QUICK FACTS:

- School Subjects: Chemistry, Technical/shop

- Personal Skills: Mechanical/manipulative Technical/scientific

- Minimum Education Level: High school diploma

- Salary Range: $30,000 to $35,000 to $40,000+

- Certification or Licensing: None available

- Outlook: About as fast as the average

- DOT: 772

- GOE: 01.06.01

- NOC: 9413

- O*NET-SOC: 51-9021.00, 51-9022.00, 51-9031.00, 51-9032.03, 51-9051.00, 51-9195.04

OVERVIEW

There are approximately 108,000 glass manufacturing workers in the United States, employed in factories and plants that make glass and glass products from raw materials.These products include flat glass, such as window and plate glass; pressed glass items, such as glass dishes; blown glass items, such as light bulbs and many kinds of bottles; and various special products, such as glass blocks used in building construction, safety glass windshields, and glass for optical instruments.

HISTORY

People have been manufacturing glass for about 4,500 years. The earliest glass objects were produced taking little advantage of the special qualities of hot glass. A major advance came around 200 B.C., when techniques were devised (probably in Syria) for blowing air into gobs of molten glass to shape the glass into useful objects. The new knowledge about working with hot glass spread quickly among glassmakers, and soon other peoples, notably the Romans, were making blown glass items. With the decline of Rome, much of the knowledge of working with glass was lost, not to be revived until glassworkers in Venice created a thriving industry around the 13th century. For hundreds of years, Venice was the leading center of glass production. In time, Venetian methods spread, new kinds of glass were developed, and good-quality blown glass was produced across much of Europe.

Skilled glassmakers were among the early European colonists in North America. However, not until the 18th century did glassmaking become a successful industry in the United States. Even at that time, glass was still made by hand and was so difficult to produce that it was expensive and seldom found in poor homes. In the 19th century, a steady stream of technological innovations simplified the various methods of production and made glass much more common. More efficient furnaces melted raw materials much faster; new molds made bottles much easier to mass produce; improved methods simplified the production of flat glass; and better polishing equipment greatly increased the output of plate glass for windows, creating a new look in buildings.

Major advances in the scientific understanding of glass and its properties have brought changes in manufacturing processes and new applications for glass products. Many new types of glass, such as heat-resistant glass, glass fabrics, and laminated glass, have been introduced. Although some craftsworkers and artists still follow the old ways of making glass by hand, most modern glass is made in factories that use highly organized, automated industrial processes.

THE JOB

Glass manufacturing involves a number of basic operations, including mixing and melting materials; forming molten glass by blowing, pressing, casting, drawing, or rolling; heat-conditioning and controlled cooling; and finishing glass by polishing, coating, and using other surface processes. Different kinds of glass may involve different processes and require specialized workers. Most of today’s glass manufacturing workers tend to specialized machines used as part of a continuous mechanized operation.

Glass is usually made from sand (silicon dioxide), limestone (calcium carbonate), soda ash (sodium carbonate), and other raw ingredients. In many plants where glass is made, mixers tend equipment that blends ingredients. They either weigh and mix batches of materials or monitor machines that automatically supply the correct mix for melting in furnaces. Cullet crushers tend machines that crush and wash cullet, or broken waste glass, which will be recycled and melted with the raw ingredients. In some plants, batch-and-furnace operators control automatic equipment that can weigh and mix ingredients, then dump them into a furnace. Combustion analysts test and regulate the temperature of the furnace to manufacturing specifications. When the temperature is properly controlled, bubbles and impurities can be eliminated.

Many workers are concerned with machine-forming of the hot glass so they can take advantage of glass’s malleable quality. Among these workers are forming machine operators, who set up and operate machines that press, blow, or spin lumps of molten glass into molds to make a wide variety of glass products, such as bottles, containers, and cathode-ray tubes. Under operator control, the machines deliver gobs of hot glass from the supply emerging from the furnace. Often, a puff of air is used to blow the glass firmly into a mold. The glass temperature is regulated until the molded item is ejected for further processing. Pressers tend press molds that force molten glass into shapes, making cast glassware items such as plates and automobile headlights. Others tend machines that extrude fiberglass filaments, mold optical glass blanks, form bulbs, and shape other glass products.

