You can noticeably improve almost any bathroom with a variety of basic amenities.

From hanging a mirror to adding an exhaust fan, the installations and modifications

explained in this section not only modernize a bathroom but also make it safer,

more accessible, and generally more agreeable to family members and guests

alike.

Hanging a Mirror

Installing a Glass Tub Enclosure

Making the Bathroom Safe and Accessible

- Applying Grip Strips

- Grab Bars for Shower and Tub

- Shock-proofing an Electrical Outlet

- Adapting a Bathroom for Special Needs

How to Increase Storage Space

- Clearing the Way for a Vanity

- Disassembling Pedestal Basins

- Anchoring a Vanity Base and Countertop

- Surf ace-Mounted Medicine Cabinets

- A Medicine Cabinet between Two Studs

- Recessing a Wide Medicine Cabinet

Fresh Air for the Bathroom

- Mounting an Exhaust Fan Housing

- Channeling the Air Flow Outdoors

- Making Electrical Connections

- Final Assembly and Testing

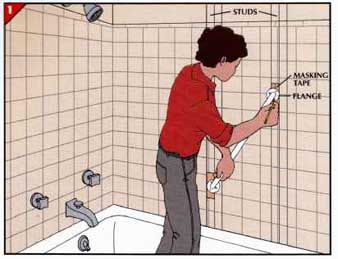

Positioning a glass tub enclosure.

++++++++++++++

Hanging a Mirror

Placing a large mirror above the bathroom washbasin not only aids grooming,

it seems to enlarge the room. Buy i-inch glass mirror and have the dealer

cut it. Ask to have the edges seamed, which removes the sharp side of each

edge. In determining the dimensions, plan for at least inch of clear space

around the mirror to ease installation and to allow for settling of the house.

--Methods for Mounting: Hanging a mirror on the wall requires special hardware,

which comes in several varieties. In the system illustrated here, J clips

and L clips anchor the mirror. Made of metal, J clips support the weight of

the glass and provide a 0.25-inch ventilation space behind the mirror to prevent

corrosion. Plastic L clips keep the top of the mirror in place.

Self-adhesive felt pads stuck to the back of the mirror help to maintain

the ventilation space and pre vent the mirror from flexing. In areas subject

to earthquakes, a bulky adhesive called mirror mastic not only sticks the

mirror to the wall but also serves instead of felt pads as a spacer.

--Avoiding Corrosion: A mirror’s reflective coating is easily damaged by

moisture and harsh chemicals. Never mount a mirror so that it touches a backsplash;

water creeping onto the backing could ruin it. Let a freshly plastered or

painted wall dry for a week before installing a mirror. When cleaning the

glass, avoid preparations with ammonia.

CAUTION --- If you are carrying a mirror and it starts to fall, do what the

professionals do and get out of the way. Never try to catch it.

TOOLS:

- Electronic stud finder

- Drill

- Level

MATERIALS:

- 0.25-inch glass mirror, cut to size

- Self-adhesive felt pads

- J clips

- L clips

- 1.5” flat-head screws

- 1.5” round-head screws

- Mirror mastic

= = = = =

1. Preparing the wall.

• Mark the locations of the mirror’s bottom corners on the wall—at least

1/8-inch away from the backsplash and adjacent walls. Use a straightedge to

join the marks to make a baseline for the mirror.

• To check for bulges in the wall, run a straight board over the area the

mirror will occupy above).

• To determine the height of any bulge, center the board on it and, using

the bulge as a pivot, push one end of the board against the wall. Have your

helper measure the gap between the wall and the board at the other end and

halve this distance.

• Flatten bulges higher than 1/8-inch with a hammer.

__ Mirror-Handing Checklist:

-- Each square foot of 0.25-inch mirror weighs more than 3 pounds. Work with

a helper if your mirror is larger than 12 square feet— For example, if it’s

larger than 3 feet by 4 feet or 6 by 2.

-- When you bring a mirror home, store it on edge.

-- Salts and oils from human skin can damage mirror backing; always wear

work gloves when handling the mirror.

-- Carry the mirror on edge so it won’t sag and break of its own weight.

When working with a helper and navigating stairs, post the stronger person

at the lower end.

2. Mounting the J clips.

• Using an electronic stud finder, locate the studs in side the mirror area

nearest the ends of the baseline.

• Place the bottom corner of a J clip on the baseline at a stud near one

end of the line. Mark the location of the clip’s screw holes arid drill a

pilot hole 1.5 inches deep at each mark.

3. Placing the mirror in the J clips.

• Using a level, measure up from each J clip a distance equal to the height

of the mirror plus 0.25 inch.

• Mark and drill a pilot hole into the stud at that height.

• Stick two or more rows of felt pads on the back of the mirror, keeping

the pads several inches in from each side.

• With a helper, lift the mirror. Tilt the top edge forward and lower the

bottom edge into the I clips. If necessary, slide the mirror sideways into

its intended position.

--Mirror Mastic for a Permanent Bond--

Mirror mastic helps secure a mirror to the wall without damage to the backing.

Al though particularly suited to earthquake zones because it re mains resilient

and will flex with tremors, mastic is messy to use and permanent. Attempting

to re move a mirror glued with this adhesive usually damages both mirror and

wall.

Mastic, which takes the place of felt pads on the back of the mirror, is

applied after Step 2 of mirror installation. Lay the mirror facedown on a

clean blanket. Using a wood scrap to avoid scratching the backing, scoop mastic

onto the mirror in separate pats—each about 1.5- inches across and 0.75 inch

thick. Apply four pats for every square foot of mirror, keeping the adhesive

at least 2.5 inches from the edges. Then mount the mirror as shown in Steps

3 and 4.

• Secure the clip with flat- head screws, then cover the heads with a felt

pad (inset).

• Attach a J clip to a stud at the line’s other end.

• For a mirror wider than 5 feet, mount a J clip on every second stud.

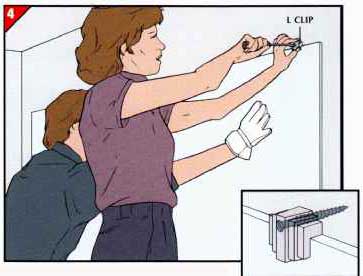

4. Mounting the L clips.

• Push the mirror toward the wall, listening carefully for the muted sound

of felt pads making contact. A sharp sound indicates the mirror is hitting

the wall; add pads on top of the first ones. Test again and add a third layer

of pads if necessary.

• While a helper steadies the mirror, drive a round-head screw through the

hole in an L clip and into each pilot hole (inset). Tighten each fastener

no more than needed to pre vent movement of the mirror when you push on

it.

++++++++++++++++++++++++++++++

Installing a Glass Tub Enclosure

Replacing an old-fashioned shower- curtain rod with a glass tub enclosure

not only helps to keep shower spray where it belongs but also adds an elegant

touch to the bathroom. Most tub enclosures are designed to fit a standard

5-foot tub between two side walls and are made of glass and extruded aluminum.

They come in many styles: Panels may be clear, frosted, or mirrored, and frames

may be polished bright or anodized in gold or other colors.

---Preparing the Tub Area: Before buying an enclosure kit, check your tub

rim and side walls with a level and a framing square. If the tub is as much

as 0.25 inch off level, or if the walls are out of plumb by that amount, you

can compensate by adjusting the enclosure’s panel rollers; if the variance

is much greater, an enclosure may be impractical.

For a tub with tiled walls that don’t extend as high as the top of the enclosure

frame, add filler tiles as needed, securing them with a water proof bathroom

adhesive.

