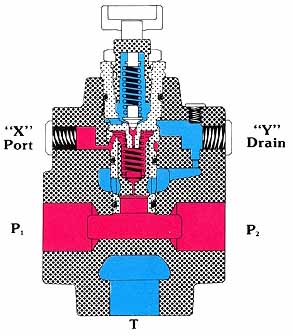

Above:

(See Color code legend for

above image)

Advantages

The through ported relief is the most economical relief when you consider initial system costs. With three ports, you simply have to pipe to the inlet from the pump, an outlet to the system, and a tank return. Since the number of fittings is reduced, so are the possible points for leakage.

Disadvantages

Since the valve’s physical location in the system is deter mined by the piping, adjustment access for the operator is not always easy to achieve. For serviceability, this valve more than any other, should be of cartridge construction, since the housing is located in the main artery of the system. More often than not, servicing requires a major system disassembly.

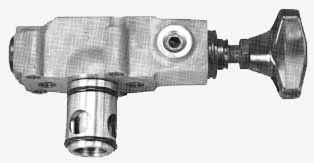

CARTRIDGE UNITS

The operational cross section shows that the cartridge unit consists of a small low mass poppet which offers a large flow area with minimum stroke. These design features allow the relief function to be performed quickly and quietly. Forces on the poppet are always in balance at any flow rate. Because of this, the valve is not only inherently stable, but it also operates with minimal pressure override. Likewise, the cart ridge design offers better serviceability and flexibility in mounting style that is not possible with parts and body construction.

Above: Cartridge units (See Color code

legend for

above image)

Cartridge units are available today in two basic versions: the threaded insert, and the slip-in cartridge. Since both types offer the same advantages and disadvantages, we will discuss their merits as one.

Advantages

Although cartridges can be mounted in either a subplate mount, or a thread valve housing, they are basically intended for custom manifolding. The cartridge greatly improves the serviceability of the relief function no matter whether it is mounted in a custom manifold or in a standard valve housing.

Disadvantages

The cartridge in itself cannot function. Consequently, it must be used in conjunction with a standard valve housing, or with some type of custom manifold. Of course, due to the high cost of both engineering and low quantity machining, the cartridge is often not an economical consideration.

| Top of Page | PREV.: Operating Principles of Various Main Poppet Designs | NEXT: Symbols for Pilot-Operated Reliefs | Home |