Flat glass is an extremely important product for windows, doors, and many other items. The float-glass process is used to produce much of the flat glass made today. In this process, molten glass flows from the furnace where it has been heated onto the surface of a pool of molten tin. The result is a glass with a good polish and flatness that requires less costly finish processing than other flat glass.

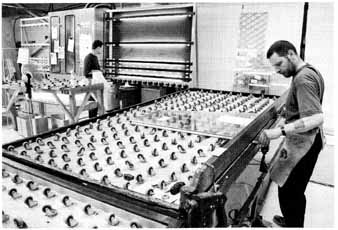

A worker operates machinery in a glass manufacturing

factory.

The glass manufacturing workers who make flat glass by other methods include drawing-kiln operators, who operate machines that process molten glass into continuous sheets by drawing molten glass upward from a tank and cooling it before it runs and loses its shape. Sometimes sheets of glass are made by rolling-machine operators, who operate equipment that rolls molten glass flat.

Some workers form hot glass by hand. They include glassblowers, who shape gobs of molten glass into glassware by blowing through a blowpipe, in much the same way that glass has been blown for centuries. Glassblowers produce certain kinds of special scientific equipment, as well as unique tableware and art objects. Other craft- workers shape and attach hot glass to other objects to make handles and pedestals.

Some glass is further processed with controlled reheating and slow cooling to eliminate flaws and internal stresses. Lehr tenders operate lehrs, which are tunnel-like automatic ovens used to heat- treat flat glass and glassware and fuse painted designs on glass.

Many glass products are not complete until they have been given other finishing treatments. Among the workers who do these tasks are glass decorators, who etch or cut designs into the surface of glass articles. Glass grinders remove rough edges and surface irregularities from glassware using belt or disk grinders. Polishers polish the edges and surfaces of flat glass, using polishing wheels.

REQUIREMENTS

High School

Many workers in glass manufacturing occupations, such as machine tenders, can be hired as inexperienced beginners and learn the skills they need on the job. If you plan to work in glass manufacturing, a good background includes high school courses in shop, general mathematics, and applied sciences. A high school diploma is not required, but many employers often prefer candidates that have graduated or at least have a general equivalency diploma.

Postsecondary Training

Apprenticeship programs are recommended for training skilled glassmaking workers. These programs combine on-the-job training with formal instruction in related fields. Some apprenticeships are sponsored and run by local joint union-employer committees or by large glass manufacturing firms. The content of the training pro grams may vary somewhat, but programs usually last about three years. An example is the program of the Glass, Molders, Pottery, Plastics and Allied Workers International Union, which involves on- the-job work experience as well as classroom study.

Other Requirements

Because they work mostly with automated processes, glass manufacturing workers usually need only enough strength to lift light- or medium-weight objects. They must be able to tolerate repetitive work yet maintain careful attention to what they are doing while they oversee the operation of machines. Also, although union membership is not a requirement for employment (for example, most flat-glass workers do not belong to a union), many workers in the glass manufacturing industry are represented by a union, such as the Glass, Molders, Pottery, Plastics and Allied Workers International Union and the United Steel Workers of America Flint/Glass Industry Conference.

EXPLORING

If you are interested in making glassware, art and shop courses in high school will help you develop manual dexterity and learn about some of the tools and techniques used in glassmaking. Community art centers and adult education programs frequently offer classes in glassblowing, molding, and stained-glass construction. With the help of a teacher or guidance counselor, arrange to visit a glass manufacturing plant or a shop where artisans work with glass. One interesting field trip would take you to the Corning Museum of Glass at the Corning Glass Center in Corning, New York. The museum has more than 45,000 glass objects, from 3,500 years ago to the present; its library is the main research center for students of glass. And you can see a demonstration of actual glassblowing at the museum’s Hot Glass Show.

EMPLOYERS

Approximately 108,000 glass manufacturing workers are employed in the United States. Most workers in glass manufacturing work in factories in or near big cities in many sections of the country, where they work with pressed or blown glass. Others work in plants making glass containers, and some work with flat glass. One of the world leaders in specialty glass materials is Corning, the company that supplied the glass for Thomas Edison’s first light bulb and influenced the use of red, yellow, and green lights for traffic control. Among the applications for Corning’s glass technology were the first mass-produced TV tubes, freezer-to-oven ceramic cookware, and car headlights. In the 1970s, Corning pioneered the development of optical fiber and auto emission technology; in 1993, the company was chosen by AT&T to provide fiber-optic couplers for its undersea telecommunications system and developed an electrically heated catalytic converter that could meet strict California emissions standards. The company is the world’s number-one producer of tableware and cookware, led by its patented Pyrex and Corning Ware heat-resistant oven containers.