---A Sturdy Installation: Methods for securing the enclosure frame in place

vary depending on whether there are studs located where the frame is to be

attached. When studs are present, drill through the finished wall and attach

the frame to the stud with 1 No. 8 wood screws. When studs are not present,

the frame should be secured with hollow-wall anchors.

---Care and Maintenance: To keep water from spraying between the panels into

the bathroom when showering, keep the inner panel to ward the shower head.

The only up keep required is periodic cleaning with a nonabrasive window cleaner

and, when necessary, adjusting the panel rollers in their slots.

TOOLS

Tape measure Hacksaw with metal-cutting blade

- Miter box

- Metal file

- Grease pencil

- Utility knife

- Level Electric drill

SAFETY TIPS---If you must drill into ceramic tile with a carbide bit, wear

safety goggles and use a dust mask.

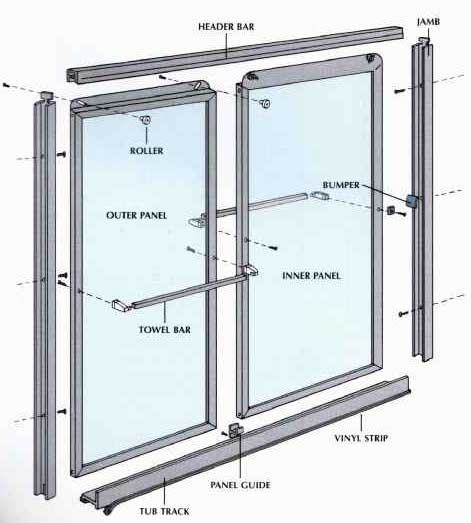

- - — Anatomy of an enclosure.

The typical glass tub enclosure at left consists of a frame and sliding panels.

The frame includes side jambs, a header bar, and a tub track, which is sealed

against the tub rim with a flexible vinyl strip. The tempered glass panels,

each with a towel bar in this example, ride inside the header bar on adjustable

rollers and are held in the tub track by a panel guide. Bumpers keep the panels

from hitting the jambs too hard.

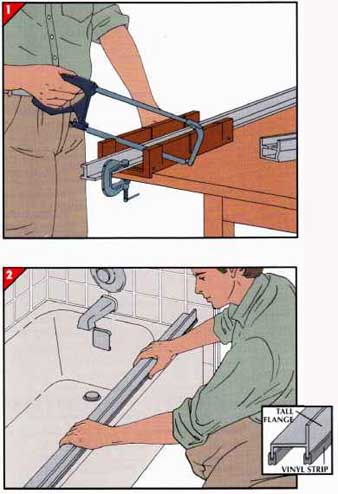

1. Cutting the pieces.

• Measure the tub rim between the two side walls, then subtract 1/16-inch

to avoid too tight a fit. Mark the tub track to this length and cut it with

a hacksaw, using a miter box to ensure a square cut (left).

• To measure for the header bar, set one of the jambs on the tub rim against

a side wall and mark the wall at the top of the jamb. Mark the second wall

the same way, then determine the distance between the two marks. Subtract

1/16-inch and cut the header bar to that length.

• Smooth the cut edges of both pieces with a metal file.

2. Fitting the tub track.

• Center the tub track on the tub rim, with the tall flange toward the room.

Mark the position of the track on the tub rim with a grease pencil.

• If the enclosure kit includes vinyl sealing strips, press them onto the

flanges on the underside of the tub track; trim off any excess with a utility

knife. For kits with no vinyl strips, apply a bead of silicone caulk along

the edges at the bottom of the track.

• Set the track on the tub rim between the marked lines. Secure it in place

with masking tape until both of the jambs are installed.

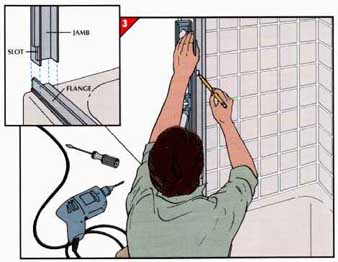

3. Marking the walls.

• Place a jamb at one end of the tub track so that the slot in the jamb goes

over the track flange (inset). Adjust the jamb against the wall with a level

to get it upright, then mark the wall through each screw hole. Set the jamb

aside. Repeat the process for the facing wall with the other jamb.

• Drill holes at each mark for the fasteners: 3/32-inch pilot holes for wood

screws if a stud is present behind the wall, or larger holes for hollow-wall

anchors. Use a carbide-tipped bit for ceramic tile.

• Put the bumper in place on one of the jambs, place the jamb on the track

as before, and fasten the jamb to the wall. Don’t install the other jamb yet.

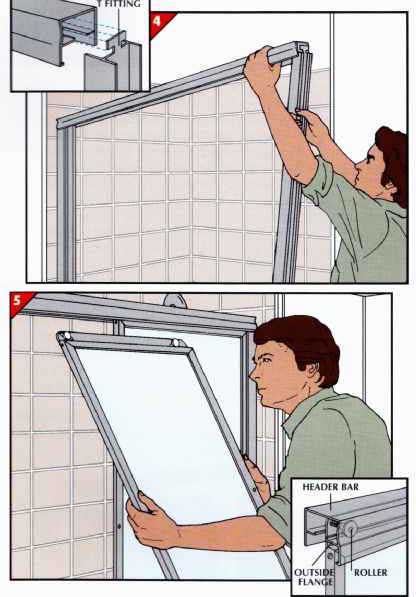

4. Completing the frame.

• Place the bumper on the unattached jamb and set the jamb aside.

• Slide one end of the header bar into the top of the installed jamb, inserting

the bar into the jamb’s T-shaped fitting.

• Angle the free end of the bar slightly outward and connect it to the T

fit ting on the unattached jamb (inset).

• Gently lift the bottom of the jamb into place on the tub track and fasten

the jamb to the wall.

• Remove the masking tape from the tub track now that the track is held in

place by the jambs.

5. Hanging the panels.

With the frame installation complete, put the door panels in place.

• Place a roller in each of the diagonal slots at the tops of the door panels;

don’t tighten the roller screws yet.

• Hold the inner panel with its rollers facing the tub. Lift the panel to

set the rollers over the lip of the header bar’s in side flange. Install the

outer panel so that its rollers rest on the outside flange of the bar (inset).

• Slide the panels against the jambs. If a panel does not slide freely or

does not hang straight, adjust it by removing the panel from the frame and

shifting the position of one or both of the rollers within the diagonal slots.

Tighten each roller screw and re-hang the panel.

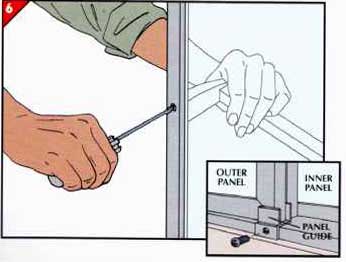

6. Attaching the hardware.

• Secure the panel guide (inset) to the tub track so that it will retain

the bottom edges of both panels.

• Attach any accessories supplied with the kit—in this case, two towel bars.

• Apply a thin bead of silicone caulk where the frame meets the tub and walls.

Smooth the caulk if necessary with a finger dipped in liquid deter gent.

Let the caulk cure overnight before using the tub.

+++++++++++++++++++++++++

Making the Bathroom Safe and Accessible

Most bathrooms combine at least three potentially dangerous elements: electricity,

water, and slick surfaces. You can improve the safety of your bathroom and

the ease with which you can use it by undertaking some or all of the modest

projects described here.

---Measures against Falls: A water- slicked shower floor or tub can be dangerous.

To reduce the likelihood of accident, add texture to either surface with grip

strips.

