AMAZON multi-meters discounts AMAZON oscilloscope discounts

Besides wearing a mask or respirator for protection, you can deal with uncaptured fine dust by using ventilation or air-filtration methods. Ventilation relies on a strong fan to suck dusty air out of the shop and expel it outdoors.

Ventilation is an inexpensive and effective way of keeping small shop spaces from being filled with choking dust. As in a spray-finishing booth, it is best to set up ventilation so that the source of the dust is between you and the fan and that fresh air is coming into the shop from behind you. You can further enhance the air flow by placing a second fan upwind of you to blow fresh air toward you (just don’t let it blow so hard as to churn up settled dust and whisk it around the shop).

In hot or cold climates, blowing heated or cooled air out of the shop doesn’t make sense, so using ventilation for clearing dust is limited. In such circumstances, it’s better to keep the shop closed and filter fine particles out of the air with n air-filtration device (AFD).

Plastic vs. Metal Ductwork

Choosing what kind of pipe to use for your ductwork has become one of the most controversial aspects of installing a central sys tem. Plastic pipe is inexpensive and easy to work with, but it is flammable and difficult to ground properly, so it is not officially recommended for woodshop dust-collection piping. Metal spiral pipe pro vides industrial-strength piping but at a high cost of materials and installation time.

Don’t Rely on Air Filtration Alone

It’s important to note that an air-filtration device (AFD) is not a good substitute for primary collection, which traps the lion’s share of the dust and chips produced at the source. If you regularly use power tools and machines in your shop, don’t bother with an AFD until you have installed a central dust-collection system or portable collector to your machines.

We recommend metal snap-lock HVAC pipe (24- or 26-gauge, not thinner 30-gauge stovepipe), which is easy to ground, much less expensive than spiral pipe, and easier to install. Lengths of snap-lock pipe and special fittings pop-rivet together for easy assembly.

Air-filtration devices: Whether commercially produced or shop-made, an AFD is basically a cabinet with a motorized fan and filters that capture airborne dust as it circulates around the shop.

If you put your hand over the intake of a running AFD, you’ll immediately notice that even a big unit generates very little suction. Most fine-dust particles find their way to an

AFD only if they are carried there on an air cur rent. Fortunately, an AFD’s exhaust air is powerful enough to create air movement in the shop, but careful placement is crucial to develop the necessary circular air current.

The top figure here shows the best placement for an AFD unit in a typical rectangular shop to encourage air movement. The illustration also contains the formula to use for sizing an AFD unit to the cubic footage of your shop.

Sanding a tabletop in a work shop where carpenters works, one must wear a dust mask and rely on a ventilation fan, which is mounted in the wall behind the worker, to remove the fine sanding dust being generated with an orbital sander.

Improving Dust Collector Performance

You’ll improve the performance of a single-stage unit by retrofitting it with oversized filter bags or improve a two- stage central system by adding more filter bags. Doing this increases the amount of area that escaping air has to get through, thus reducing air resistance, just like a muscle car enthusiast soups up a car by fitting a “free flowing” exhaust system.

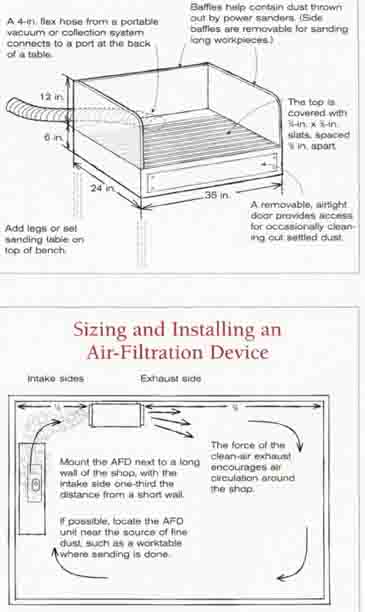

A Downdraft-Style Sanding Vacuum Table:

A 4-in. flex hose from a portable vacuum or collection system connects to a port at the back of a table.

Baffles help contain dust thrown out by power sanders. (Side baffles are removable for sanding long workpieces.)

Add legs or set sanding table on top of bench.

The top is covered with 3/4-in. x 3/8-in. slats, spaced 3/8 in. apart.

Add legs or set sanding table on top of bench.

A removable, airtight door provides access for occasionally cleaning out settled dust.

Sizing and Installing an Air-Filtration Device:

Intake sides; Exhaust side

Mount the AFD next to a long wall of the shop, with the intake side one-third the distance from a short wall.

The force of clean-air exhaust encourages air circulation around the shop.

If possible, locate the AFD unit near the source of fine dust, such as a worktable where sanding is done.

Formula for Sizing an AFD Unit to Your Shop

[Cubic-foot volume of shop (length x width x height) x 6 (# of air changes/hour for hobby use)

OR 8 (* of air changes/hour for full-time use)] / 60 = cfm air moving capacity of AFD

Prev.: Central

dust-collection system

Next: Compressed-Air Systems