STARTING OUT

If you want an entry-level job in the glass manufacturing industry, you can apply directly to factories that may be hiring new workers. You might find leads to specific job openings through the classified ads in newspapers and the local offices of your state’s employment service. Because many workers in this field are union members, it’s a good idea to check out local union offices for job listings and general information about local opportunities.

If you want to be an apprentice in the industry, you might find information through union offices, glass manufacturing companies, and state services. After finishing your apprenticeship program, you could be rehired by the same company for which you apprenticed.

ADVANCEMENT

Advancement opportunities for glassworkers are similar to those in many other fields. Glass manufacturing workers who are disciplined, motivated, and reliable have the best chance for promotion and increased earnings. Glassworkers can be trained to operate many types of equipment, either through their company or with the help of their union. After they have gained some seniority and a diversity of glassmaking skills, glassworkers would be qualified to transfer to other jobs, shifts, or supervisory positions when they become available.

EARNINGS

Earnings of glass manufacturing workers depend on the type of industry they work in, their specific duties, union membership, the shift they work, and other factors. Production workers in flat-glass manufacturing average about $30,000 per year; those in pressed and blown glassmaking production jobs earn an average of $35,000 per year; those who produce glass containers average $34,000. Managers may earn $40,000 or more annually. Those who work more than eight hours a day or 40 hours per week receive overtime pay, and they are usually paid at higher rates if they work at night, on weekends, or on holidays.

Workers in many factories are union members, and their earnings are established according to agreements between the unions and company management. In addition, glassworkers often receive benefits, such as retirement plans and health and life insurance.

WORK ENVIRONMENT

Glass factories usually operate around the clock, 24 hours every day of the year, because the furnaces have to be kept going all the time. For this reason, many workers work at night, on weekends, and on holidays. Although the standard workweek is about 40 hours, many workers put in overtime hours on a regular basis.

Factory conditions in glass plants have greatly improved over the years. On the job, workers may have to contend with some heat and fumes, but for the most part ventilation and heat shielding in modern plants have reduced worker exposure to these factors to accept able levels. Workers who tend furnaces and ovens are the most likely to work in hot conditions. Glass plants can be noisy, and workers may have to spend long periods of time on their feet.

OUTLOOK

Glass is so common in our lives that as long as we continue to use it in its myriad forms, workers in glass manufacturing will be needed. It is difficult to say with any accuracy, however, whether job growth will be fast or slow or will remain the same. Much of the environment in the glass industry depends on other industries that use glass, like automobiles, spacecraft, nuclear energy, electronics, and solar energy. There are two markets for which new developments may be more important than others and thus require new workers: switch- able glass (in which the ability of the glass to be seen through is changed by electronic and other means) and glass used in energy conservation.

FOR MORE INFORMATION

The following is a museum and educational site that has more than 45,000 objects of glass on view, a comprehensive library on the art and history of glass, and a studio that offers classes for all skill levels.

Corning Museum of Glass

One Museum Way

Corning, NY 14830-2253

Tel: 800-732-6845

Email: education@cmog.org

The following union represents glass manufacturing workers.

Glass, Molders, Pottery, Plastics & Allied Workers International Union

608 East Baltimore Pike

P0 Box 607

Media, PA 19063-0607

Tel: 610-565-5051

Email: gmpiu@gmpiu.org

This is a nonprofit trade association that represents the flat-glass industry and offers educational services, such as the Glass Management Institute.

National Glass Association

8200 Greensboro Drive, Suite 302

McLean, VA 22102-38 81

Tel: 866-342-5642

The following union represents glass manufacturing worker:

United Steel Workers of America Flint/Glass Industry Conference

Five Gateway Center

Pittsburgh, PA 15222-1214

Tel: 412-562-2400

http://www.uswa.org/uswa/program/content

For information on the glass industry, visit Glasslinks.com

Prev: Manufacturing Cost Estimators

Next:

Home top of page