Also consider installing grab bars as handholds on walls surrounding the

bathing area. Towel bars are too weak to rely on. Choose grab bars made from

metal tubing without sharp corners. And avoid hanging towels on them; someone

could accidentally grasp the towel instead and fall.

---Preventing Electric Shock: To minimize the hazards of operating electrical

appliances near water, the National Electrical Code re quires that new bathroom

electrical circuits be equipped with a device that is called a ground-fault

circuit interrupter, or GFCI. If your bath room does not have this protection,

you can add it by installing a GFCI outlet in place of the receptacle that

already exists.

---Adaptations for Disabilities: For someone with a disability, the typical

bathroom can be difficult, or even impossible, to use. Ideally, a bathroom

for a family member who needs a wheelchair, a walker, or simply some assistance

with standing up or sitting down is designed from the outset for their comfort

and capabilities. As described below, you can also make an old bathroom somewhat

more accessible with a variety of products and modifications.

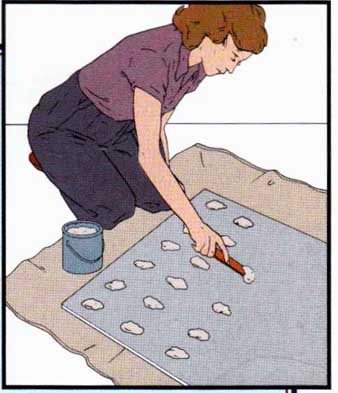

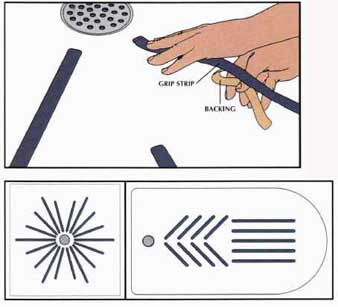

APPLYING GRIP STRIPS

Laying a safe pattern of strips.

• Wash the shower or tub floor, clean it with rubbing alcohol, and let it

dry.

• For a shower, plan a star pattern of strips; for a tub, arrange strips

both in a chevron pointed at the drain and in parallel lines.

• To apply each strip, peel the backing from one end and press it firmly

in place, then continue peeling as you work (left). If you must cut a strip,

round the corners so they won’t curl later.

GRAB BARS FOR SHOWER AND TUB

1. Positioning the bar.

The grab bar shown here is de signed so each flange is anchored by two screws

in a stud and a toggle bolt through the wall. (To support someone weighing

more than about 250 pounds, double the studs from the other side of the wall

and use three screws.)

• Locate studs above the tile with an electronic stud finder.

• Drop a plumb line at the center of each stud and mark the width of the

stud with masking tape at the height you intend to anchor the flanges.

• Place the grab bar so that two mounting holes in each flange lie on the

tape. Mark all six hole locations with a pencil.

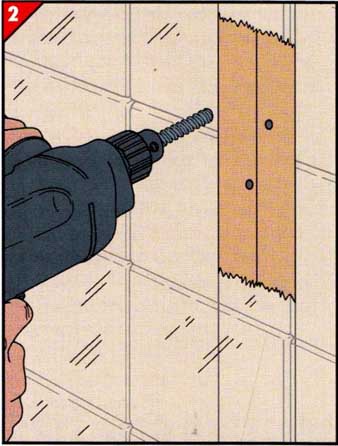

2. Drilling holes.

• At each hole location, tap a punch with a hammer to break through the slick

tile glaze.

• Wearing safety goggles, use carbide- tipped bits to drill a 0.5-inch hole

through the wall for each toggle bolt. For the screws, drill a hole through

the tile slightly larger than the screw diameter, then use an ordinary bit

to drill a smaller hole into the wooden stud.

• Remove the tape from the wall.

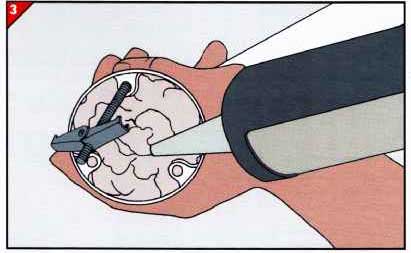

3. Mounting the bar.

• Insert a 3/16-inch toggle bolt into its hole on a flange and fill the in

side of the flange with silicone caulk. Prepare the other flange the same

way.

• Position the bar on the wall, pushing the toggle bolts into place. Insert

3-inch-long screws into the remaining holes and tighten screws and toggle

bolts with a screwdriver.

• Caulk around each flange and let dry for 24 hours.

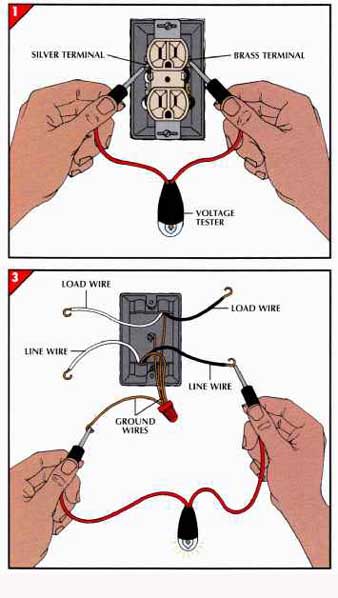

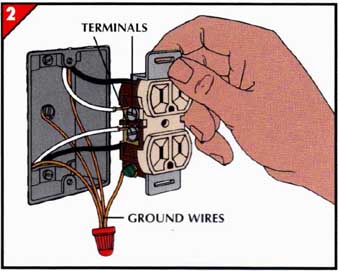

SHOCKPROOFING AN ELECTRICAL OUTLET

1. Checking for power.

• Turn off the electricity to the bathroom receptacle at the service panel.

Then unscrew and remove the cover plate.

• Test for power at the receptacle with a voltage tester (left). Holding

the tester by its insulated wires, touch the probes to each pair of brass

and silver terminals; the tester won’t light if the power is off.

2. Removing the receptacle.

Unscrew the receptacle and pull it from the box. Look in side; consult an

electrician if the wiring is aluminum, if there are no ground wires, or if

the box is less than 2 .75 inches deep. Otherwise, detach all wires from the

receptacle terminals.

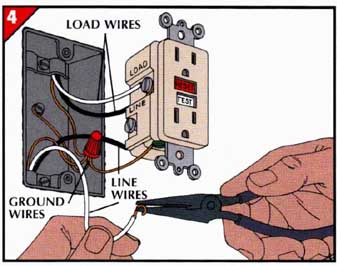

3. Identifying line and load wires.

To install a GFCI receptacle, you need to know which black wire in the box

brings power from the service panel.

• To identify this so-called line wire, stretch out all the wires so they

touch neither each other nor the box. Then turn the power on.

• Keeping your hands away from any bare wires, touch one probe of the voltage

tester to a ground wire and the other to each black wire. The one that causes

the tester to glow is the line wire (above); the other is called the load

wire.

4. Installing the GFCI.

• Turn the power off. Attach the wires of the line and load cables to the

corresponding terminals on the GFCI, connecting the black wires to the brass

terminals. Attach the ground wire to the green terminal.

