AMAZON multi-meters discounts AMAZON oscilloscope discounts

Although a condenser pipe and drain remove most moisture from your air system, it’s still a good idea to install filtration devices. These will remove any contaminants, including fine oil droplets, dirt, and dust particles, as well as any residual moisture from the air. This is most important if the system will feed spray-finishing guns and equipment, which are most sensitive to contaminants.

If you can afford it, it’s best to fit filters at the end of each drop line, closest to where the spray gun or air device is used. On a portable compressor, a filter/regulator unit can be mounted at the air tank, or the unit, fed by a flexible hose, can be temporarily mounted on the wall above where the compressor is located so moisture will drain back down into the air tank. This is your best assurance that only the driest, cleanest air will get to your hose.

Regulators and gauges, the final items added at the end of each drop line, are necessary to reduce the air pressure in the main pipe down to the pressure that’s desired for the device in use. A convenient but more costly alternative is to fit each device with its own regulator, which allows you to change pressure whenever needed without having to walk back to the drop line. This is especially useful with spray guns, where fine adjustment of the air pressure is often required during spraying.

(left): An automatically retracting hose

reel installed overhead in the author’s shop provides all the air hose

needed to reach work areas in and around the shop while preventing hose tangles

that quickly become a nuisance under foot.

(right) Drop lines bring pressurized air from a main pipe, run around

the shop ceiling, down to where it’s used. Each drop line terminates in a shut-off

valve and filter unit, in this case a filter with a built-in oiler designed

to service pneumatic tools.

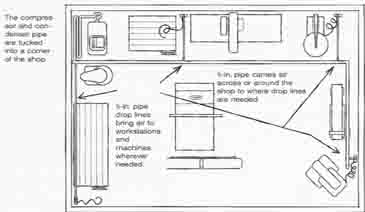

Example of a Pipe Installation for a Compressed-Air System

The compressor and condenser pipe are tucked into a corner of the shop.

3/8-in. pipe drop lines bring air to workstations and machines wherever needed.

3-4-in. pipe carries air across or around the shop to where drop line where needed.

Prev.: Installing

a compressed-air system

Next: Selecting Air

Hoses