• Screw the GFCI into place and replace the cover plate. Turn on the power,

then press the test button. If the wiring is correct, the reset button will

pop out, interrupting the power going to the receptacle. Depress the button

to reset the GFCI. LOAD WIRE; LINE WIRES; GROUND WIRES

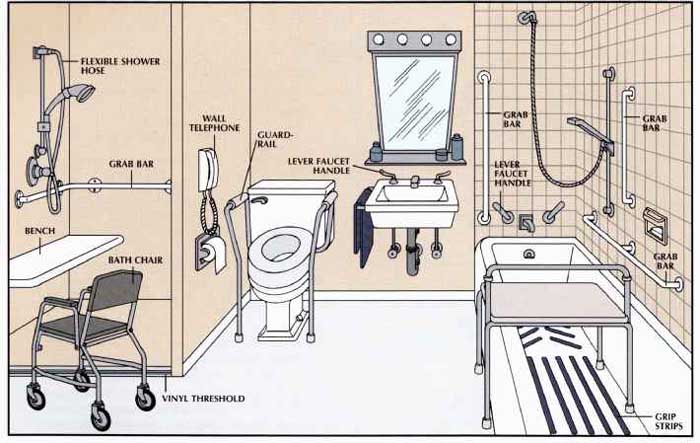

ADAPTING A BATHROOM FOR SPECIAL NEEDS

--- Helpful modifications.

Few bathrooms offer all the features in the composite illustration above,

but a person with a disability may find several of them beneficial.

--A roll-in shower. For a family member who uses a wheelchair or bath chair,

consider a shower with a low flexible-vinyl threshold; either vehicle can

easily roll across, and the vinyl keeps water from flowing out. Once inside,

a bather may transfer to a bench seat.

--An accessible telephone. A wall phone with the dial or keypad in the handset

provides a link to help.

--An easier-to-use toilet. A thicker- than-usual toilet seat and adjust able

guardrails may help someone who has difficulty sitting down or standing up.

Alternatively, install a grab bar beside the toilet.

--A convenient mirror. Tilt mirrors downward a bit to make them useful for

a person in a wheelchair.

--Lever handles. Equip faucets with long handles, rather than knobs that

must be grasped.

--Washbasin access. A wall-hung basin lets someone in a wheelchair roll up

to the sink; insulate the hot- water pipe to prevent burns.

--Grab bars and grip strips. As in any bathroom, grab bars and grip strips

in tubs and showers help to prevent falls while bathing.

--Seating in the bath. Place a bench or bath chair in a tub or shower; install

a showerhead with a flexible hose, and mount it on a sliding bar or within

easy reach.

--A nonslip floor. Floor tiles in a bathroom are a poor choice for someone

who may slip and fall. Carpet or vinyl sheet flooring are among the alternatives.

---Easing the Way for a Wheelchair---

--A door opening 32 inches wide is usable if the bathroom opens onto a wide

hallway, but an opening of 36 inches is better.

-- Inside the bathroom, the clear floor space should be at least 60 inches

square to allow a wheel chair to turn around completely.

--Sinks must be no more than 34 inches high, and they must not rest on a

vanity.

--Buy an add-on toilet seat from a medical-supply store to raise the seat

4 inches—the same height as most wheelchair seats. Mount such items as the

telephone at 33 to 36 inches.

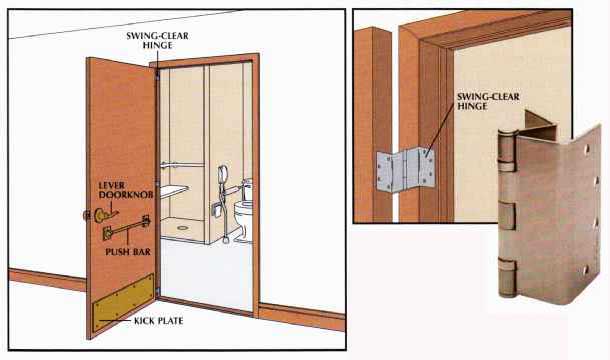

A doorway that provides easier access.

To maximize the width of a door opening, install a pocket door or a sliding

door. Re-hang a hinged door to open out ward (left); you can increase its

effective width with swing-clear hinges (right,), which add 14 to 2 inches

to the opening. Other useful door hardware includes a kick plate, a lever

doorknob (below), and a push bar to help open and close the door.

Installing a swing- clear hinge. (above right)

• Buy swing-clear hinges that fit the cavities that were cut into the door

edge and jamb for the old hinges.

• Unscrew the old hinges from the door and the jamb; set the door aside.

• If new screw holes are required, pack lengths of dowel, coated with glue,

into the existing holes. Let the glue dry overnight, then drill pilot holes

for the new screws.

• Attach the swing-clear hinges and re-hang the door.

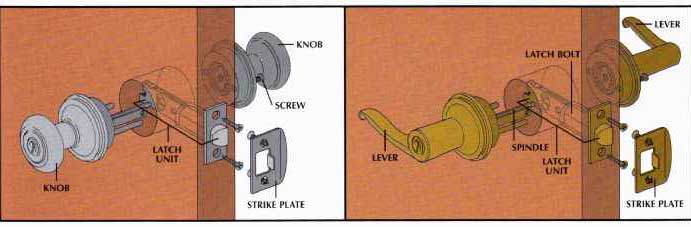

Putting in place a lever-knob assembly.

• Unfasten the two screws that secure the knob plate and pull it off with

the knob. If no screws are visible, depress the metal tab that holds one knob

on its shaft. Then remove the knob and the underlying cover plate to reveal

the screws.

• Pull off the other knob.

• Remove the two screws holding the latch unit in place and slide it out

of the door.

• With a half-round rasp, enlarge the lock and latch holes as needed to accommodate

the new mechanism.

• Set the latch unit of the lever knob in the door. Screw it to the door

edge.

• Insert the spindle attached to one of the two lever handles so that it

en gages the latch unit; then install the other lever. Secure the assembly

with screws.

• Check to make sure the strike plate aligns with the latch bolt.

+++++++++++++++++++++++++++++++

How to Increase Storage Space

Storage space is often at a premium in a bathroom. A simple way to make more

room is to install a larger medicine cabinet or a supplementary one, mounted

on the wall or recessed into it. For even more space, you can discard a stand-alone

washbasin and instead install a vanity with a sink in the countertop.

--- Considerations for a Vanity: Ready-made cabinets are available in many

widths. Choose a vanity that is at least wide enough to cover the holes left

in the wall by the bracket for the old washbasin but not so large that the

bathroom be comes cramped. For ease of installation and maintenance, choose

a one-piece counter- top like the one shown below.

If you plan to tile, wallpaper, or paint the bathroom walls, do so before

installing the vanity. This way the new cabinet will cover the edges of the

finish.

--- Installing a Medicine Cabinet: A surface-mounted cabinet can be hung

virtually anywhere, but recessed cabinets require more consideration. Most

are designed to fit in the space between existing studs, commonly 14.5 inches

but sometimes 22.5 inches. If the cabinet location is not critical, simply

fit it between the studs.

A unit wider than a single stud space—or one that must be centered on a wall

or above the wash basin—requires cutting out sections of one or more studs.

--- A Suitable Wall: The technique for cutting away studs shown on these

pages applies only to nonbearing walls, which carry no weight from the structure

above. Usually such walls run parallel to joists. A basement ceiling or attic

floor is the best place to find exposed joists, which usually have the same

orientation from floor to floor. Treat all exterior walls, and any walls about

which you are uncertain, as load-bearing walls. Avoid them.

--- Making Holes in Walls: Whenever possible, avoid cutting into a part of

a wall that might conceal pipes or wires. To check for wires, note the locations

of switches, outlets, and lights on both sides of the wall and in the rooms

above and below. Also observe where pipes and drains enter and leave walls

and floors.

Before you cut or drill, turn off electricity to any circuit that might run

through the wall. Drill only enough to penetrate the wallboard or plaster

and lath, usually less than 1 inch; plan to cut studs, if necessary, as a

second step. Stop at once if the drill bit hits a hard surface; it might be

a pipe or electrical junction box. If you puncture a pipe, turn off the main

water supply and call a plumber. Severed cables usually require an electrician’s

help.

TOOLS

- Wrenches

- Screwdriver

- Cold chisel

- Saber saw

- Electronic stud finder

- Utility knife

- Pry bar

- Level

- Electric drill with screwdriver bit

- Backsaw

- Dry-wall saw

MATERIALS

- Wood shims

- 2.25-inch No. 6 dry-wall screws

- Adhesive caulk 1.5- and 2.5-inch finishing nails

- 0.75-inch brads

- Scribe molding

- Shoe molding

- Hollow-wall anchors

- 2-by-4s

- Wallboard

SAFER TIPS---To protect your eyes, wear safety goggles when drilling or sawing

at or above the level of your waist.

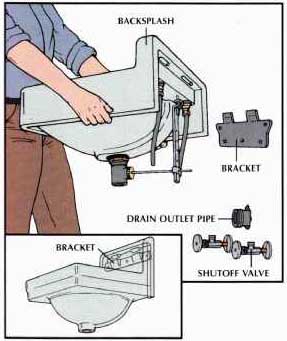

CLEARING THE WAY FOR A VANITY

Dismounting wall-hung basins.

• Turn off the water at the basin shutoff valves or at the house’s main valve.

Disconnect the supply lines and the drainpipe assembly.

• To remove a basin hung on a bracket behind the backsplash as shown in the

drawings at left, simply lift the basin straight up.

• Unscrew the bracket from the wall.

An angle bracket mounting.

To detach a basin supported from be low by angle brackets, have a helper

hold the basin while you loosen the mounting bolts with a wrench and remove

them. Set the basin aside and unscrew the brackets from the wall.

DISASSEMBLING PEDESTAL BASINS

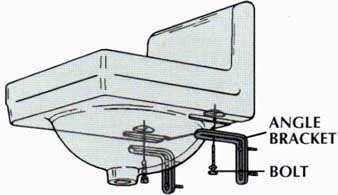

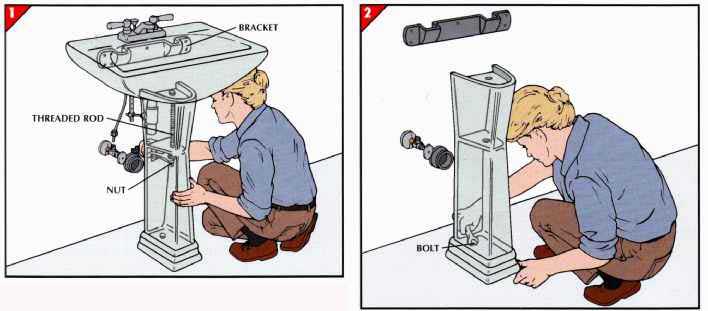

1. Removing a two-piece pedestal basin.

• Shut off the water and disconnect the water-supply lines and drainpipe

assembly.

• Look inside the pedestal for a long threaded rod connecting the basin to

its base. In the absence of such a rod, simply lift the basin from its wall

bracket and set it aside. Otherwise, reach inside the pedestal with a wrench

and re move the nut at the lower end of the rod. Lift the basin off its pedestal

and wall bracket, then remove the rod from the basin.

2. Removing the pedestal. (above right)

• Unscrew any fasteners you find holding the pedestal base to the floor,

then lift the pedestal away.

• If the pedestal is secured to the floor with grout, gently rock it back

and forth to break the seal. Loosen old grout from the floor with a cold chisel.

• For a pedestal and basin molded as a single unit, unscrew the pedestal

from the floor. Then lift the entire fix ture free of the basin wall bracket.

• Detach the basin bracket from the wall.

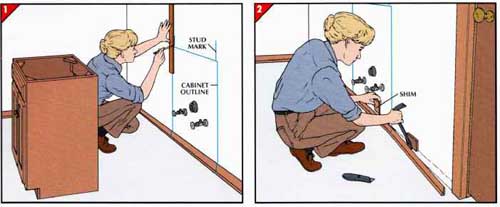

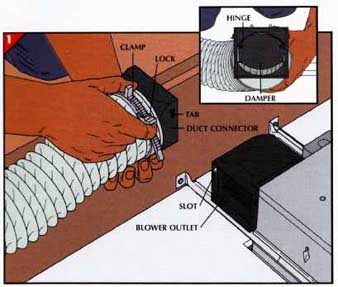

ANCHORING A VANITY BASE AND COUNTERTOP

1. Aligning the cabinet.

• Position the vanity so that shutoff valves and drainpipe are roughly centered

within the frame. If the vanity has a back, mark openings for the pipes, then

cut the holes with a saber saw.

• Push the vanity against the wall. Mark the outline of the cabinet on the

wall with light pencil lines, then set the cabinet aside.

• With a stud finder, locate wall studs that fall within the cabinet outline.

Mark the center of each stud above the outline as shown here.

2. Dealing with baseboard. (above right)

• For wooden baseboard, run a utility knife along the joint between the wall

and the top of the baseboard section extending across the planned area for

the vanity, breaking any paint seal.

• At one end of the base board section, tap a small pry bar into the joint.

Place a shim behind the bar, then lever the molding away from the wall. Slip

a shim into the gap.

• Continue prying and shimming to loosen the base board section, then pull

it free and set it aside.

To remove vinyl molding, cut it at the cabinet outline with a utility knife

guided by a straightedge. Peel away the piece below the pipes.

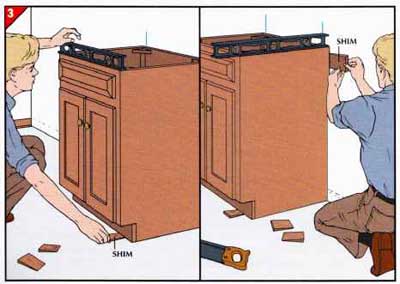

3. Securing the vanity.

• Reposition the vanity against the wall and level it from side to side by

inserting shims under the cabinet. Level the cabinet from front to back by

shimming it away from the wall.

• Mark each shim at cabinet edges. Remove one shim at a time, saw it to length,

and slide it back into place.

• For wallboard or plaster walls drive 2.25-inch No. 6 dry-wall screws through

the back of the cabinet about inch from the top and into the studs that

were marked earlier.

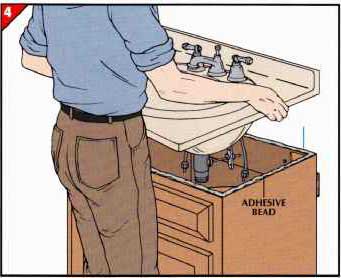

4. Mounting the countertop.

• Attach as many of the faucet and drain fittings to the countertop as possible.

• Apply a bead of adhesive caulk along the top edges of the cabinet, then

press the countertop into place. Wipe off excess caulk immediately.

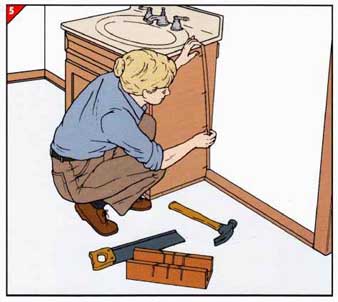

5. Finishing up.

• Connect the water-supply lines and the drain.

• If you detached a section of wooden baseboard earlier, use a backsaw to

cut the baseboard at the lines marking the sides of the vanity. Discard the

center section and nail the others to the wall with 2.5” finishing nails.

• Cover gaps at the sides of the vanity with scribe molding that matches

the cabinet finish; attach the molding with 0.75-inch brads. Cover a gap at

the floor with shoe molding secured with 1.5” finishing nails.

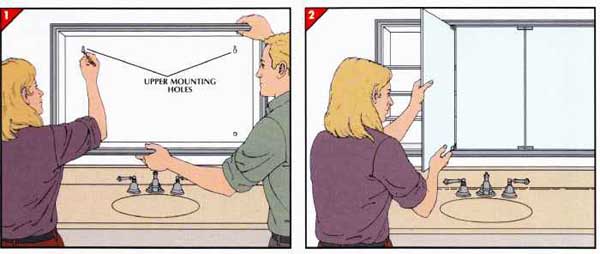

SURFACE-MOUNTED MEDICINE CABINETS

1. Hanging the cabinet.

• Locate studs where the cabinet will go. Have a helper hold it with at least

one upper mounting hole on a stud.

Mark through the upper holes and lower the cabinet. With a level, align the

marks.

• If both marks are over studs, drive screws into the studs until the heads

are inch from the wall.

• Otherwise, mark for the lower mounting holes as well.

For marks not on a stud, drill holes for hollow-wall anchors, tap the anchors

into place, and tighten. Loosen both anchor screws inch from the wall.

• Slip the cabinet’s mounting holes over the screwheads.

Drive screws through the other holes and tighten them all.

2. Adding shelves and doors.

• Position the shelves on the interior brackets.

• Attach the door hinges and the doors. Mounting systems vary, but doors

commonly are first attached to the upper hinge, then adjusted for fit at the

bottom hinge.

• Complete the installation by affixing door catches and any hardware provided

by the manufacturer.

A MEDICINE CABINET BETWEEN TWO STUDS

Cutting on opening.

• Use a stud finder to locate the studs on each side of the cabinet location.

• Draw the dimensions of the desired opening on the wall between the studs.

With a level, ensure that the top and bottom lines are horizontal.

• Cut away the outlined section, using a dry-wall saw for wallboard. A saber

saw fitted with hacksaw blades works well for plaster walls; change blades

as they dull.

• Drive a dry-wall screw partway into each stud, 1.5 inches above edge of

the opening.

• Cut a 2-by-4 header to fit snugly between the studs, and push it up against

the screws. To anchor the header, angle two screws through each end into the

stud.

• In the same way, install a 2-by-4 sill at the bottom of the opening.

• Set the cabinet into the recess. Through the pre drilled holes on each

side, drive screws partway into the studs. Level the cabinet and tighten

the screws while maintaining the level.

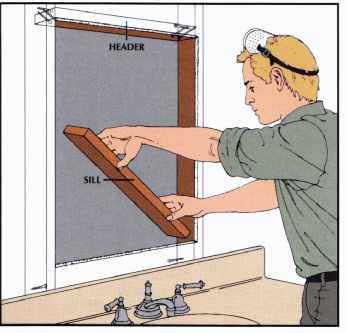

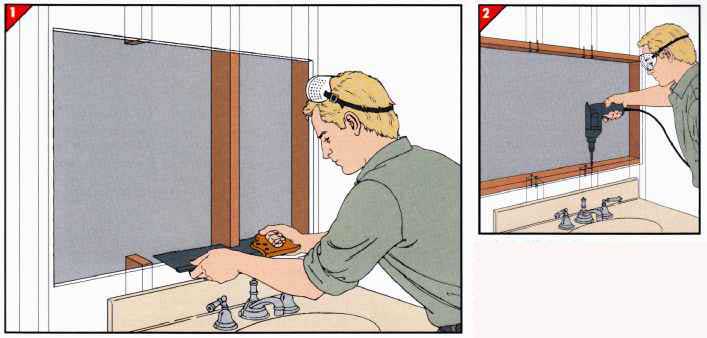

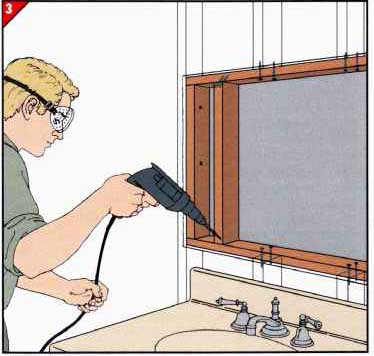

RECESSING A MEDICINE CABINET

1. Cutting out studs.

• Mark the proposed opening on the wall, then with a stud finder locate a

stud to the right and left of the outline.

• On the wall between these studs, mark horizontal lines 1.5 inches above

and below the proposed opening.

• Cut away the rectangle of wall bounded by these lines and the studs.

• Use a backsaw to cut through studs in the cabinet space, flush with the

edges of the opening.

• Gently pry the stud segments away from the wall behind them. Nails that

hold the wall surface to the studs may pull through, and you may have to re

pair some damage on the other side.

2. Framing the opening.

• From 2-by-4s, cut a header and a sill to fit snugly between the studs at

the left and right of the opening. Screw the header and sill to the cut ends

of the studs. Fasten header and sill ends with screws that are angled into

the studs at the sides of the opening.

• Screw vertical 2-by-4s to both end studs to provide a surface for patching

wallboard.

3. Customizing the fit.

• If the cabinet does not fill the framed opening, cut two 2-by-4s to the

height of the opening. At the sides of the planned recess, secure them to

the sill and header with angled screws.

• Cut and fit wallboard patches to cover the sides of the opening to the

inner edges of the cabinet framing.

• Position the cabinet inside the framing, using shims at the bottom and

sides to make it level and plumb. Drive at least two screws through each

side of the cabinet, through the shims and into the framing.

++++++++++++++++++++++++++++++

Fresh Air for the Bathroom

Often stale and humid, the atmosphere in a bathroom fogs mirrors and promotes

mold and mildew. Over time, the moisture can damage paint, wallpaper, and

even walls.

An exhaust fan solves these problems by venting odors and humidity outdoors.

The fan shown on these and the following pages also incorporates an infrared

bulb to add a measure of heat on cold mornings.

--Planning Steps: Before buying a fan, first determine how you will vent

it. Through an unfloored attic to the roof is often the most direct route

from a second-floor bathroom. With a finished floor overhead, you must run

the ventilation duct between floor joists to an outside wall.

After estimating the length of duct required, use the estimator be low to

determine the air-handling capacity, in cubic feet per minute (CFM), of a

fan that will renew the bathroom air every 7 minutes.

-- Ducting Choices: Flexible duct, best for runs of less than 16 feet, can

be bent around corners or obstructions. It comes in sections that stretch

to 8 feet and can be bought in kits that include a weatherproof wall or roof

cap, and the plastic bands needed to clamp the duct to the fan and to the

cap.

Rigid duct is often a better choice for longer runs; its inner surface is

smooth and offers less resistance to air flow. Rigid duct cannot be bent,

so special elbow fittings are needed to detour around obstacles.

-- Wiring Considerations: Before planning any wiring, first check lo cal

building and electrical codes for possible restrictions. Because exhaust fans

require little power, they can usually be added to an existing circuit. The

most convenient power source is often a junction box mounted on an attic joist.

-- Switching: Since the fan and heat lamp are designed to run separately

or together, you will need two switches. You can mount separate switches in

side-by-side boxes, or you can use a dual switch that fits into a single box.

In either case, you will need three-conductor cable to serve the two switches.

CAUTION --- Don’t open any electrical box without shutting off power to the

circuit at the fuse or circuit-breaker box and double-checking with a voltage

tester.

TOOLS:

- Electric drill

- Keyhole saw

- Hammer

- Carpenter’s pencil

- Utility knife

- Saber saw

- Tape measure

- Putty knife

- Nail set

- Voltage tester

- Pliers

- Cable ripper

- Wire stripper

- Screwdriver

- Fish tape

- Socket wrench

MATERIALS:

- Duct kit

- Dual switch

- Switch box

- Wire caps

- Electrician’s tape

- Two- and three-conductor 14-gauge cable

- Cable clamps 0.5-inch plastic staples

- 1.25-inch roofing nails

- Roofing cement

SAFETY TIPS --- Wear goggles to protect your eyes from dust and flying debris

while hammering or sawing. A hard hat guards against painful encounters with

rafters and exposed roofing nails. Before handling insulation in an attic,

put on a long-sleeved shirt, gloves, and a disposable dust mask.

--- Calculating fan capacity. Use your bathroom dimensions in the estimator

at left to determine the mini mum air-handling capacity for an exhaust

fan. If the result falls between two fan sizes, choose the larger. And for

long duct runs—more than 8 feet of flexible duct or 16 feet of rigid duct—pick

the next larger fan.

Length Width Height

_____ x _____ x _____ / 7.5 = _____ (CFM)

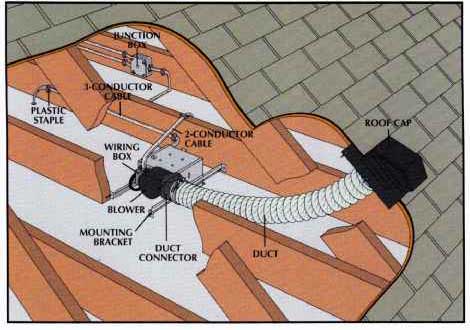

Anatomy of a fan installation.

Seen at left in an attic above a bath room ceiling, a heater fan consists

of a lamp housing fitted with a blower and a wiring box. Designed for a 250-watt

heat lamp, the unit is fastened to joists with adjustable mounting brackets.

A length of flexible duct, extending from the blower outlet to a hole cut

through the roof, carries moisture outdoors through a roof cap. Dampers at

the roof cap and inside a duct connector at the blower outlet prevent backdrafts

when the fan is off. Power comes to the unit from a junction box by way of

a two-conductor electrical cable. A three-conductor cable leads to a pair

of switches in the bathroom below; one is for the fan, and the other is for

the heat lamp.

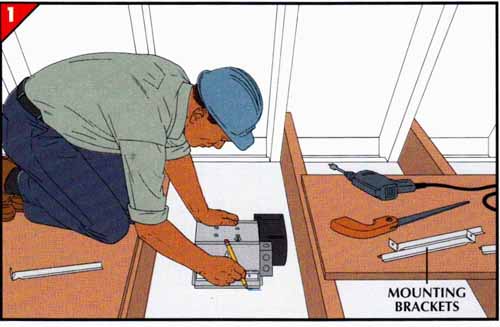

MOUNTING AN EXHAUST FAN HOUSING

1. Cutting a ceiling opening.

• In the bathroom, drill a 1/8-inch test hole in the center of the ceiling.

If the bit hits a joist, fill the hole with spackling and drill another hole

several inches away. Push a length of wire up through the test hole to mark

the spot.

• Lay plywood across attic joists to support you and your tools and the mounting

brackets for the fan. Push aside any insulation you find, then remove the

marker wire. Center the lamp housing between the joists on either side of

the test hole and outline the housing on the ceiling.

• Drill a 0.75-inch hole at each corner of the outline, then cut along the

lines with a keyhole saw, stationing a helper in the bathroom to support and

catch the cutout.

2. Fastening the mounting brackets.

• Slide a mounting-bracket section into each end of the channel on one side

of the lamp housing, then push the pieces together until they overlap. Repeat

this procedure for the channel on the opposite side of the housing.

• While your helper in the bathroom holds a board across the ceiling opening,

orient the blower outlet toward the exit point for the duct, then lower the

housing through the ceiling to rest on the board.

• Extend the mounting brackets until their nailing flanges touch the joists,

and fasten both brackets with a 1.25-inch nail in each end.

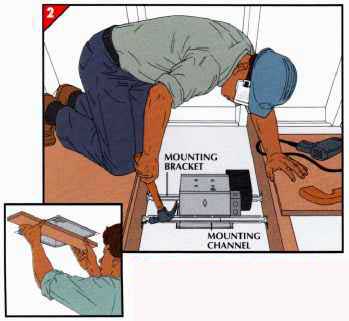

CHANNELING THE AIR FLOW OUTDOORS

1. Attaching the flexible duct.

• Check that the damper inside the duct connector swings freely on its hinges,

then slide a length of duct onto the circular end of the connector.

• Wrap a plastic clamp around the connection, then thread the clamp’s serrated

end through the lock. Tighten the connection by squeezing together the two

projections on the clamp.

• Holding the connector so that the damper hinge is at the top, attach the

connector to the blower outlet. In this unit, tabs on the connector snap into

matching slots in the outlet.

2. Making a roof opening.

• In the attic, hold the other duct end on the roof midway between two rafters.

Mark around the duct with a carpenter’s pencil, then drive a nail through

the center of the circle.

• On the roof, find the marker nail. Draw a 5-inch-diameter circle, with

it as the center.

• Within the circle, pull out all roofing nails. Cut away shingles and roofing

paper with a utility knife. Drill a starter hole inside the circle, then saw

around the circumference.

CAUTION ---If the slope of your roof is greater than 15 degrees, have the

root work performed by a professional.

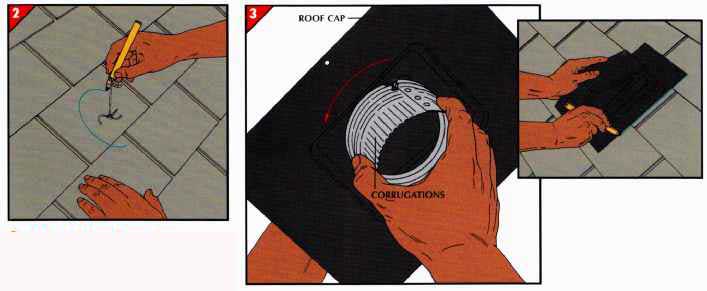

3. Assembling the roof cap.

• Holding the corrugated end of the duct connector, insert it into the underside

of the roof cap. Lock the connector to the cap by turning it clockwise for

some models, counter clockwise for others.

• Insert the connector into the roof opening, and mark the outline of the

roof cap on the shingles.

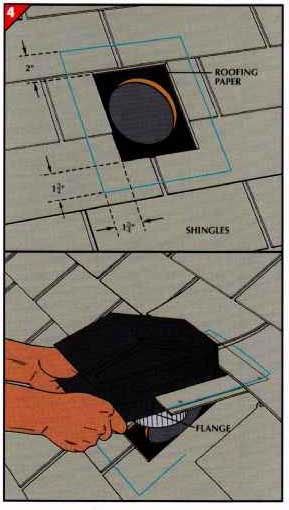

4. Installing the roof cap.

• Lift the roof cap out of the hole and set it aside.

• Within the outline marked in Step 3, measure 2 inches from the upper edge

and draw a line. In the same manner, mark lines 1.75 inches in from the sides

and bottom edge.

• Within this smaller area, cut away the shingles, but not the roofing paper.

• Holding the cap at a 45-degree angle, slide the upper edge and sides of

the flange under the shingles, and fit the duct connector into the 5-inch

roof hole.

• Nail the flange to the sheathing through the holes provided, lifting shingles

as needed to do so. Apply roofing cement with a putty knife to seal the nailheads

and shingle edges to the roof cap flange.

• In the attic, use a plastic clamp to connect the flexible duct to the roof

cap’s duct connector.

MAKING ELECTRICAL CONNECTIONS

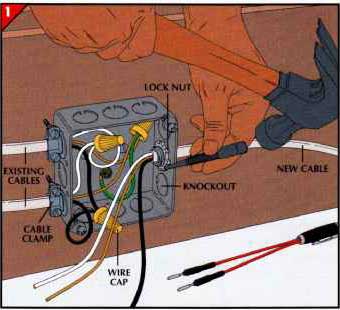

1. Topping power.

• At the service panel, turn off power to the circuit you plan to extend.

• Remove the junction box cover, then, with a hammer and nail set, dislodge

one of the removable disks called a knockout. Break it off with pliers.

• With a cable ripper, strip 8 inches of sheathing from a length of two-conductor

cable. Use a wire stripper to re move inch of insulation from the ends of

the black and white wires. Slip a cable clamp onto the cable and tighten the

clamp on the cable sheathing with a screwdriver.

• Insert the clamp into the knockout hole and screw a lock nut onto the clamp.

Tighten the nut with a hammer and nail set as shown at left.

• Include the new wires under the wire caps that join the old wires, connecting

black to black, white to white, and bare wire to bare wire. (In some cases,

larger wire caps will be needed to accommodate the added wires.)

• Route the cable from the junction box to the fan wiring box, securing it

to joists with plastic staples.

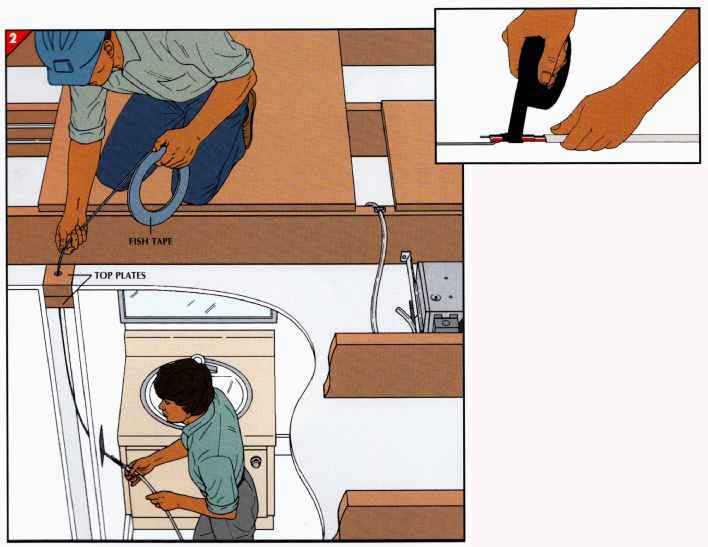

2. Fishing cable.

• In the bathroom, cut an opening for a new switch box in the wall near the

doorway. Use the template included with the box, or the box itself, to out

line the opening.

• In the attic, locate the top plates of the bathroom wall that has the new

opening. Drill a 0.75-inch hole through the plates above the opening.

• Push the end of a fish tape through the hole. Maneuver the tape until a

helper below can pull it out through the switch opening.

• Have your helper strip 8 inches of sheathing from a length of the three-

conductor cable and attach the wires to the fish tape (inset).

• With your helper feeding cable from below, pull it into the attic with

the fish tape. Unhook the cable and route it to the fan wiring box.

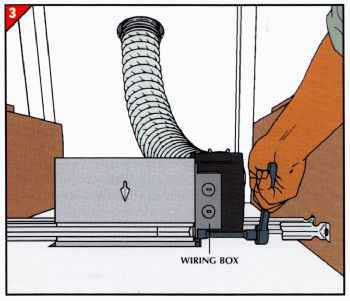

3. Preparing the wiring box.

• Unfasten the screw holding the wiring box to the housing. As shown at left,

a socket wrench can be handy for hard-to-reach screws, most of which have

hexagonal heads. Set the screw aside and remove two knockouts from the wiring

box.

• Strip 8 inches of sheathing from the ends of both the two-conductor and

three-conductor cables, then remove 0.75 inch of insulation from the insulated

wires in each. Attach each cable to the wiring box with a cable clamp as

shown above in MAKING ELECTRICAL CONNECTIONS.

4. Wiring connections.

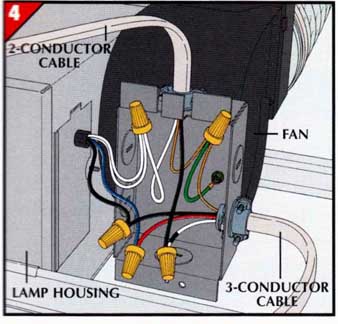

Using wire caps, make the following connections:

• Black wire of the switch cable to the black wire from the lamp housing.

• Red wire of the switch cable to the other colored wire from the lamp housing,

blue in this case.

• White wire of the switch cable to the black wire of the power cable. Color

the white insulation black to indicate a current-carrying wire.

• Bare wire of the switch cable to the bare wire of the power cable and to

a jumper wire (green) screwed to the wiring box.

• White wire from the power cable to the two white wires coming from the

lamp housing.

• Fold all connections into the box, and refasten it to the housing.

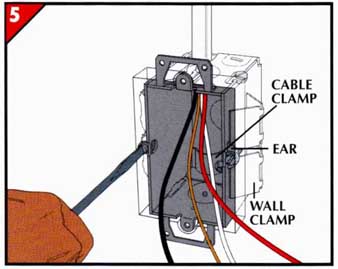

5. Adding a switch box.

• In the bathroom, remove a knockout from a switch box with built-in cable

clamps top and bottom.

• With a screwdriver, loosen the clamp at the top of the box.

• Cut the switch cable to length, then strip off 8 inches of sheathing.

• Thread the cable wires into the box through the knockout, and tighten the

clamp on the cable sheathing.

• Insert the box into the wall opening so both ears touch the wall surface.

• Turn the screw on each side of the box to draw the wall clamps against

the inside of the dry wall. Continue turning until the box fits tightly. CABLE

CLAMP; EAR; WALL CLAMP

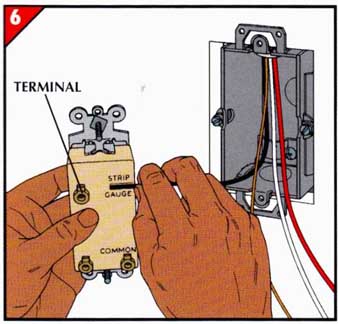

6. Wiring the switch.

• Using the strip gauge on the back of a two-function switch, mark the insulation

of all three conductors for stripping (left). The gauge shows how much insulation

must be removed so that no bare wire is exposed when the conductors are inserted

in the terminals.

• After stripping the wires, push the end of the white wire all the way into

the terminal marked COMMON. Color the white insulation black.

FINAL ASSEMBLY AND TESTING

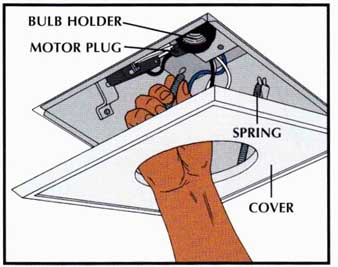

Final assembly and testing.

• From the bathroom, plug the fan motor into the base of the bulb holder.

• Hook the two cover springs to clips inside the housing.

• Screw an infrared heat bulb into the socket; adjust the cover to center

the bulb in the opening.

• Insert the red wire into either of the two remaining terminals, and insert

the black wire into the other. Screw the bare wire to the box.

• Fold the wires into the box and screw the switch to the box, then in stall

the cover plate provided.

• At the service panel, restore power to all circuits turned off for safety,

then check that the switch in the bathroom operates the fan and heat lamp

both separately and together.

• At the roof cap, confirm that the damper opens with the fan running and

closes when the air flow stops.

|